Patents

Literature

48results about How to "Step can be unnecessary" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

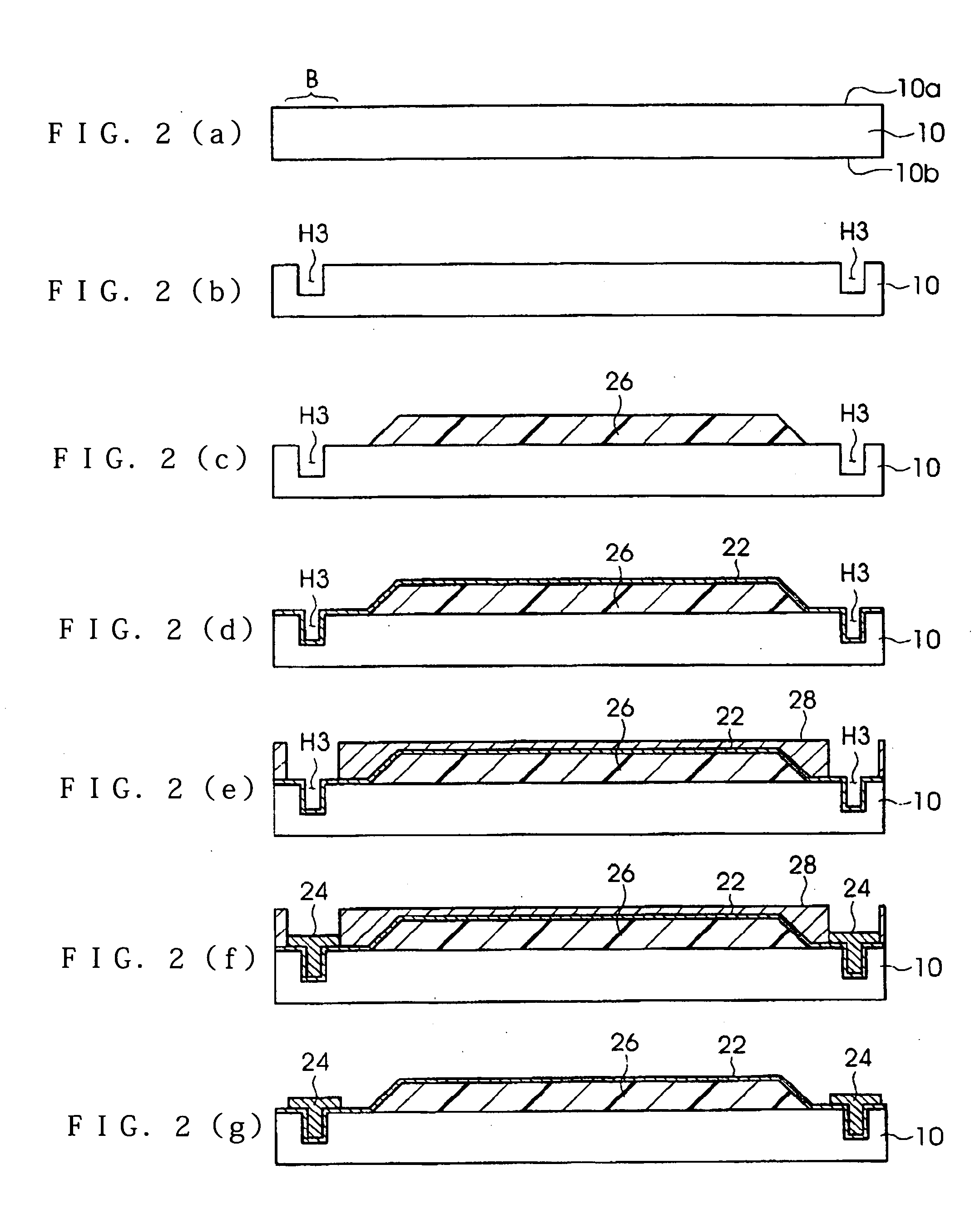

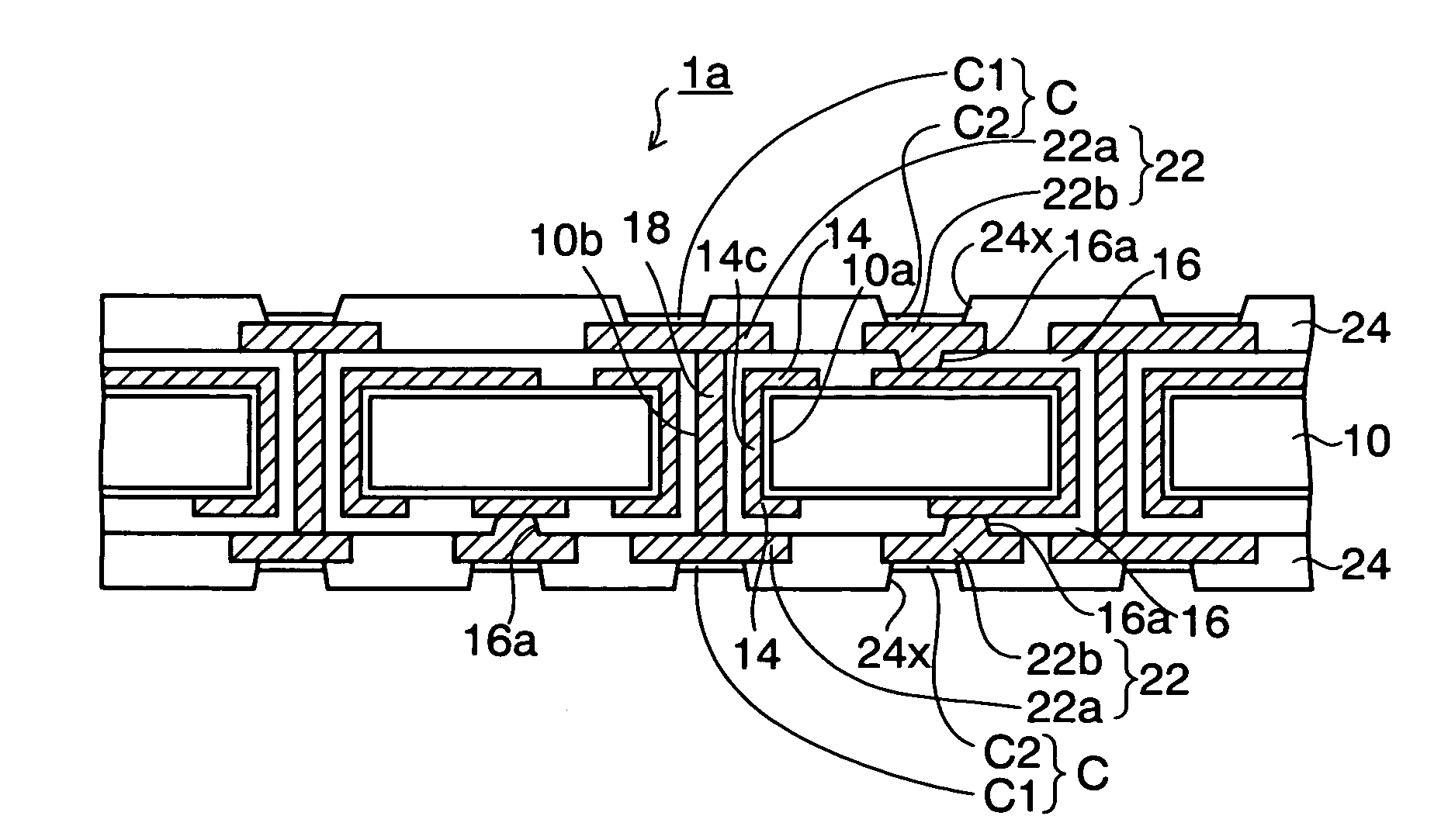

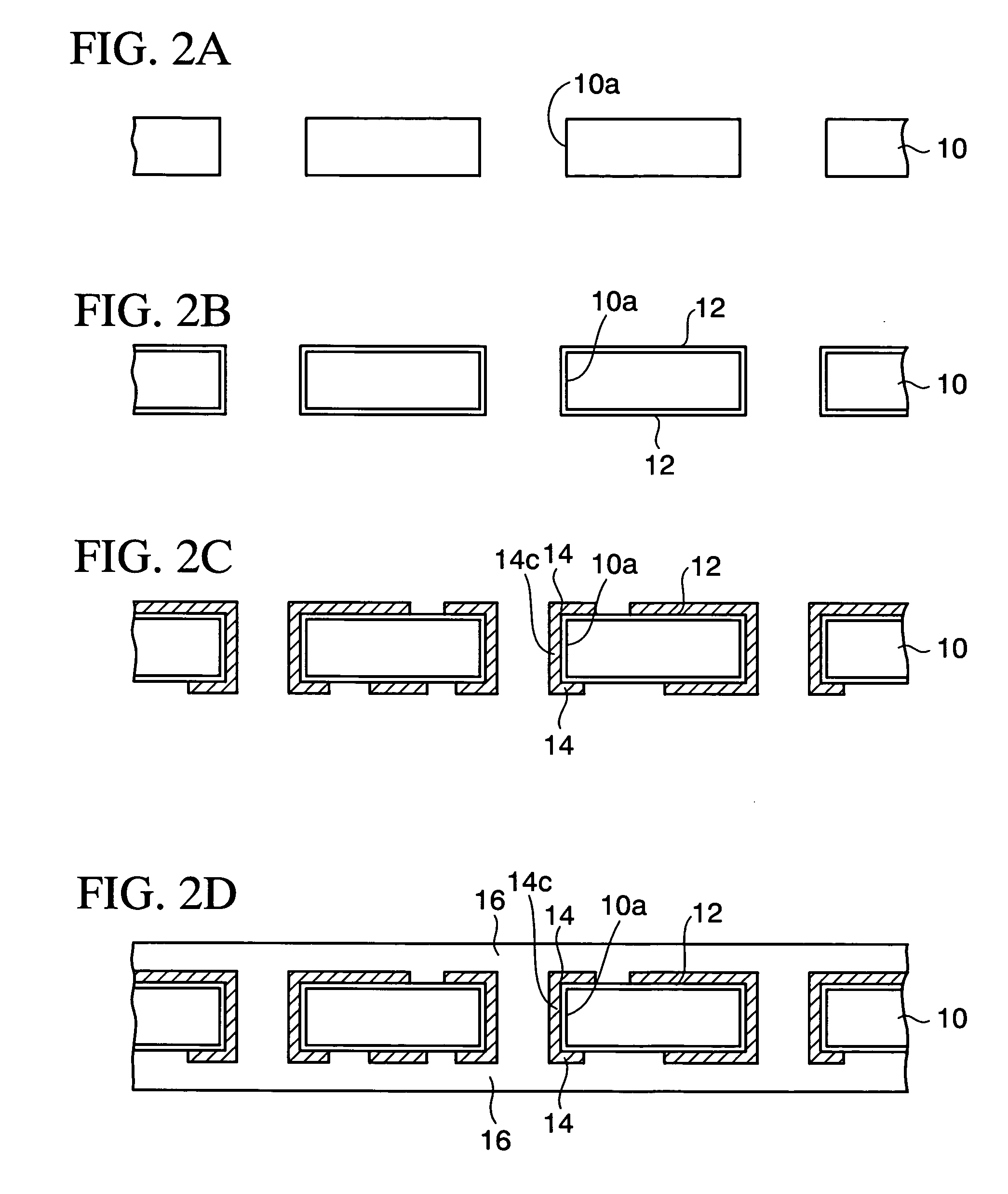

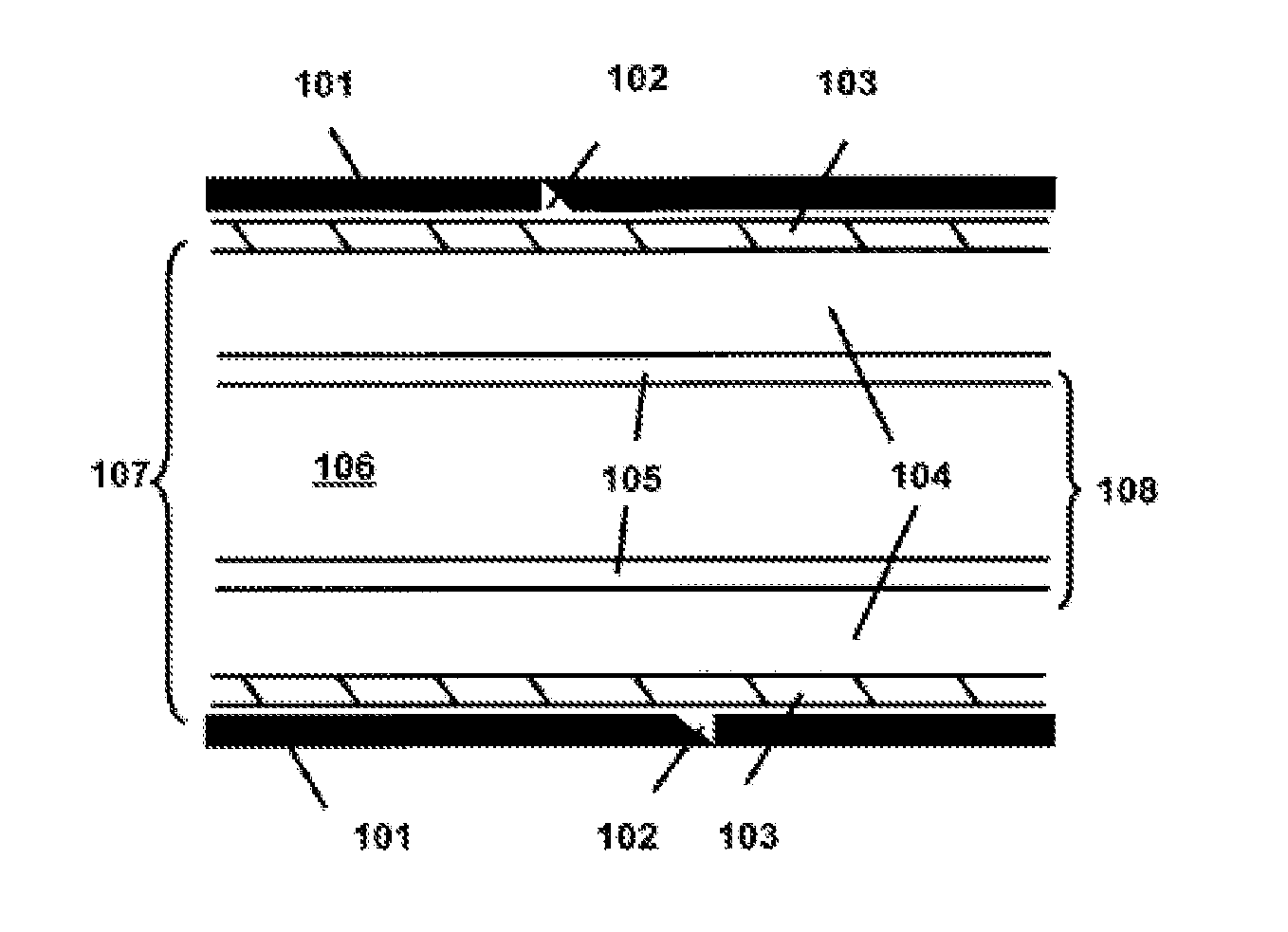

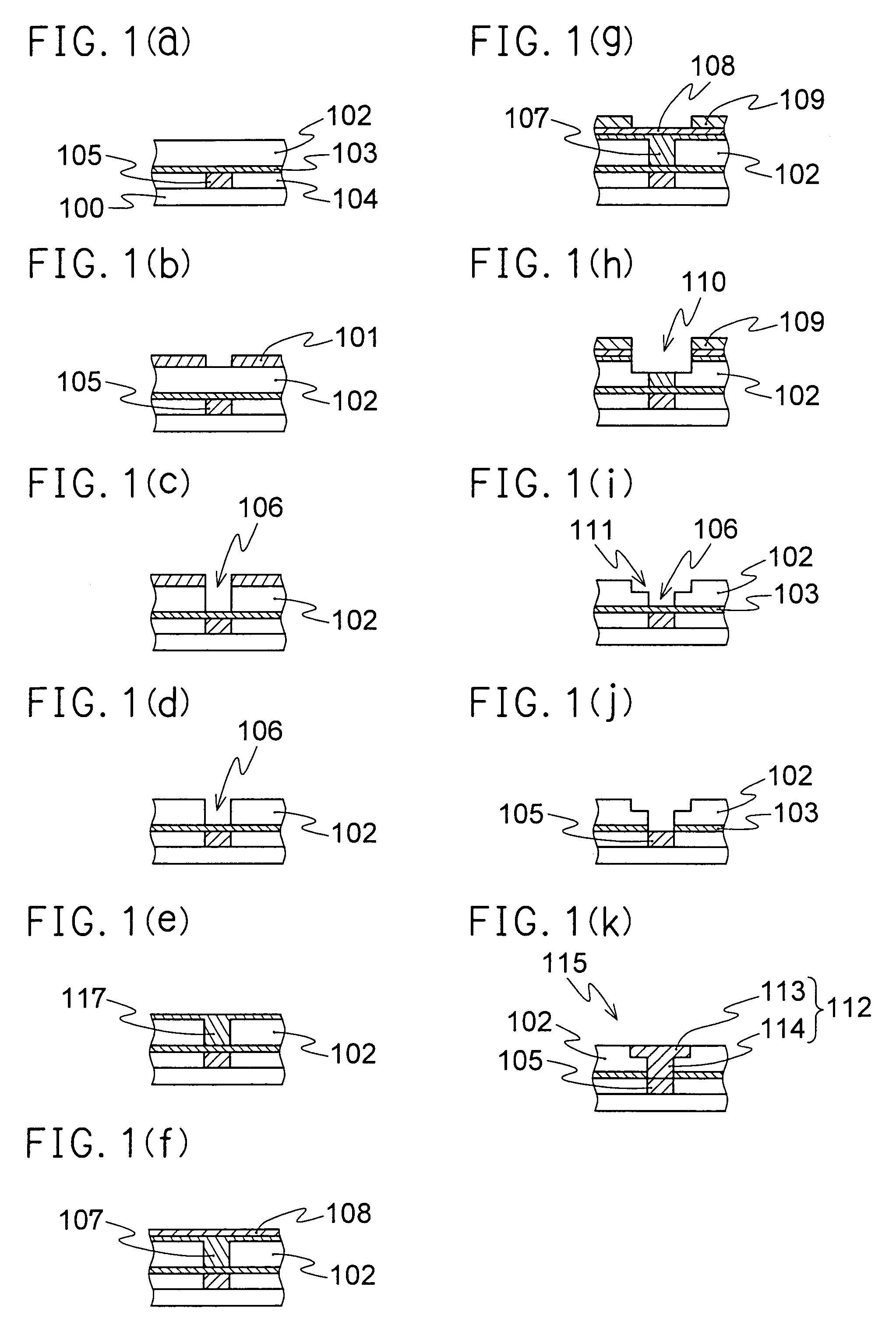

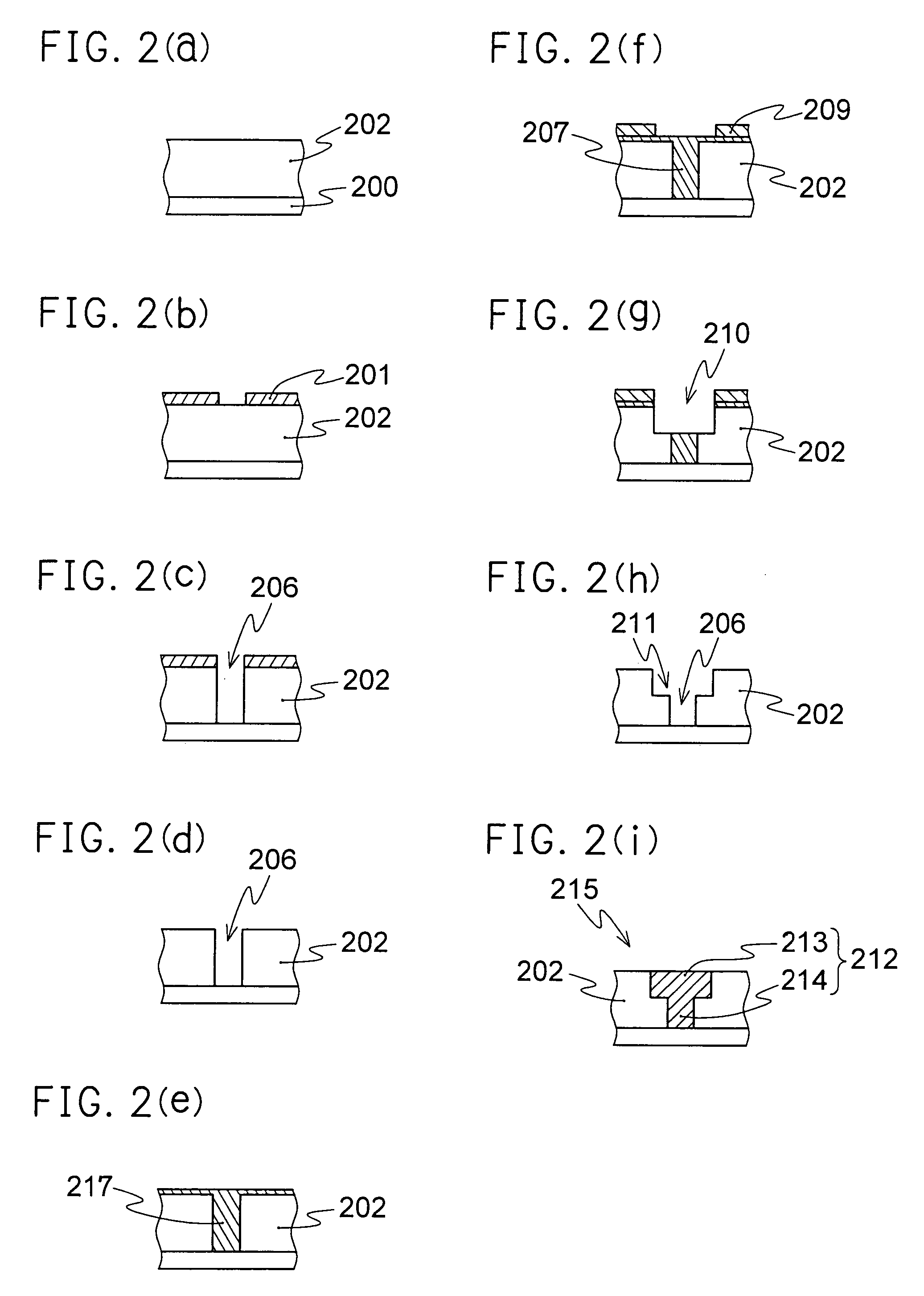

Circuit substrate and method of manufacturing the same

ActiveUS7508079B2Well formedWithout limiting a wiring layoutSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductorEngineering

