Expansion flame-proof organosilicon fluid sealant and method of producing the same

A technology of intumescent flame retardant and intumescent flame retardant, which is applied in the field of flame retardant materials, can solve problems such as ship sinking and threat to ship safety, and achieve the effects of ensuring personnel and property safety, good fire resistance and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

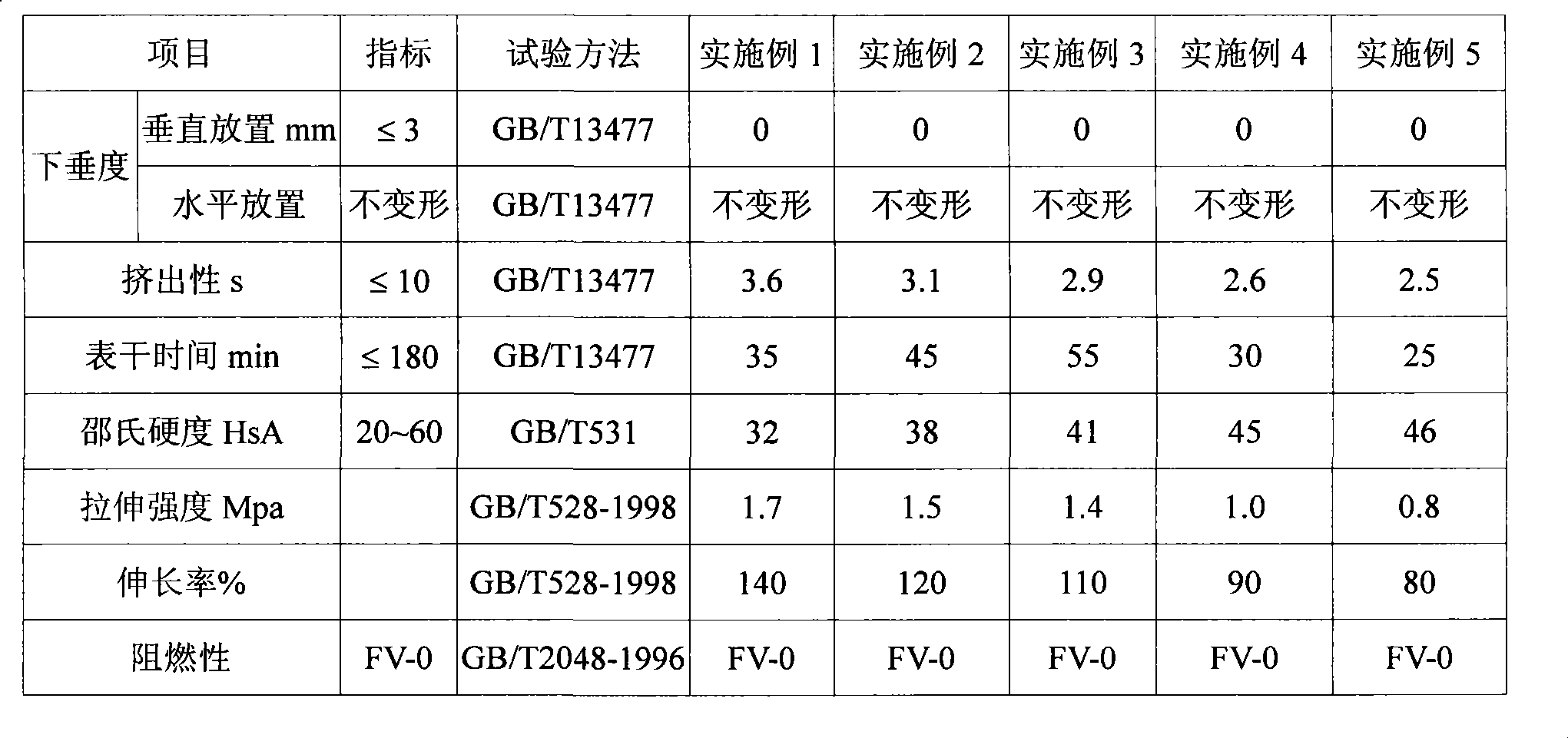

[0036] 90 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 100,000mPa·s, 10 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 500mPa·s, and 30 parts of colloidal calcium carbonate , 40 parts of aluminum hydroxide, 20 parts of basic zinc carbonate, and 15 parts of polyphosphate amine were added to a vacuum planetary mixer at a temperature of 80 ° C, a vacuum degree of -0.06 ~ -0.095 MPa, dehydration and blending for 1 hour; cooled to room temperature, and 8 parts of methyltrimethoxysilane, 1 part of γ-aminopropyltriethoxysilane, 0.2 parts of dibutyltin dilaurate, 10 parts of dimethyl silicone oil, α, ω-dimethoxy polydimethylsilane Add 10 parts of base siloxane and 5 parts of inorganic pigment iron oxide red into the vacuum planetary mixer, the vacuum degree is -0.06~-0.095MPa, and blend for 1.5 hours to obtain intumescent flame-retardant silicone sealant. The performance of the product in different states The test structure is shown in Table 1.

Embodiment 2

[0038] 100 parts of α, ω-dihydroxy polydiethylsiloxane with a viscosity of 50,000mPa·s, 10 parts of fumed silica, 20 parts of kaolin, 80 parts of magnesium hydroxide, 20 parts of zinc borate, and 20 parts of expanded graphite Add one part into a vacuum planetary mixer at a temperature of 100 ° C, vacuum degree of -0.06 ~ -0.095 MPa, dehydration and blending for 1 hour; cool to room temperature, add 14 parts of methyltriethoxysilane, γ-aminopropyltrimethoxy Add 2 parts of silane, 0.6 parts of butyl titanate, 10 parts of branched chain silicone oil, and 0.5 parts of inorganic pigment carbon black into a vacuum planetary mixer at a vacuum degree of -0.06 to -0.095 MPa, and blend for 2 hours to obtain an intumescent flame-retardant organic compound. Silicone sealant, the performance test structure of the product in different states is shown in Table 1.

Embodiment 3

[0040] 60 parts of α, ω-dihydroxypolydiethylsiloxane with a viscosity of 50,000mPa·s, 40 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 2000mPa·s, and 40 parts of colloidal calcium carbonate 20 parts of quartz powder, 80 parts of magnesium hydroxide, 20 parts of basic zinc carbonate, and 25 parts of expanded graphite were added into a vacuum planetary mixer at a temperature of 120°C and a vacuum of -0.06~-0.095MPa, and dehydration and blending for 1.5 hours; Cool to room temperature, add 18 parts of methyl tributyl ketoxime silane, 2 parts of γ-aminopropyl trimethoxysilane, 0.5 parts of isobutyl titanate, 8 parts of dimethyl silicone oil, and 3 parts of inorganic pigment iron oxide blue In the vacuum planetary mixer, the vacuum degree is -0.06~-0.095MPa, and the blending is for 1.5 hours to obtain the intumescent flame-retardant silicone sealant. The performance test structure of the product in different states is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com