UV matte environment-friendly offset printing ink and preparation method thereof

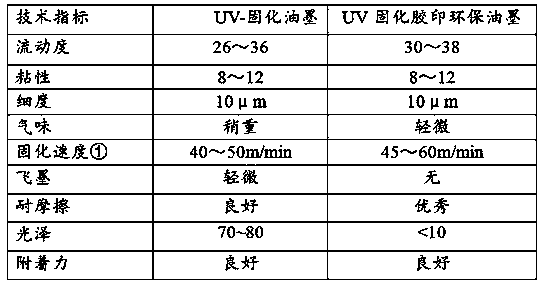

An offset printing ink and environmental protection technology, applied in the field of UV matte environmentally friendly offset printing ink and its preparation, can solve the problems affecting the use performance and safety of UV offset printing ink, poor wear resistance, and non-environmental protection, and achieve excellent matte effect, Good printability and low irritation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The invention discloses a UV matte environment-friendly offset printing ink, which is composed of the following components based on the total amount of 100kg of raw materials:

[0024] Acrylic emulsion 15kg, choose Hanwha R20 or R90 series;

[0025] Polyester acrylic resin 21kg, choose Changxing 6311-100 model;

[0026] Polymethylurea resin 1kg, select Detron 0G861 for use; The polymethylurea resin has matting effect, also has excellent wear resistance and hardness;

[0027] Self-dulling polyurethane resin 1kg, select Wengkaier PU550 model for use; The use of described self-dulling polyurethane resin and polymethylurea resin can effectively improve the matte effect of ink;

[0028] Reactive diluent 5kg, described reactive diluent is acrylic acid reactive diluent, the acrylic acid monomer of low irritation, has low surface tension, low viscosity and less curing shrinkage;

[0029] 7 kg of photoinitiators, the photoinitiators are hydrogen abstraction photoinitiators or ...

Embodiment 2

[0034] The invention discloses a UV matte environment-friendly offset printing ink, which is composed of the following components based on the total amount of 100kg of raw materials:

[0035] Acrylic emulsion 28kg, choose BASF JONCRYL61;

[0036] Polyester acrylic resin 11kg, choose Sartomer CN293 model;

[0037] Polymethylurea resin 7kg, select Detron 0G863 for use; Described polymethylurea resin has matting effect, also has excellent wear resistance and hardness;

[0038] 7kg of self-dulling polyurethane resin is selected from Gaodebaoli GP-6084 model; the use of the self-dulling polyurethane resin and polymethylurea resin can effectively improve the matte effect of the ink;

[0039] Reactive diluent 8kg, described reactive diluent is acrylic acid reactive diluent, the acrylic acid monomer of low irritation, has low surface tension, low viscosity and less curing shrinkage;

[0040] 5 kg of photoinitiators, the photoinitiators are hydrogen abstraction photoinitiators or cra...

Embodiment 3

[0045] The invention discloses a UV matte environmental protection offset printing ink, which is composed of the following components by mass:

[0046] Acrylic emulsion 20kg, choose Hanwha R20 or R90 series;

[0047] Polyester acrylic resin 15kg, choose Cytec EB450 model;

[0048] Polymethylurea resin 5kg, select Yabao M3 for use; the polymethylurea resin has matting effect, also has excellent wear resistance and hardness;

[0049] Self-dulling polyurethane resin 5kg, select Henchenke PU-3000 model for use; The use of described self-dulling polyurethane resin and polymethylurea resin can effectively improve the matte effect of printing ink;

[0050] Reactive diluent 8kg, described reactive diluent is acrylic acid reactive diluent, the acrylic acid monomer of low irritation, has low surface tension, low viscosity and less curing shrinkage;

[0051]7 kg of photoinitiators, the photoinitiators are hydrogen abstraction photoinitiators or cracking photoinitiators, and also includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com