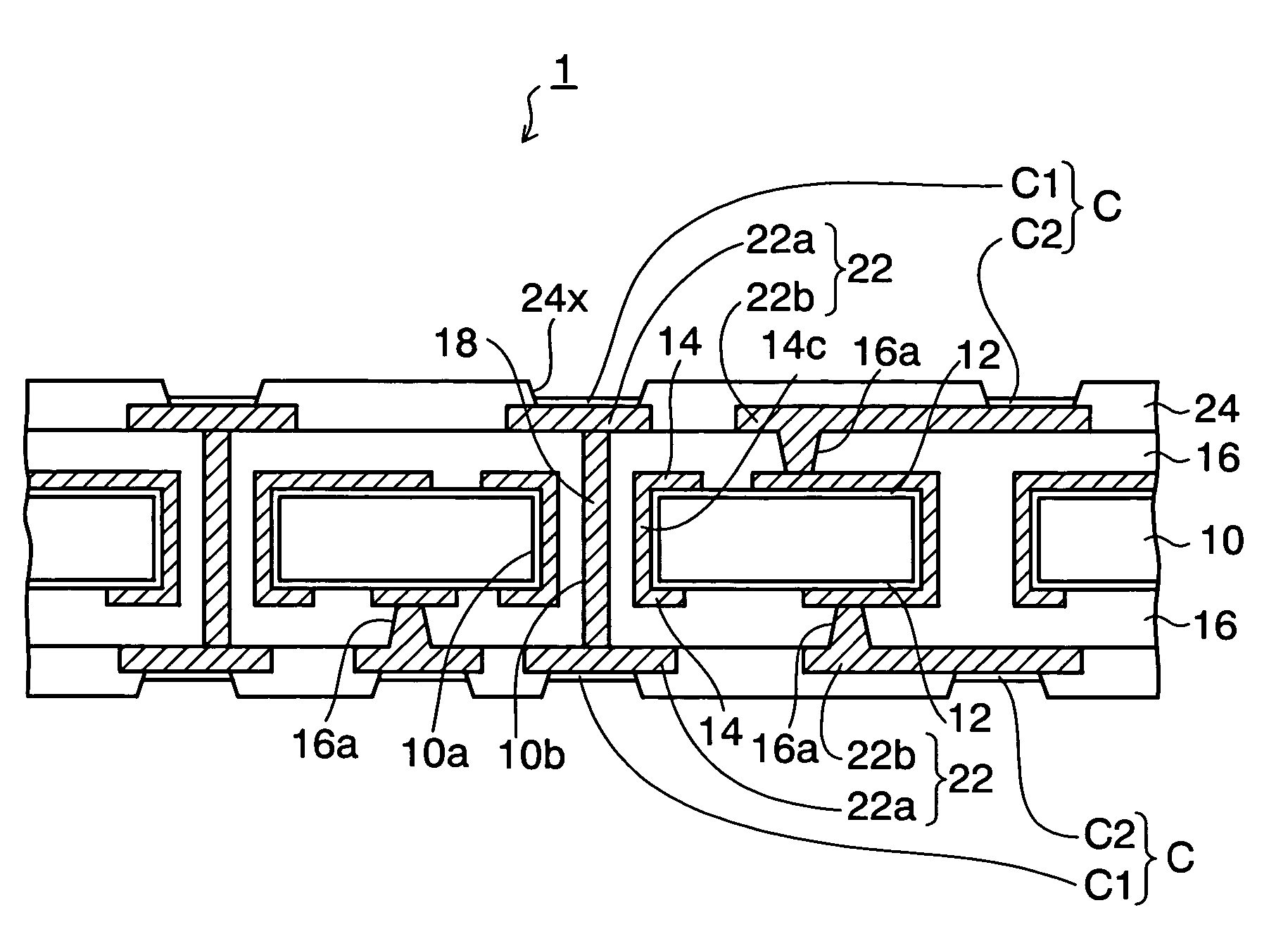

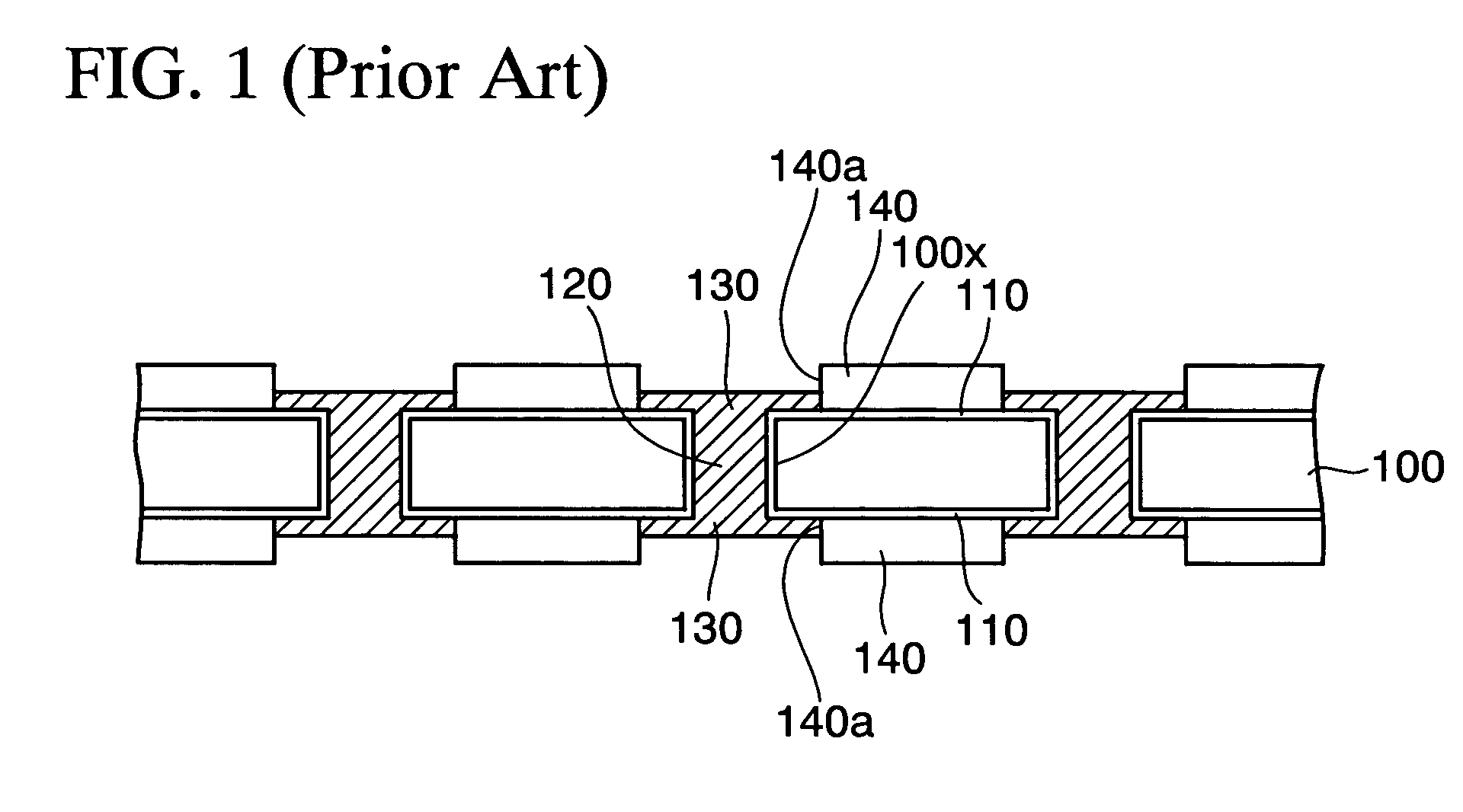

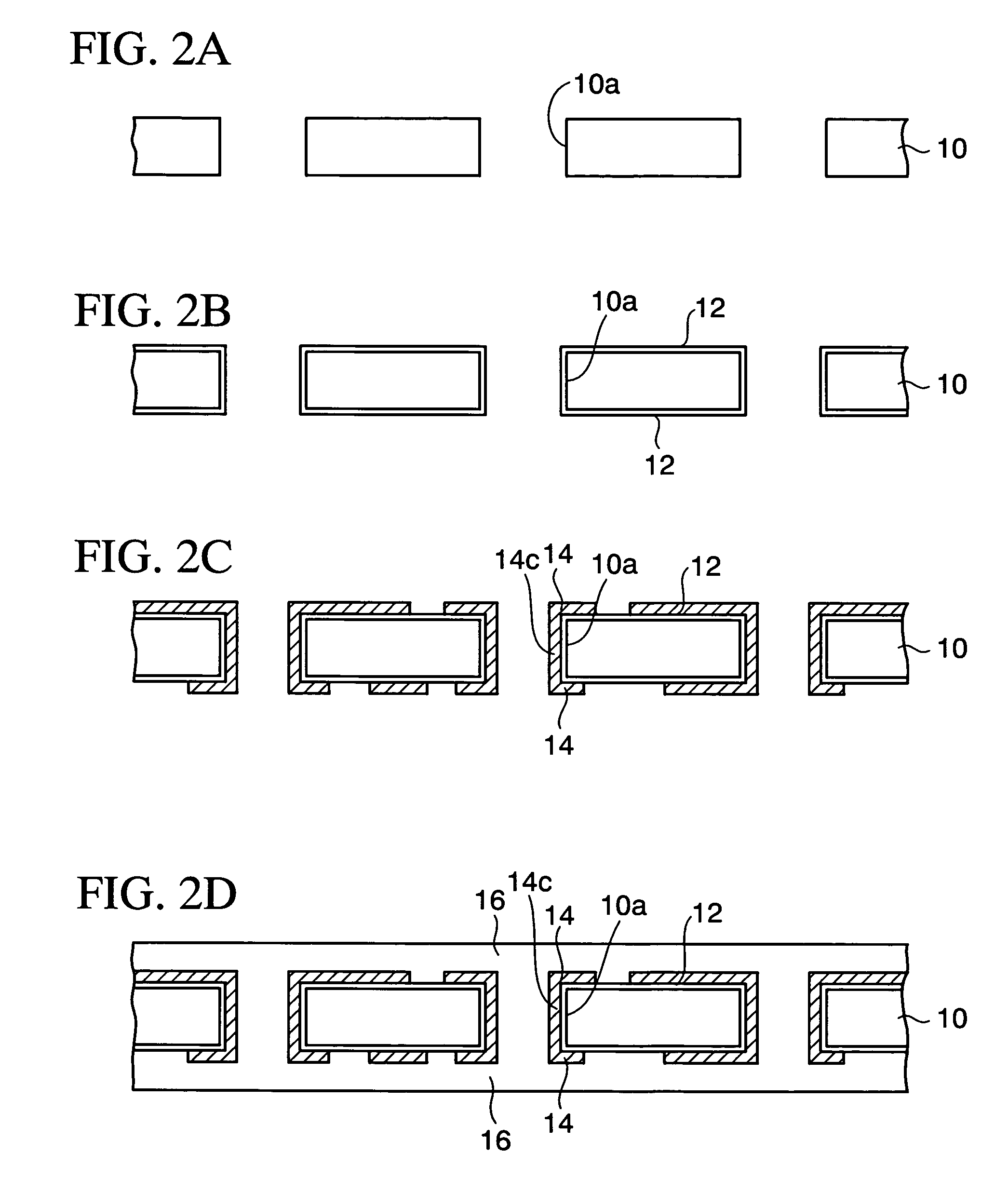

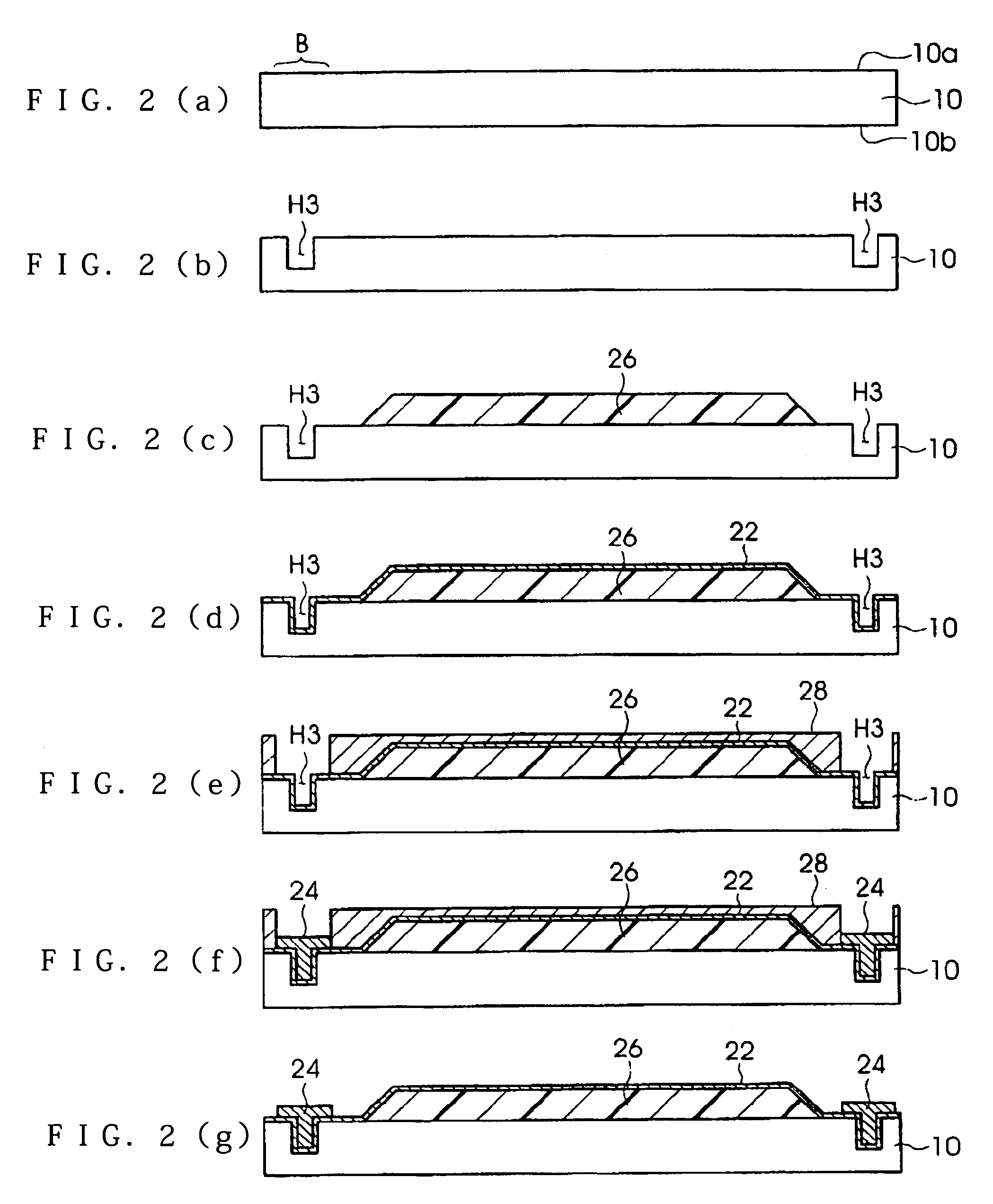

In a method of manufacturing a circuit substrate of the present invention, a first through hole is formed in a semiconductor substrate and a first insulating layer is formed on the entire surface of the semiconductor substrate, and then first wiring layers connected to each other via an outer through conducting portion provided on the inner surface of the first through hole are formed on both sides of the semiconductor substrate, and then a second insulating layer is formed which covers the first wiring layers on both sides of the semiconductor substrate and the outer through conducting portion on the inner surface of the first through hole, the second insulating layer has a structure in which a second through hole is provided in a central portion of the first through hole, and then second wiring layers connected to each other via an inner through conducting portion provided in the second through hole are formed on the second insulating layer on both sides of the semiconductor substrate.

Owner:SHINKO ELECTRIC IND CO LTD

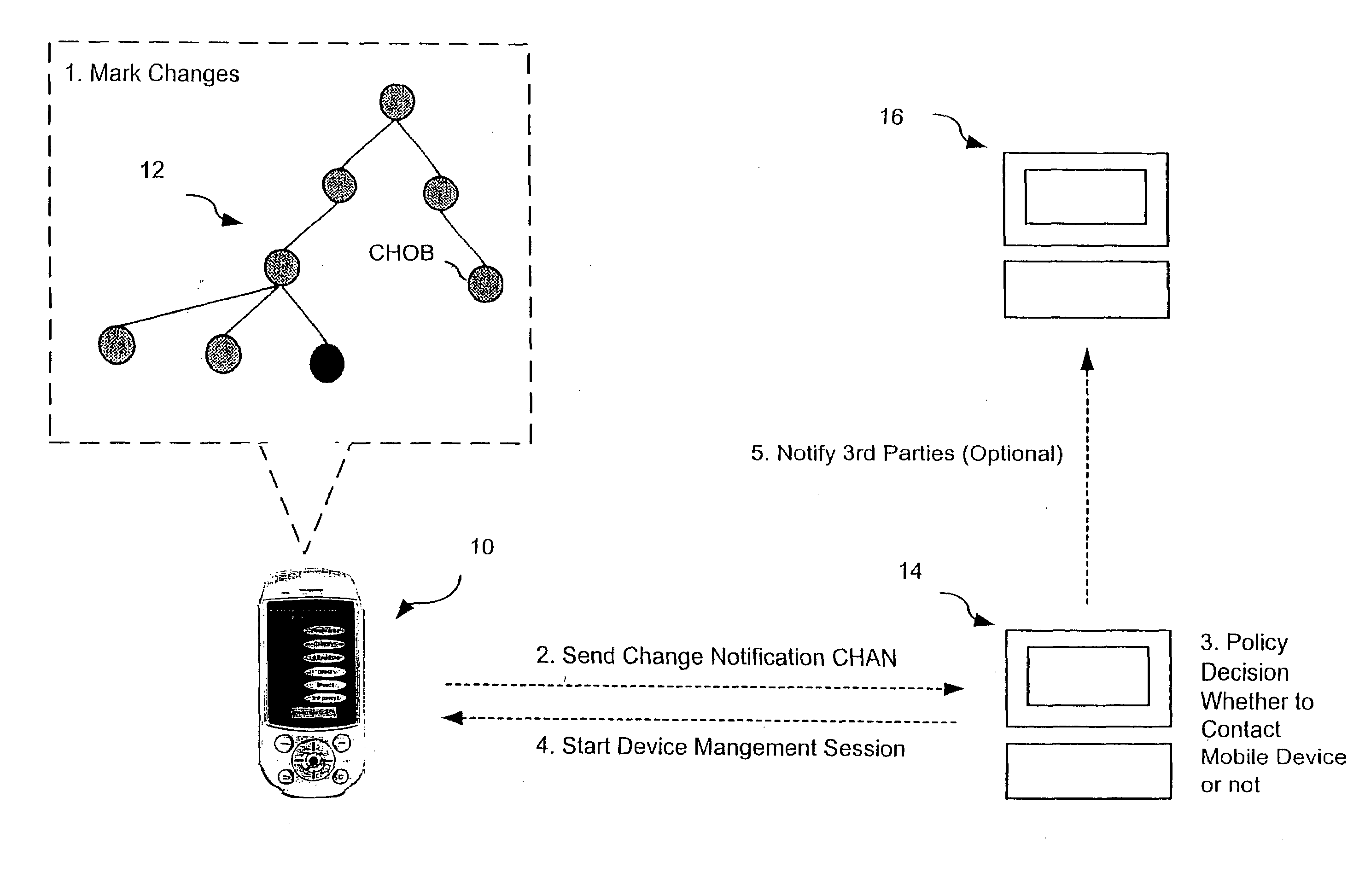

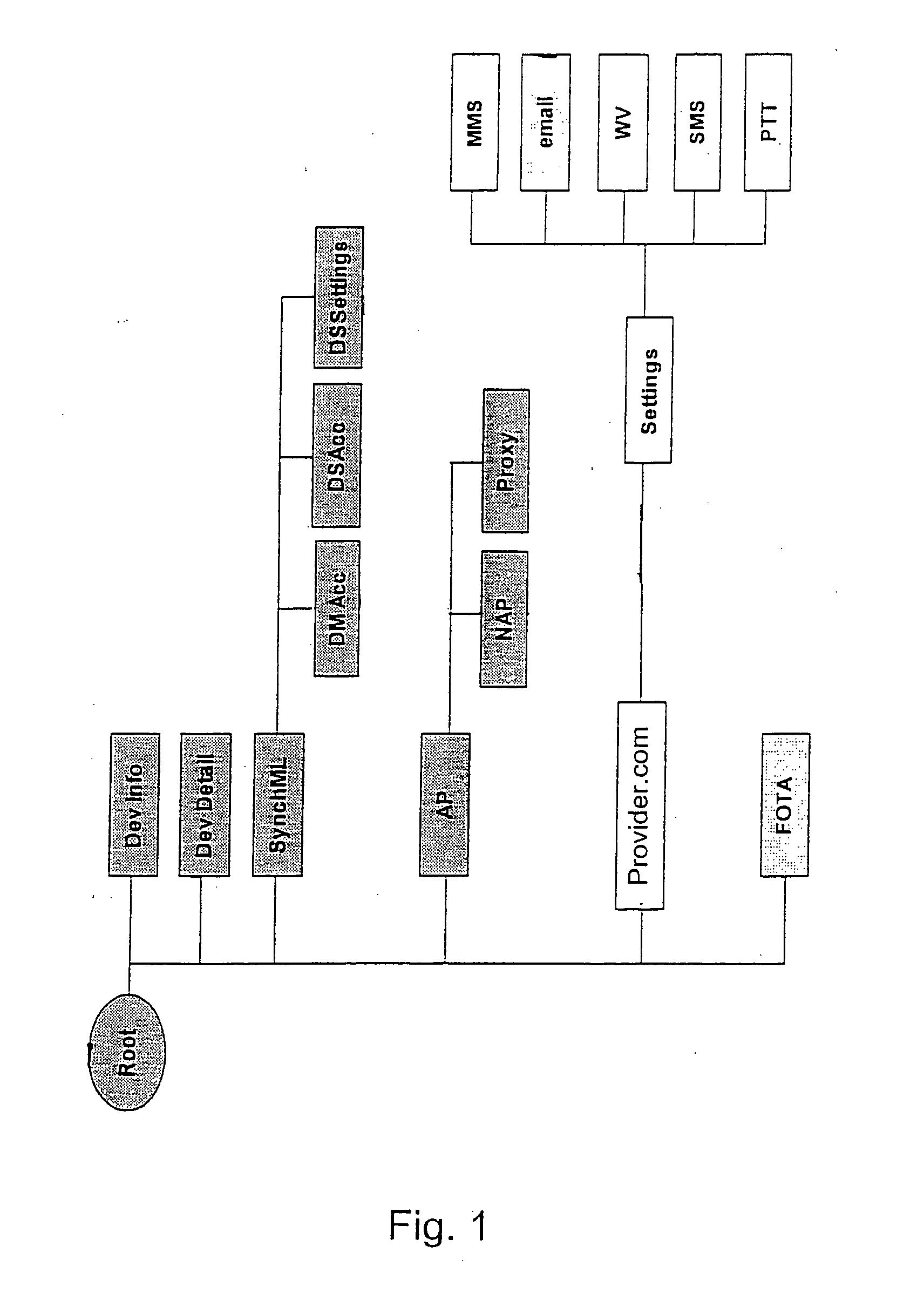

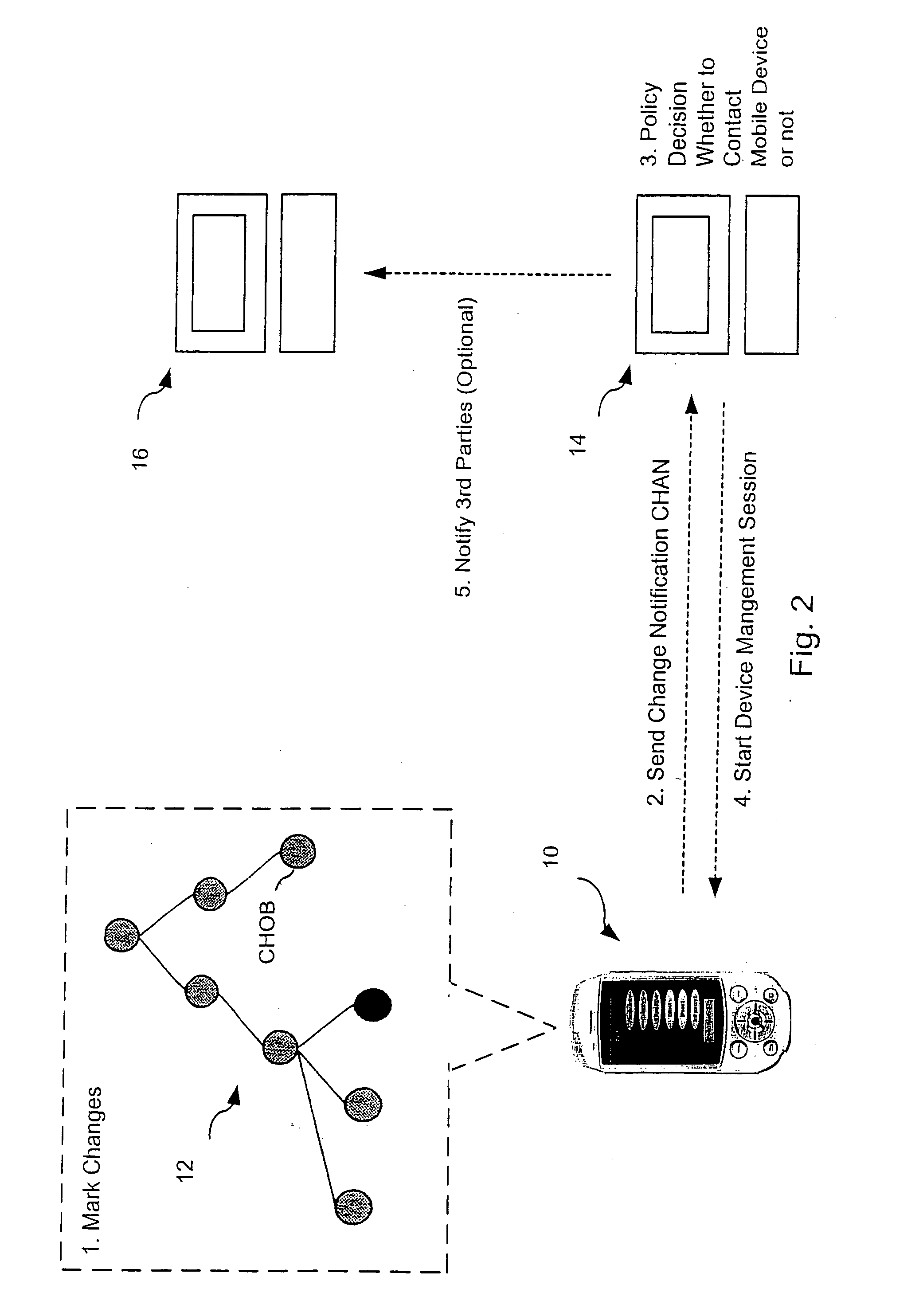

Automatic Device Capabilites Change Notification

ActiveUS20080220759A1Step can be unnecessarySpecial service for subscribersTransmissionCapability managementPolicy decision

The present invention relates to an improved approach to mobile device capability management. Heretofore, a capability management device is provided at a mobile communication network. Upon change of a mobile device capability, a related notification is sent to the capability management device which applies a policy decision whether to track the capability change at the network side or not. Should the decision be ‘yes’, the capability management device starts a device management session to collect further information on a mobile device capability change beyond the information made available with the mobile device capability change notification. After retrieval of the mobile device capability change information, the capability management device will update its mobile device capability state accordingly. Optionally, the capability management device may share the generated information with third party cooperating with the mobile device for, e.g., service delivery.

