Solvent-free epoxy coal tar heavy duty anticorrosive coating and preparation process thereof

A manufacturing process, coal tar technology, applied in the field of solvent-free epoxy coal tar heavy anti-corrosion coating and its manufacturing process, can solve the problems of wear resistance, impact resistance and other performance reduction, long drying time, high labor intensity, etc. Achieve the effects of improving corrosion resistance, fast curing speed and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A solvent-free epoxy coal tar heavy anti-corrosion coating, including two components A and B, wherein, component A includes: 35 mass units of low-molecular epoxy resin, 10 mass units of reactive diluent, 0.5 mass unit of fluid Variable additive, 0.5 mass unit of defoamer, 0.5 mass unit of leveling agent, 1 mass unit of wetting and dispersing agent, 0.5 mass unit of fumed silica and 52 mass unit of mineral filler;

[0018] Component B includes: 20 mass units of amine curing agent, 30 mass units of coal tar, 0.5 mass unit of defoamer, 0.3 mass unit of leveling agent, 0.5 mass unit of wetting and dispersing agent, 0.7 mass unit of Fumed silica and 48 mass units of mineral filler.

Embodiment 2

[0020] A solvent-free epoxy coal tar heavy anti-corrosion paint, including two components A and B, wherein, component A includes: 36 mass units of low-molecular epoxy resin, 13 mass units of reactive diluent, 1.2 mass units of fluid Variable additive, 1.1 mass units of defoamer, 1.1 mass units of leveling agent, 1.5 mass units of wetting and dispersing agent, 1.1 mass units of fumed silica and 45 mass units of mineral filler;

[0021] Component B includes: 18 mass units of amine curing agent, 28 mass units of coal tar, 1.3 mass units of defoamer, 1.2 mass units of leveling agent, 1.2 mass units of wetting and dispersing agent, 1.3 mass units of Fumed silica and 49 mass units of mineral filler.

Embodiment 3

[0023] A solvent-free epoxy coal tar heavy anti-corrosion coating, including two components A and B, wherein, component A includes: 40 mass units of low-molecular epoxy resin, 12 mass units of reactive diluent, 2 mass units of fluid Variable additive, 2 mass units of defoamer, 2 mass units of leveling agent, 3 mass units of wetting and dispersing agent, 2 mass units of fumed silica and 37 mass units of mineral filler;

[0024] Component B includes: 20 mass units of amine curing agent, 30 mass units of coal tar, 2 mass units of defoamer, 2 mass units of leveling agent, 2 mass units of wetting and dispersing agent, 2 mass units of Fumed silica and 42 mass units of mineral filler.

[0025] Among them, the mineral fillers described in Examples 1, 2, and 3 use silicon-oxygen bonded mineral fillers, and the amine curing agent uses Mannich base curing agents.

