Method of heat accumulation and heat accumulation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0081]Hereinafter, a Thermal Storage Method as a First preferred embodiment of the present invention will be described with reference to the accompanying drawings.

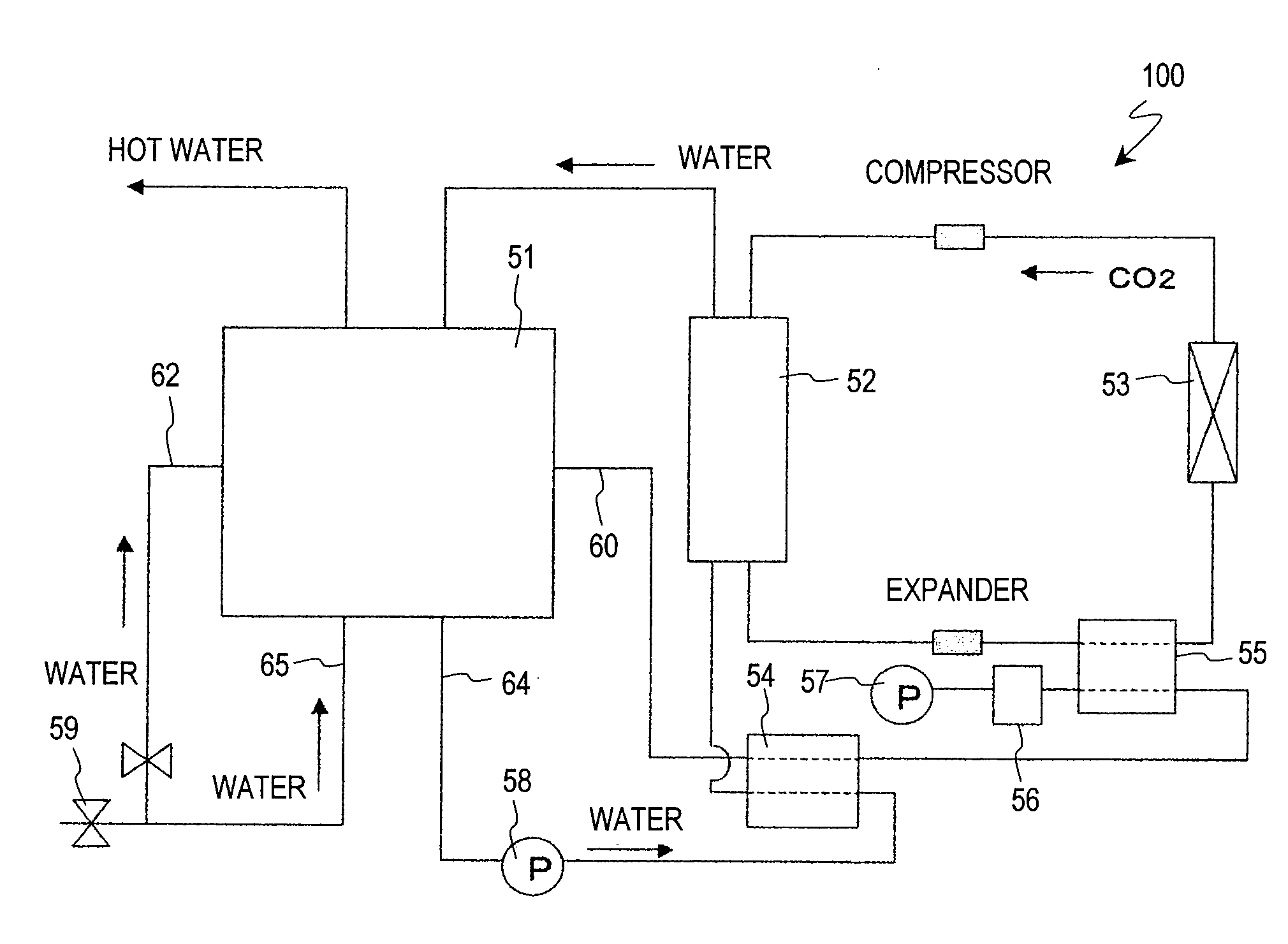

[0082]FIG. 1 illustrates an example of thermal storage and release processes according to this preferred embodiment. In FIG. 1, the abscissa represents the concentration of the composition and the ordinate represents the temperature, and a phase diagram, showing what phases are present in an inorganic salt and water, is shown.

[0083]In this example, Composition A (with an inorganic salt concentration c1) to be an n-hydrate in solid phase at a temperature T1 is used as the first composition. The temperature T1 may be equal to room temperature, for example.

