Thermoplastic resin composition and preparation method and application thereof

A thermoplastic resin and composition technology, applied in the field of thermoplastic resin composition and its preparation, can solve the problems of affecting the mechanical properties and heat resistance of materials, reducing the gloss of polycarbonate/polyester systems, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention is described in more detail by the following examples, but the present invention is not limited by the following examples.

[0084] The source of raw material used in the present invention is as follows:

[0085] Polypropylene: PP 7033N, ExxonMobil Chemical;

[0086] Polycarbonate: Bisphenol A polycarbonate, 20,000 Daltons, produced by Teijin;

[0087] Polyester: polybutylene terephthalate, its melting point is 224°C, its intrinsic viscosity is 0.8~1.0 dl / g, produced by Yizheng Chemical Fiber;

[0088] Impact modifier: methacrylate-butadiene-styrene, 60% butadiene, produced by LG Chem;

[0089] Compatibilizer: ethylene-acrylate-glycidyl methacrylate, ethylene content is 48%;

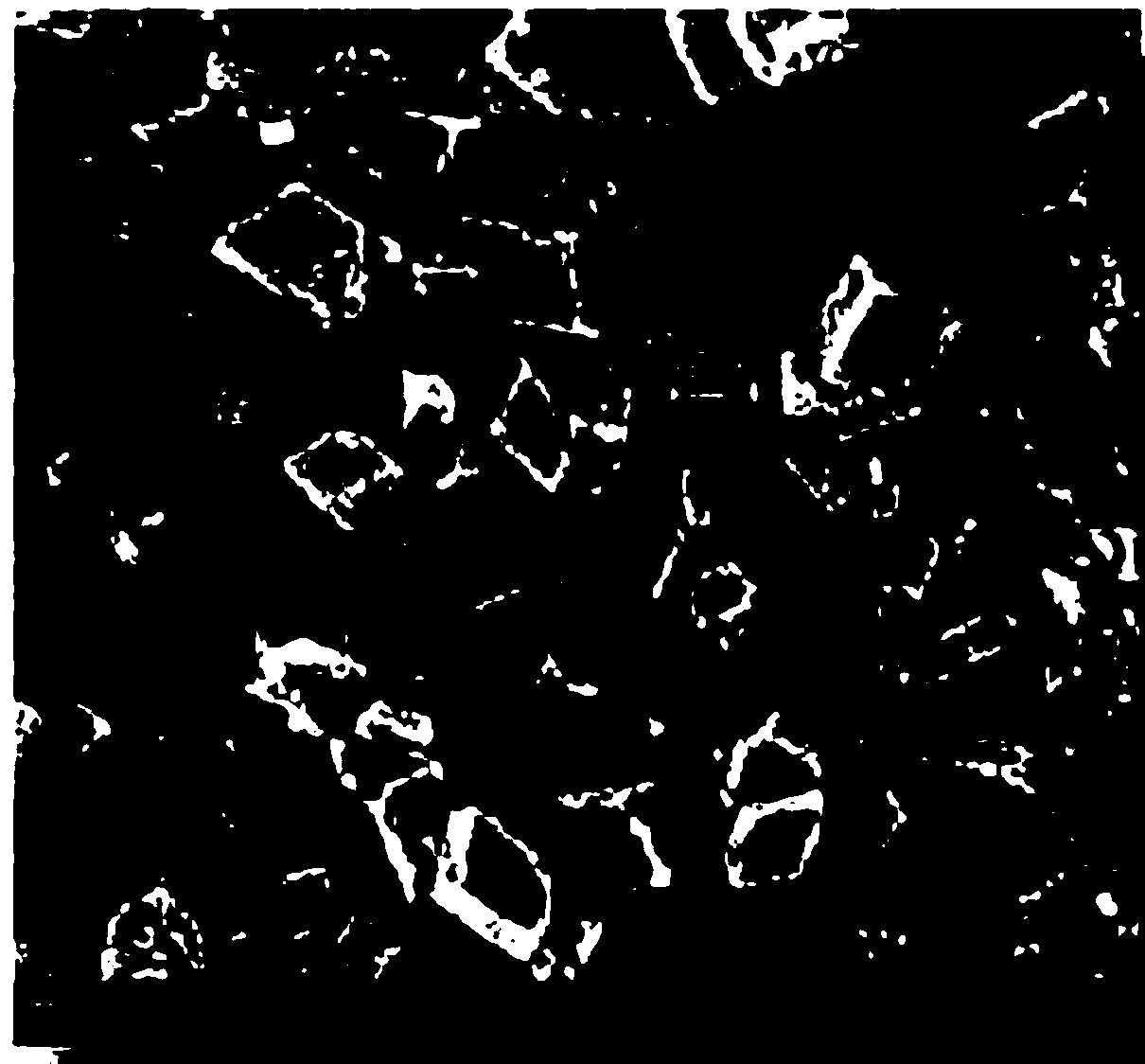

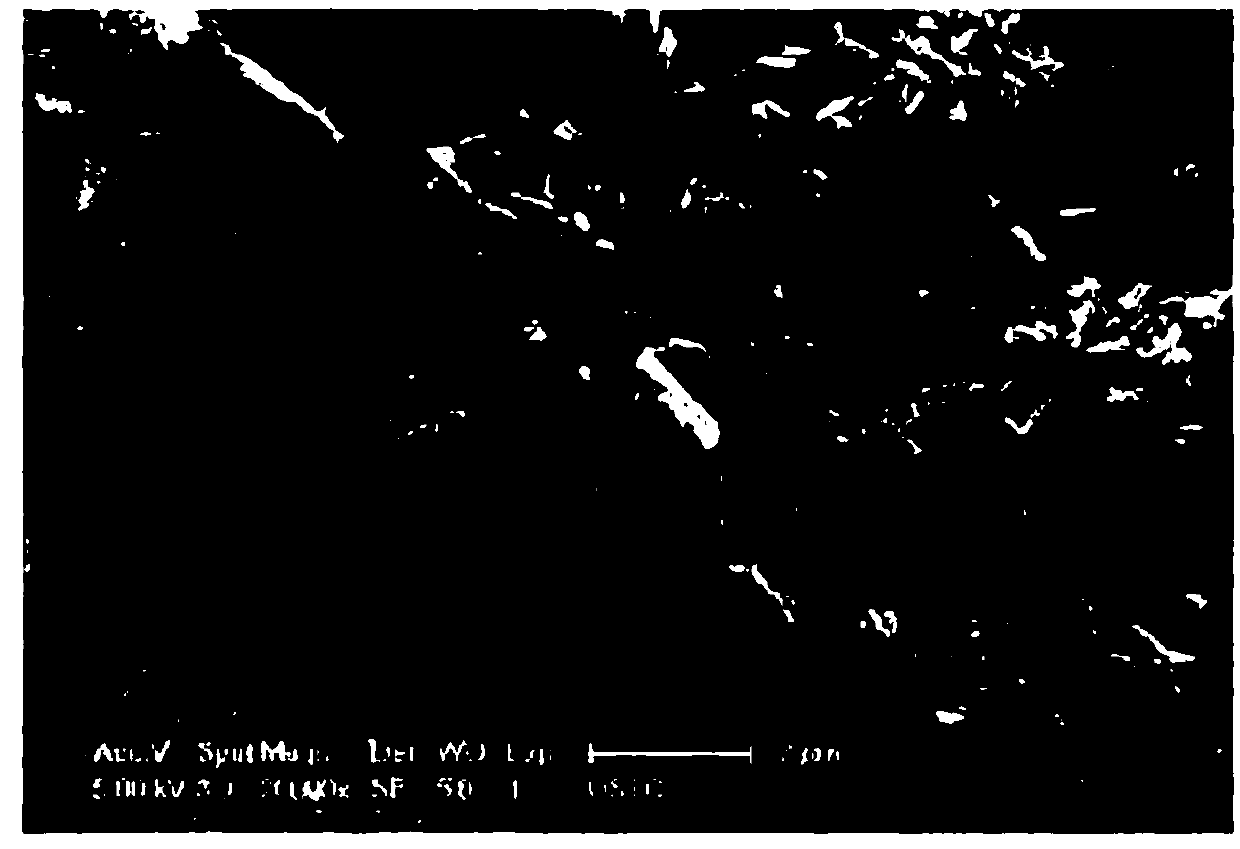

[0090] Boehmite A: cube-shaped, with an average particle size of 1.0 microns, an Fe element content of 80ppm, and a rough karst-like cliff appearance on the surface;

[0091] Boehmite B: cube-shaped, with an average particle size of 2.0 microns, an Fe element content of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com