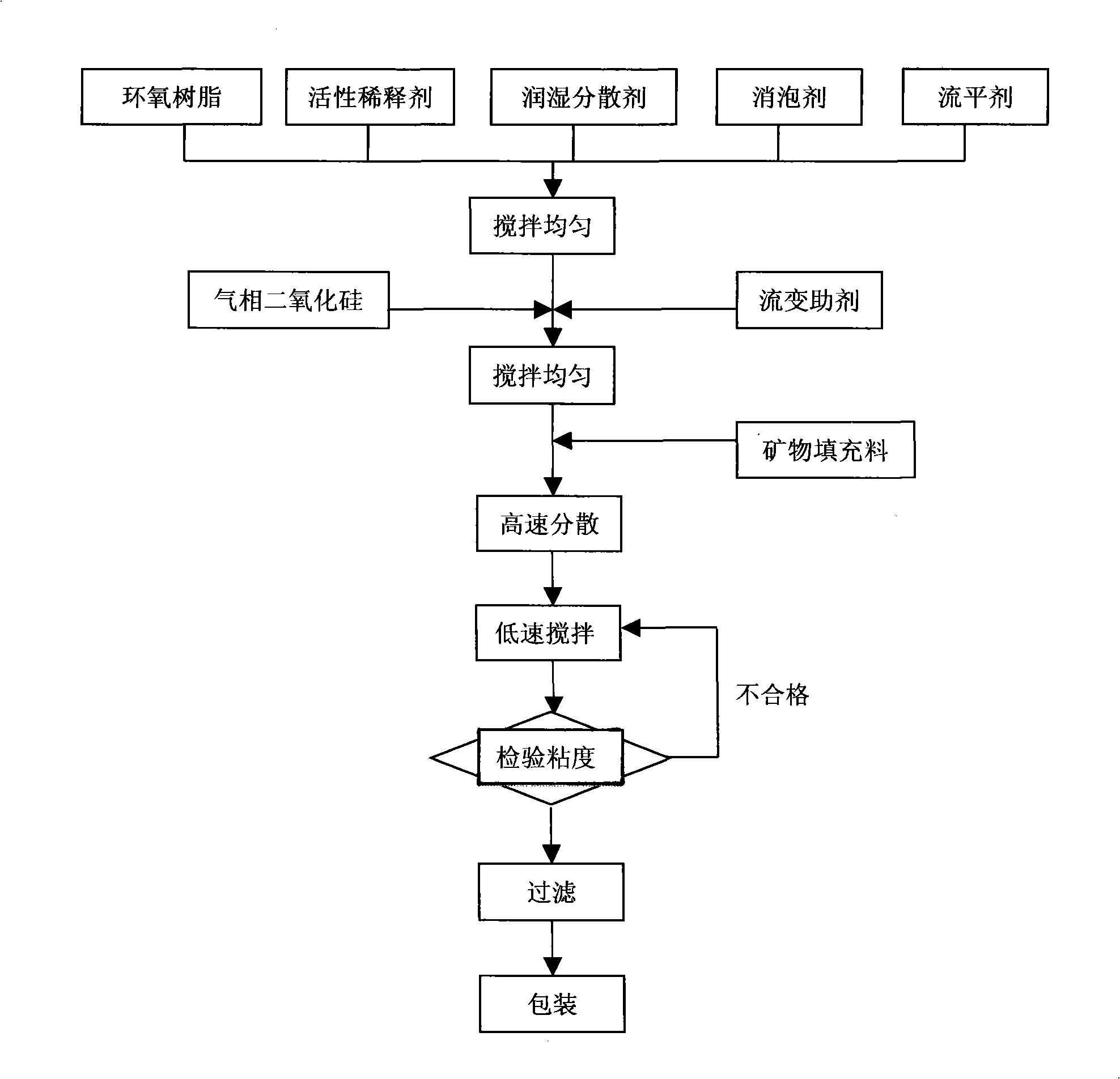

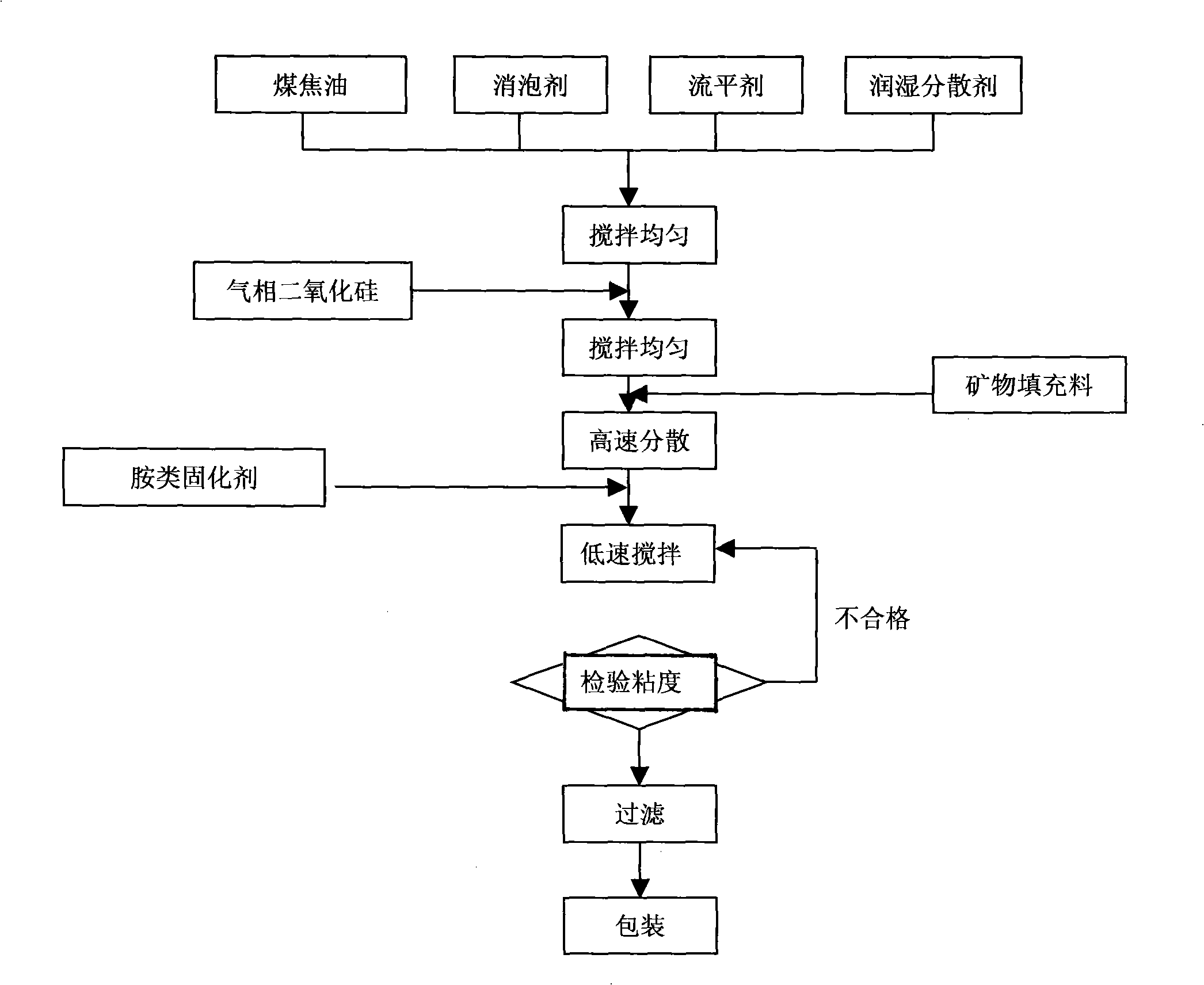

[0026] The process of processing and manufacturing solvent-free epoxy coal tar heavy anticorrosion coating is as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com