X-ray camera and manufacturing method thereof

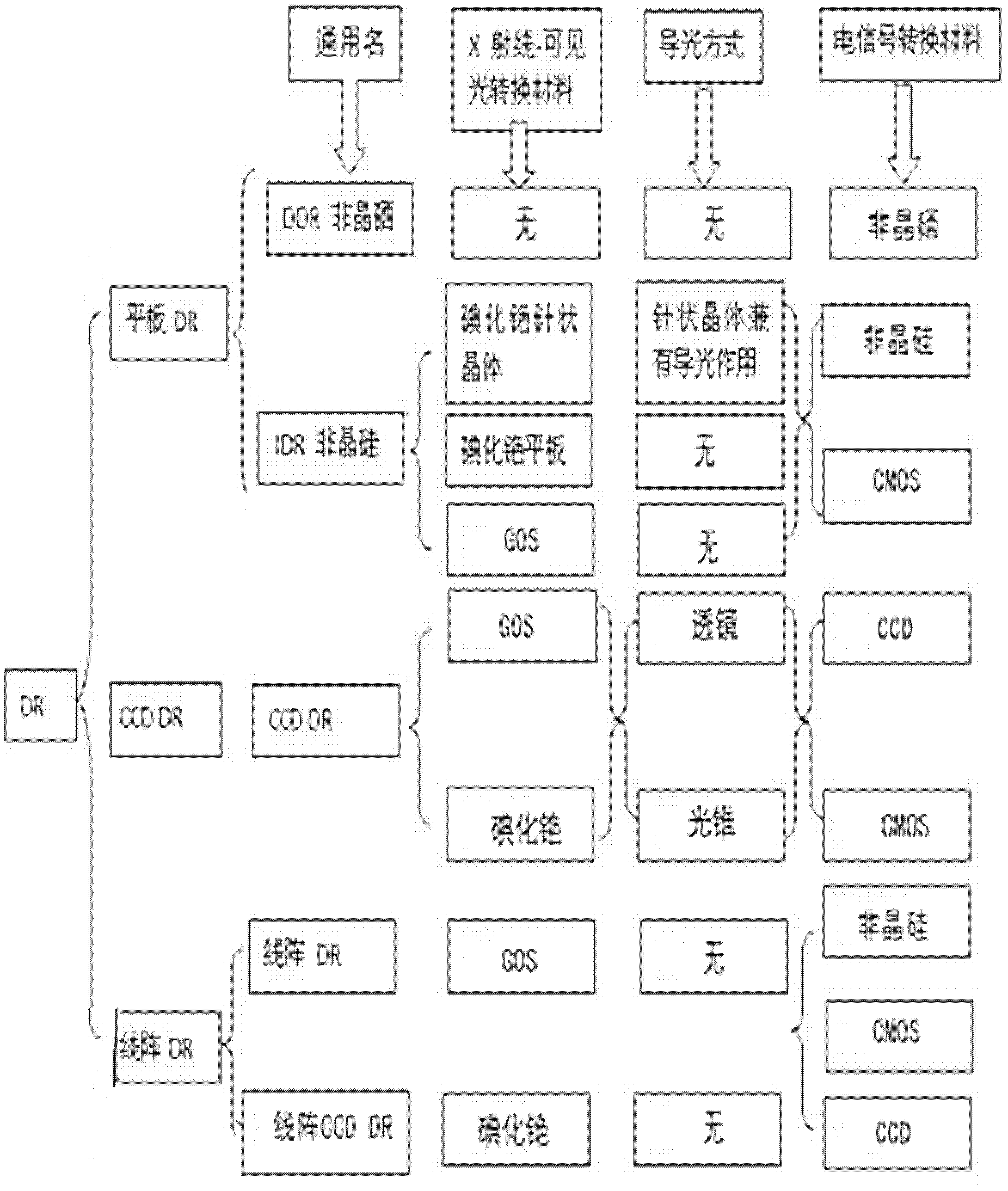

An X-ray and camera technology, applied in the field of X-ray imaging, can solve the problems that X-ray cameras cannot obtain high resolution and high conversion efficiency at the same time, and achieve the effect of improving modulation transfer function, high conversion efficiency and good resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