[0084]In the thermal storage process, first, when the temperature of the n-hydrate is increased from the temperature T1 to a temperature T2, which is higher than the phase change temperature Tm, as indicated by the arrow 10, an m-hydrate in solid phase is produced through t...

embodiment 2

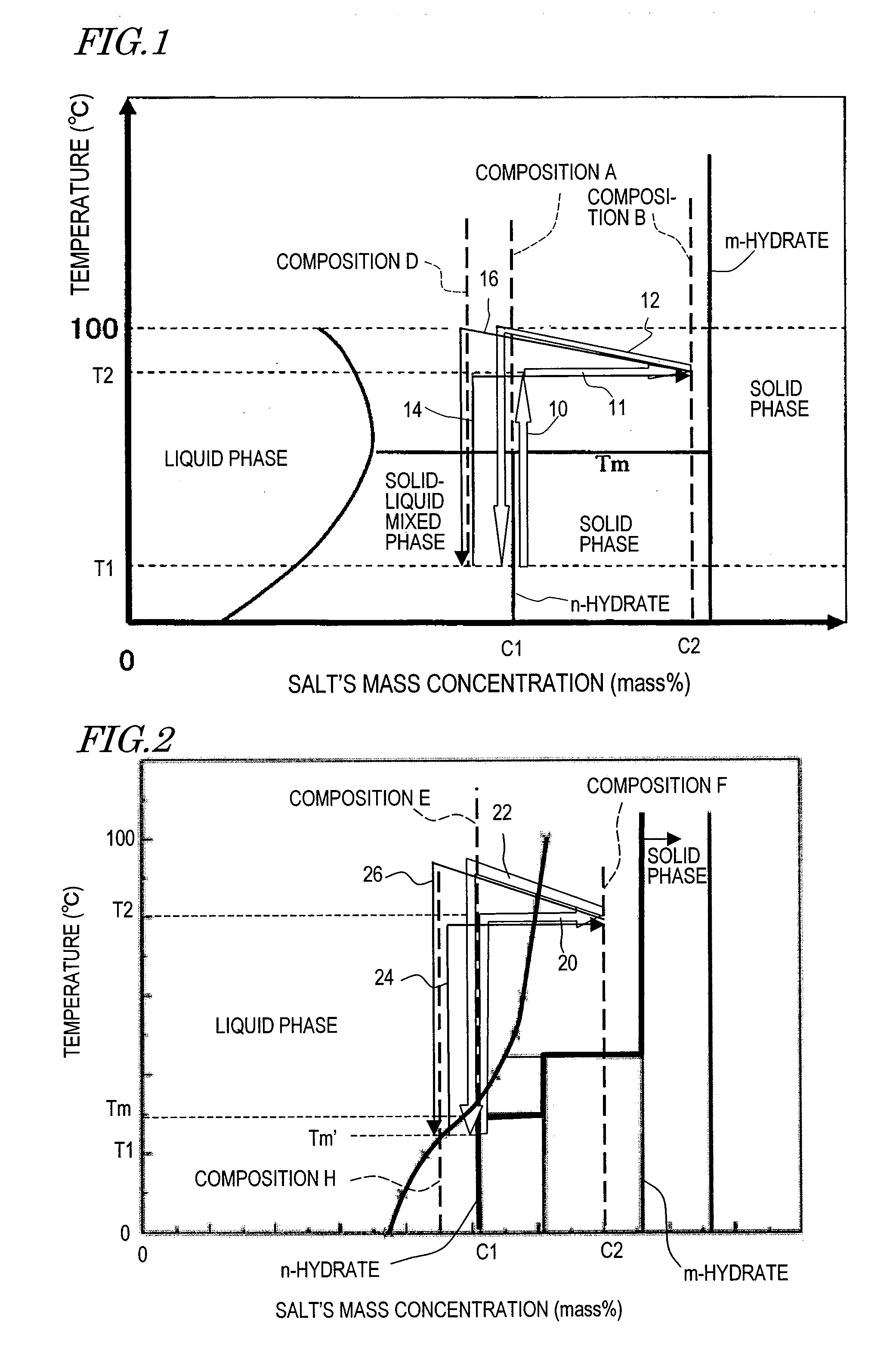

[0097]Hereinafter, a thermal storage method as a second preferred embodiment of the present invention will be described with reference to the accompanying drawings. This preferred embodiment is different from the preferred embodiment described above in that the first composition becomes the second composition by going through a simple liquid phase in the thermal storage process. More specifically, in the preferred embodiment described above, a solid-liquid mixed phase is produced by heating the first composition to the temperature T2 and the second composition is obtained by separating water from the first composition in the solid-liquid mixed phase. Meanwhile, according to this preferred embodiment, when the first composition is heated to the temperature T2, an aqueous solution is produced, and the second composition is obtained by separating water from that aqueous solution.

[0098]FIG. 2 illustrates an example of thermal storage and release processes according to this preferred emb...

example 1

[0137]Hereinafter, specific examples of a thermal storage method according to the present invention will be described with reference to the accompanying drawings.

[0138]In a first specific example of the present invention, using a hydrate including magnesium sulfate and water at a molar ratio of one to seven, thermal storage and heat release processes are carried out with the thermal storage system that has already been described with reference to FIGS. 10 and 11. FIG. 12 is a phase diagram of magnesium sulfate and water, where the thermal storage process of this specific example is indicated by the arrow 90.

[0139]First, magnesium sulfate heptahydrate is put as a first composition 91 into the thermal storage vessel 51. The temperature of the magnesium sulfate heptahydrate is supposed to be room temperature (of approximately 15° C.).

[0140]Next, a thermal storage process is carried out by obtaining a second composition 92 in solid-liquid mixed phase at approximately 80° C. from the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com