Particle Counter with Laser Diode

a laser diode and particle counter technology, applied in the field of light scattering particle counters, can solve the problems of in-situ systems taking more time to achieve a statistically significant determination of fluid cleanliness, and their operation principles are very different from the principles used in particle counters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

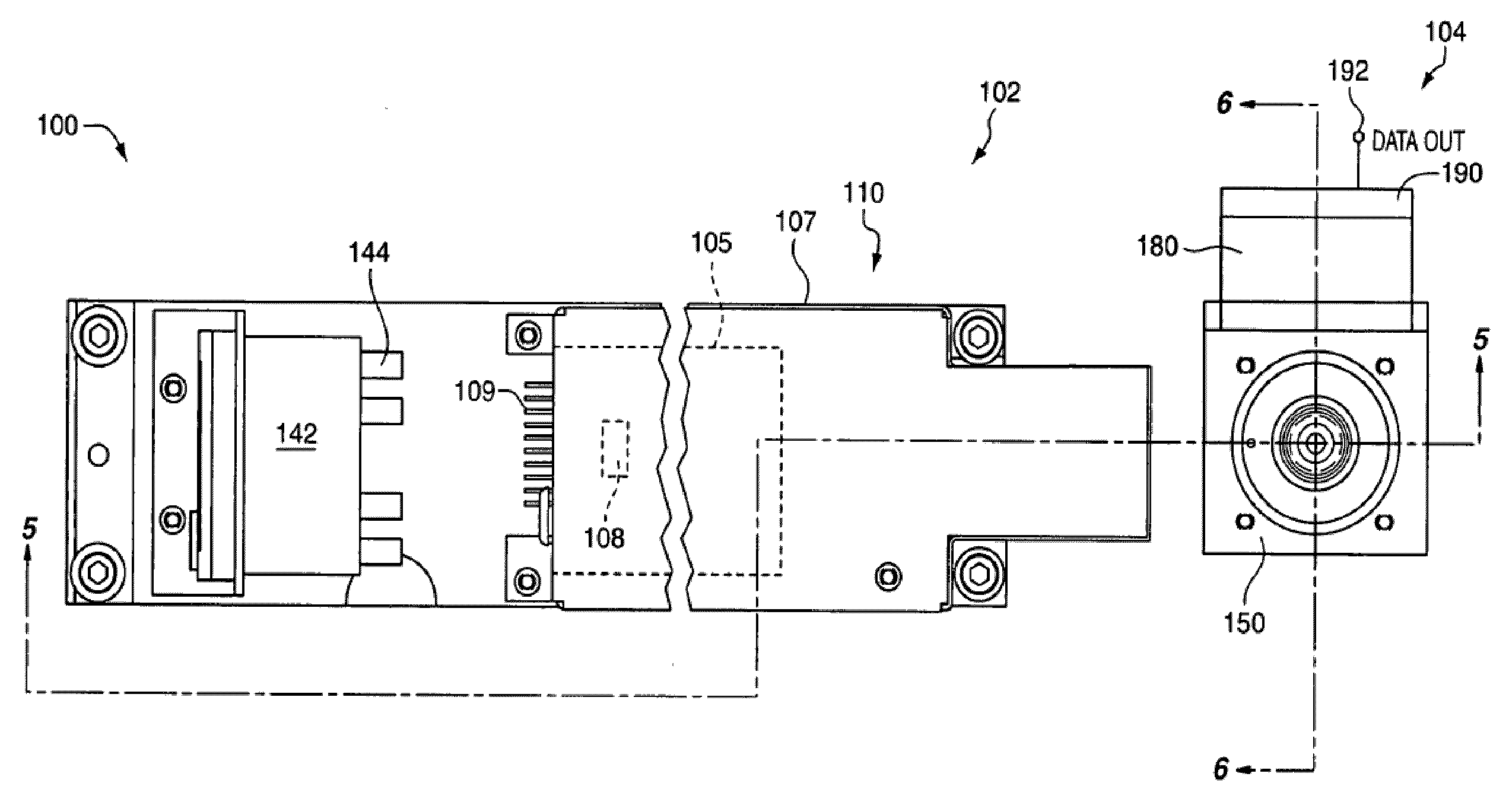

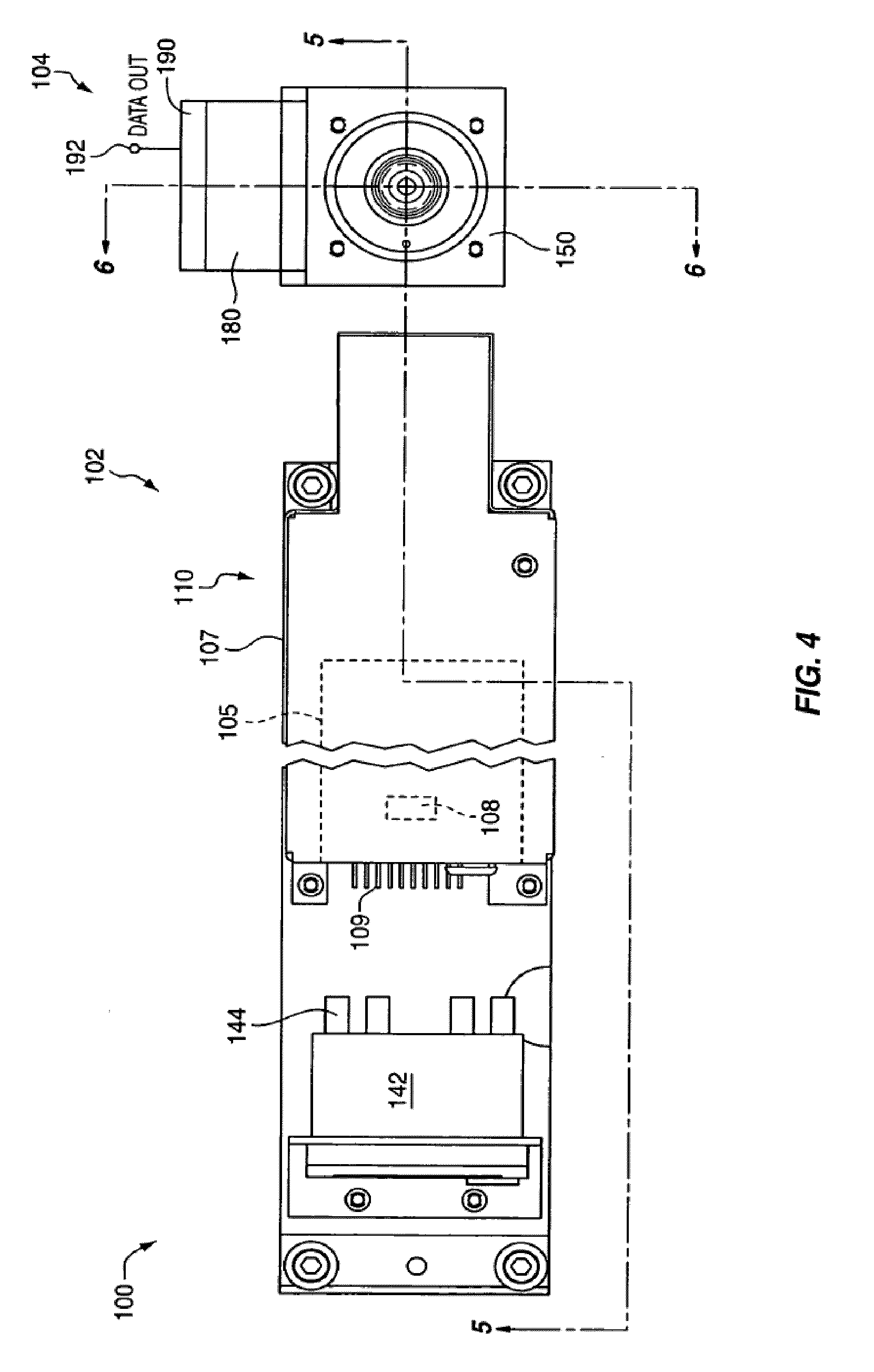

Image

Examples

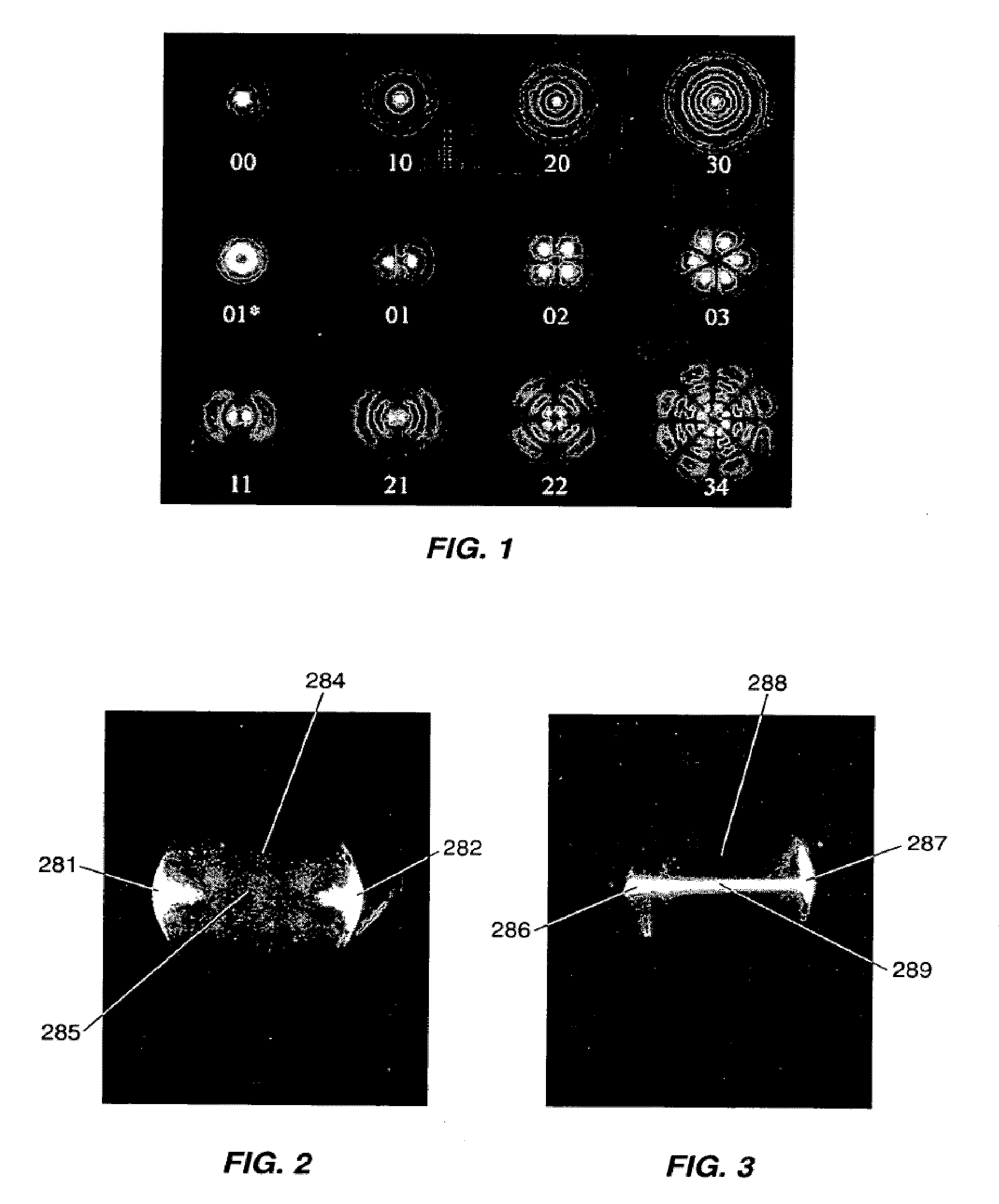

Embodiment Construction

[0034]In this disclosure, the term light is not limited to visible radiation but is used in a broad sense meaning any electromagnetic radiation. Stray light includes any light that is not wanted; i.e., light that is not light scattered from particles but which can get into the collection optics. Multiply reflected light is a significant source of stray light in a particle counter. That is, light that is reflected once, scattered from a scattering source, or diffracted by a lens or aperture can usually be blocked out by other apertures or absorbing black walls because the source of the unwanted light is. However, multiple reflections make it difficult to determine the direction of the light, and thus often cannot be apertured or otherwise blocked out. The terms in-situ and volumetric are used as described in the Background of the Invention above. It is also noted that this disclosure is limited to fluid particle counters, which is a term of art. There are particle counters that detec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com