High gain transmissive viewing screen

A high-gain, screen technology, applied in the field of transmissive screens and video rear-projection screens, can solve the problems affecting the viewing effect of screen images, and achieve the effect of high gain and large viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

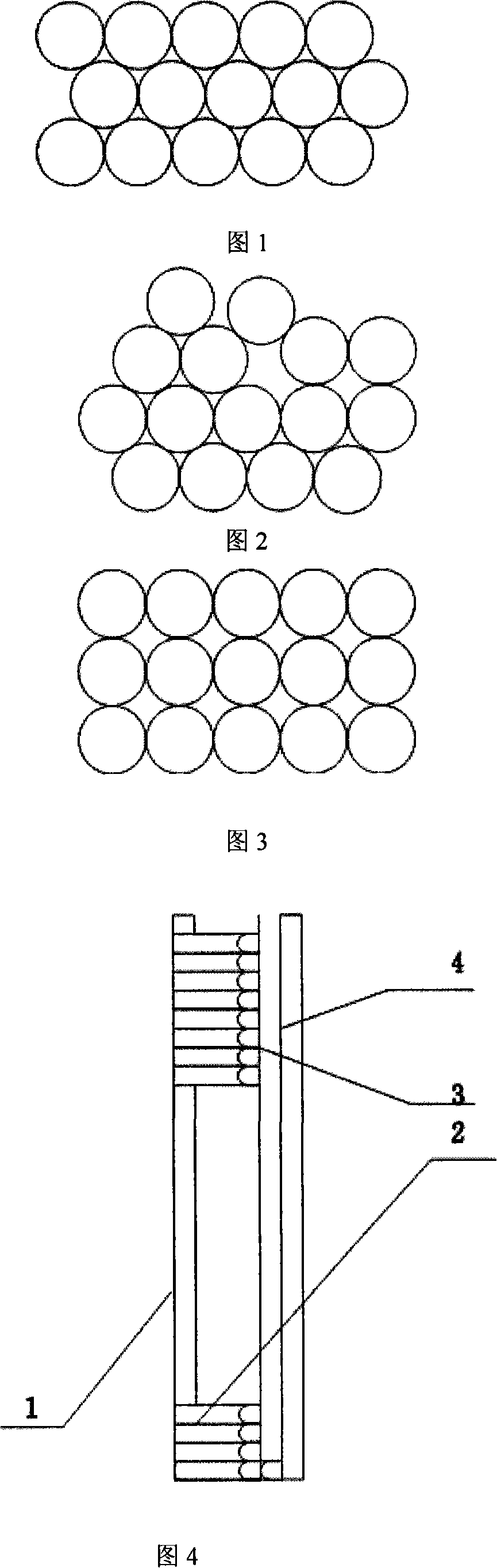

Embodiment 1

[0022] Example 1: Arrange the optical fibers of 5-40mm with exactly the same length in the screen frame of the required size as shown in Figure 1. The optical fibers can be fixed with or without glue. After tightening, the plane of the optical fiber head is integrated After polishing, the optical fiber head is directly made into a flat mirror. After pasting the front transparent layer and the rear transparent layer, the pixel light beams are transmitted by the optical fiber and form a divergent point light source behind the flat mirror. The divergence angle of the pixel point light source is large, and the light is in the The rear end of the screen is imaged in the light-transmitting layer, and the viewing angle of the manufactured screen is relatively large. Using this method, if the optical fibers have been connected and fixed by glue, the front light-transmitting layer of the screen can be omitted, and the screen manufactured by this method has the characteristics of a trans...