Owner:TELEFON AB LM ERICSSON (PUBL)

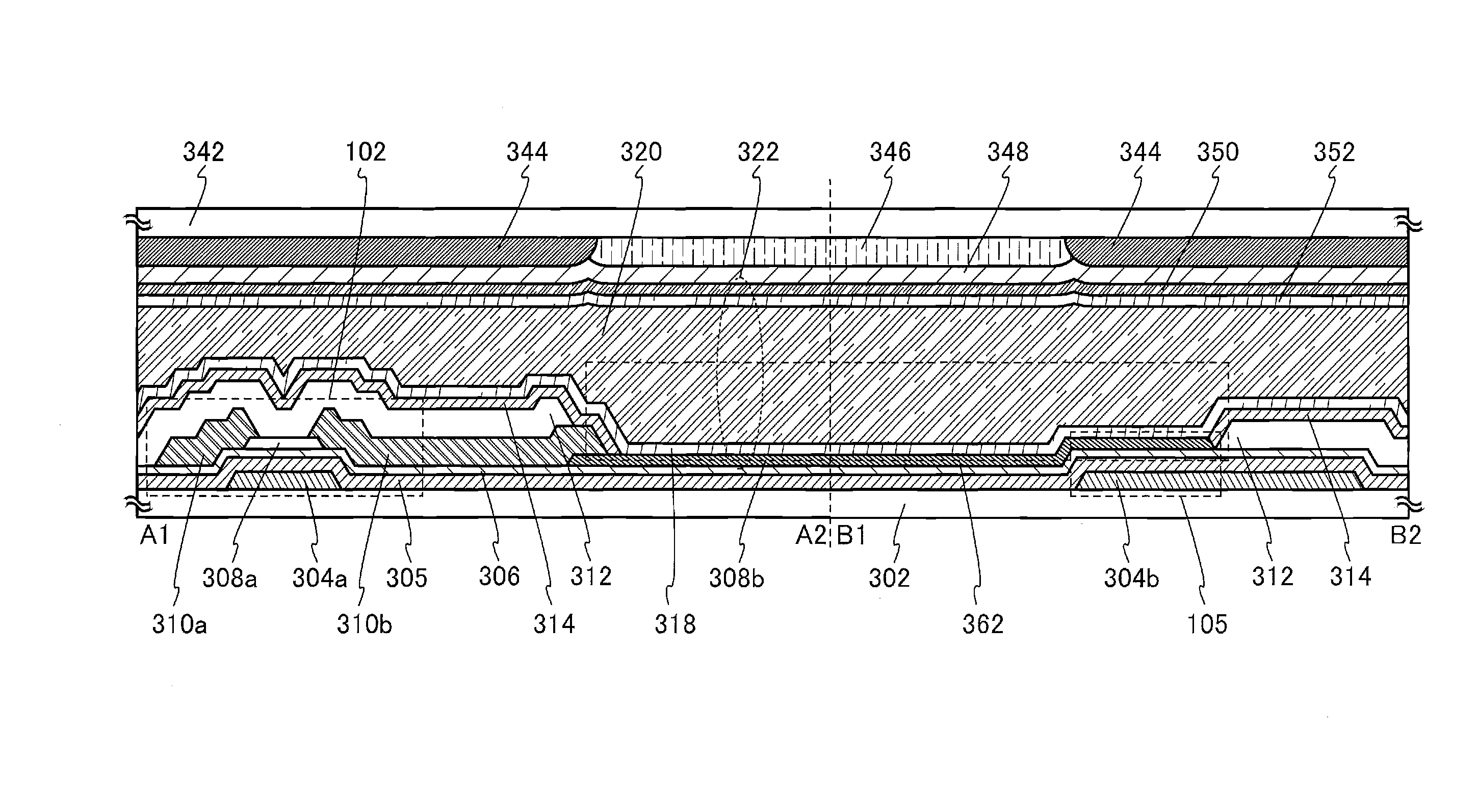

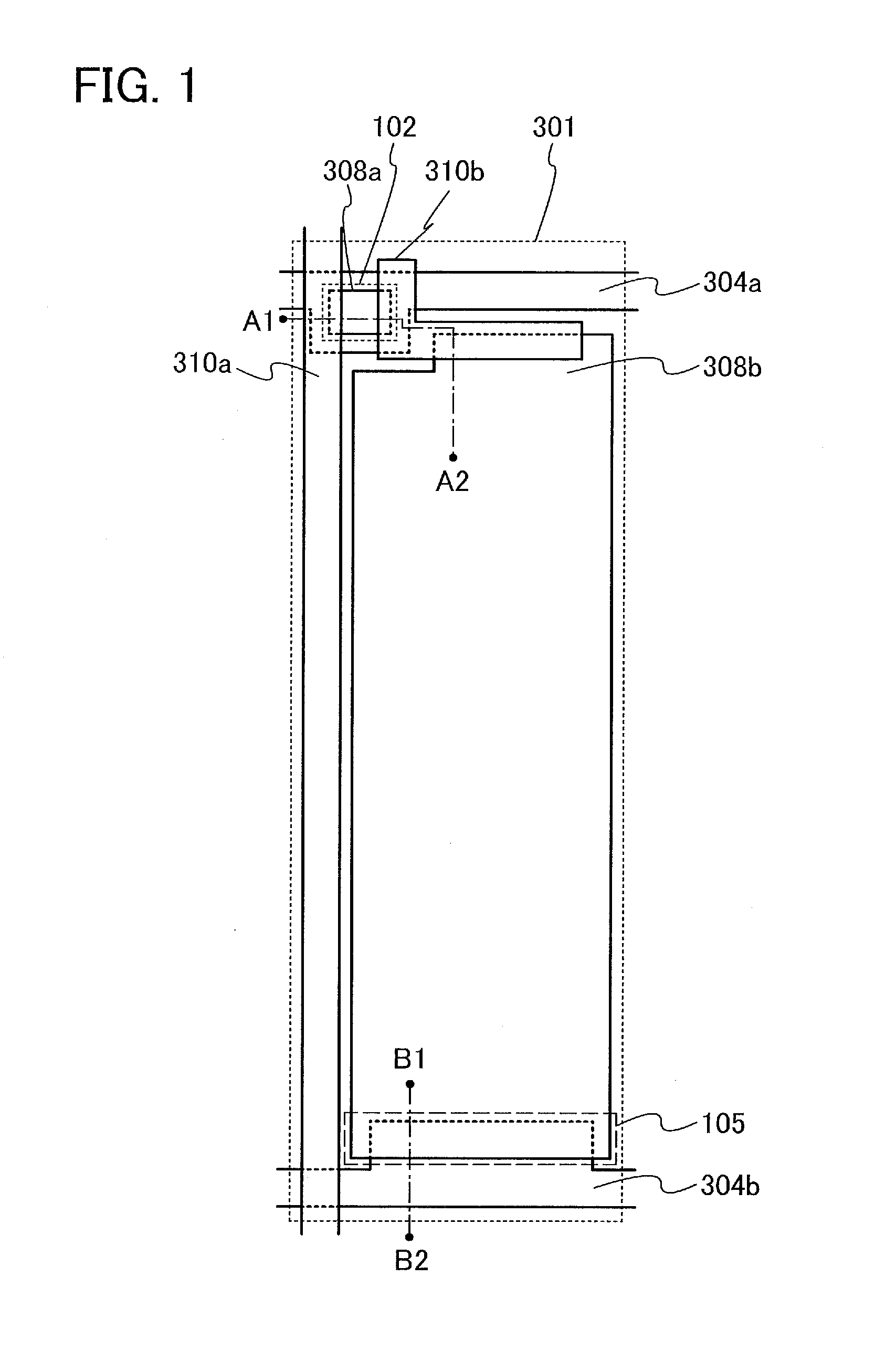

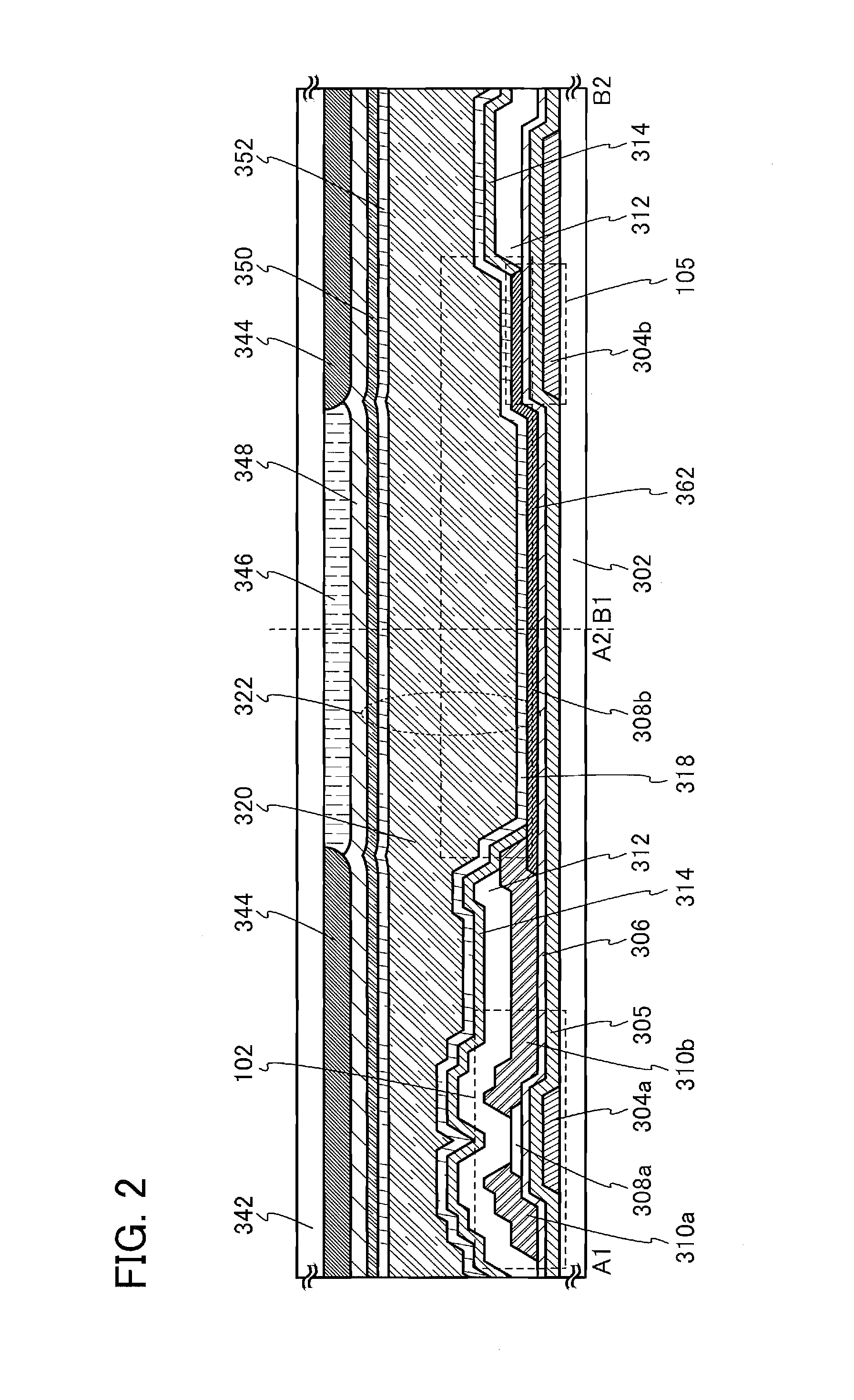

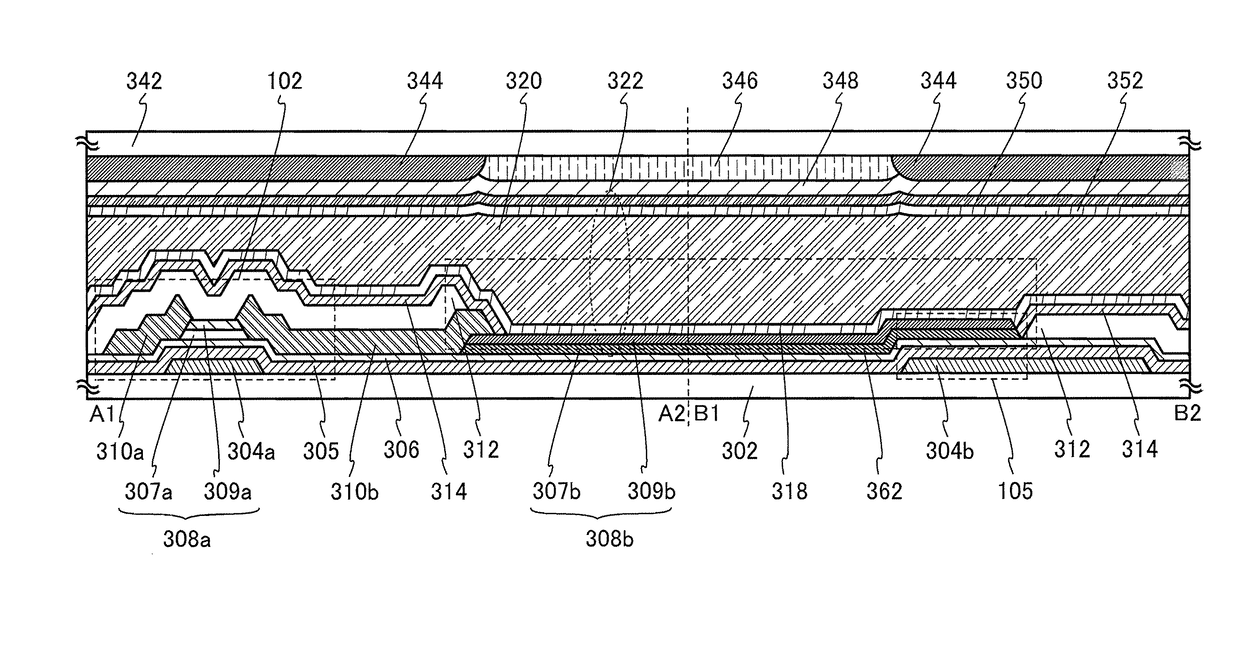

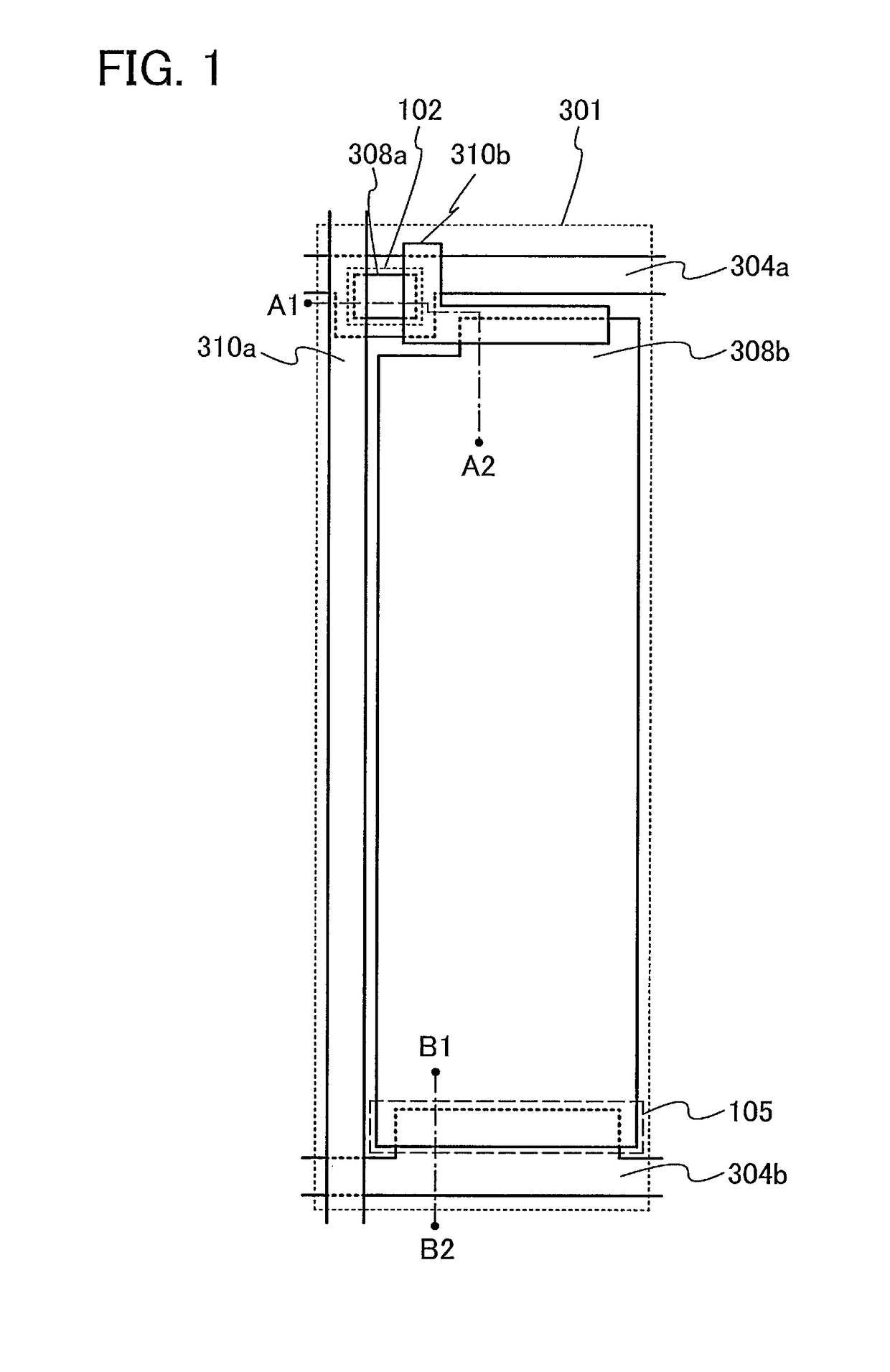

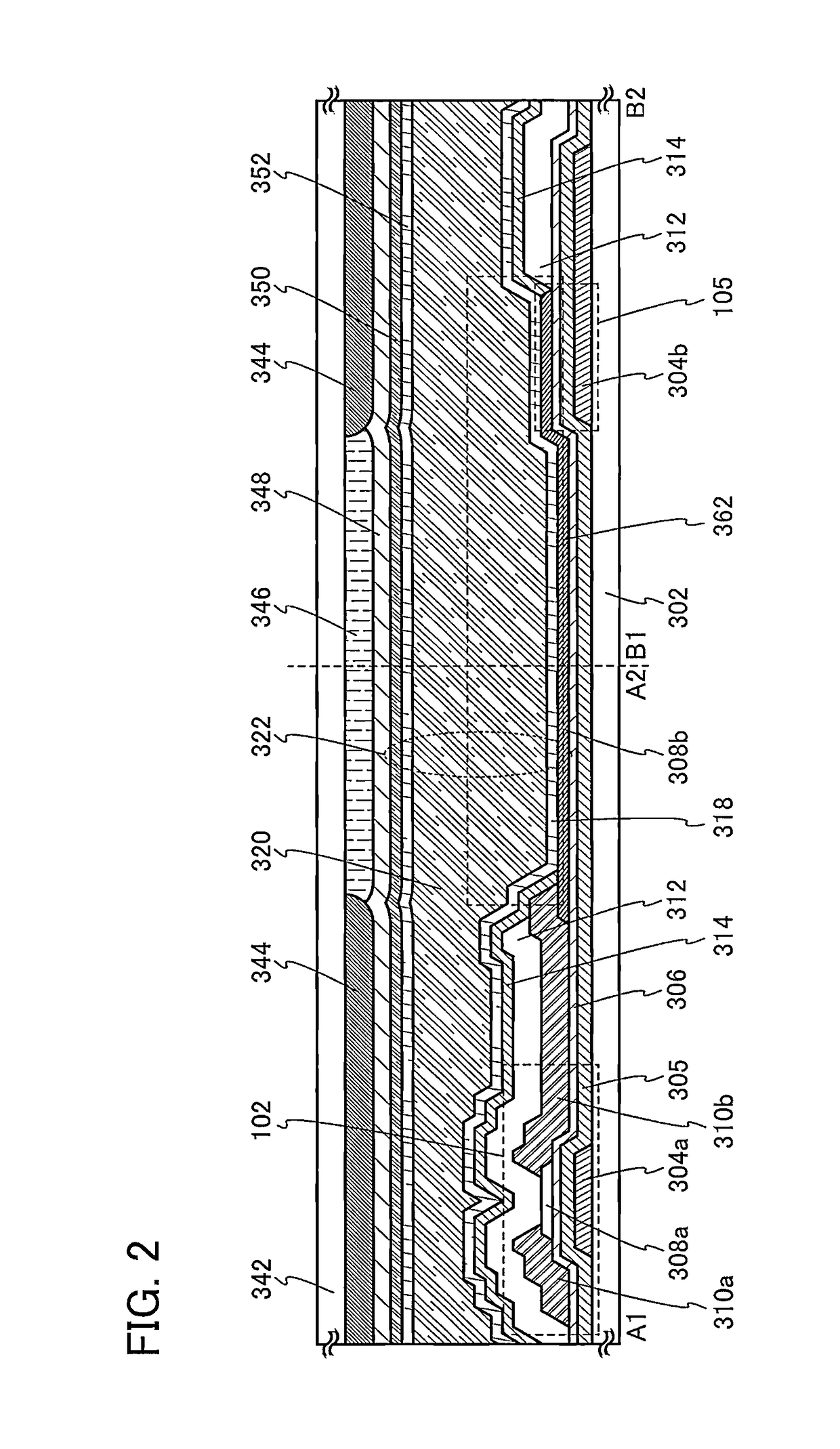

Display device and electronic device including the display device

ActiveUS20140333864A1Improve featuresReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceDielectric layer

To provide a display device including a transistor that includes an oxide semiconductor and has favorable characteristics, a pixel electrode electrically connected to the transistor, and a capacitor electrically connected to the pixel electrode. To provide a display device that can be manufactured at low cost. The display device includes a display element including a pixel electrode, a transistor that performs switching of the display element and includes a first oxide semiconductor layer serving as a channel formation region, a capacitor that is electrically connected to the display element and includes a dielectric layer between a pair of electrodes. The pixel electrode is a second oxide semiconductor layer formed on the same surface as that on which the first oxide semiconductor layer is formed, and also serves as one electrode of the capacitor.