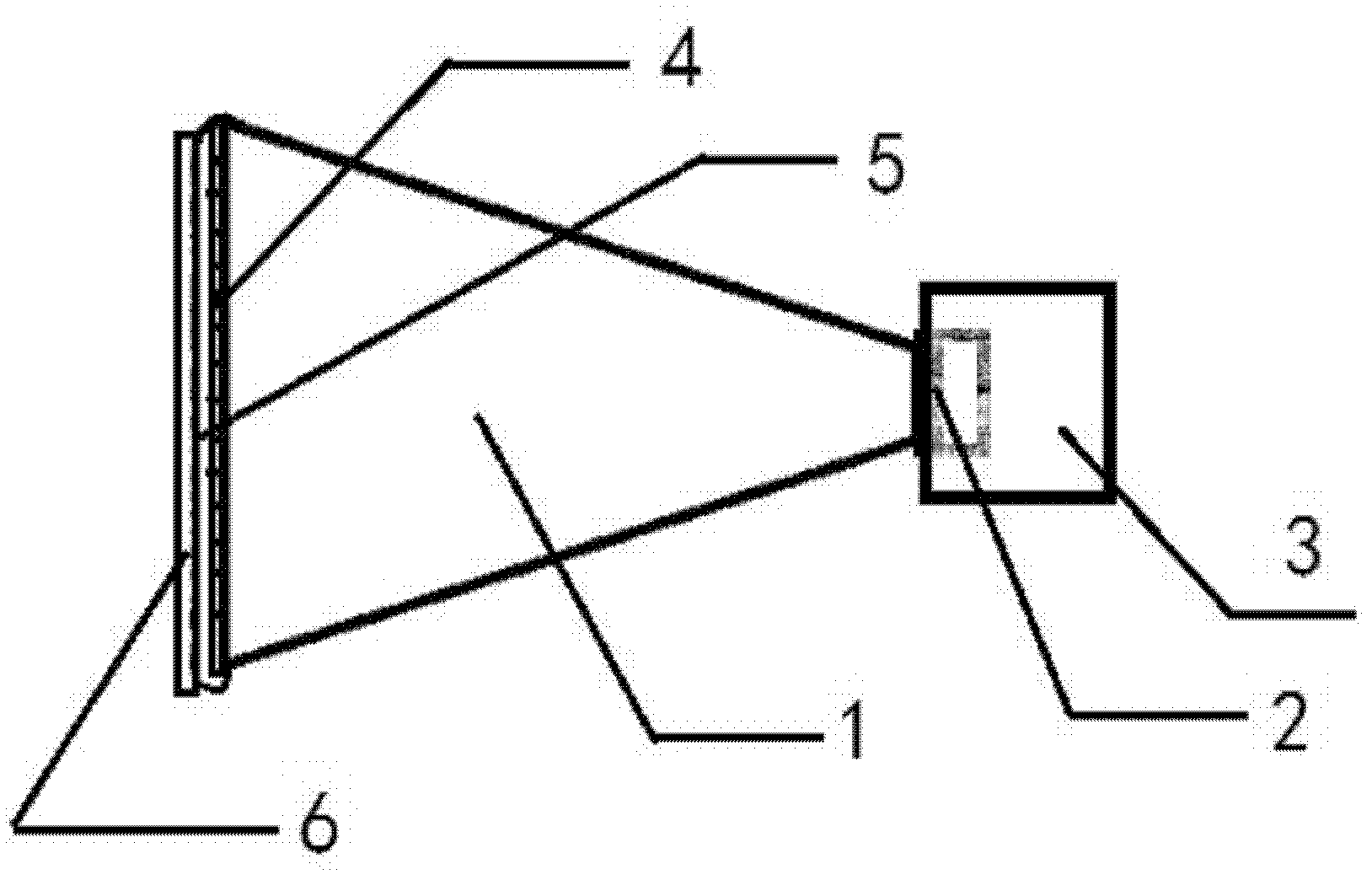

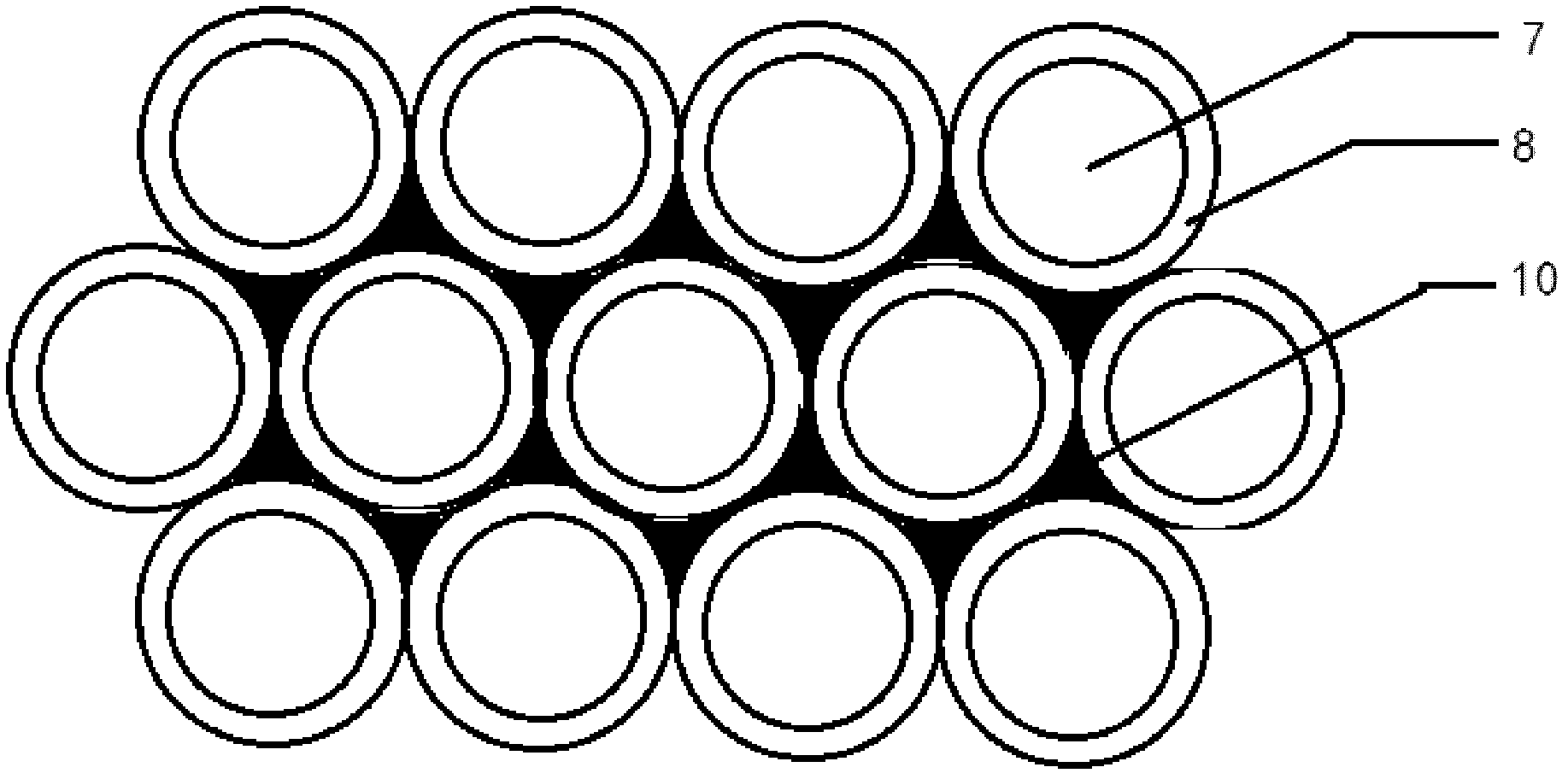

[0030] A kind of X-ray camera disclosed by the present invention, such as figure 2As shown, it is formed by coupling the light cone 1 with the CCD or CMOS camera 3, that is, the small head of the light cone is bonded with the photosensitive surface 2 on the CCD or CMOS chip through optical coupling glue, and the other end of the light cone is plated with Needle-shaped CsI crystal 4, moisture-proof film 5, aluminum film or silicon nitride film 6, the light cone 1 is formed after being drawn by a high-refractive-index core glass rod and a low-refractive-index skin glass tube used in ordinary light cones On the basis of the fine glass fiber array, a black glass leather tube or a glass tube made of glass material that can be blackened after the subsequent process is put on before the monofilament is drawn. For the convenience of descrip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com