Matte finishing pure acrylic emulsion with excellent water resistance and stain resistance and preparation method thereof

A pure acrylic emulsion, anti-staining technology, applied in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve the problems of unspecified stain resistance, low gloss, affecting the stability of varnishes and water resistance and other performance issues, to achieve the effect of controllable gloss, simple raw material process, and excellent stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

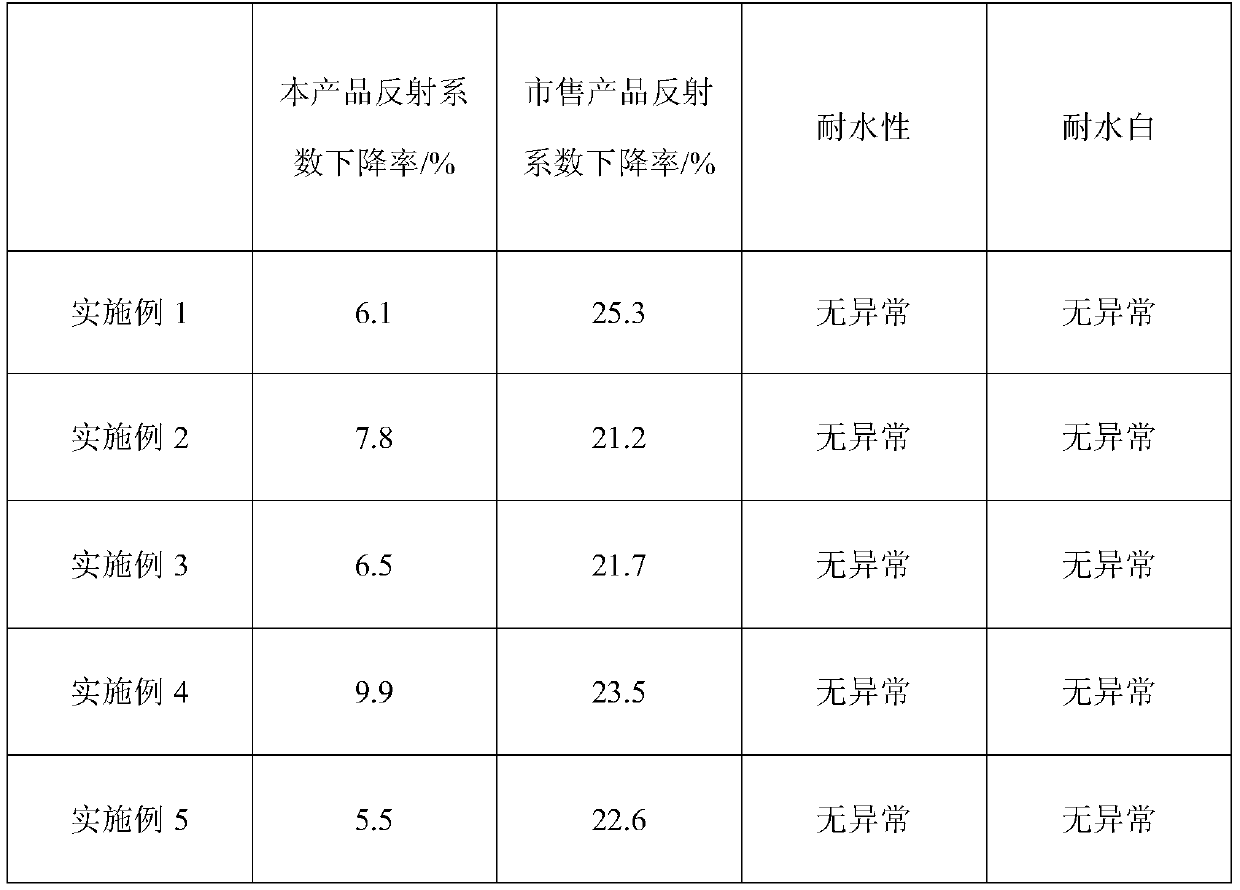

Examples

Embodiment 1

[0028] A kind of pure acrylic emulsion with matt finish and excellent water resistance and stain resistance, made of the following raw materials in parts by weight: 30 parts of methyl methacrylate, 10 parts of isooctyl acrylate, and 15 parts of butyl methacrylate Parts, silicone additives (vinyltrimethoxysilane, methacryloxypropyltrimethoxysilane) 3 parts, crosslinking monomer (acrylamide, hydroxyethyl methacrylate) 3 parts, carboxyl function 3 parts of monomer (acrylic acid), 2 parts of emulsifier (sodium lauryl sulfate, reactive emulsifier COPS-1 of Rhodia Company, reactive emulsifier SR-10 of Japan Adike Company), initiator (Ammonium persulfate) 1 part, film-forming aid (2,2,4-trimethyl-1,3-pentanediol monoisobutyrate) 5 parts, pH regulator (ammonia water) 5 parts, deionized 65 parts of water.

[0029] The preparation method of the pure acrylic emulsion with excellent water resistance and stain resistance, comprising the following steps:

[0030] 1) Under normal temperatu...

Embodiment 2

[0038] A kind of pure acrylic emulsion with excellent water resistance and stain resistance, made of the following raw materials in parts by weight: 15 parts of methyl methacrylate, 5 parts of isooctyl acrylate, and 13 parts of butyl methacrylate Parts, silicone additives (vinyl triethoxysilane, vinyl tris (β-methoxyethoxy) silane) 2 parts, crosslinking monomer (acrylamide, ethylene glycol dimethacrylate) 5 parts, 2 parts of carboxyl functional monomer (methacrylic acid), emulsifier (sodium dodecylbenzene sulfonate, sodium vinyl sulfonate, reactive emulsifier COPS-2 of Rhodia Company, Japan Adico The company's reactive emulsifier SR-10) 1.5 parts, initiator (potassium persulfate) 0.9 part, film-forming aid (Eastman's OE-300) 1 part, pH regulator (ammonia and sodium hydroxide) 3 parts, 55 parts of deionized water.

[0039] The preparation method of the pure acrylic emulsion with excellent water resistance and stain resistance, comprising the following steps:

[0040] 1) Under...

Embodiment 3

[0048] A kind of pure acrylic emulsion with matt finish and excellent water resistance and stain resistance, made of the following raw materials in parts by weight: 25 parts of methyl methacrylate, 8 parts of isooctyl acrylate, and 10 parts of butyl methacrylate 1 part, silicone additive (vinyltrimethoxysilane, γ-(2,3-glycidyloxy) propyltrimethoxysilane) 1 part, crosslinking monomer (acrylamide, glycidyl methacrylate ) 0.5 parts, 4 parts of carboxyl functional monomers (methacrylic acid, itaconic acid), emulsifier (sodium lauryl sulfate, alkyl polyoxyethylene ether, reactive emulsifier SR-10 of Japan Adike Company , SR-20) 3 parts, initiator (sodium persulfate) 0.5 parts, film-forming aid (propylene glycol phenyl ether) 3 parts, pH regulator (ammonia, 2-amino-2-methyl-1-propanol) 4 parts, 60 parts of deionized water.

[0049] The preparation method of the pure acrylic emulsion with excellent water resistance and stain resistance, comprising the following steps:

[0050] 1) U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Minimum film forming temperature | aaaaa | aaaaa |

| Minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com