Matt glaze

A matte glaze and raw material technology, applied in the field of architectural ceramics, can solve the problems of poor transparency and antifouling performance of the glaze layer, low gloss, and high initial melting temperature of dry glaze, and achieve excellent matte effect and excellent mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

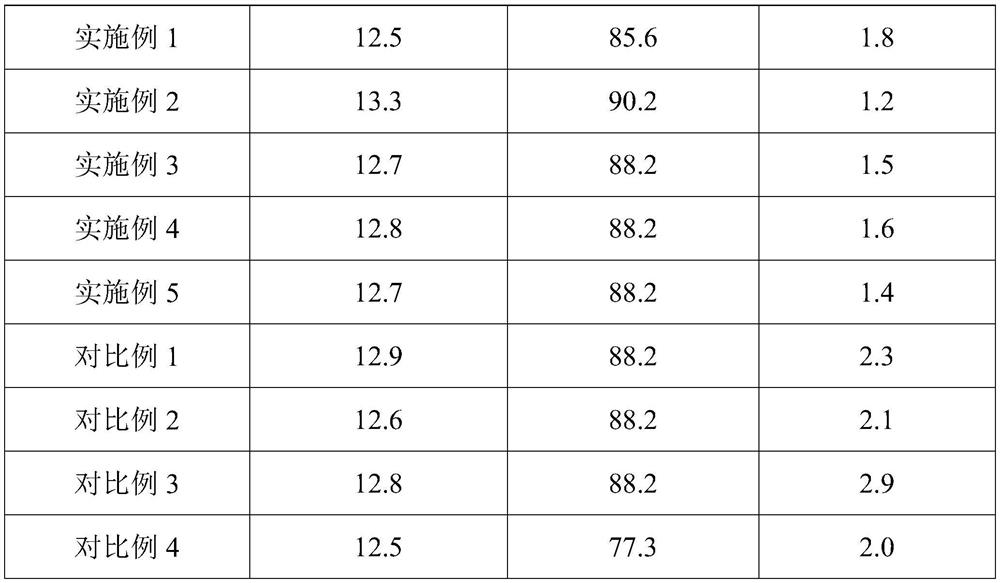

Embodiment 1

[0028] This embodiment provides a matte glaze, the matte glaze comprises a dry granular glaze and a protective glaze located on the surface of the dry granular glaze;

[0029] The raw materials of the dry glaze in parts by weight include: 14.0-16.0 parts of feldspar, 10.0-13.0 parts of quartz, 10.0 parts of barium carbonate, 6.0 parts of calcined talc, 5.0 parts of kaolin, 30.0 parts of wollastonite, and 2.0 parts of burnt soil , 6.0 parts of zinc oxide, 1.0 part of corundum, 1.0 part of X-type carbon nanotubes and 5.0 parts of diatomaceous earth;

[0030] The raw materials of the protective glaze in parts by weight include: 10 parts of potassium feldspar, 20 parts of albite, 8 parts of washed soil, 2 parts of indium hydroxide, 2 parts of zinc oxide, 2 parts of burnt talc, and 8 parts of wollastonite , 8 parts of dolomite, 2 parts of quartz, 5 parts of strontium carbonate, 0.2 parts of barium phosphate, 0.2 parts of white corundum, 5 parts of calcined soil, 2 parts of calcite,...

Embodiment 2

[0032] This embodiment provides a matte glaze, the matte glaze comprises a dry granular glaze and a protective glaze located on the surface of the dry granular glaze;

[0033] The raw materials of the dry glaze in parts by weight include: 16.0 parts of feldspar, 13.0 parts of quartz, 13.0 parts of barium carbonate, 9.0 parts of burnt talc, 7.0 parts of kaolin, 33.0 parts of wollastonite, 5.0 parts of burnt soil, and 9.0 parts of zinc oxide. 3.0 parts of corundum, 3.0 parts of X-type carbon nanotubes and 10.0 parts of diatomaceous earth;

[0034] The raw materials of the protective glaze in parts by weight include: 20 parts of potassium feldspar, 30 parts of albite, 12 parts of washed soil, 5 parts of indium hydroxide, 8 parts of zinc oxide, 6 parts of burnt talc, and 12 parts of wollastonite , 12 parts of dolomite, 8 parts of quartz, 10 parts of strontium carbonate, 0.5 parts of barium phosphate, 1 part of white corundum, 10 parts of calcined soil, 6 parts of calcite, and 2 pa...

Embodiment 3

[0036] This embodiment provides a matte glaze, the matte glaze comprises a dry granular glaze and a protective glaze located on the surface of the dry granular glaze;

[0037] The raw materials of the dry glaze in parts by weight include: 15.0 parts of feldspar, 11.5 parts of quartz, 11.5 parts of barium carbonate, 7.5 parts of burnt talc, 6.0 parts of kaolin, 31.5 parts of wollastonite, 3.5 parts of burnt soil, and 7.5 parts of zinc oxide. 2.0 parts of corundum, 2.0 parts of X-type carbon nanotubes and 8.0 parts of diatomite;

[0038] The raw materials of the protective glaze in parts by weight include: 12 parts of potassium feldspar, 26 parts of albite, 10 parts of washed soil, 3 parts of indium hydroxide, 5 parts of zinc oxide, 4 parts of burnt talc, and 10 parts of wollastonite , 10 parts of dolomite, 5 parts of quartz, 1 part of strontium carbonate, 0.25 parts of barium phosphate, 0.5 parts of white corundum, 6 parts of calcined soil, 4 parts of calcite, and 1 part of alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com