Novel aging technology of mesohigh voltage aluminum electrolytic capacitor

An aluminum electrolytic capacitor, medium and high voltage technology, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of shortened life, increased leakage, negative electrode breakdown, etc., to improve reliability, reduce leakage, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

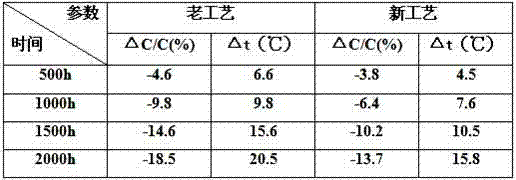

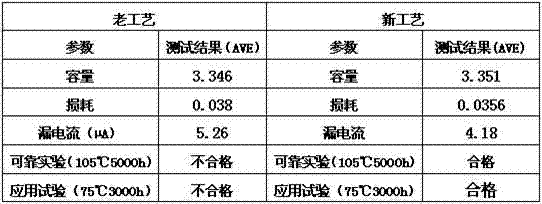

[0018] A new aging process for medium and high voltage aluminum electrolytic capacitors. The aging method adopts the aging method of AC and DC. First, 10±0.5 V AC voltage is applied to the negative electrode for pre-aging, and the aging time is 9 minutes. Then, a DC pulse current is applied to the positive and negative terminals of the capacitor. DC pulse aging is carried out, which is processed by 12 levels of power supply in stages, of which levels 1-8 are aging at room temperature, and levels 9-12 are aging at high temperature and constant voltage. The total DC pulse aging time is 180 min±5min. The rated voltage of the capacitor is 200V, and the aging voltage value of the 8th level is set to 1.2 times the rated voltage of the capacitor, which is 240V. 60 V, 90 V, 120 V, 150 V, 180 V, 210 V step by step. The aging time of grades 1~8 is 100min±5min; the aging temperature of grades 9~12 is 105±2℃, the setting value of aging voltage is the same as the aging voltage value of gra...

Embodiment 2

[0020] A new type of aging process for medium and high voltage aluminum electrolytic capacitors. The aging method adopts the aging method of AC and DC. First, 10±0.5 V AC voltage is applied to the negative electrode for pre-aging. The aging time is 11 minutes, and then a DC pulse current is applied to the positive and negative terminals of the capacitor. DC pulse aging is carried out, which is processed by 12 levels of power supply in stages, of which levels 1-8 are aging at room temperature, and levels 9-12 are aging at high temperature and constant voltage. The DC pulse aging time is 180 minutes in total. The rated voltage of the capacitor is 400V, and the aging voltage value of the 8th level is set to 1.15 times the rated voltage of the capacitor, which is 460V. 115 V, 172 V, 230 V, 2878 V, 345 V, 402 V step by step. The aging time of grades 1~8 is 100min±5min; the aging temperature of grades 9~12 is 105±2℃, the setting value of aging voltage is the same as the aging voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com