Film stripping and winding device

A film winding and winding device technology, applied in thin material handling, transportation and packaging, sending objects, etc., can solve the problems of mixing foreign objects or air bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

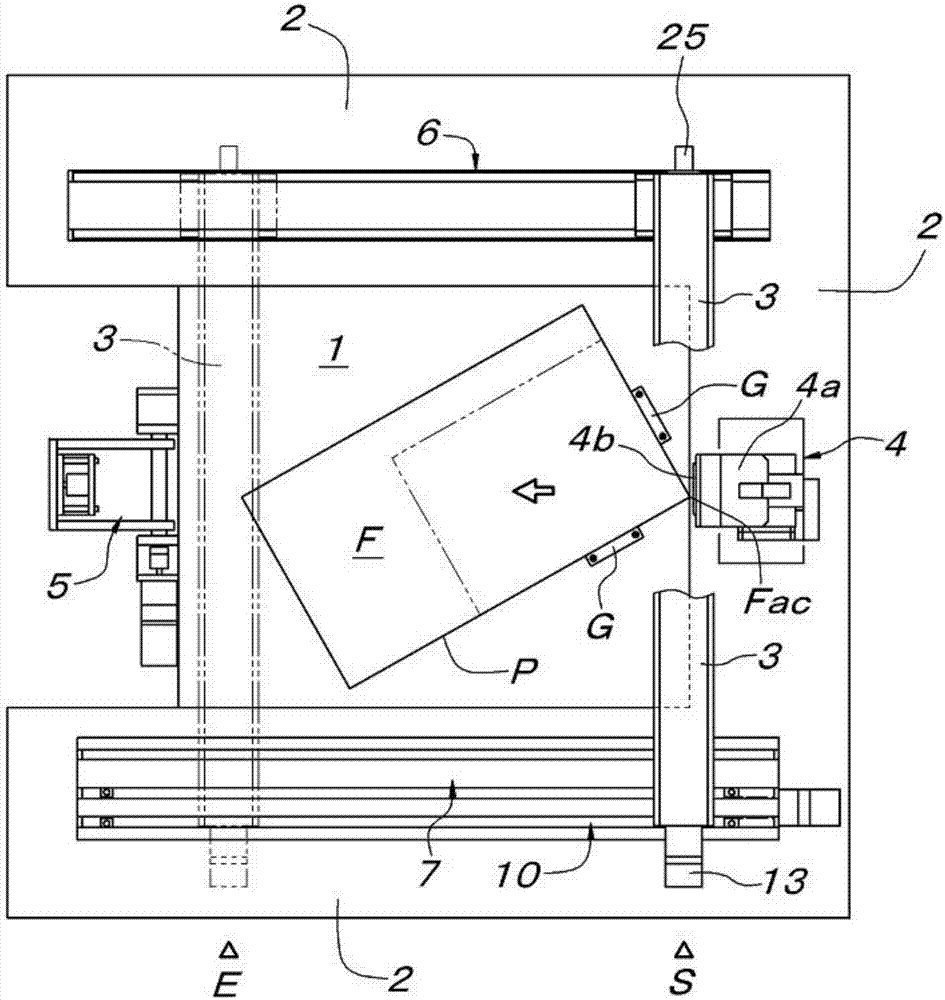

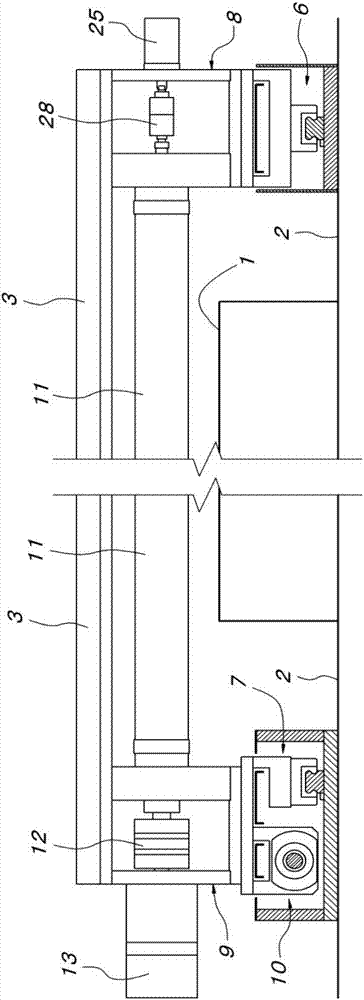

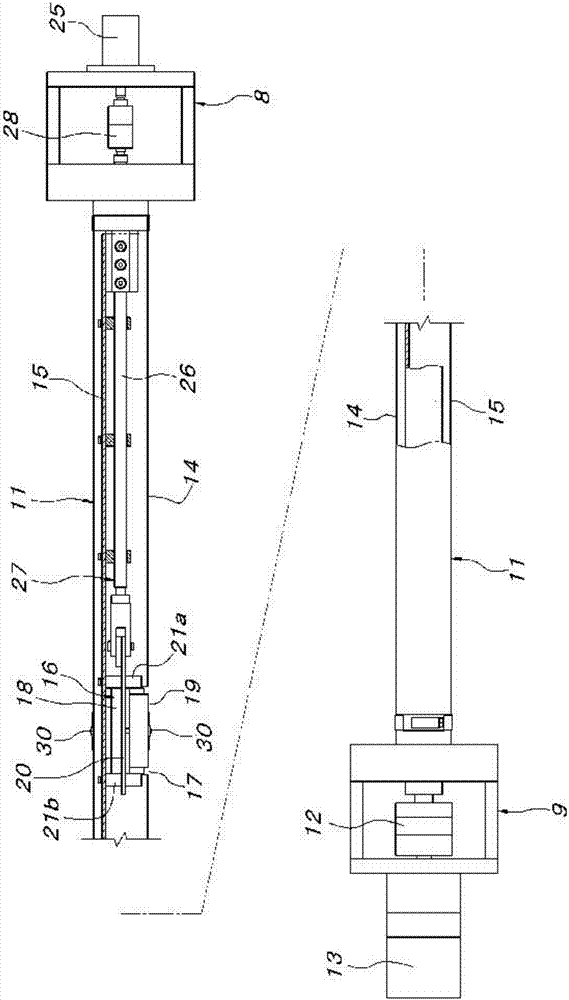

[0059] exist figure 1 and figure 2 Among them, 1 is a horizontal substrate having a plate support water plane for supporting a rectangular plate (glass substrate, etc.) P, and is laid on a platform 2 . 3 is at a certain height above the plate support water plane of the horizontal base plate 1, and between the traverse start position S on the front end side of the horizontal base plate 1 and the traverse end position E on the rear end side of the horizontal base plate 1 A traverse body that moves freely back and forth horizontally. 4 is a film corner peeling device provided outside the front end of the horizontal base 1 , and 5 is a winding film recovery device provided outside the rear end of the horizontal base 1 .

[0060] The traverse body 3 includes support platform portions 8, 9 supported by sliding support members 6, 7 provided on the left and right sides of the horizontal base 1 and parallel to each other on the lower sides of both ends, and supported by sliding supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com