High-joule type voltage dependent resistor and production method thereof

A technology of piezoresistors and raw materials, which is applied in the field of high-joule piezoresistors and its preparation, can solve the problems of poor performance of piezoresistors, waste water and liquid pollution, and low manufacturing costs, and achieve strong combined wave resistance and process Simple, low-cost-to-manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

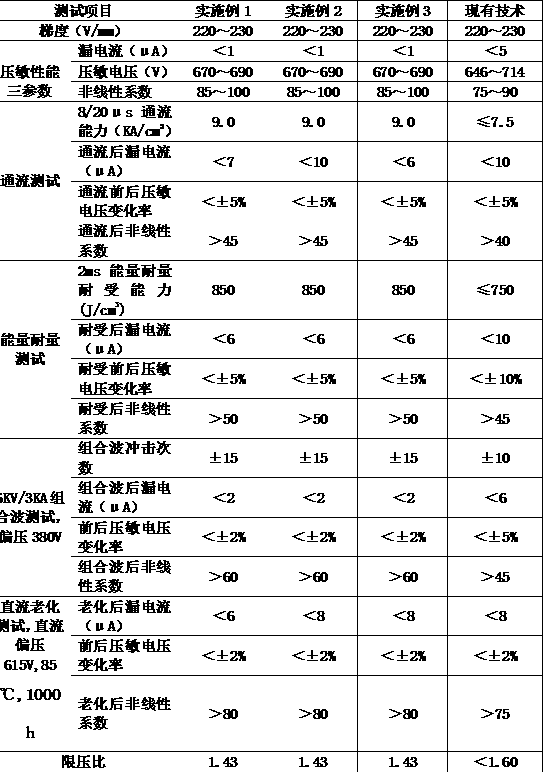

Examples

Embodiment 1

[0022] A preparation method of a high-joule varistor is carried out according to the following steps:

[0023] 1. First weigh 26.0761 grams of industrial superior grade ZnO powder and analyze the pure raw material Nb 2 o 5 85.1420 g, TiO 2 25.5819 grams obtain mixed powder;

[0024] 2. Add 547.2 grams of zirconium balls and 273.6 grams of deionized water to the mixed powder weighed in step 1, wet ball mill and mix for 4 hours, dry quickly at 130°C until completely dried, and then calcined at 1050°C for 4 hours to obtain ZnTiNb 2 o 8 Pre-fired powder;

[0025] 3. The ZnTiNb in step 2 2 o 8 Add 513 grams of zirconium balls and 220 milliliters of absolute ethanol to the calcined powder, planetary ball mill for 8 hours, pass all the ball-milled mixture through a 325-mesh molecular sieve, and then dry slowly at 80°C until completely dried to obtain 136.8 g ZnTiNb 2 o 8 ultrafine powder;

[0026] 4. Weigh and analyze the pure raw material 6861.5 g Bi respectively 2...

Embodiment 2

[0033] A preparation method of a high-joule varistor is carried out according to the following steps:

[0034] 1. First weigh 103.4274 grams of industrial superior grade ZnO powder and analyze the pure raw material Nb 2 o 5 337.705 grams, TiO 2 101.4676 grams obtain mixed powder;

[0035] 2. Add 2,034.75 grams of zirconium balls and 813.9 grams of deionized water to the mixed powder weighed in step 1, wet ball mill and mix for 4 hours, dry quickly at 150°C until completely dried, and then calcined at 1100°C for 3 hours to obtain ZnTiNb 2 o 8 Pre-fired powder;

[0036] 3. The ZnTiNb in step 2 2 o 8 Add 2170.4 grams of zirconium balls and 900 milliliters of absolute ethanol to the calcined powder, planetary ball mill for 8 hours, pass all the ball-milled mixture through a 325-mesh molecular sieve, and then dry slowly at 60°C until completely dried to obtain 542.6 g ZnTiNb 2 o 8 ultrafine powder;

[0037] 4. Weighing and analyzing 7696.3 grams of pure raw materia...

Embodiment 3

[0044] A preparation method of a high-joule varistor is carried out according to the following steps:

[0045] 1. First weigh 41.4587 grams of industrial superior grade ZnO powder and analyze the pure raw material Nb 2 o 5 135.3683 grams, TiO 2 40.6731 grams obtain mixed powder;

[0046] 2. Add 815.6 grams of zirconium balls and 435 grams of deionized water to the mixed powder weighed in step 1, wet ball mill and mix for 3 hours, dry quickly at 150°C until completely dried, and then calcined at 1075°C for 4 hours to obtain ZnTiNb 2 o 8 Pre-fired powder;

[0047] 3. The ZnTiNb in step 2 2 o 8Add 870 grams of zirconium balls and 360 milliliters of absolute ethanol to the calcined powder, planetary ball mill for 7 hours, pass all the ball-milled mixture through a 325-mesh molecular sieve, and then dry slowly at 60°C until completely dried to obtain 217.5 g ZnTiNb 2 o 8 ultrafine powder;

[0048] 4. Weighing and analyzing 7117.4 grams of pure raw materials respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com