Owner:SEMICON ENERGY LAB CO LTD

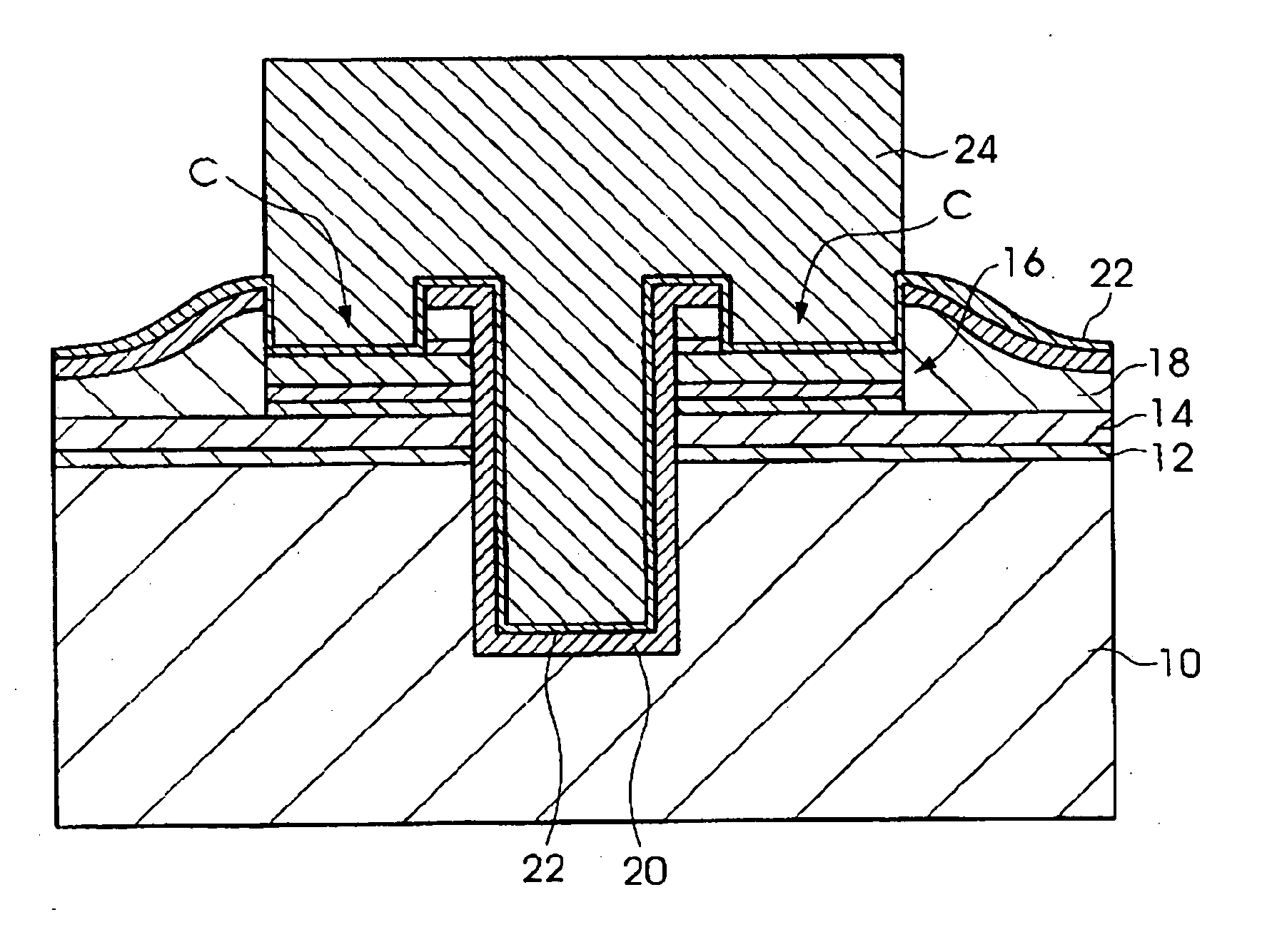

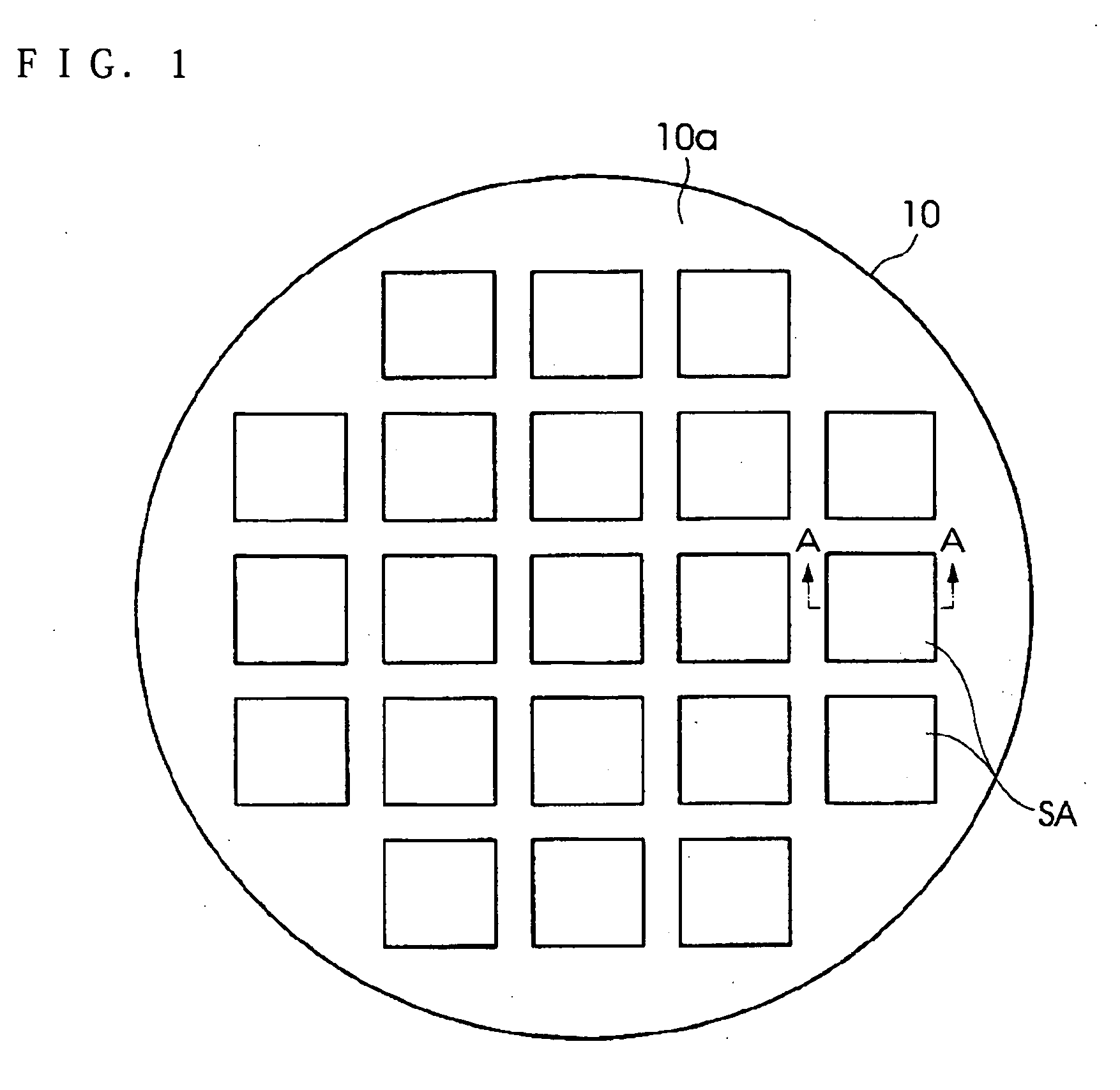

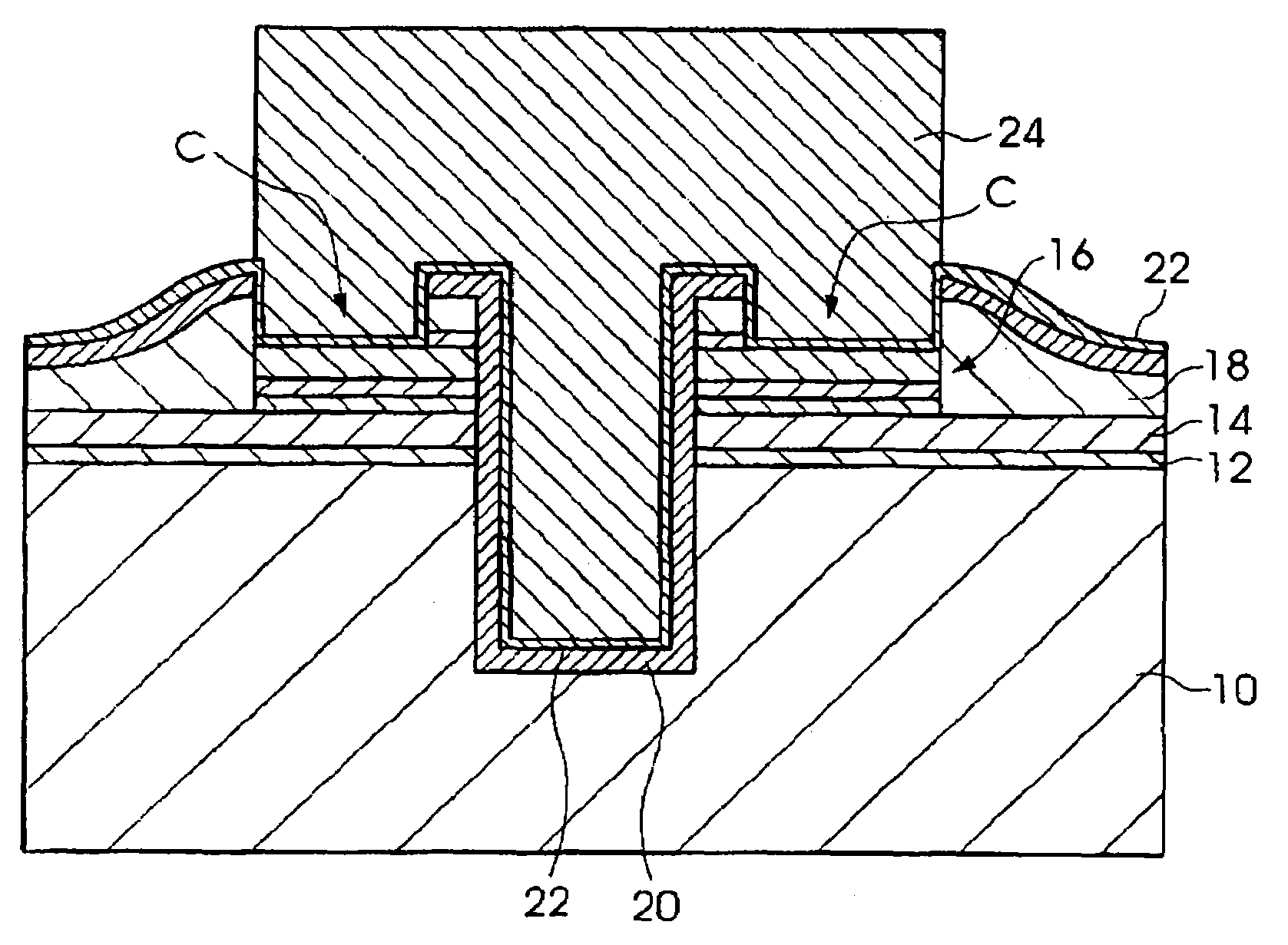

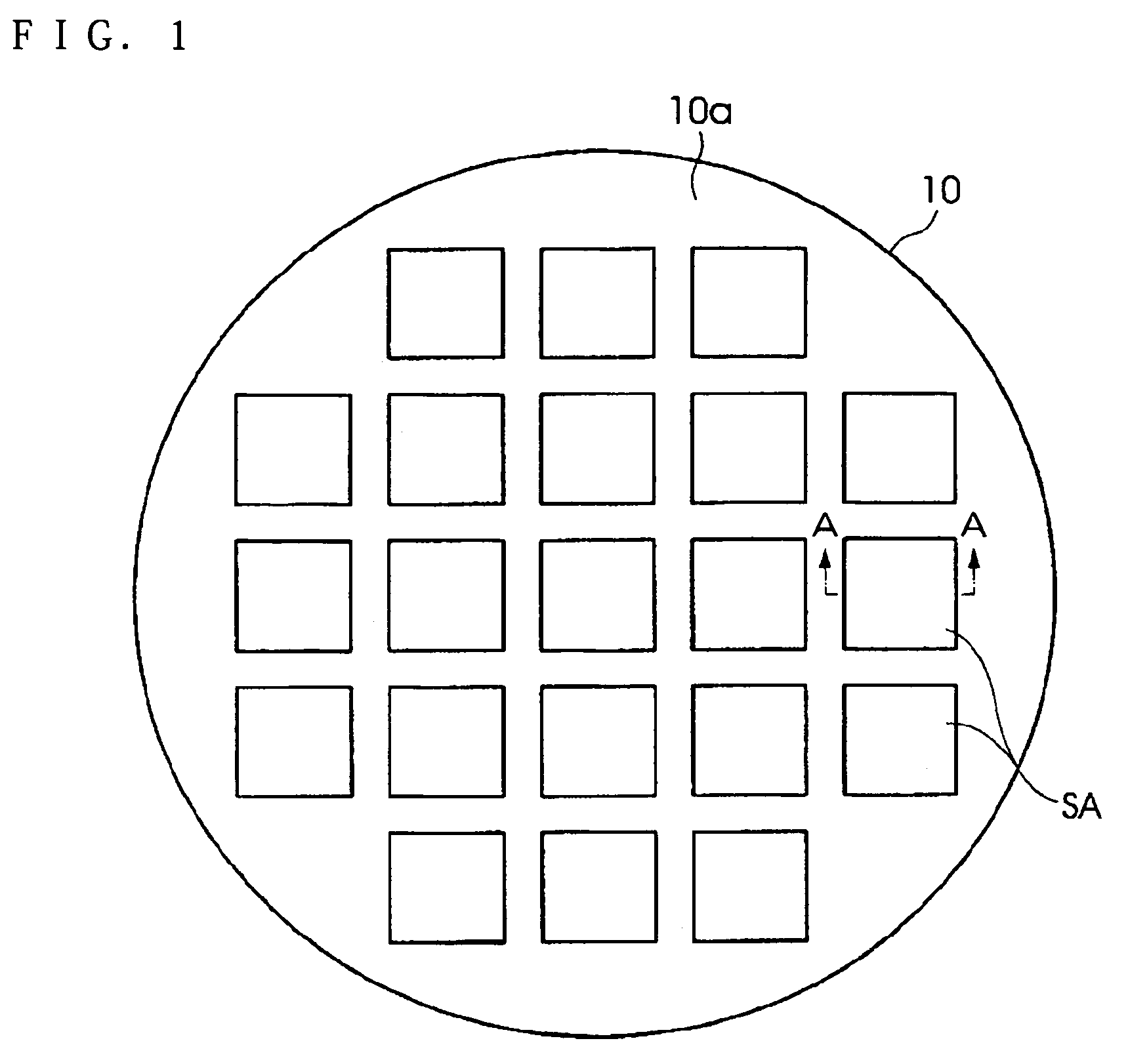

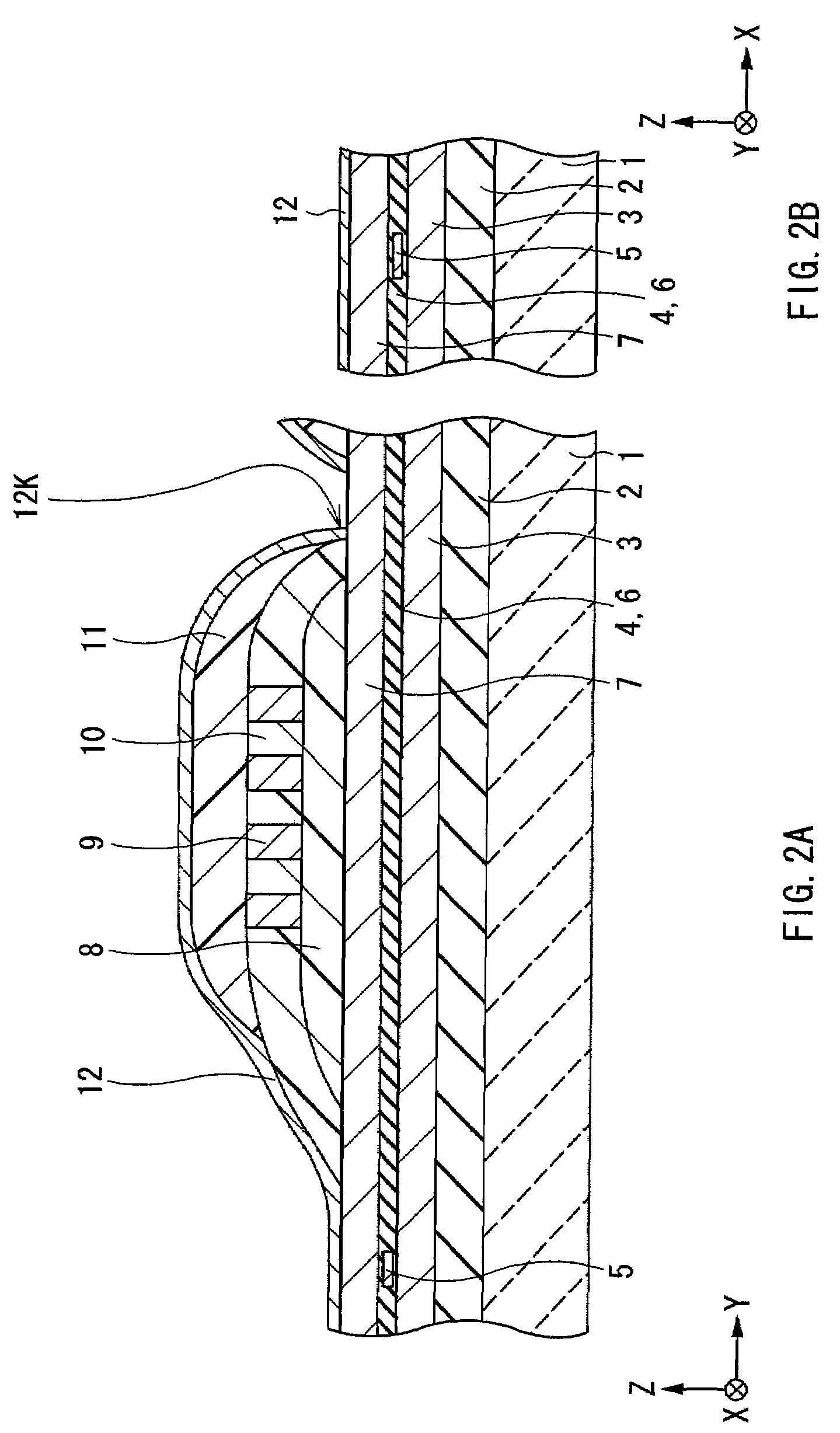

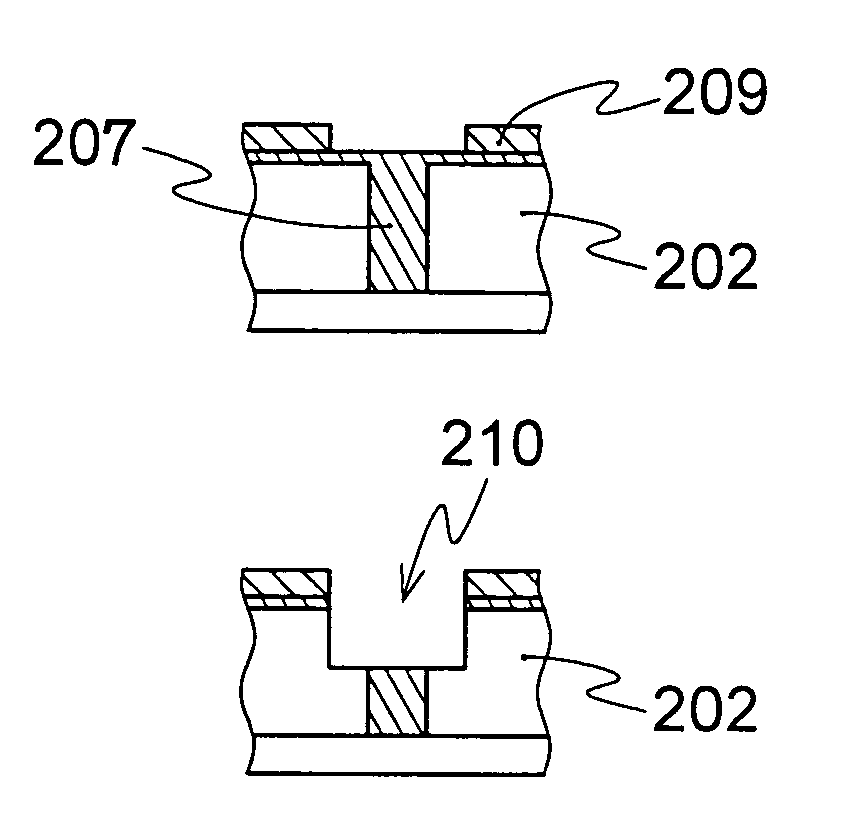

Manufacturing method of semiconductor device, semiconductor device, circuit substrate and electronic equipment

ActiveUS20050136568A1Well formedSimple stepsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialCoupling

A method of manufacturing a semiconductor device is provided. The method includes embedding and forming a coupling terminal as an external electrode of an electronic circuit on an active surface side of a substrate having an active surface formed with a plurality of electronic circuits, exposing a part of the coupling terminal by polishing a back surface side of the substrate, mounting a semiconductor chip on the back surface side of the substrate via the coupling terminal, sealing the semiconductor chip mounted on the substrate by a sealing material, and cutting the substrate for every forming area of each electronic circuit and dividing it into a plurality of semiconductor devices.

