Matte printing ink, preparation method thereof and shading adhesive tape

A technology of matte ink and light-shielding tape, which is applied in the direction of ink, adhesive, film/sheet adhesive, etc., can solve the problem of non-fitting surface not being scratch-resistant, and achieve good light-shielding effect and good scratch resistance The effect of low performance and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

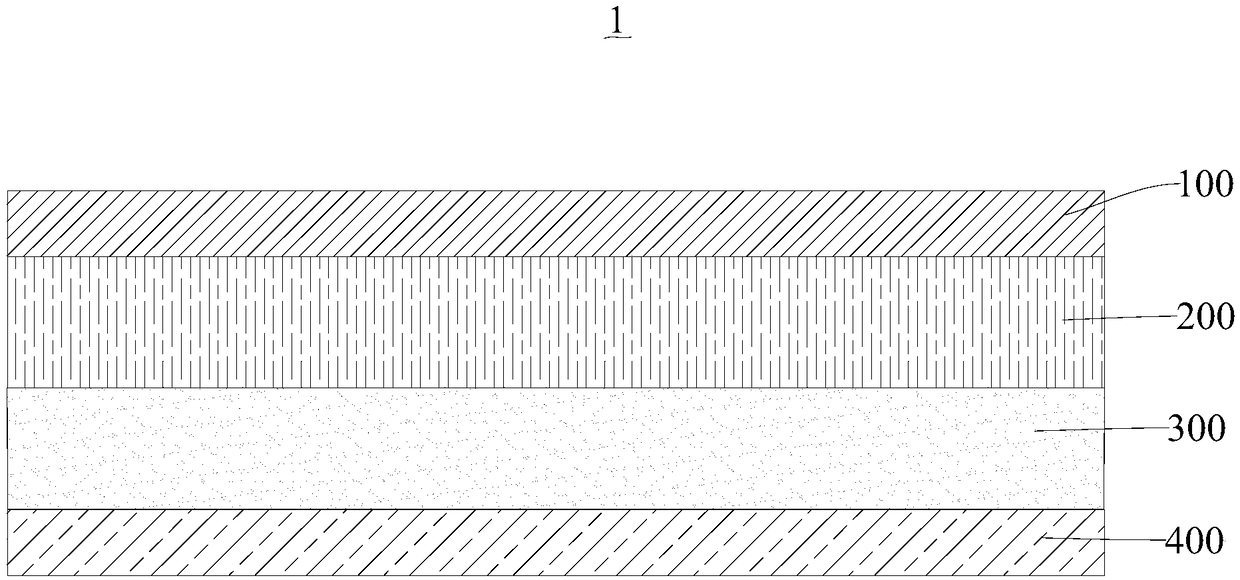

Image

Examples

preparation example Construction

[0044] A preparation method of matte ink, characterized in that: comprising:

[0045] 92.8-98.8 parts of polyurethane modified acrylate resin, 0.5-3 parts of matting powder and 0.5-2 parts of wax powder are mixed and ground, then 0.5-2.2 parts of the first curing agent are added and mixed evenly to obtain matte ink.

[0046] It should be noted that the above polyurethane-modified acrylate resin is used as a film-forming substance, the matting powder is used to form a matte effect, the wax powder is used to improve the scratch resistance of the ink layer, and the first curing agent is used to carry out the film-forming substance. Cross-linking and curing to improve mechanical properties.

[0047] The consumption of above-mentioned polyurethane-modified acrylate resin can specifically be listed as 92.8 parts, 93.6 parts, 94.4 parts, 95 parts, 95.8 parts, 96.5 parts, 97.2 parts, 98 parts or 98.8 parts etc.; parts, 1 part, 1.5 parts, 2 parts, 2.5 parts or 3 parts, etc.; the amount ...

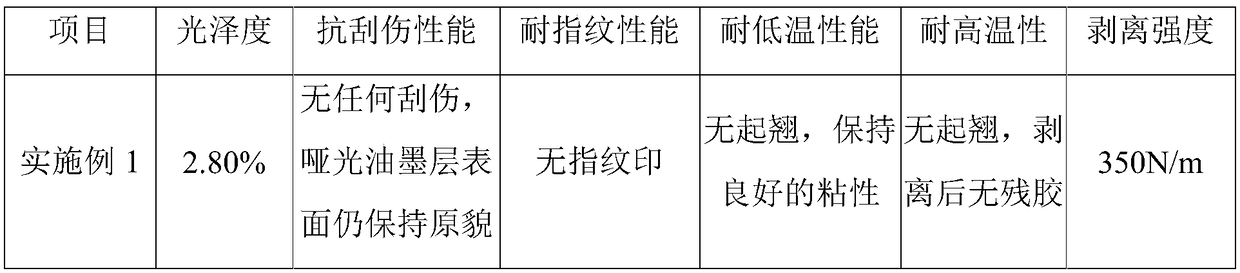

Embodiment 1

[0102] (1) After mixing 92.8 parts of polyurethane-modified acrylate resin, 0.5 part of diatomaceous earth and 0.5 part of polyethylene, grind for 5 hours with a sand mill at a speed of 500 r / min, and then add 0.5 part of 2,4-diisocyanate The trimer of cresyl acetate is uniformly dispersed, and then ethyl acetate is added to adjust the viscosity, so that the viscosity of the obtained matte ink is 60±10mPa.s.

