White and interference-color matte flaky cored pigment and preparation method thereof

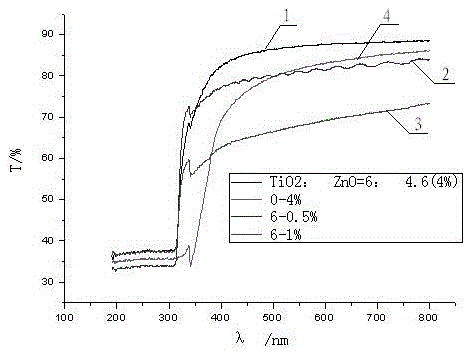

A core-coated pigment and interference color technology, which is used in the field of white and interference color matte flake core-coated pigments and its preparation, can solve the problems of uneven particle size distribution of substrates, loss of pigment properties, and difficulty in grinding, and achieves UV light. Good absorption effect, soft and delicate water dispersibility, high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of off-white and interference color matte flaky nucleated pigment is:

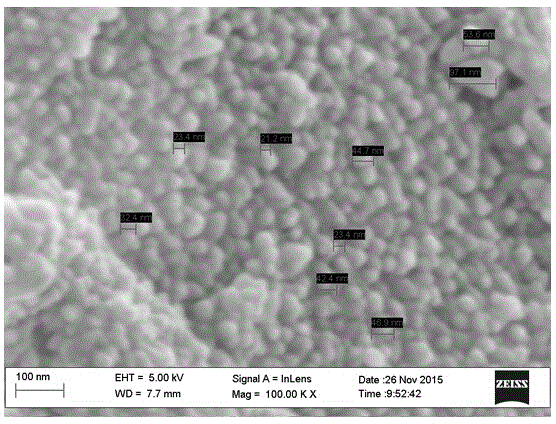

[0033] Put 35g of natural mica powder with a particle size of D50=4μm into a reaction kettle equipped with 1L of deionized water, stir at a stirring speed of 500r / min to form a suspension, and put the grain regulator polyethylene glycol into the suspension under stirring conditions. Alcohol 0.5g, continue to stir and heat to 65°C, adjust the pH value of the suspension to 1.5 with 10% dilute hydrochloric acid, add 4ml of SnCl with a concentration of 160g / l at a drop rate of 20ml / h 4 ·5H 2 O solution, stir at constant temperature for 15 minutes after feeding, raise the temperature to 75 ° C, adjust the pH value of the suspension to 1.9 with 10% dilute hydrochloric acid, and add 390 ml of TiCl with a concentration of 2 mol / l at a drop rate of 25 ml / h 4 Solution, while using 32% sodium hydroxide solution to keep the suspension constant, continue to stir for 15 minutes after the a...

Embodiment 2

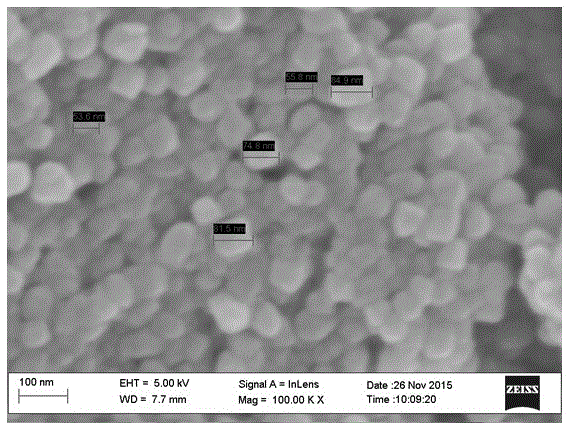

[0035] Put 25g of synthetic mica fine powder with a particle size of D50=3.7μm into a reactor equipped with 1L of deionized water, stir at a stirring speed of 500r / min to form a suspension, and add 4g of urea to the suspension under stirring conditions, Continue stirring and heating to 65°C, adjust the pH value of the suspension to 1.5 with 10% dilute hydrochloric acid, and add 3ml of SnCl with a concentration of 160g / l at a drop rate of 15ml / h 4 ·5H 2O solution, stir at constant temperature for 15 minutes after feeding, raise the temperature to 75°C, adjust the pH value of the suspension to 1.9 with 10% dilute hydrochloric acid, and add 280ml of TiCl with a concentration of 2mol / l at a drop rate of 30ml / h 4 Solution, while using 32% calcium hydroxide solution to keep the suspension constant, continue to stir for 15 minutes after the addition, adjust the pH value of the suspension to 5.7 with 10% dilute hydrochloric acid, add 0.2g anti-agglomeration agent dodecyl sulfonate So...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com