Owner:SAMSUNG ELECTRONICS CO LTD

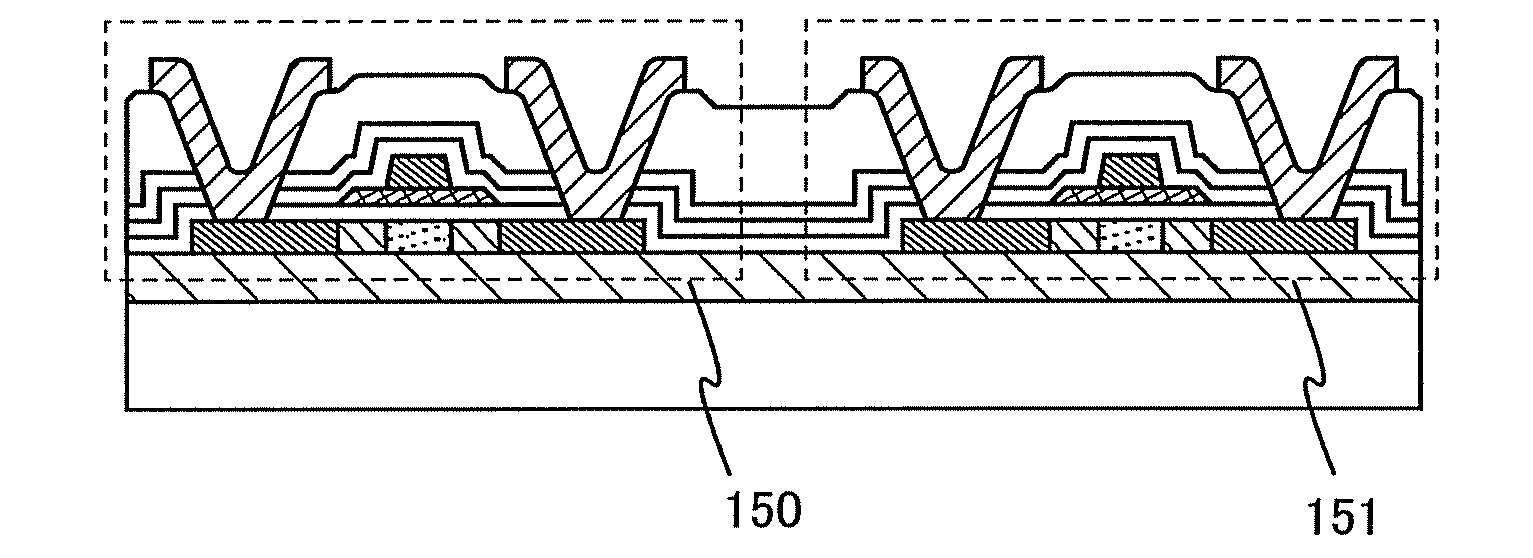

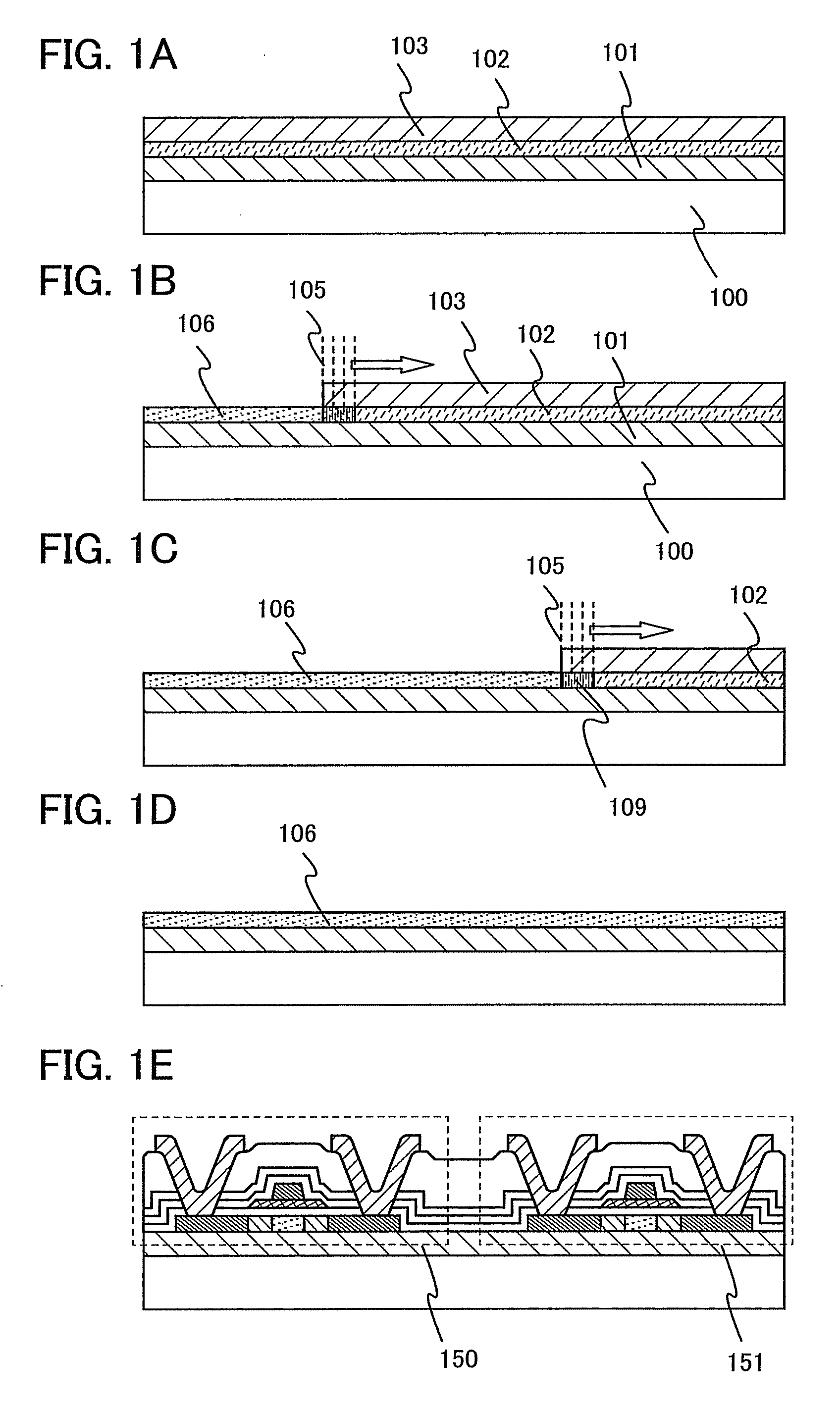

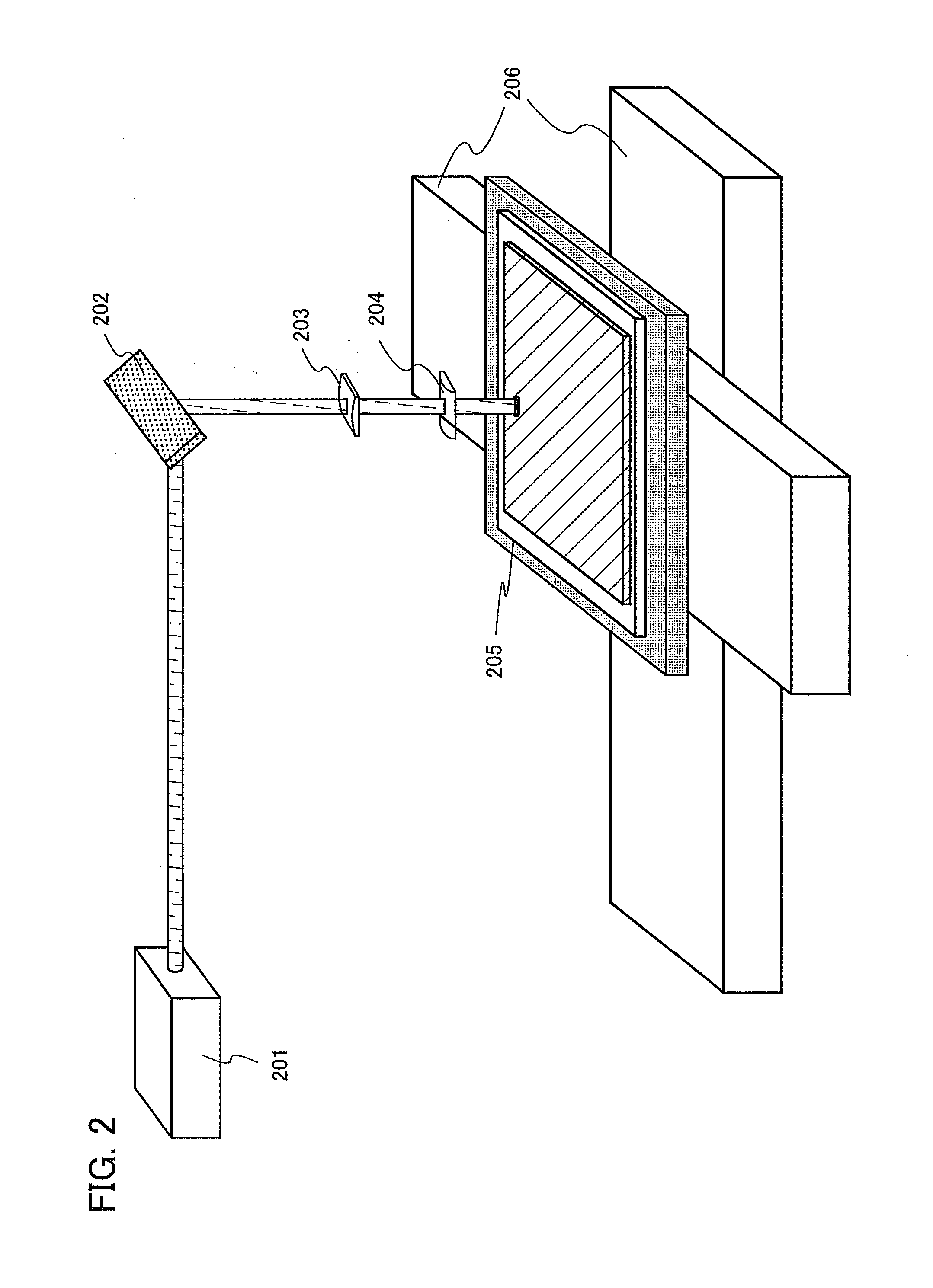

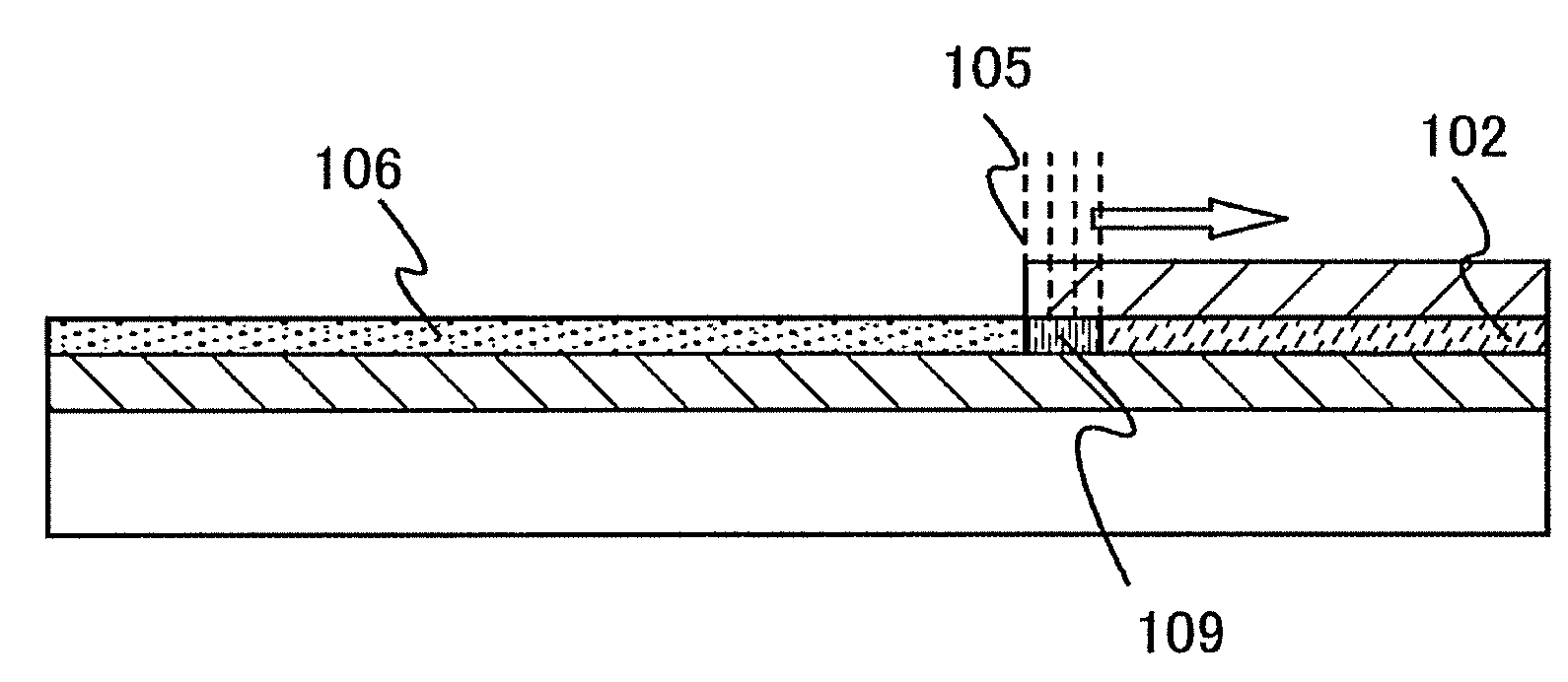

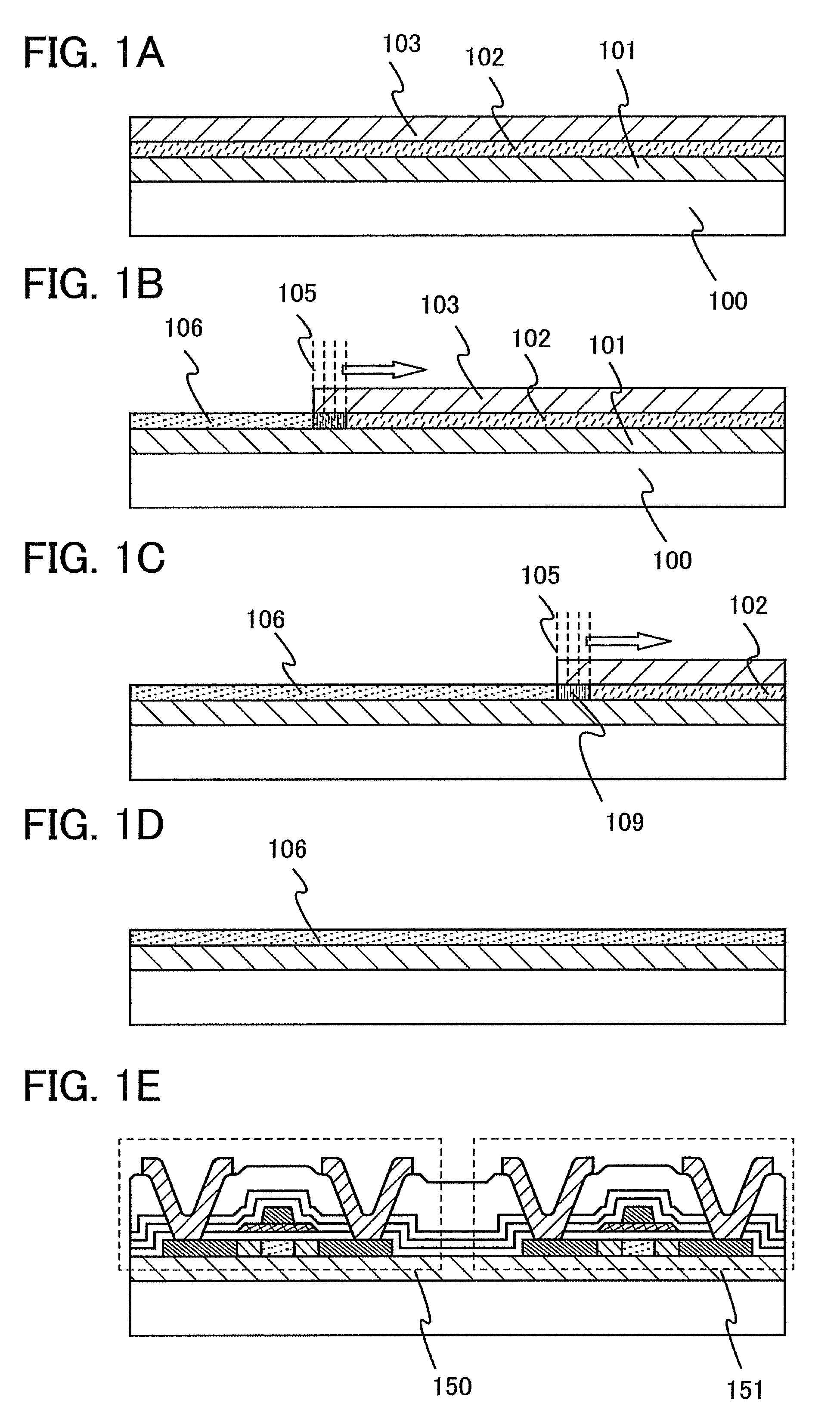

Method for Manufacturing Crystalline Semiconductor Film and Method for Manufacturing Thin Film Transistor

InactiveUS20080233719A1Low costReduce the number of stepsSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsIrradiation

The present invention relates to a method for manufacturing a polycrystalline semiconductor film that can be used for a semiconductor device. In the method, an amorphous semiconductor film is irradiated with a femtosecond laser to be crystallized. By laser irradiation using a femtosecond laser, when an amorphous semiconductor film over which a cap film is formed is crystallized with a laser, it becomes possible to perform crystallization of the semiconductor film and removal of the cap film at the same time. Therefore, a step of removing the cap film in a later step can be omitted.

Owner:SEMICON ENERGY LAB CO LTD

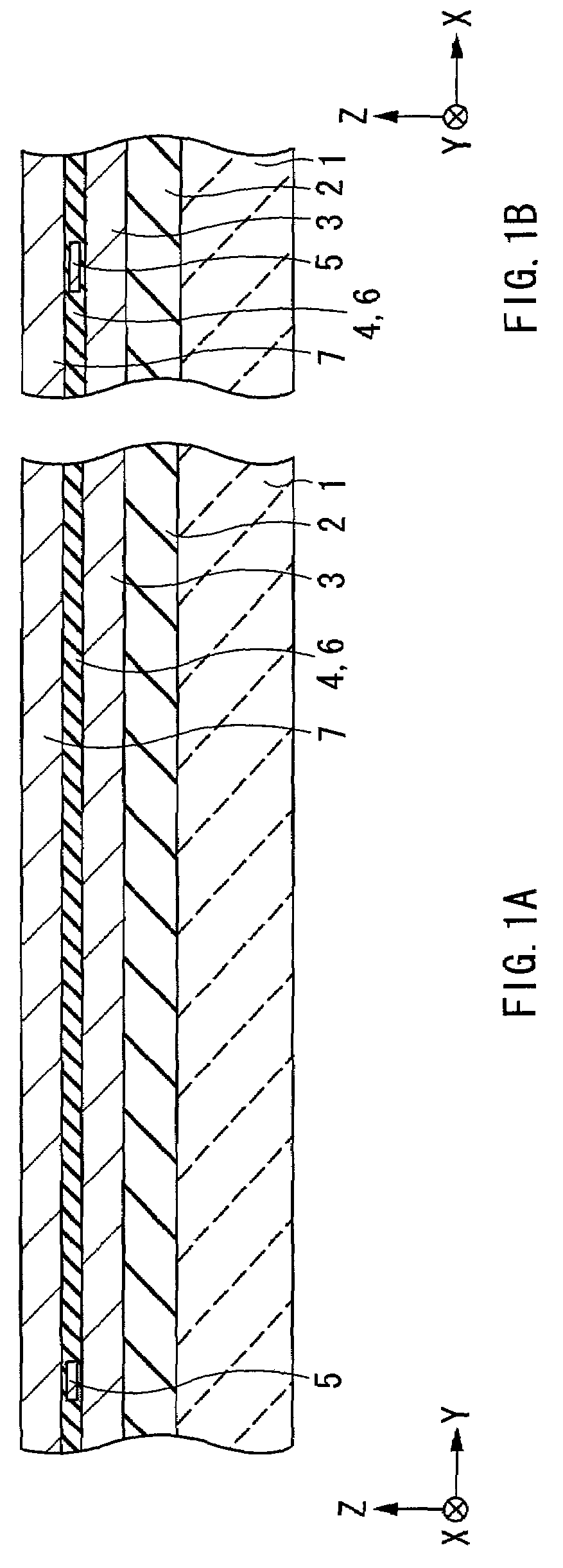

Circuit substrate and method of manufacturing the same

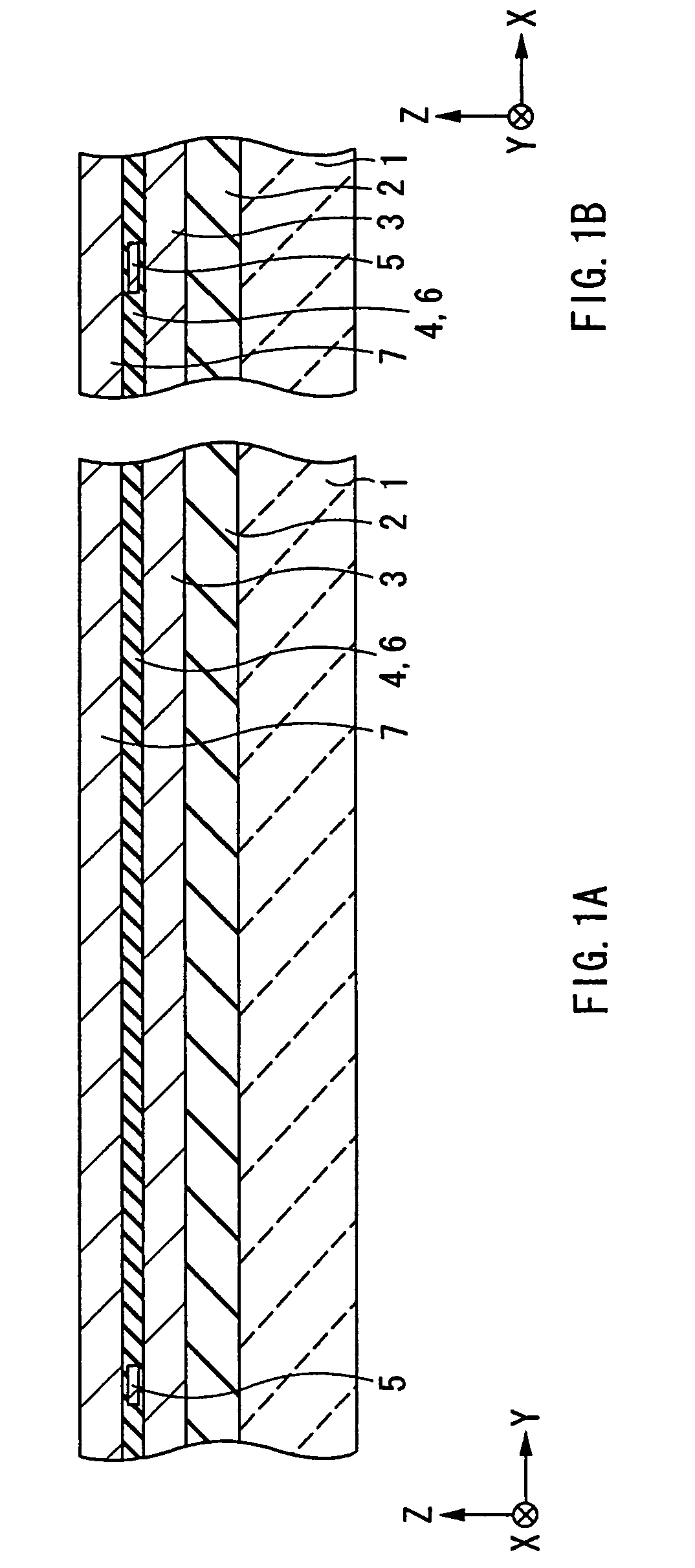

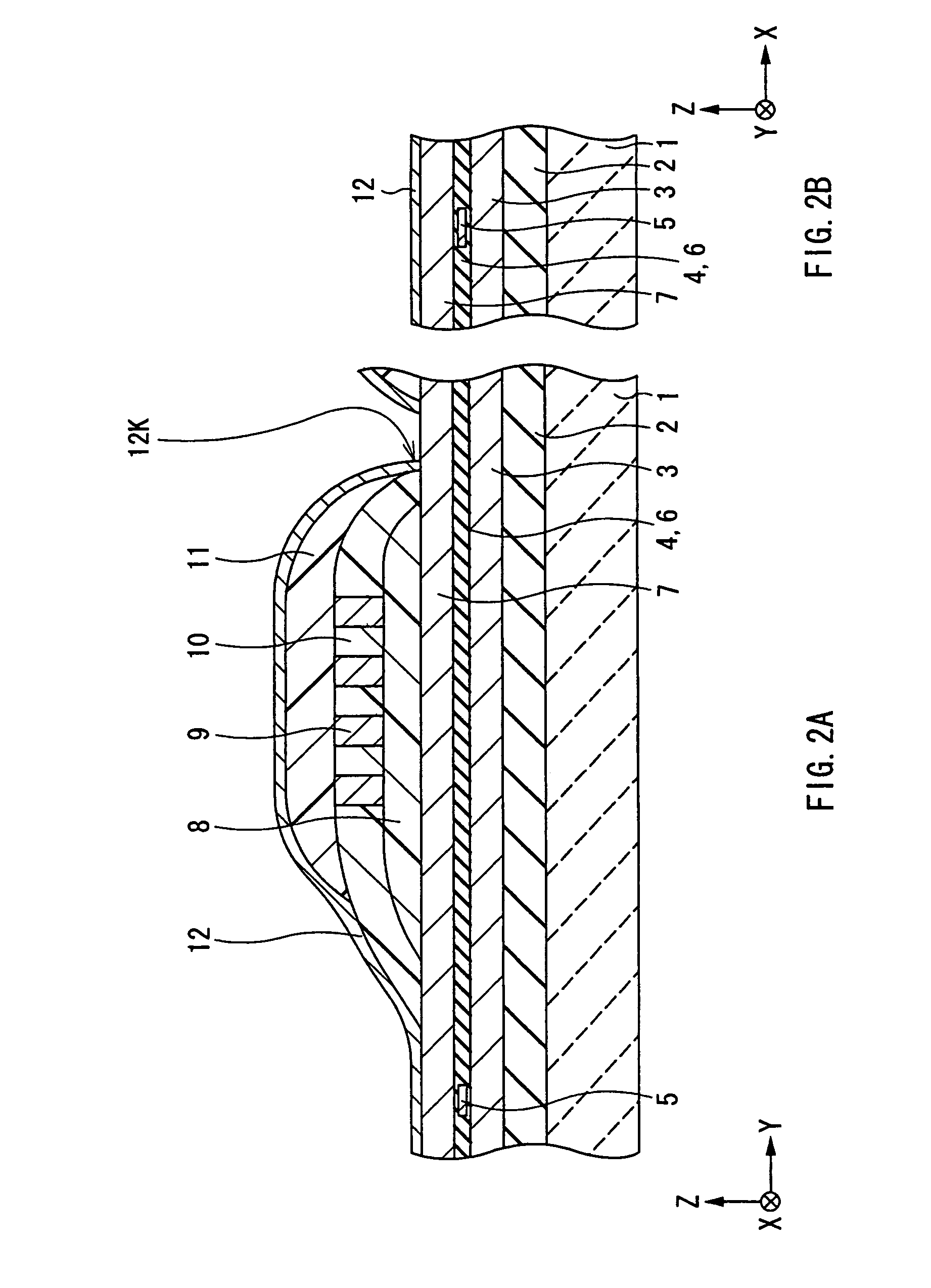

ActiveUS20070020914A1Cost reductionEasily copeSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringElectrical and Electronics engineering

In a method of manufacturing a circuit substrate of the present invention, a first through hole is formed in a semiconductor substrate and a first insulating layer is formed on the entire surface of the semiconductor substrate, and then first wiring layers connected to each other via an outer through conducting portion provided on the inner surface of the first through hole are formed on both sides of the semiconductor substrate, and then a second insulating layer is formed which covers the first wiring layers on both sides of the semiconductor substrate and the outer through conducting portion on the inner surface of the first through hole, the second insulating layer has a structure in which a second through hole is provided in a central portion of the first through hole, and then second wiring layers connected to each other via an inner through conducting portion provided in the second through hole are formed on the second insulating layer on both sides of the semiconductor substrate.

Owner:SHINKO ELECTRIC IND CO LTD

Manufacturing method of semiconductor device, semiconductor device, circuit substrate and electronic equipment

ActiveUS7109060B2Well formedSimple stepsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialCoupling

A method of manufacturing a semiconductor device is provided. The method includes embedding and forming a coupling terminal as an external electrode of an electronic circuit on an active surface side of a substrate having an active surface formed with a plurality of electronic circuits, exposing a part of the coupling terminal by polishing a back surface side of the substrate, mounting a semiconductor chip on the back surface side of the substrate via the coupling terminal, sealing the semiconductor chip mounted on the substrate by a sealing material, and cutting the substrate for every forming area of each electronic circuit and dividing it into a plurality of semiconductor devices.

Owner:SAMSUNG ELECTRONICS CO LTD

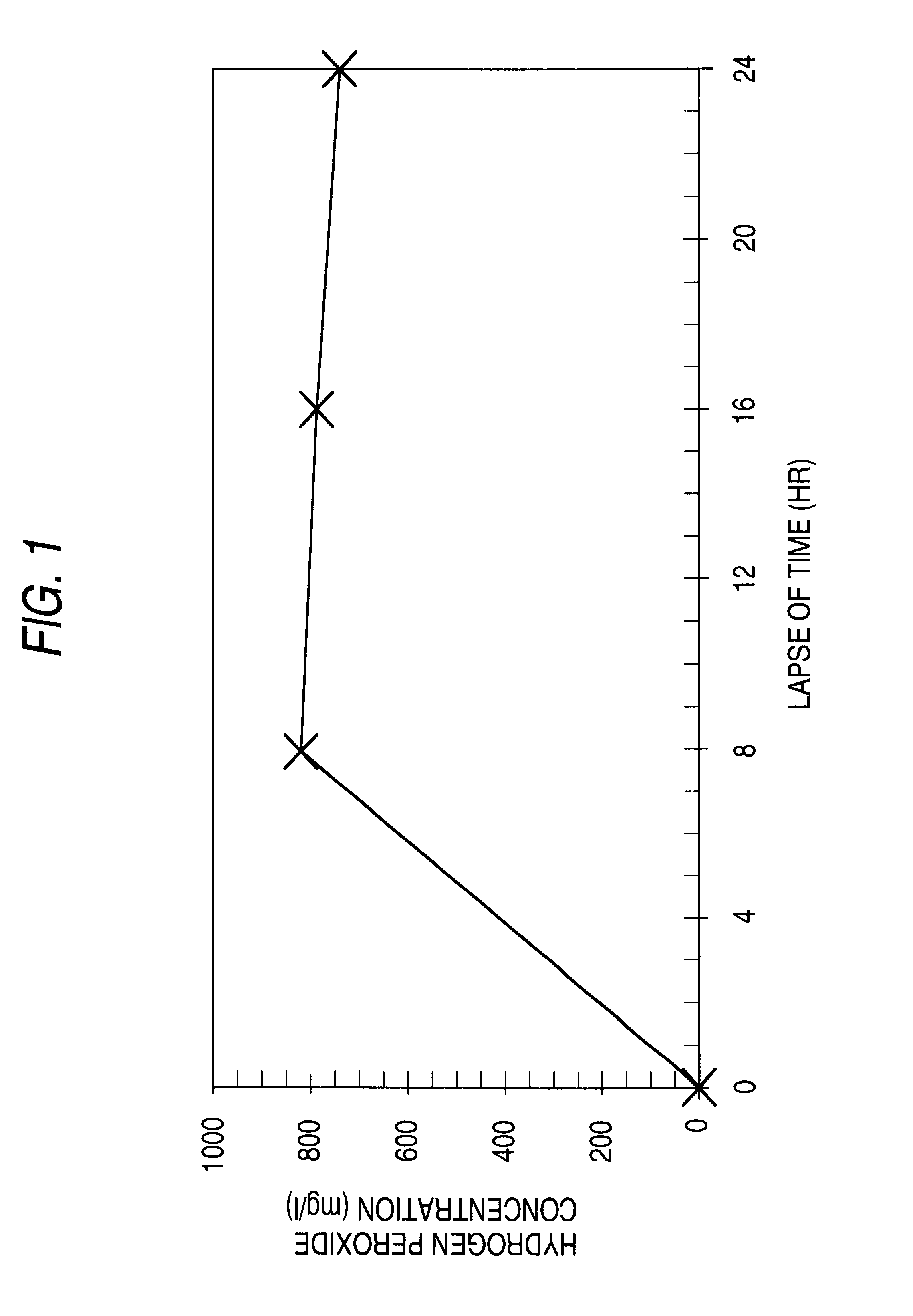

Ice composition containing hydrogen peroxide and method of storing perishable food

