Iron-red-series low-gloss lamellar pigment and preparation method thereof

A low-gloss, series technology, applied in inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of low gloss, high energy consumption, low gloss of pearlescent pigments, etc., and achieves obvious skin-friendly effect, Simple preparation process and outstanding matte effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

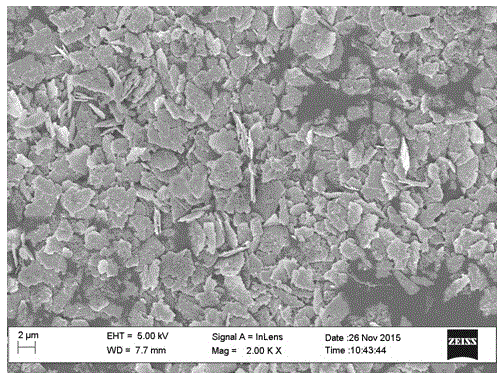

Embodiment 1

[0030] The preparation method of this iron red series low-gloss lamellar pigment is as follows:

[0031] A. Take 22g of natural mica powder with a fine particle size of D50=2.17μm in dry weight, put it into a reaction pot with 800ml of deionized water and mix it, stir it at a stirring speed of 480r / min for 30 minutes to form a suspension, add grains to adjust Add polyethylene glycol 0.1g, stir for 15-40min;

[0032] B. After heating to 75°C in a constant temperature water bath, adjust the pH value of the suspension to 3.2 with 10% dilute hydrochloric acid;

[0033] After steps C and B are completed, continue to stir for another 30 minutes, then dropwise add ferric chloride solution with a concentration of 60g / l to the suspension at a rate of 20ml / h for hydrolysis coating, and simultaneously drop into the suspension with a concentration of 10% Ammonia solution is used to keep the pH value of the suspension stable within the range of 3.1 to 3.2;

[0034] D. Add ferric chloride...

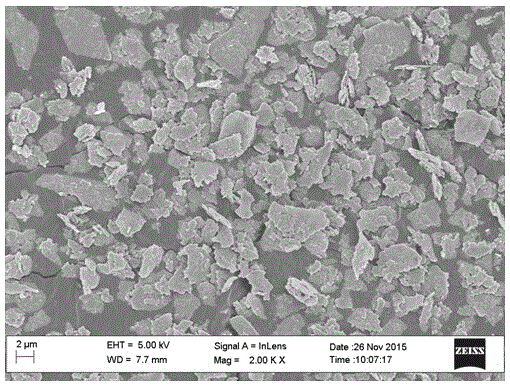

Embodiment 2

[0037] The preparation method of this iron red series low-gloss lamellar pigment is as follows:

[0038] A. Take 22g of natural mica powder with a fine particle size of D50=3.21μm in dry weight, put it into a reaction pot with 800ml of deionized water and mix it, stir it at a stirring speed of 480r / min for 30 minutes to form a suspension, add grains to adjust Add polyethylene glycol 0.1g and stir for 15-40min.

[0039] B. After heating to 75°C in a constant temperature water bath, adjust the pH value of the suspension to 3.1 with 10% dilute hydrochloric acid;

[0040]After the completion of steps C and B, stir for another 30 minutes, then dropwise add ferric chloride solution with a concentration of 60g / l to the suspension at a rate of 20ml / h for hydrolysis coating, and drop ammonia with a concentration of 10% at the same time aqueous solution to maintain the pH value of the suspension within the range of 3.1 to 3.2;

[0041] D. Add ferric chloride solution dropwise at the r...

Embodiment 3

[0044] The preparation method of this iron red series low-gloss lamellar pigment is as follows:

[0045] A. Take 22g of synthetic mica dry weight with a particle size of D50=1.51μm, put it into a reaction pot with 800ml of deionized water and mix it, stir it at a stirring speed of 480r / min for 30 minutes to form a suspension, and add the grain regulator CaCl20 .5g, stir for 15-40min;

[0046] B. After heating to 75°C in a constant temperature water bath, adjust the pH value of the suspension to 3.2 with 10% dilute hydrochloric acid;

[0047] After steps C and B are completed, continue to stir for another 30 minutes, then dropwise add ferric sulfate solution with a concentration of 0.8mol / l to the suspension at a rate of 20ml / h for hydrolysis coating, and at the same time dropwise add hydrogen with a concentration of 10% Sodium oxide solution is used to maintain the pH value of the suspension in the range of 3.1 to 3.2;

[0048] D. Add ferric sulfate solution dropwise at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com