A kind of black filled polypropylene composite material and its preparation method and application

A technology of composite materials and polypropylene, which is applied in the field of black filled polypropylene composite materials and its preparation, can solve the problems of reducing product competitiveness and increasing product costs, and achieve the goals of improving heat and oxygen aging resistance, reducing dosage, and reducing dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

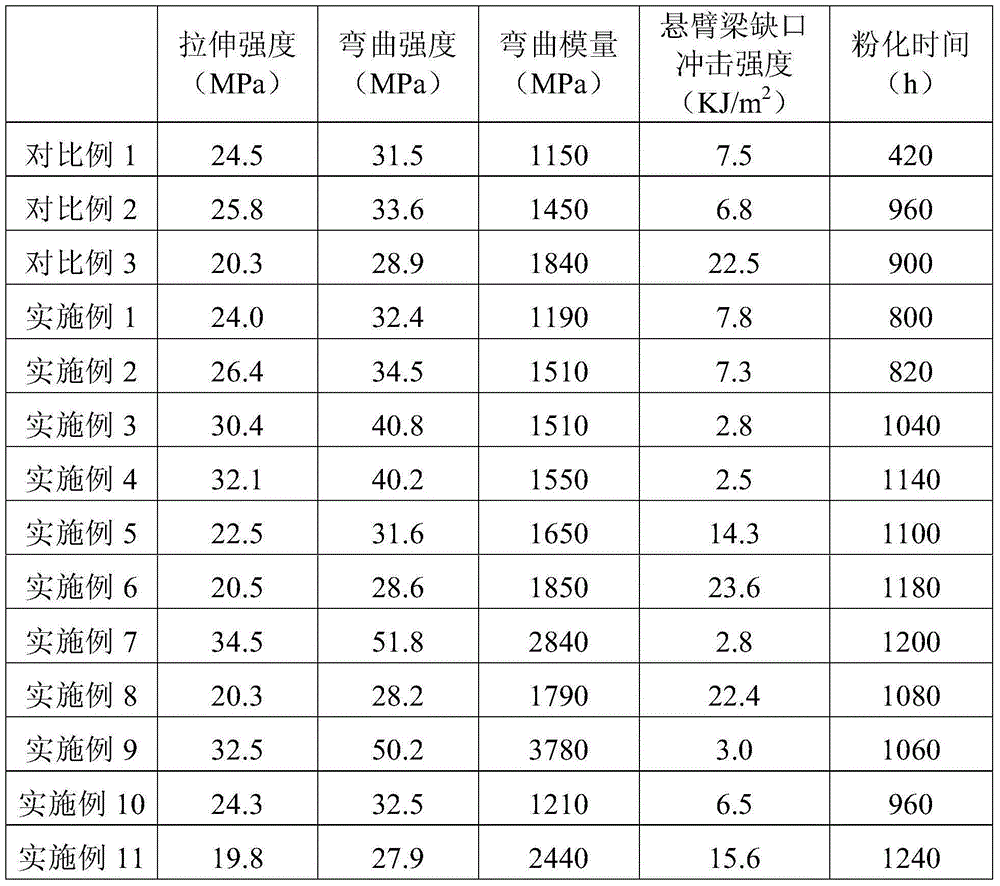

Examples

Embodiment 1

[0051] Embodiment 1: Preparation of a kind of black filled polypropylene composite material

[0052] It is composed of the following raw materials in weight percentage: polypropylene (PPHHP10, Maoming Petrochemical) 98.6%; primary antioxidant 0.2%; secondary antioxidant 0.2%; carbon black 0.6%; processing aid 0.4%.

[0053] The primary antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010) 0.2%; the secondary antioxidant is tri[ 2,4-di-tert-butylphenyl]phosphite (antioxidant 168) 0.2%; the carbon black is N330 (iodine absorption value 82mg / g); the processing aid is made of ethylene bis-stearin Amide 0.2% and Calcium Stearate 0.2%.

[0054] The preparation steps are as follows: the mixture of polypropylene, primary antioxidant, secondary antioxidant, carbon black, and processing aids uniformly mixed by a high mixer is passed into the extruder through the main feeding port of the twin-screw extruder through a feeding s...

Embodiment 2

[0055] Embodiment 2: Preparation of a kind of black filled polypropylene composite material

[0056] Composed of the following raw materials in weight percentage: polypropylene (PPHHP10, Maoming Petrochemical) 88.2%; talc powder 10%; primary antioxidant 0.4%; secondary antioxidant 0.4%; carbon black 0.6%; processing aid 0.4% .

[0057] The primary antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010) 0.4%; the secondary antioxidant is tri[ 2,4-di-tert-butylphenyl] phosphite (antioxidant 168) 0.4%; the carbon black is N220 (iodine absorption value 121mg / g); the processing aid is made of ethylene bis-stearin Amide 0.2% and zinc stearate 0.2%.

[0058] The preparation steps are as follows: the mixture of polypropylene, primary antioxidant, secondary antioxidant, carbon black, processing aids and talcum powder, which are uniformly mixed by a high mixer, are passed through a twin-screw extruder from different feeding sc...

Embodiment 3

[0059] Embodiment 3: Preparation of a kind of black filled polypropylene composite material

[0060] It is composed of the following raw materials in weight percentage: polypropylene (PPHP500N, China Sea Shell Petrochemical Co., Ltd.) 98.4%; primary antioxidant 0.4%; secondary antioxidant 0.4%; carbon black 0.4%; processing aid 0.4%.

[0061] The primary antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant 1010) 0.4%; the secondary antioxidant is thio Dioctadecyl dipropionate (DSTP) 0.4%; the carbon black is N220 (iodine absorption value 121mg / g); the processing aid consists of 0.2% ethylene bis stearamide and 0.2 calcium stearate %.

[0062] The preparation steps are: feed the mixture of polypropylene, primary antioxidant, secondary antioxidant, carbon black, and processing aids uniformly mixed by a high mixer into the extruder through the main feeding port of the twin-screw extruder. Out of the machine, the extruder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com