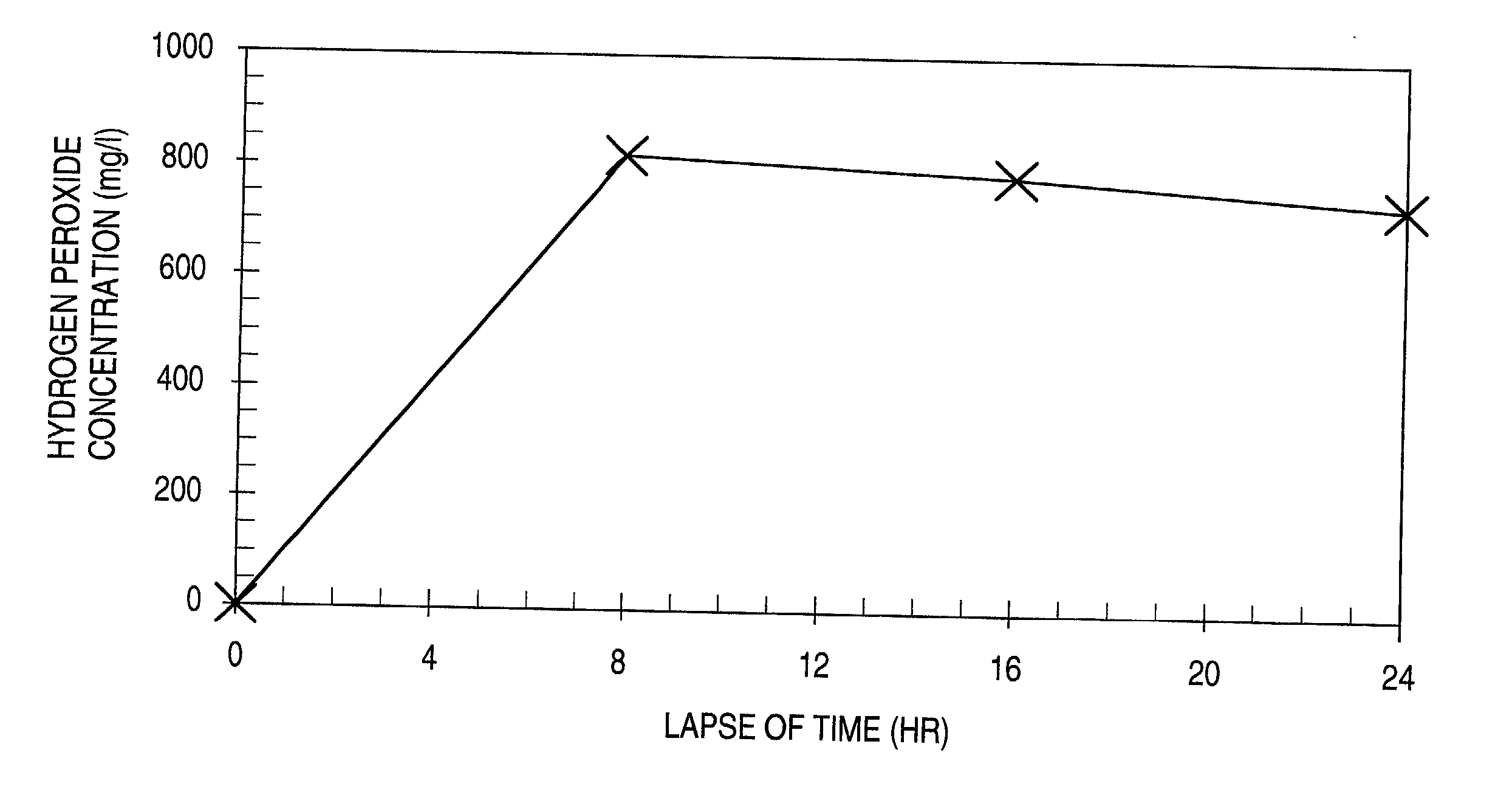

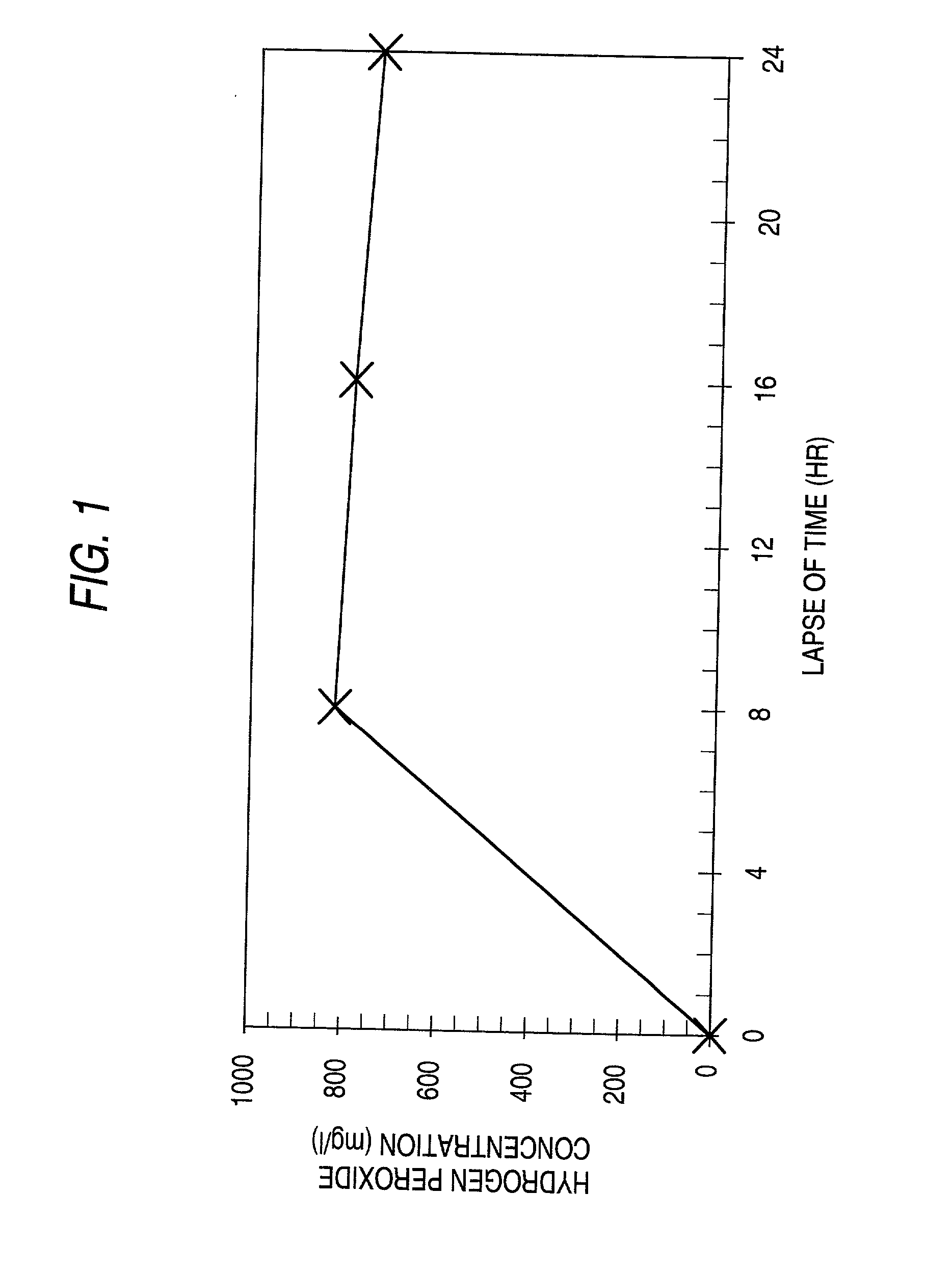

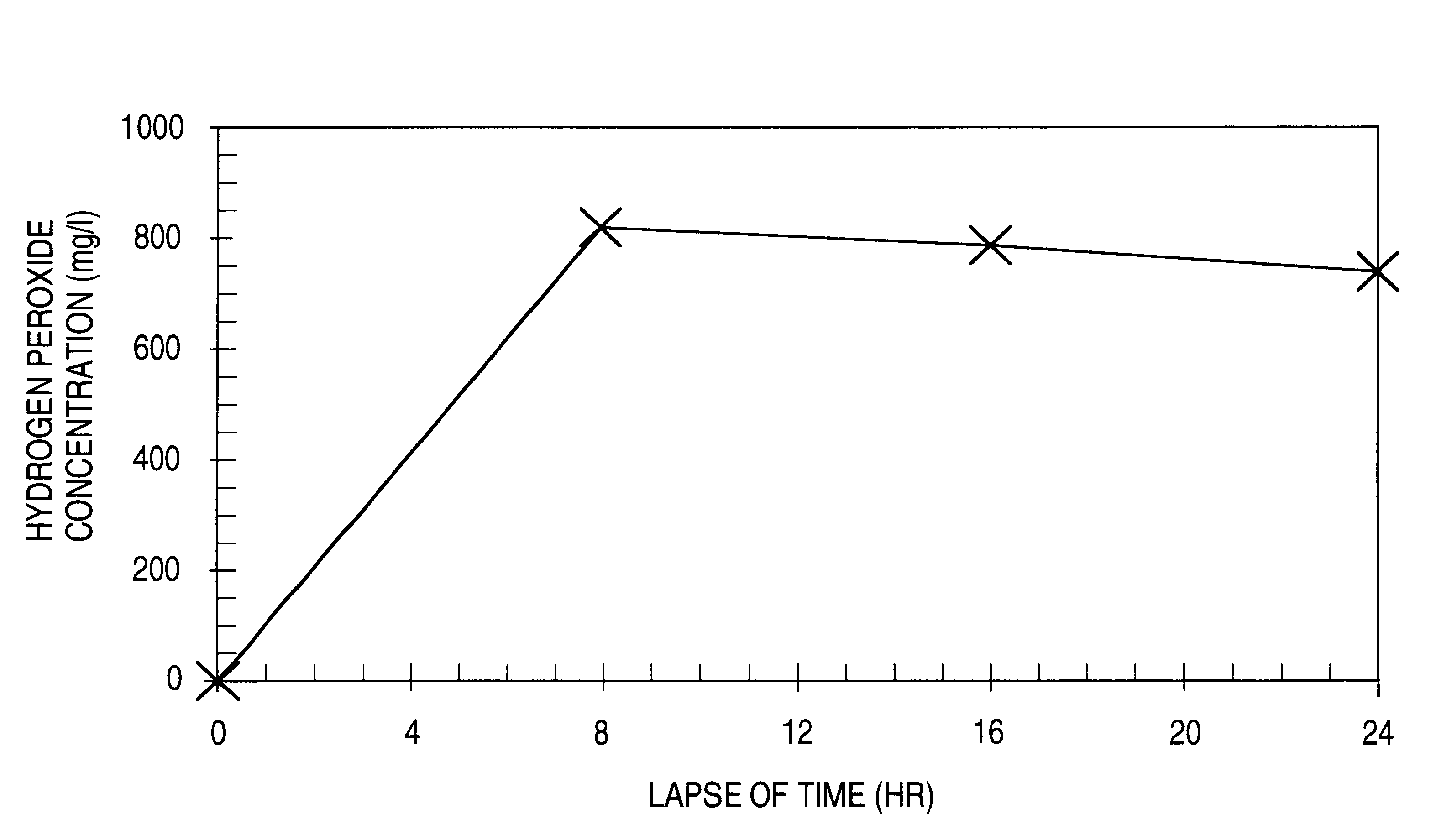

InactiveUS20020194852A1High purityPoorly water-solubleBiocideDomestic cooling apparatusPerishable foodElectrolysis

An ice composition obtained by freezing a liquid containing, dissolved therein, hydrogen peroxide produced by electrolysis; and a method of food storage using the composition. Hydrogen peroxide has a lower rate of dissipation into the air and better suitability for long-term storage than ozone. Furthermore, since hydrogen peroxide is electrolytically produced, it eliminates the trouble of transportation, storage, and dissolution. When seawater is used as a feed water for electrolysis, the ice composition thus obtained has a higher cooling effect because it has a melting point lower than 0° C.

Owner:DE NORA PERMELEC LTD

Ice composition containing hydrogen peroxide and method of storing perishable food

InactiveUS6666030B2High purityPoorly water-solubleBiocideDomestic cooling apparatusElectrolysisPerishable food

An ice composition obtained by freezing a liquid containing, dissolved therein, hydrogen peroxide produced by electrolysis; and a method of food storage using the composition. Hydrogen peroxide has a lower rate of dissipation into the air and better suitability for long-term storage than ozone. Furthermore, since hydrogen peroxide is electrolytically produced, it eliminates the trouble of transportation, storage, and dissolution. When seawater is used as a feed water for electrolysis, the ice composition thus obtained has a higher cooling effect because it has a melting point lower than 0° C.

Owner:DE NORA PERMELEC LTD

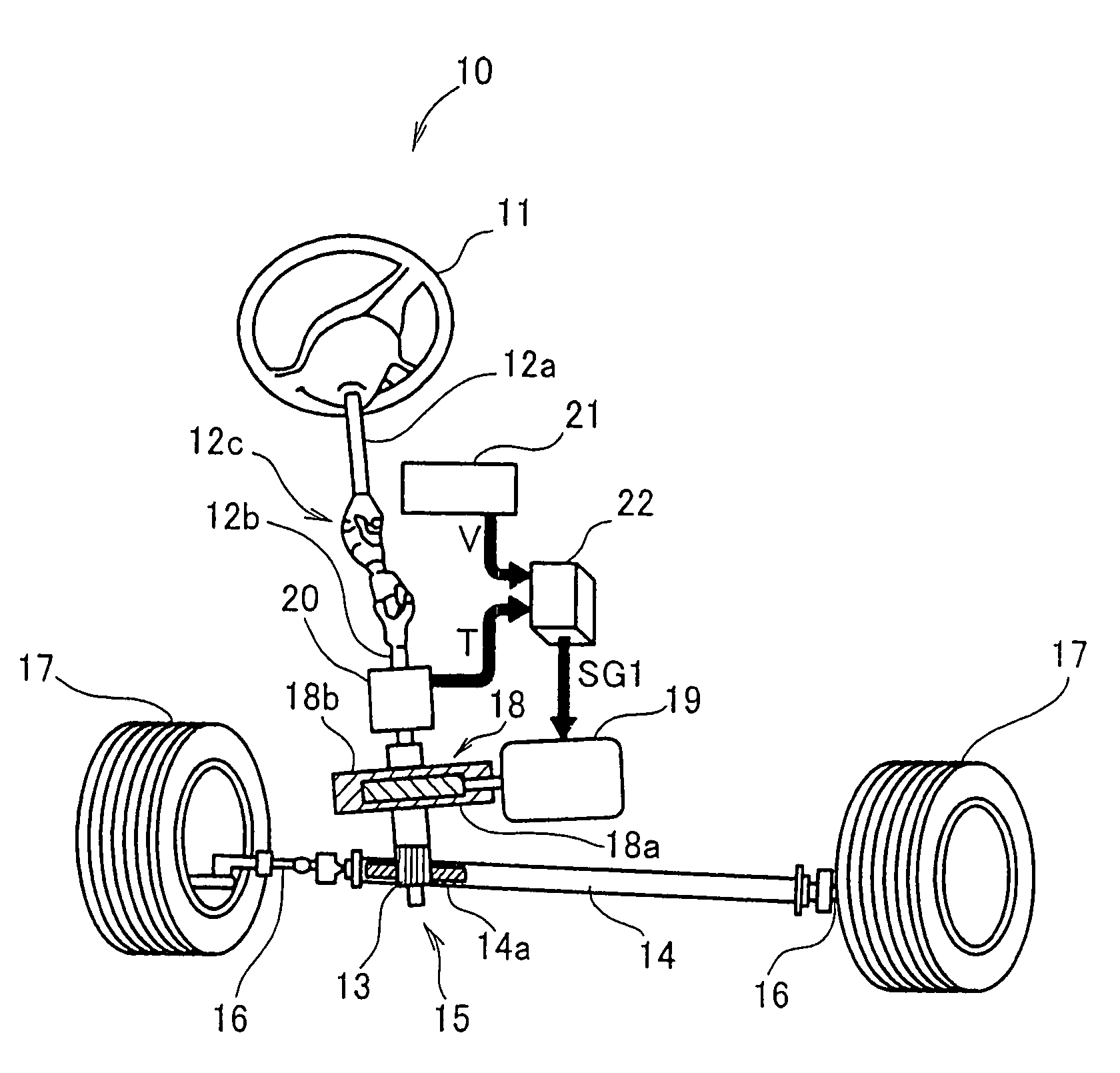

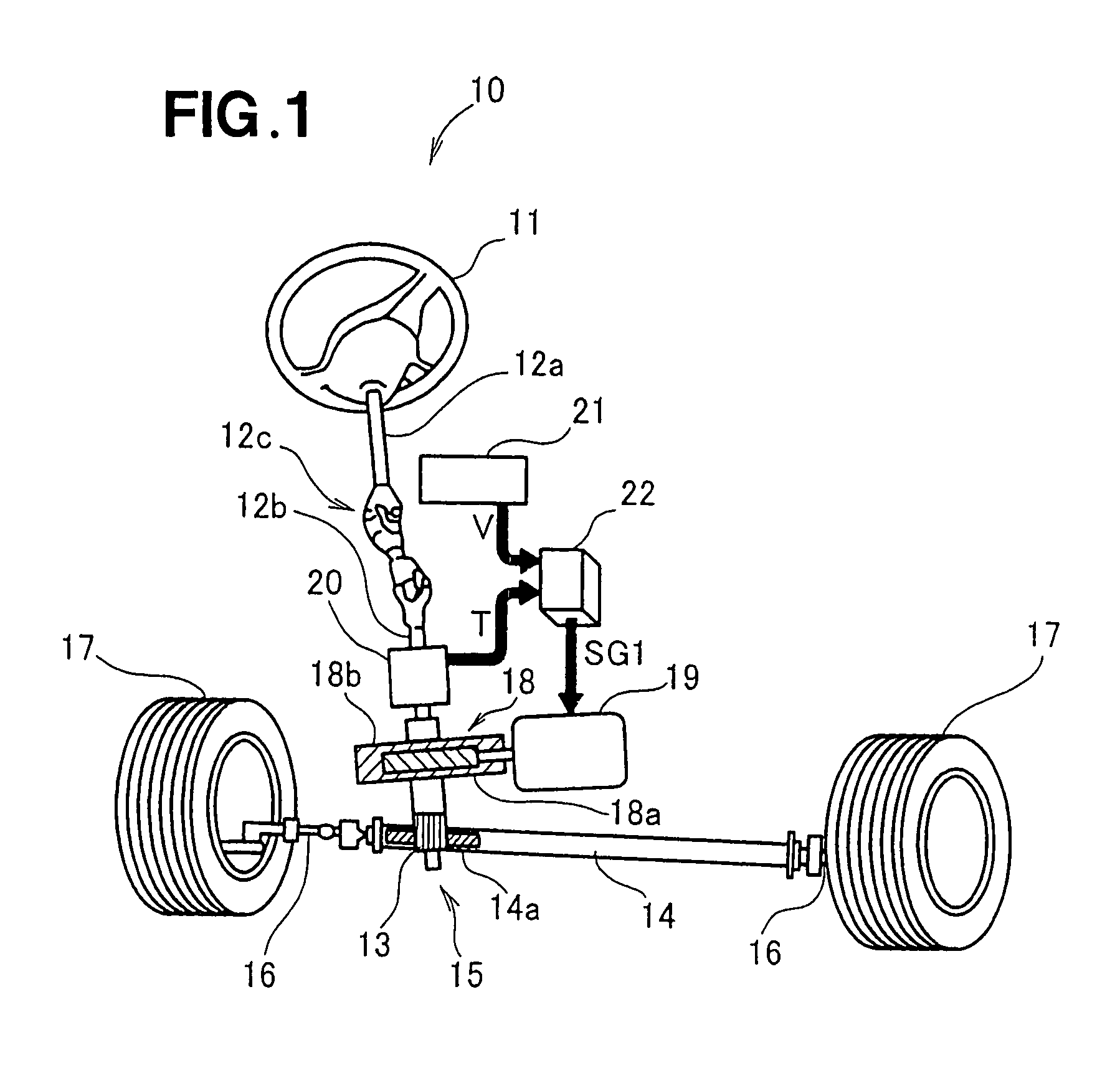

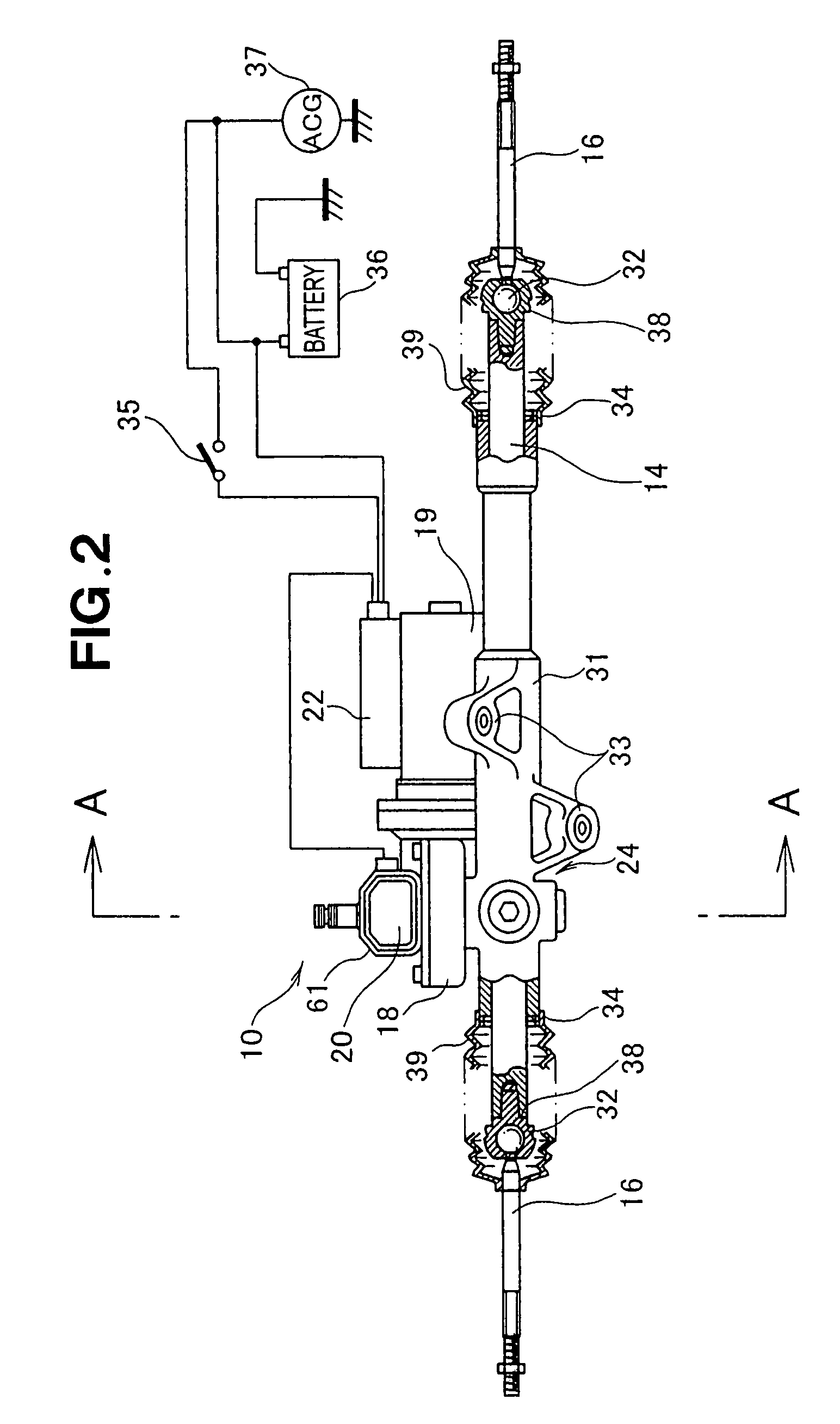

Method for manufacturing magnetostrictive torque sensor device, and electric power steering apparatus

ActiveUS7568274B2Reduce unevennessEasily manufacture and widely distributeMetal rolling stand detailsWork measurementElectric power steeringRotational axis

A method for manufacturing a magnetostrictive torque sensor device includes the steps of: providing a steering shaft or another such rotating shaft with two magnetostrictive parts endowed with magnetic anisotropy; disposing detection coils around the magnetostrictive parts to detect changes in magnetostrictive characteristics of the magnetostrictive parts; providing a detection circuit for bringing out detection signals from signals outputted from the detection coils; and adjusting a gain of a gain adjuster included in the detection circuit.