Embodiment 2

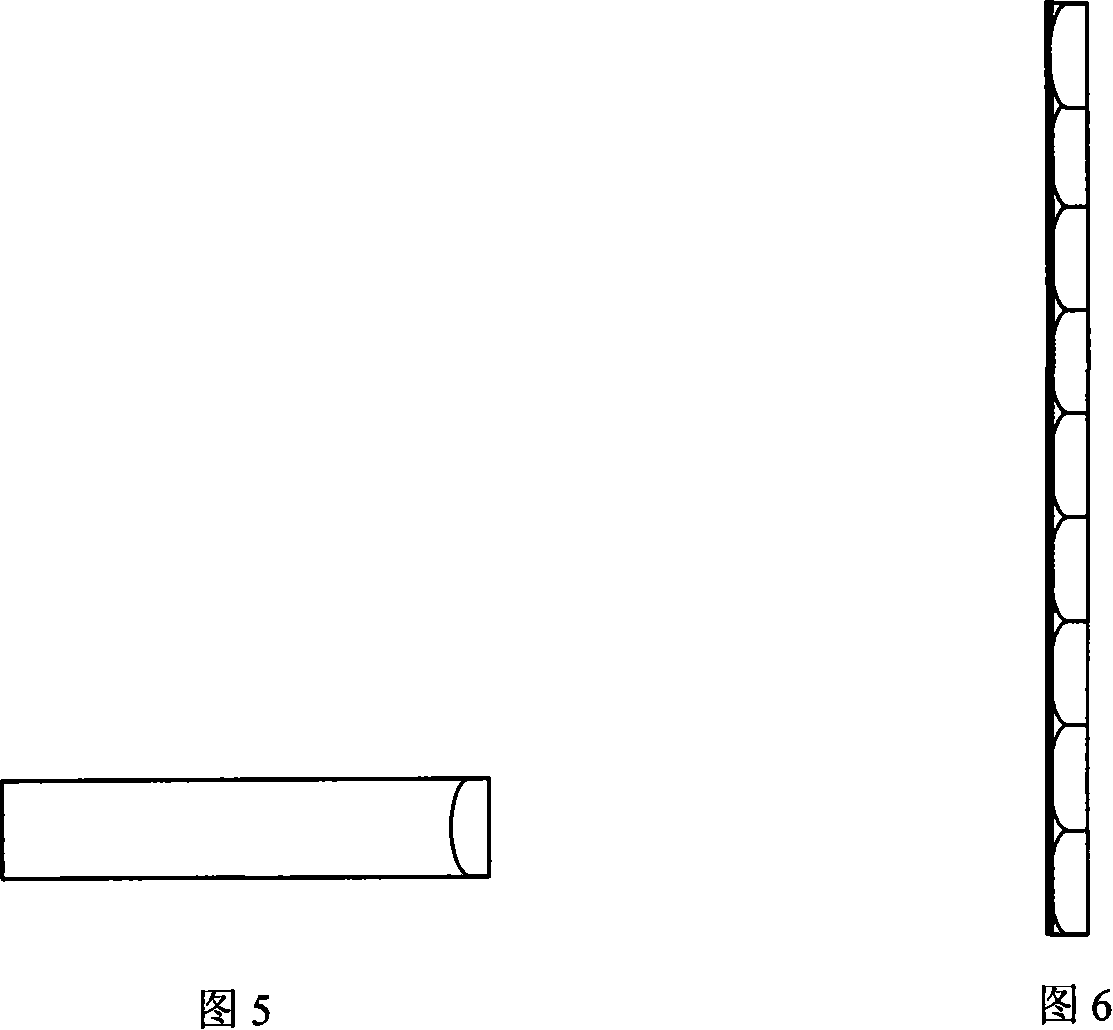

[0023] Example 2, the optical fibers with a length of 6-25000 mm can be directly stacked into the size required by the screen, and then the stacked optical fibers can be sliced sequentially according to the required screen thickness by using thermal cutting wire, and the cut pieces can be flattened at 80-150 °C After that, the fiber optic micromirror composite layer can be made. For organic plastic optical fiber, a voltage regulator can be used to adjust the temperature of the cutting resistance wire. The higher the cutting temperature, the faster the cutting speed. The cutting temperature of organic plastic optical fiber is between 180 and 800°C. The temperature is 1200-1700°C. The screen manufactured by this method can omit the front light-transmitting layer of the screen, and has the characteristics of a transmission screen that forms images in the screen.

Embodiment 3

[0024] Embodiment 3: Engraving, die-casting or spraying the micromirror layer by means of laser engraving, die-casting and spraying according to the optical fiber stacking method. This method is suitable for manufacturing trapezoidal screens, that is, screens with small light-receiving surface and large imaging surface. The bottom of the engraved micromirror layer and the optical fiber contact layer are fully transparent, and the surroundings are coated with reflective film. This method can also be used to manufacture a screen that is imaged outside the back-end light-transmitting layer, that is, outside the screen, and can achieve very high screen gain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com