Low-density flame-retardant semi-rigid polyurethane foam and preparation method thereof

A polyurethane foam, semi-rigid technology, applied in the field of polyurethane foam, can solve the problems of unmentioned foam dimensional stability and physical properties, combined polyether layered foam size, low modulus, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

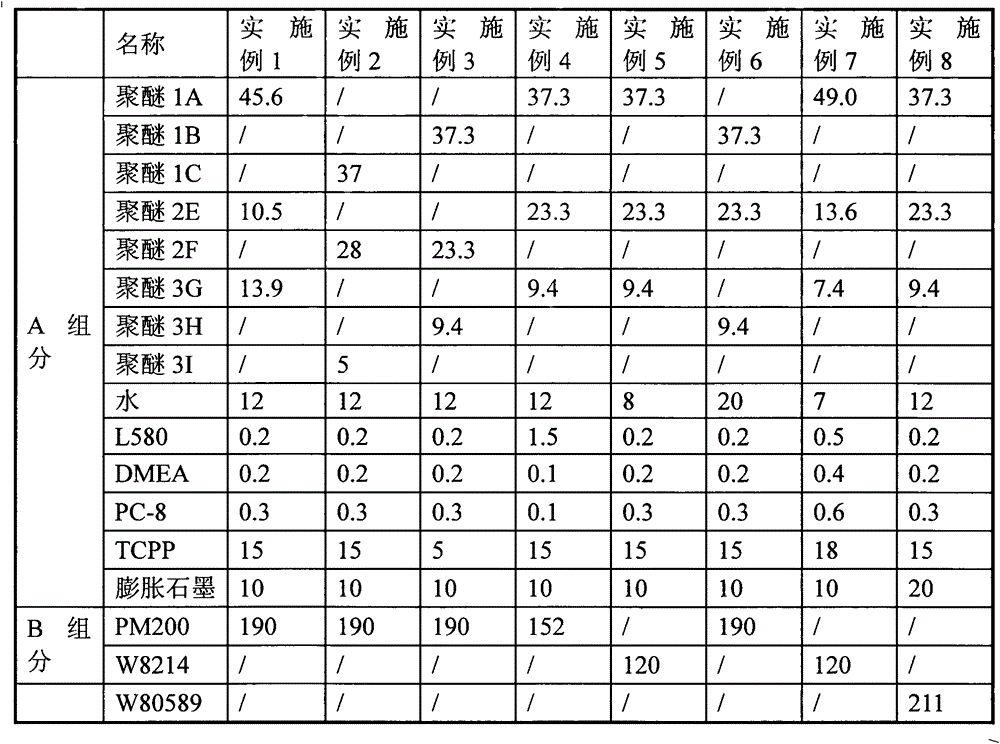

[0050] The operation process is as follows: Example 1-8 According to the example formula in Table 1, polyether 1-3, water, surfactant, catalyst, and flame retardant are added to a mixing tank and mixed evenly to form A material, MDI The isocyanate in the system is material B, control material A and B at 20-30°C, start stirring and mixing for 8-20 seconds, then pour it into an open box mold immediately, let the mixed reactant foam and rise evenly, 20-60 Minutes later, the mold was opened to take out the foam to obtain a polyurethane foam.

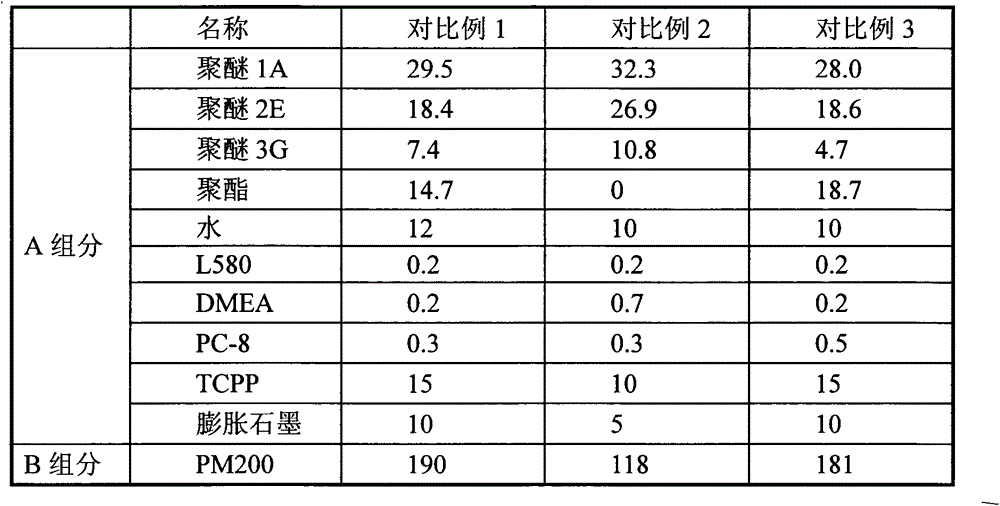

[0051] The polyurethane foam preparation method of Comparative Examples 1-3 is the same as that of Examples 1-8, and the formula is shown in Table 2.

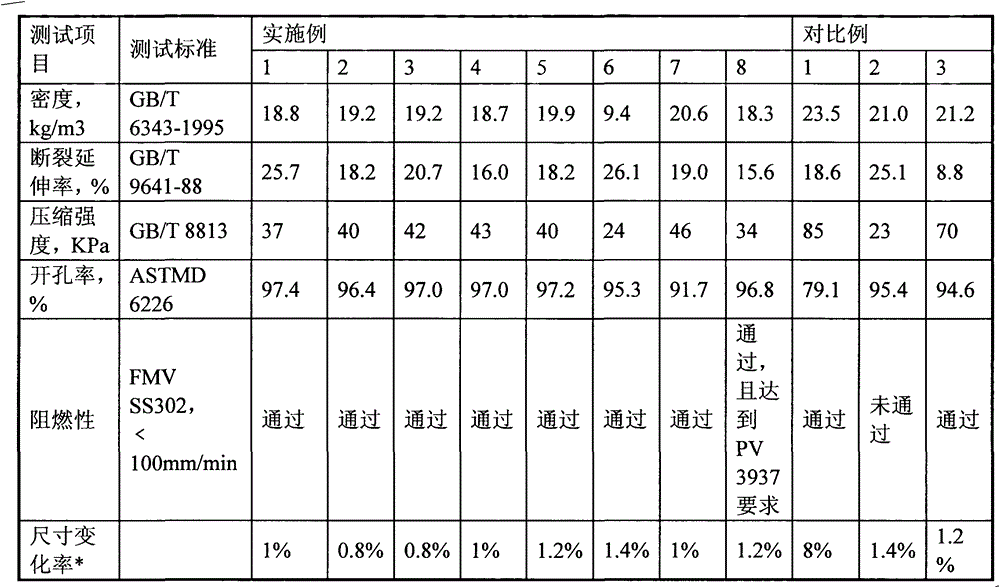

[0052] The properties of the polyurethane foams prepared in Examples 1-8 and Comparative Examples 1-3 are shown in Table 3.

[0053] The raw material that embodiment and comparative example use:

[0054] Polyether 1A: Glycerin initiator, propylene oxide ring-opening polymerization, ethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com