Owner:HONDA MOTOR CO LTD

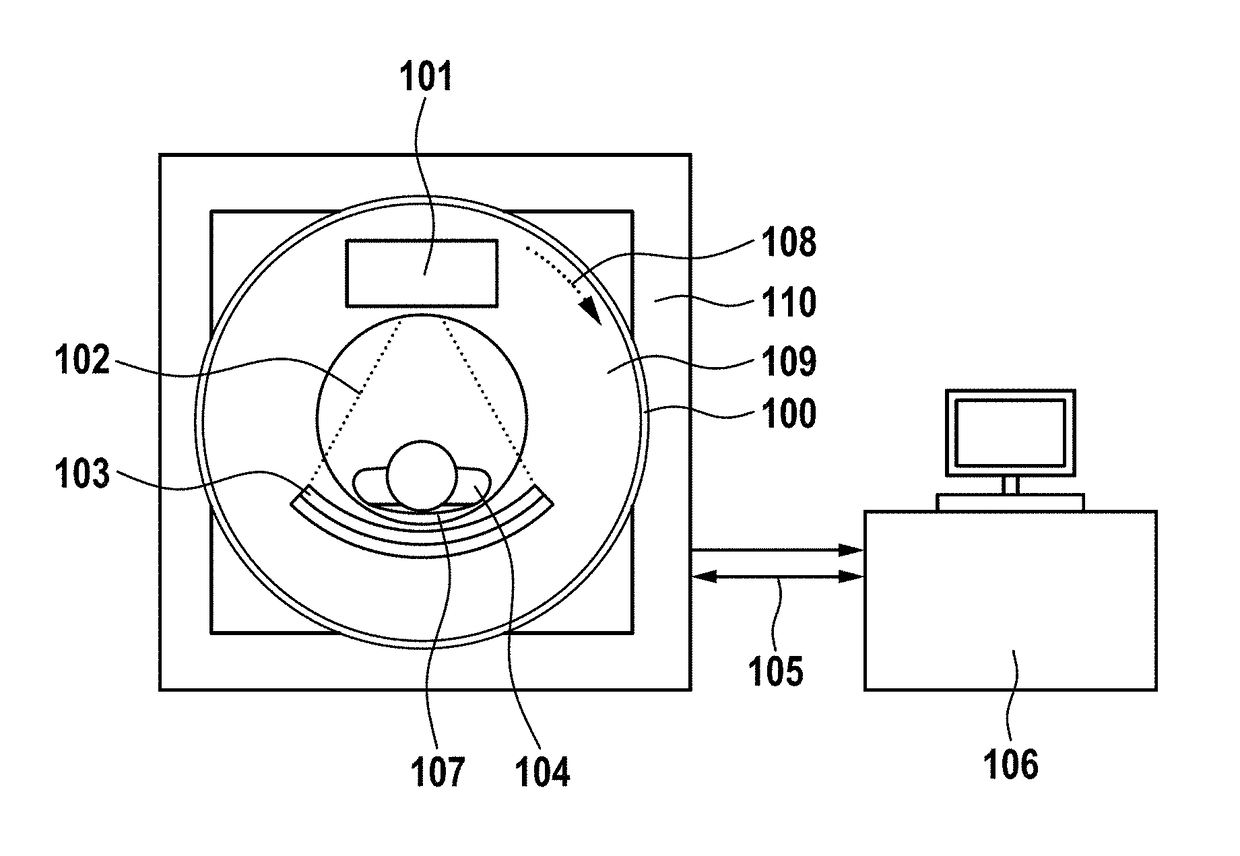

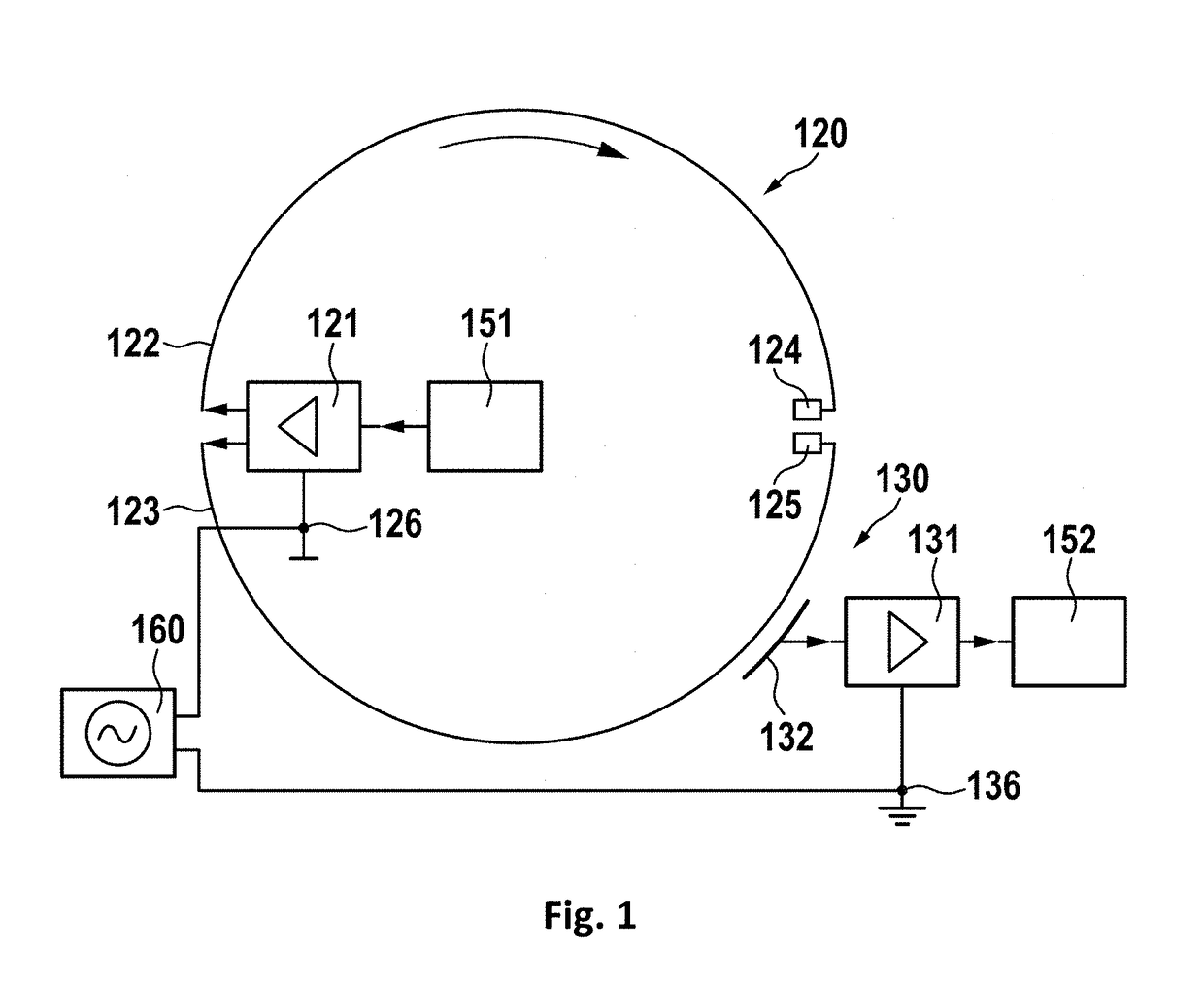

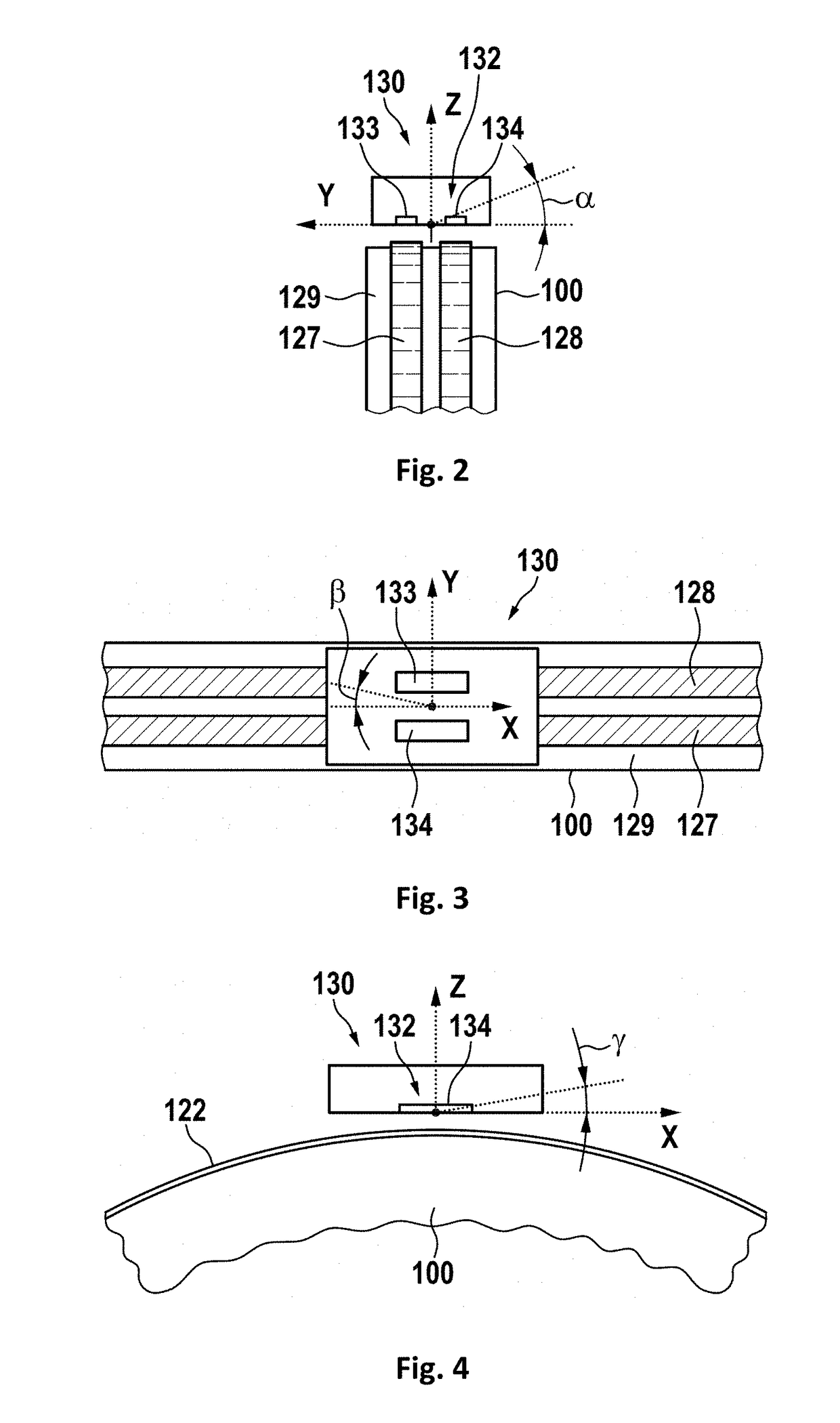

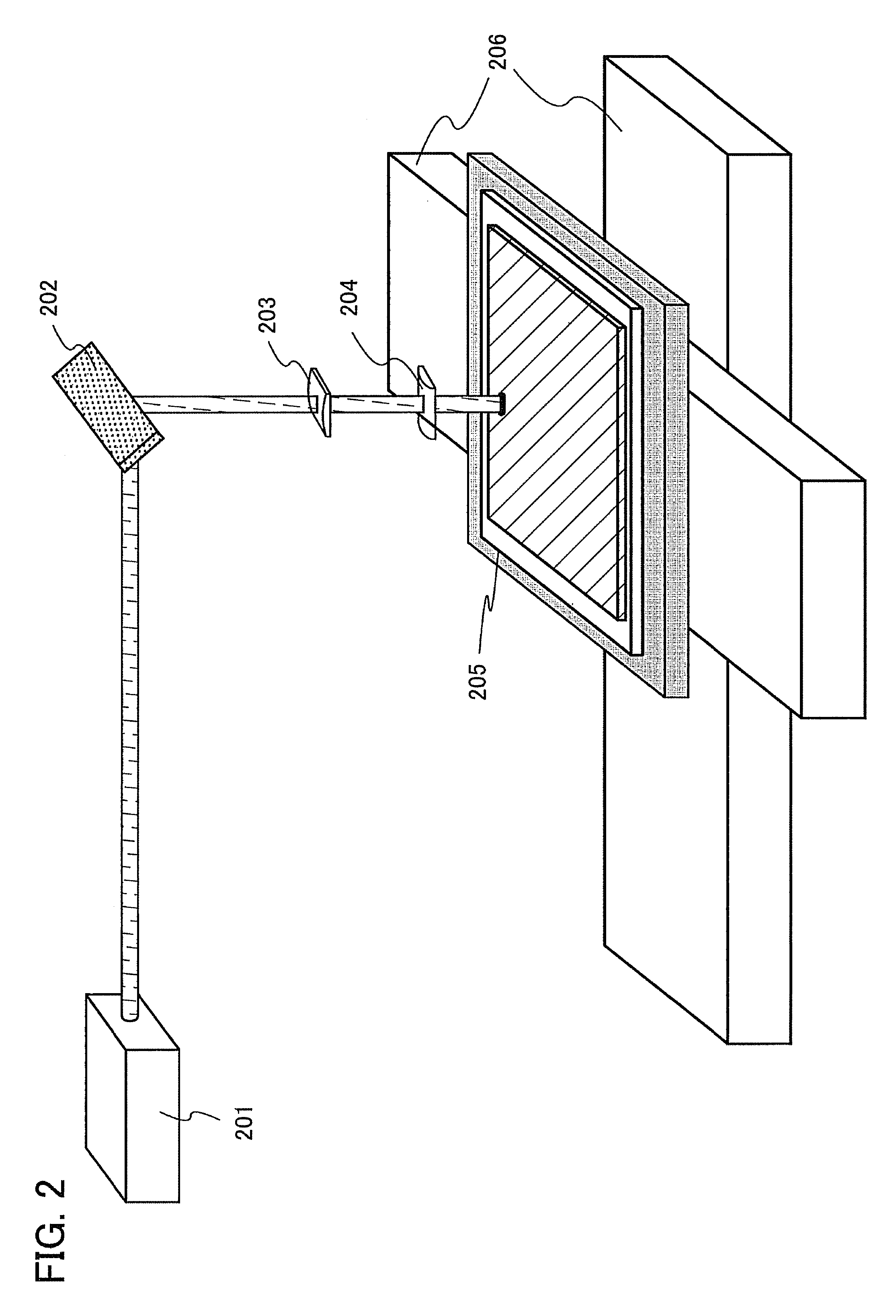

Method and device for the adjustment of contactless data links

ActiveUS9859994B2Improve EMC performanceEasy to adjustRadiation diagnosis data transmissionTransmitters monitoringElectrical conductorDifferential signaling

A test setup for testing a contactless digital rotary joint integrated in a device requiring data transmission between a rotating part and a stationary part, the rotary joint further comprises a transmitter and a receiver. The transmitter has a transmitter amplifier, which is coupled to a pair of transmission lines, which are terminated by a pair of terminations. The transmission lines are differential transmission lines comprising a pair of conductors which is driven by differential signals from the transmitter amplifier. The receiver has a receiver antenna comprising a pair of antenna sections which are differentially operated and feed a differential signal to the receiver amplifier. A transmitter ground and a receiver ground are coupled to a common mode signal generator generating a common mode signal. A data source is coupled to the transmitter amplifier feeding a test signal into the transmitter amplifier, and a data sink is coupled to the receiver amplifier for receiving the test signal and generating a test result value. Also disclosed is a method for adjusting a contactless data link integrated in a device requiring data transmission between a rotating part and a stationary part.

Owner:SCHLEIFRING & APPBAU

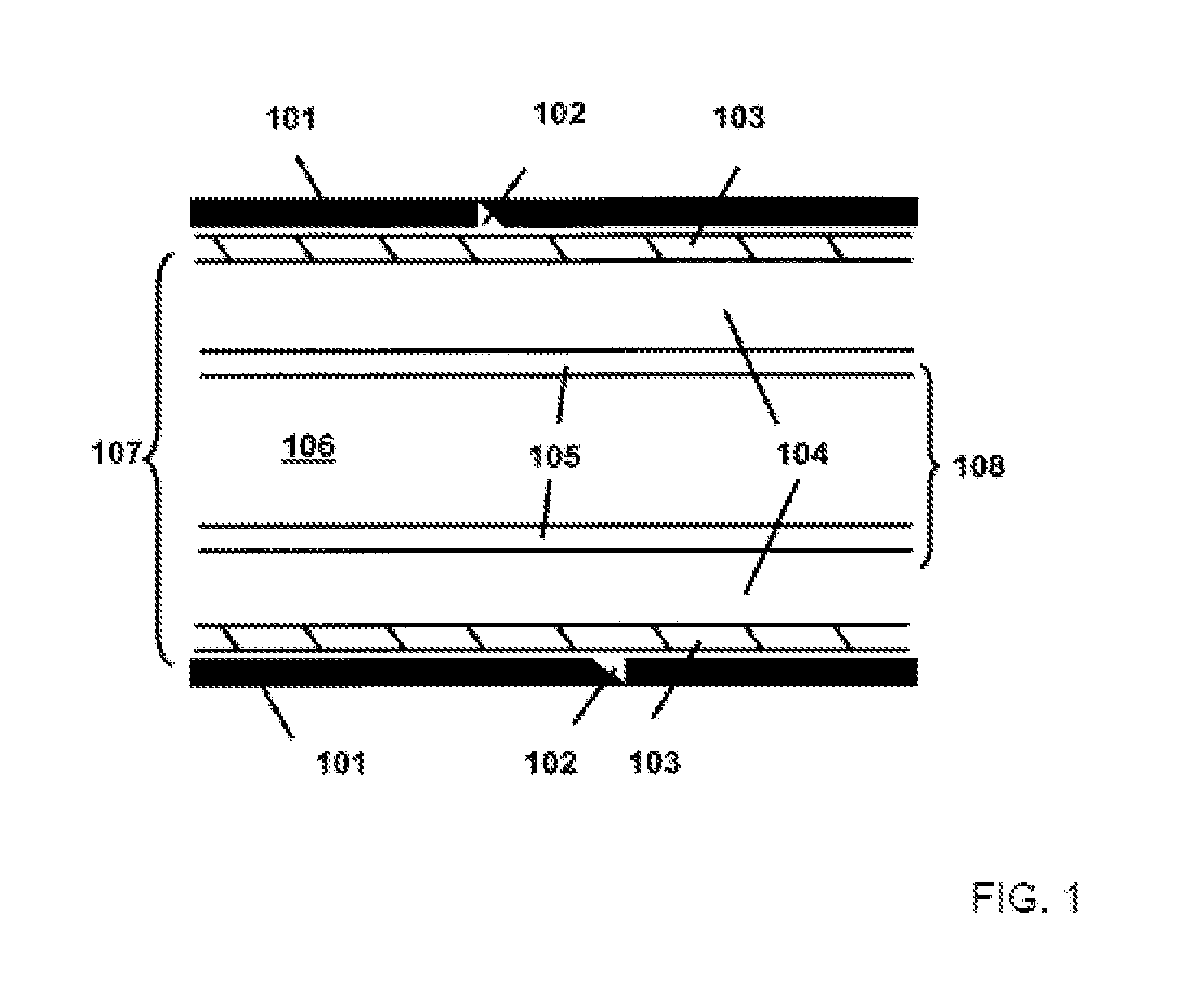

Multi-layer film permeable to UV radiation

ActiveUS20130126029A1Improve mechanical propertiesImprove good performanceSynthetic resin layered productsPipe elementsPolyamideUltraviolet

A multilayer film that is impermeable to liquids and is to some extent permeable to UV radiation, optionally in the form of a tubular film, having a layer sequence of a layer (a) comprising at least one thermoplastic olefin homo- or copolymer, as one of the external layers, an adhesive-promoter layer (b), an internal layer (c) comprising at least one homo- and / or copolyamide, an adhesive-promoter layer (d), and a layer (e) comprising at least one homo- and / or copolyamide, as one of the external layers, wherein the VICAT softening point of the thermoplastic olefin homo- or copolymer of the layer (a) is at least 100° C., and the use of said multilayer film as internally situated tube of an insertion tube for the renovation of subterranean pipes, an insertion tube of this type, and a pipe-renovation system suitable for the renovation of subterranean pipes.

Owner:BUERGOFOL

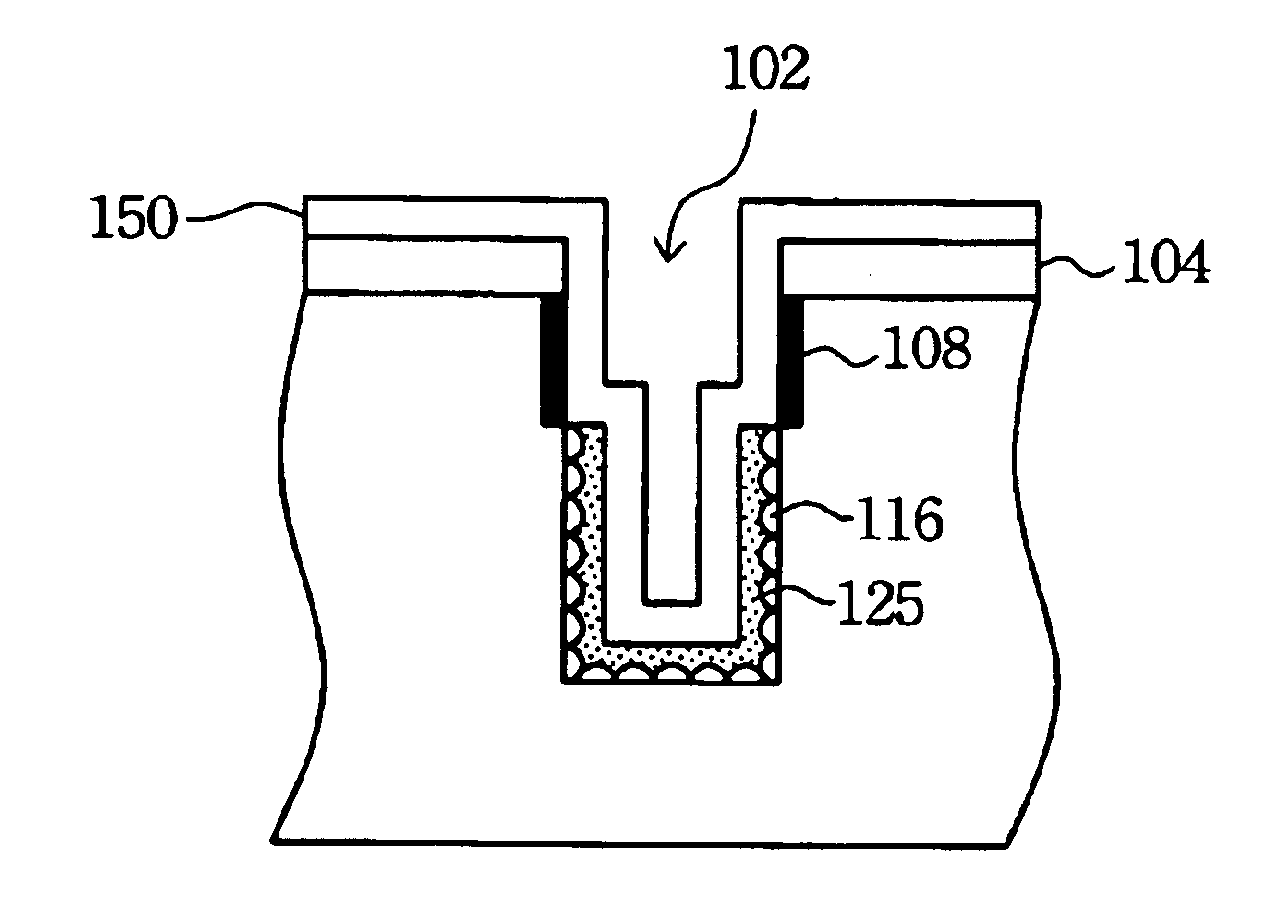

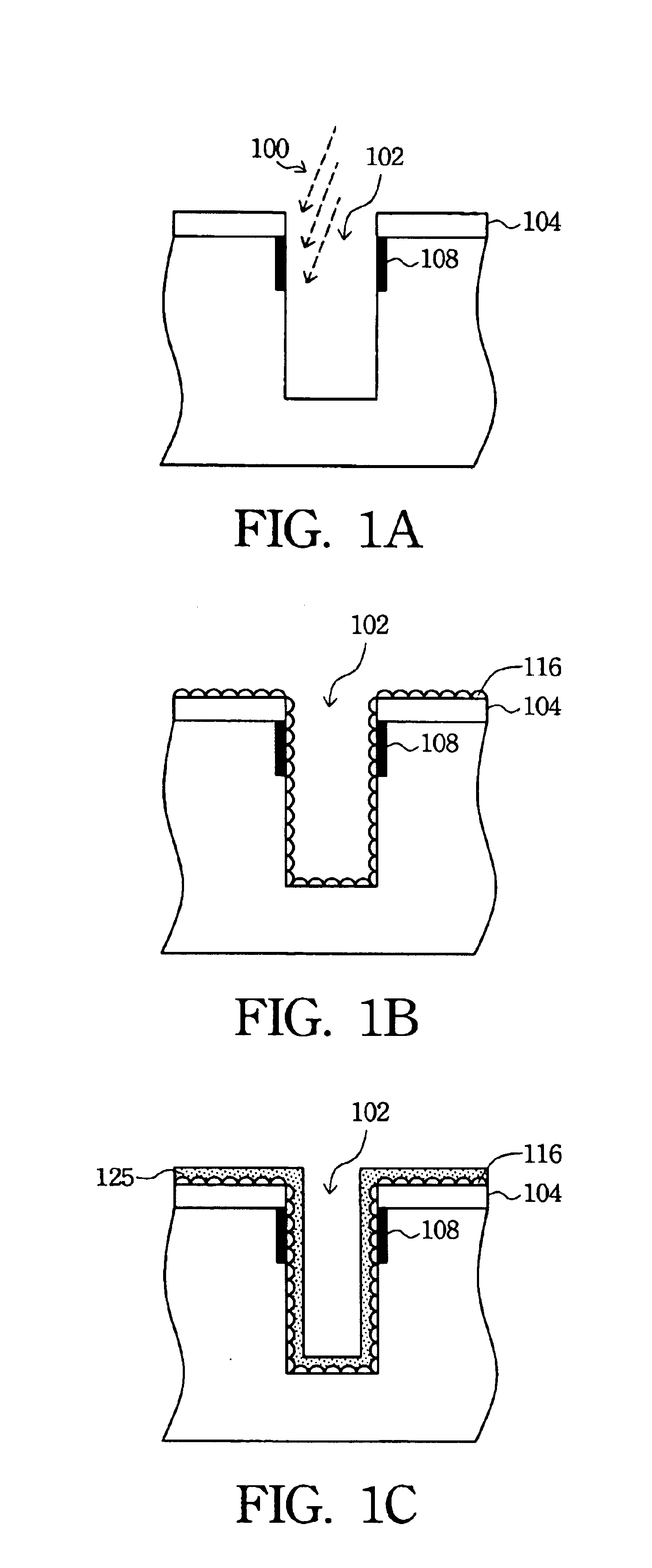

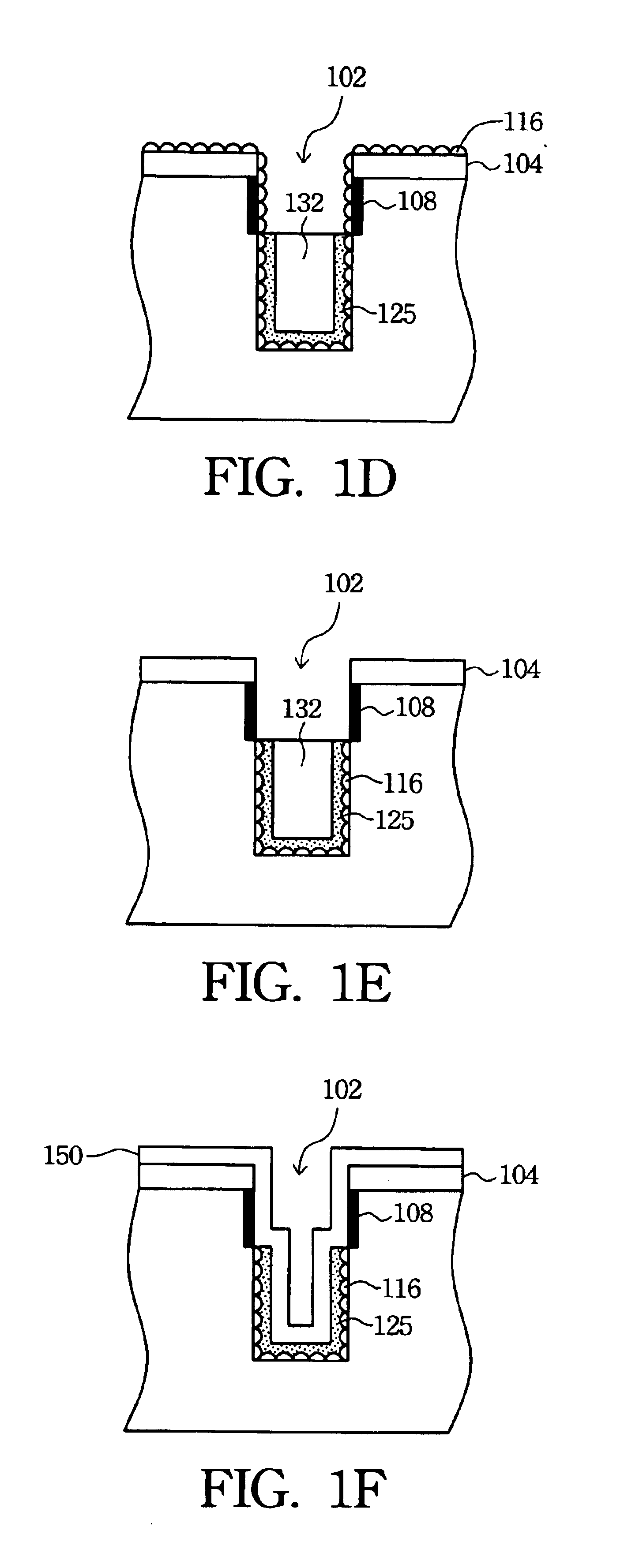

Method for removal of hemispherical grained silicon in a deep trench

ActiveUS6872621B1Increase capacitanceNo damageSolid-state devicesSemiconductor/solid-state device manufacturingCapacitancePotassium hydroxide

A method for removal of hemispherical grained silicon (HSG) in a deep trench is described. A buried silicon germanium (SiGe) layer serving as an etch stop layer is formed in the collar region of the trench, followed by depositing a HSG layer. The HSG layer is then successfully striped by wet etching with a potassium hydroxide / propanone / water etchant, that is, without damage to the trench sidewalls, since a good etch rate selectivity between the HSG layer and the SiGe layer is obtained by the wet etchant. In addition, no etch stop layer exists between the HSG layer and the bottom of the trench when manufacturing trench capacitors in accordance with the method; capacitance degradation is therefore not of concern.