[0103] (2) Take 0.098 parts of benzoyl peroxide and completely dissolve in 30 parts of toluene, then mix and stir evenly with 1 part of hydroxyethyl acrylate, 30 parts of isooctyl acrylate and 3 parts of methyl methacrylate to obtain a premixed single body; then the temperature inside the reaction kettle equipped with a condensing reflux device is first heated to 80°C by a water bath, the condensing reflux device is started to circulate the condensed water, and the stirring device of the reaction kettle is started, the stirring speed is adjusted to 150r / min, and 10 parts ...

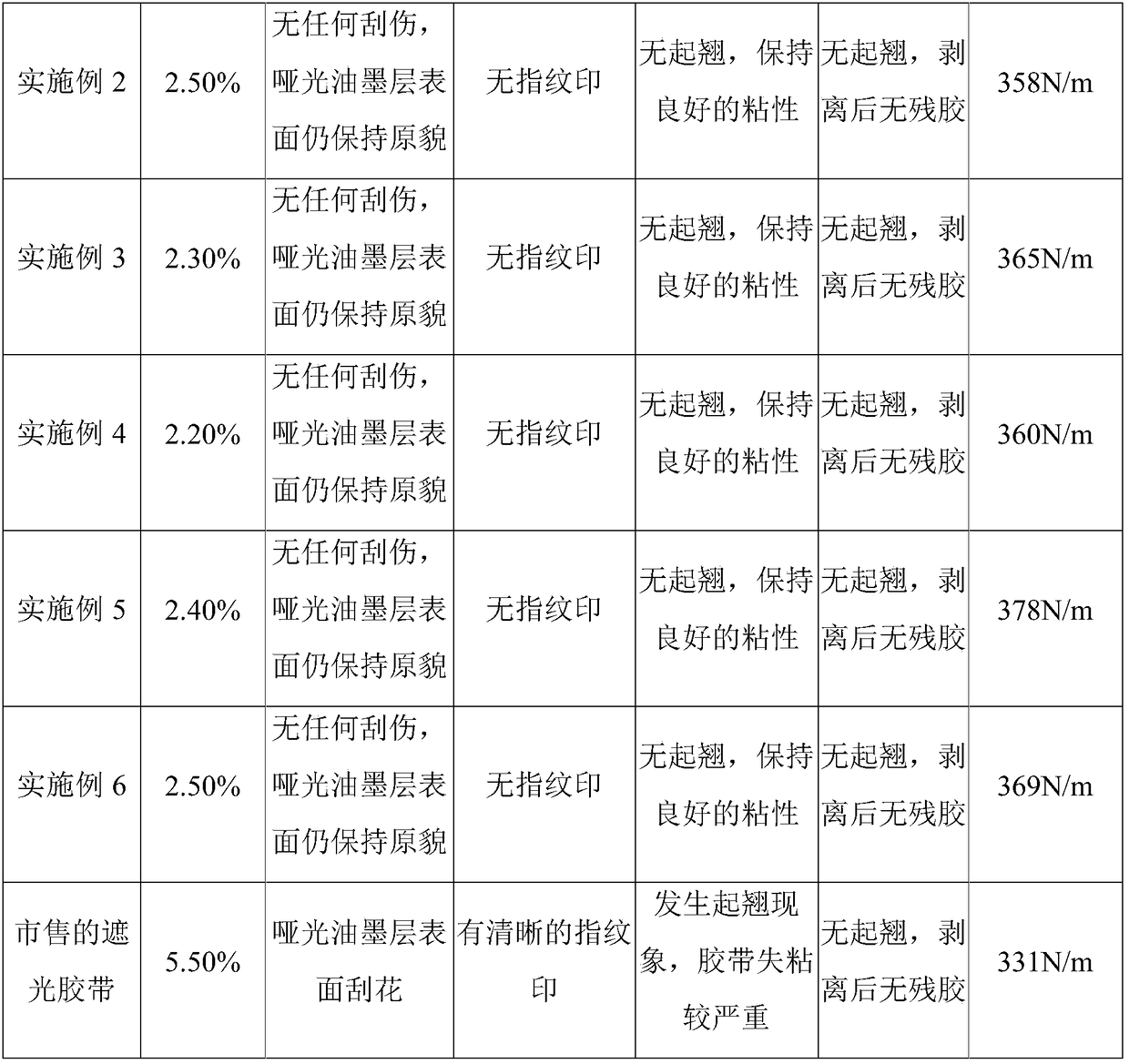

Embodiment 2

[0108] (1) After mixing 93.6 parts of polyurethane modified acrylate resin, 1 part of kaolin and 1 part of polytetrafluoroethylene, use a sand mill with a speed of 800r / min to grind for 4 hours, and then add 1 part of hexamethylene diisocyanate The trimer of cresyl ester is uniformly dispersed, and toluene is added to adjust the viscosity, so that the viscosity of the ink obtained is 60±10mPa.s.

[0109] (2) Take 0.2 parts of benzoyl peroxide and completely dissolve in 36 parts of toluene, then mix and stir evenly with 2 parts of hydroxyethyl acrylate, 35 parts of butyl acrylate and 4 parts of methyl methacrylate to obtain a premixed single body; then the temperature in the reactor equipped with a condensing reflux device is first heated to 85°C by a water bath, the condensing reflux device is started to circulate the condensed water, and the stirring device of the reactor is started, the stirring speed is adjusted to 250r / min, and 9 parts of Put toluene into the reaction kett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com