Scratch-resistant and high-impact matte oil-resistant and weather-proof ABS-PA-PMMA alloy material and preparation method thereof

An alloy material and high-impact technology, applied in the field of polymers, can solve the problems of uneven gloss distribution, affecting product appearance, reducing gloss, etc., and achieve good processing fluidity, excellent matte effect, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

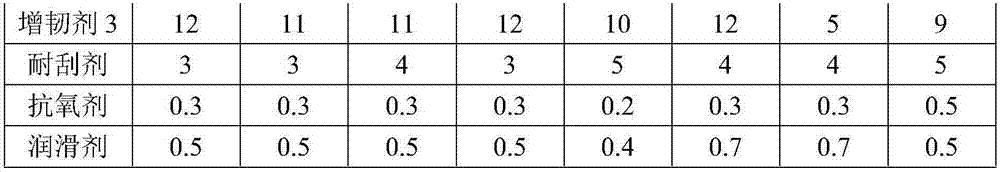

[0033] Embodiment 1~3, its preparation method comprises the steps:

[0034] According to Table 1, PA6 (M2800), ABS (757K), PMMA (CM-211), compatibilizer (SMA-700), antioxidant (1010 / 168=1:2) and lubricant ( E525) into the high-speed mixer, mix for 1 to 2 minutes, and then weigh toughening agent 1 (HR-181), toughening agent 2 (EXL-2678), toughening agent 3 (KT-915) and resistant Add the scraping agent (GM100A) to the above-mentioned uniformly mixed material, mix for 1-2 minutes, and finally add the uniformly mixed material to the hopper of the twin-screw extruder to melt and extrude it. The temperature of each section of the twin-screw extruder is: 1 The temperature in zone 2 is 100°C; the temperature in zone 2 is 230°C; the temperature in zone 3 is 225°C; the temperature in zone 4 is 210°C; the temperature in zone 5 is 220°C; 38rpm / min, the products produced in Examples 1-3 are denoted as B1-B3 respectively.

Embodiment 4

[0035] Embodiment 4, its preparation method comprises the steps:

[0036] First, weigh PA6 (M2800), PA66 (EP158), ABS (757K), PMMA (CM-211), compatibilizer (SMA-700), antioxidant (1010 / 168=1:2) according to Table 1 ) and lubricant (E525) were added to the high-speed mixer, mixed for 1 to 2 minutes, and then the weighed toughening agent 1 (HR-181), toughening agent 2 (EXL-2678), toughening agent 3 (KT -915) and anti-scratch agent (GM100A) are added to the above uniformly mixed material, mixed for 1-2 minutes, and finally the mixed material is added to the hopper of the twin-screw extruder to melt and extrude, each of the twin-screw extruder The temperature of the section is: the temperature of zone 1 is 100°C; the temperature of zone 2 is 260°C; the temperature of zone 3 is 255°C; the temperature of zone 4 is 240°C; the temperature of zone 5 is 250°C; The screw speed of machine is 38rpm / min, and the product that embodiment 4 produces is denoted as B4.

Embodiment 1

[0037] The lubricant of embodiment 1 is stearic acid;

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com