Owner:CHANG LIAO HLDG

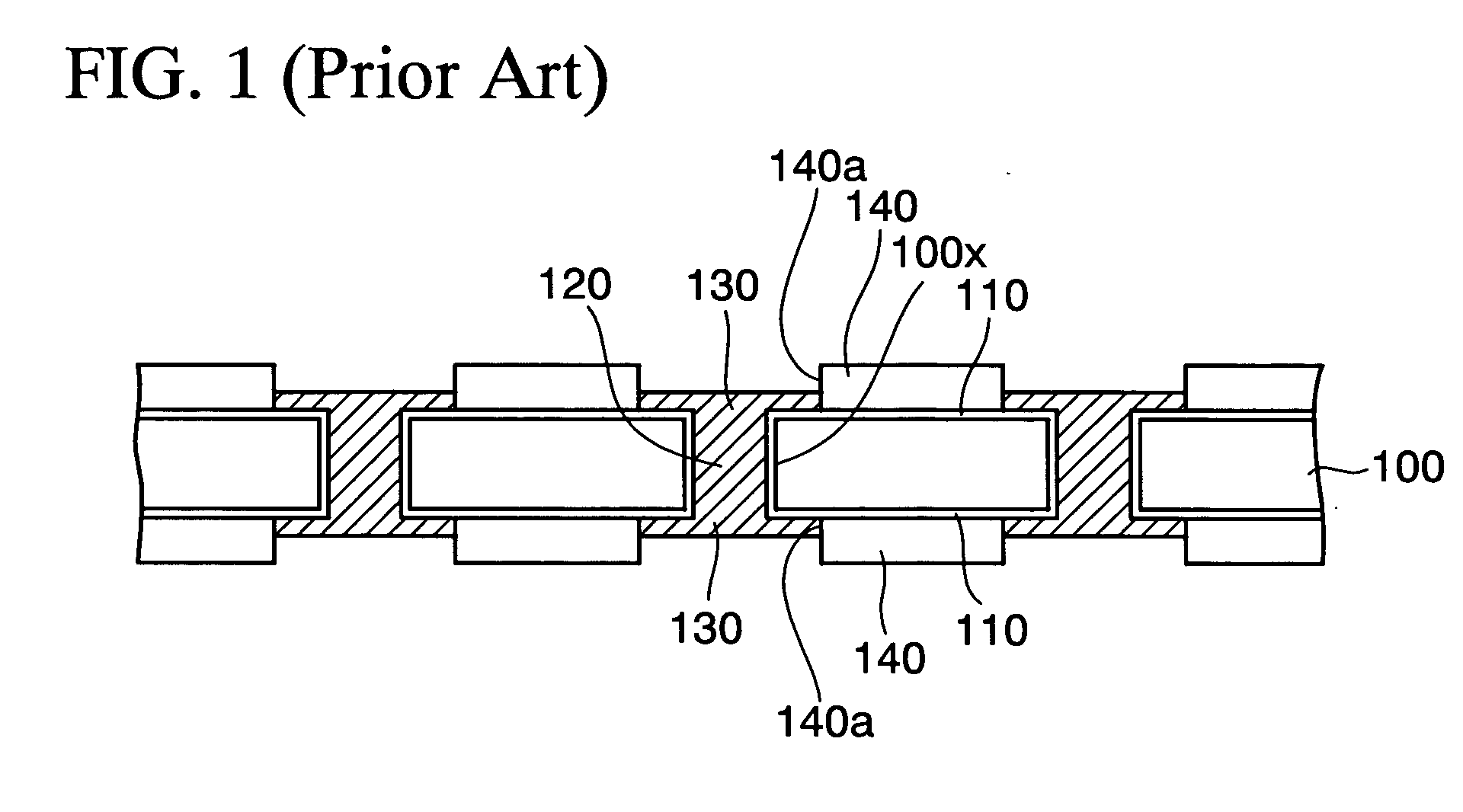

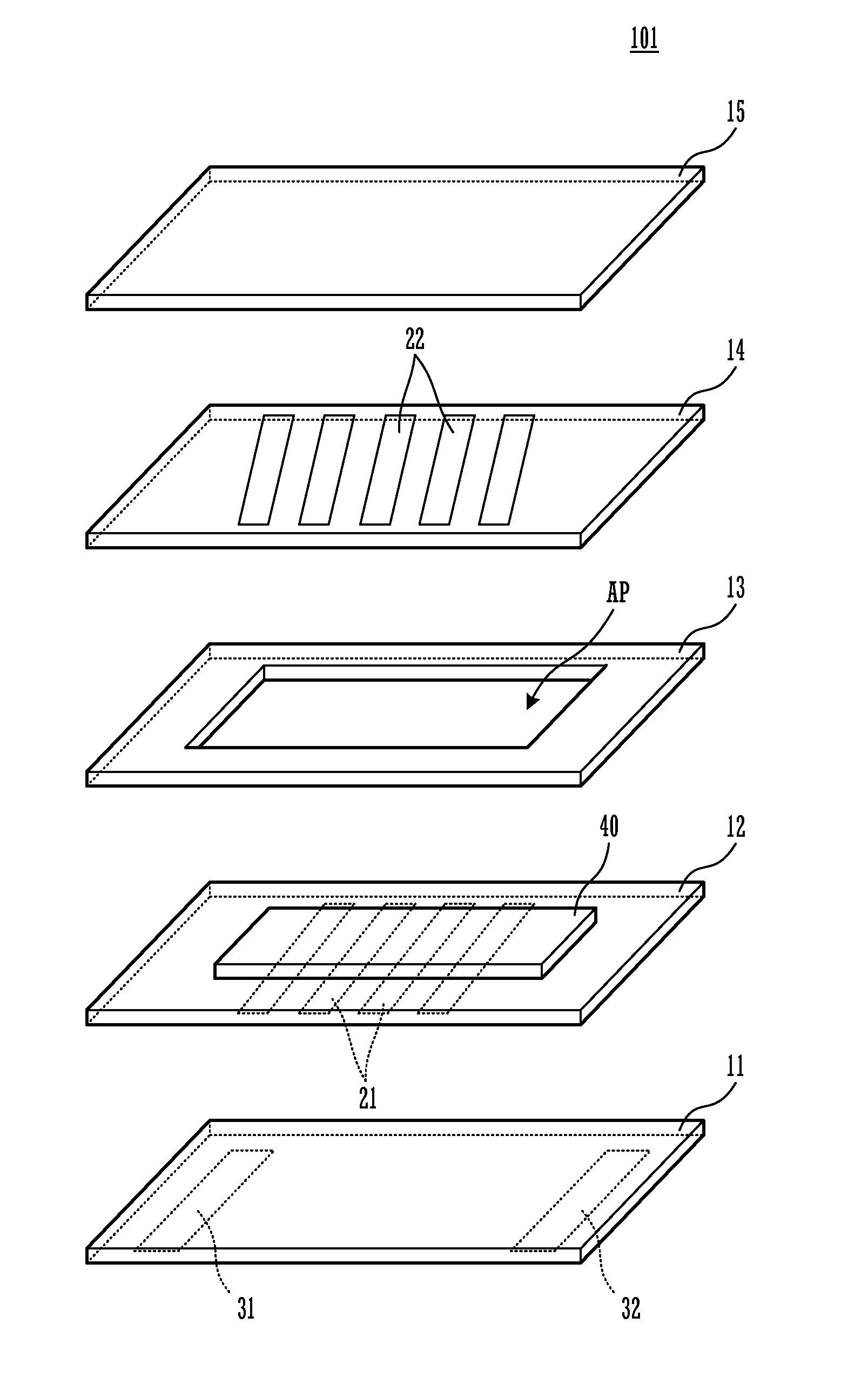

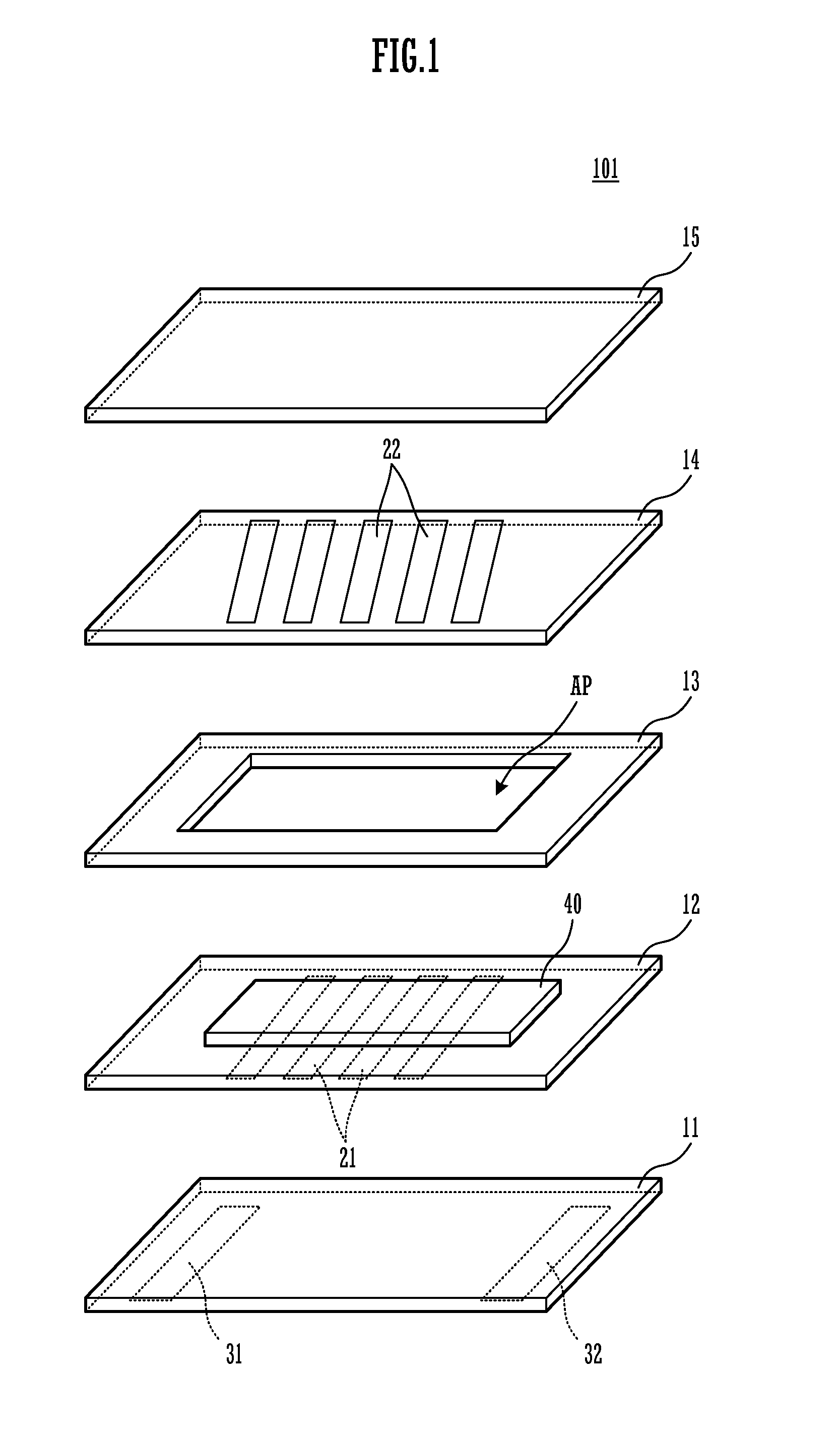

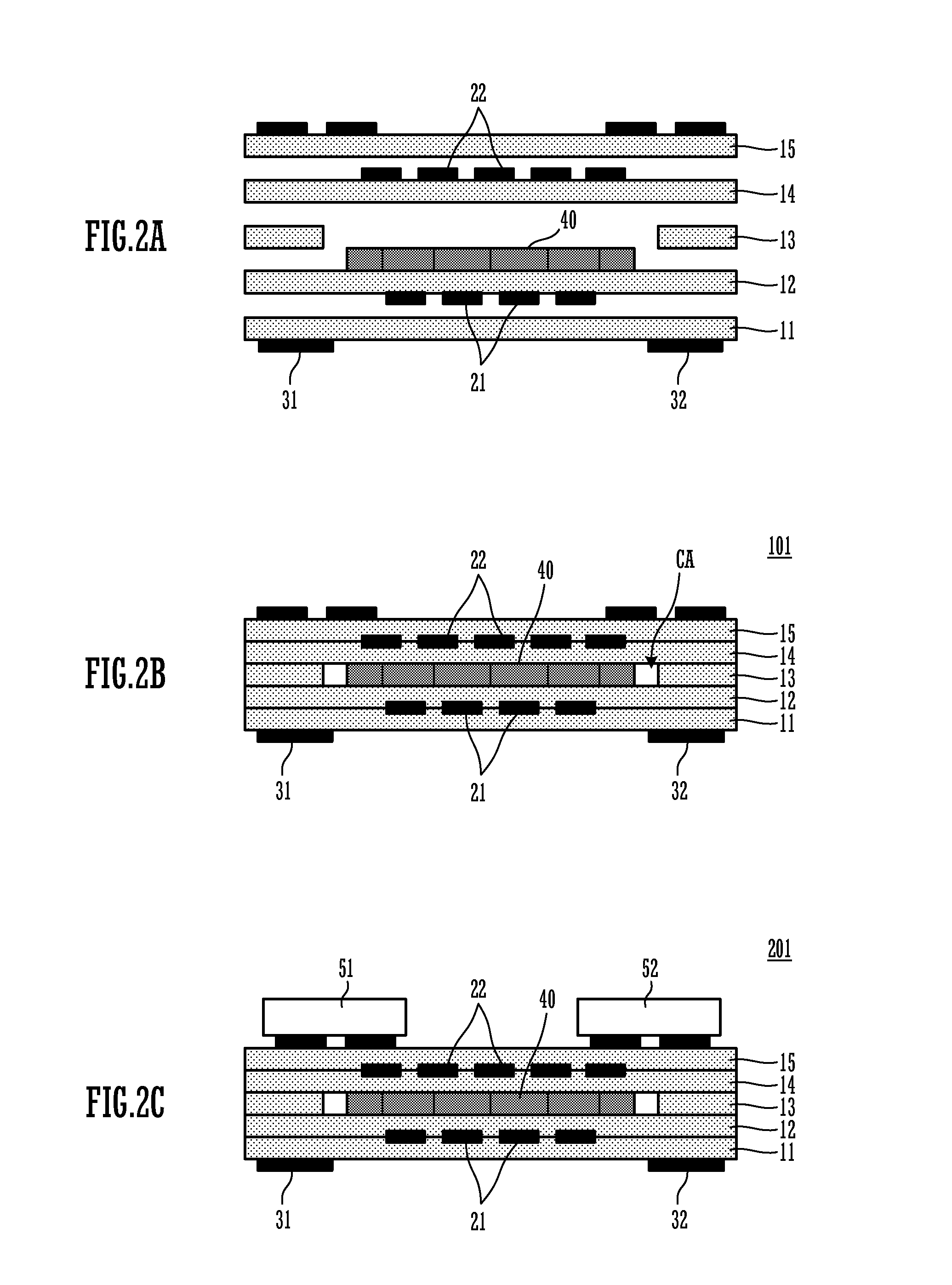

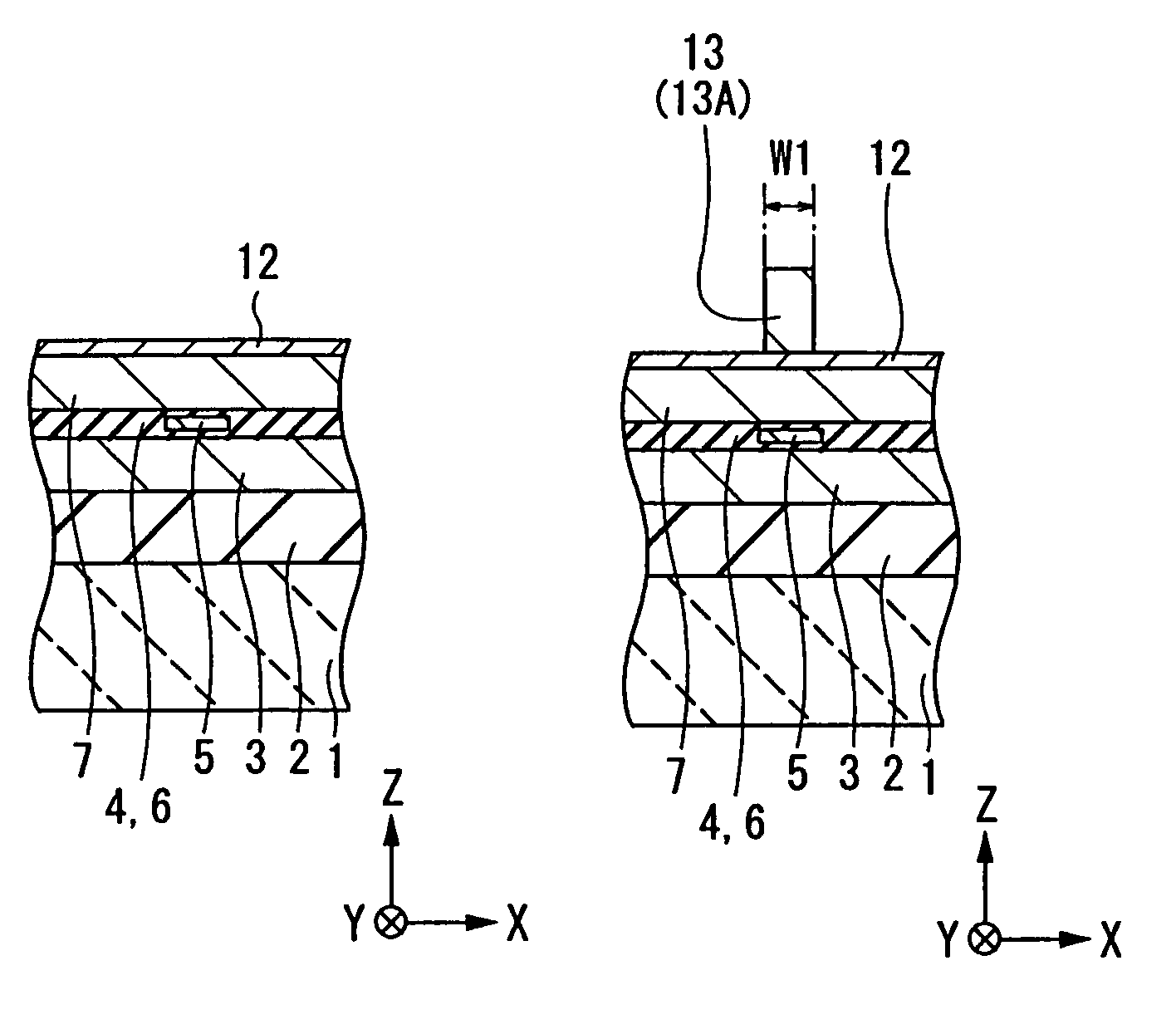

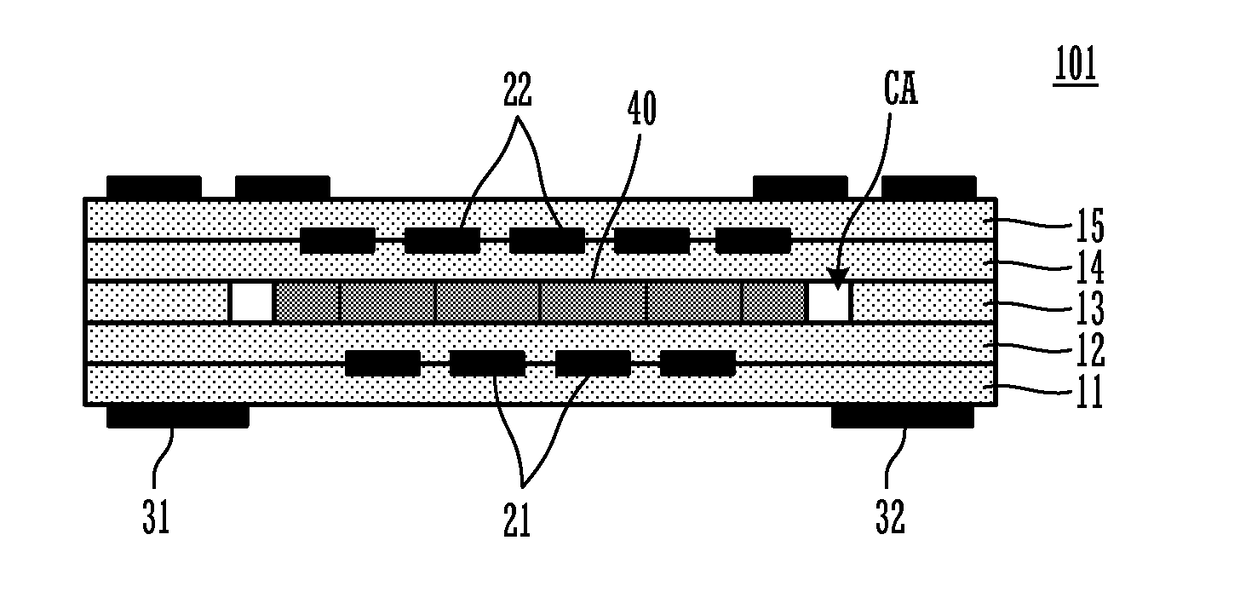

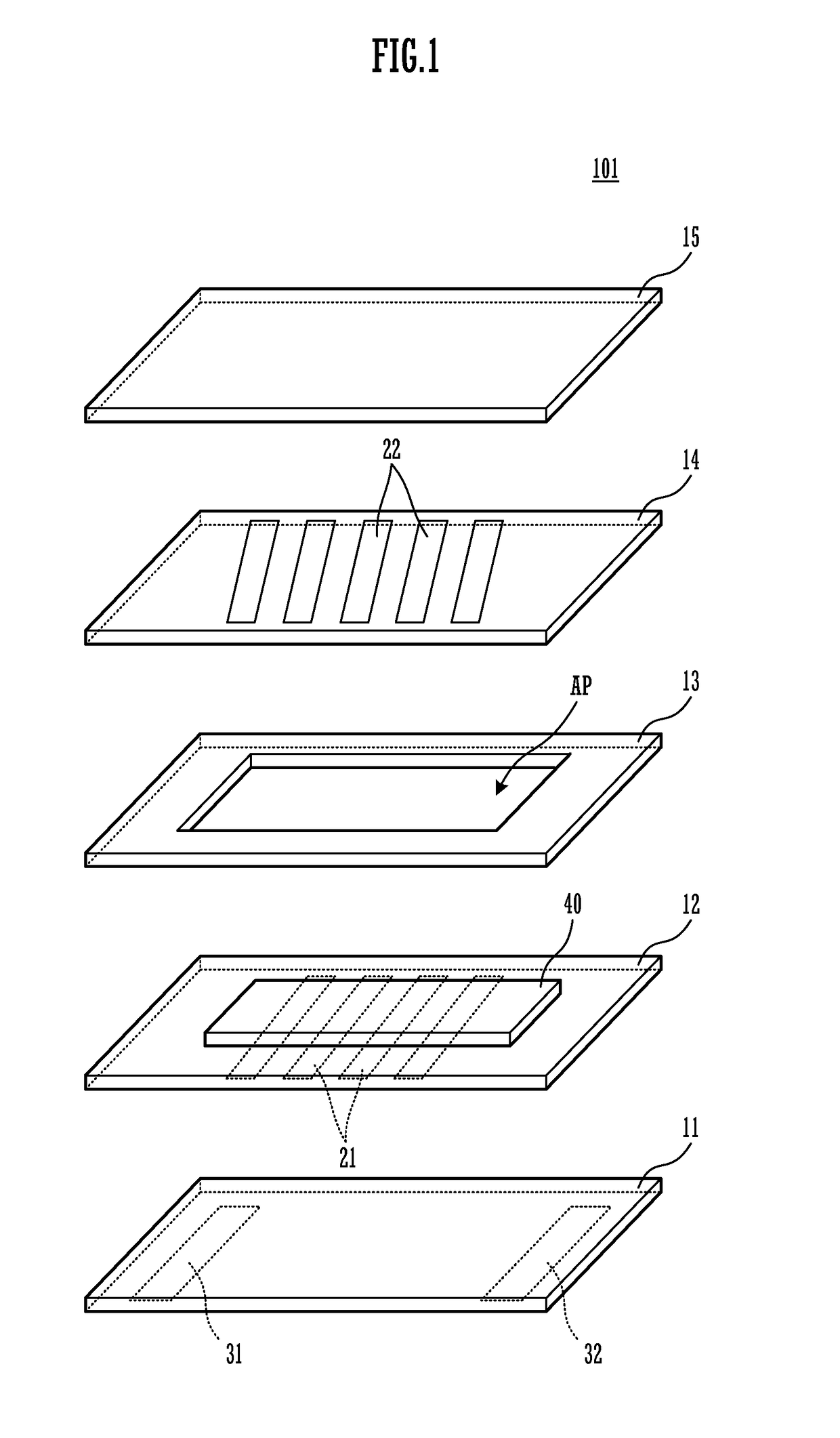

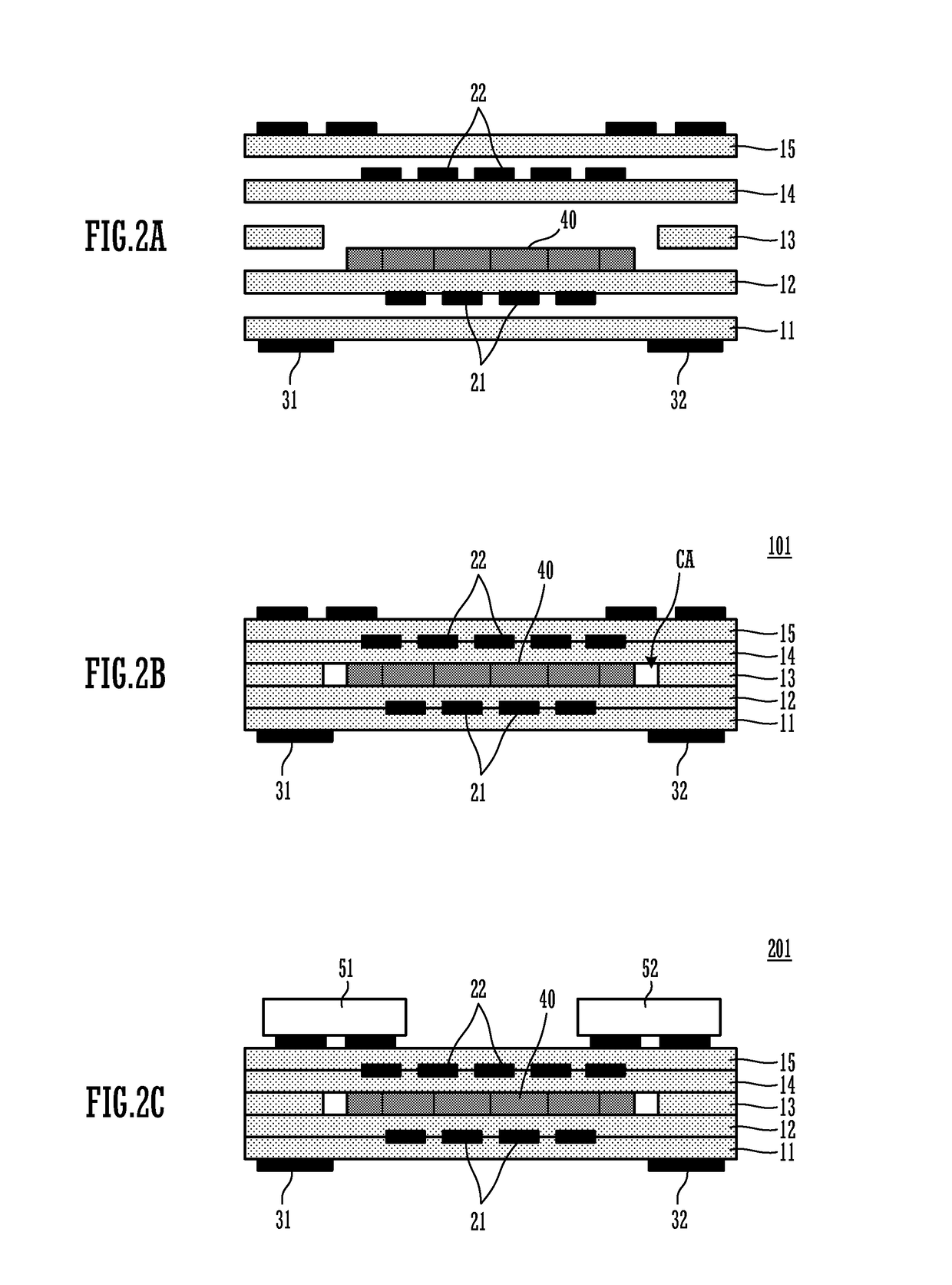

Magnetic material core-embedded resin multilayer board, manufacturing method therefor, electronic device, and antenna device

ActiveUS20150102970A1Reduce manufacturing costStep can be unnecessaryLoop antennas with ferromagnetic coreHigh frequency circuit adaptationsElectrical conductorElectron

Owner:MURATA MFG CO LTD

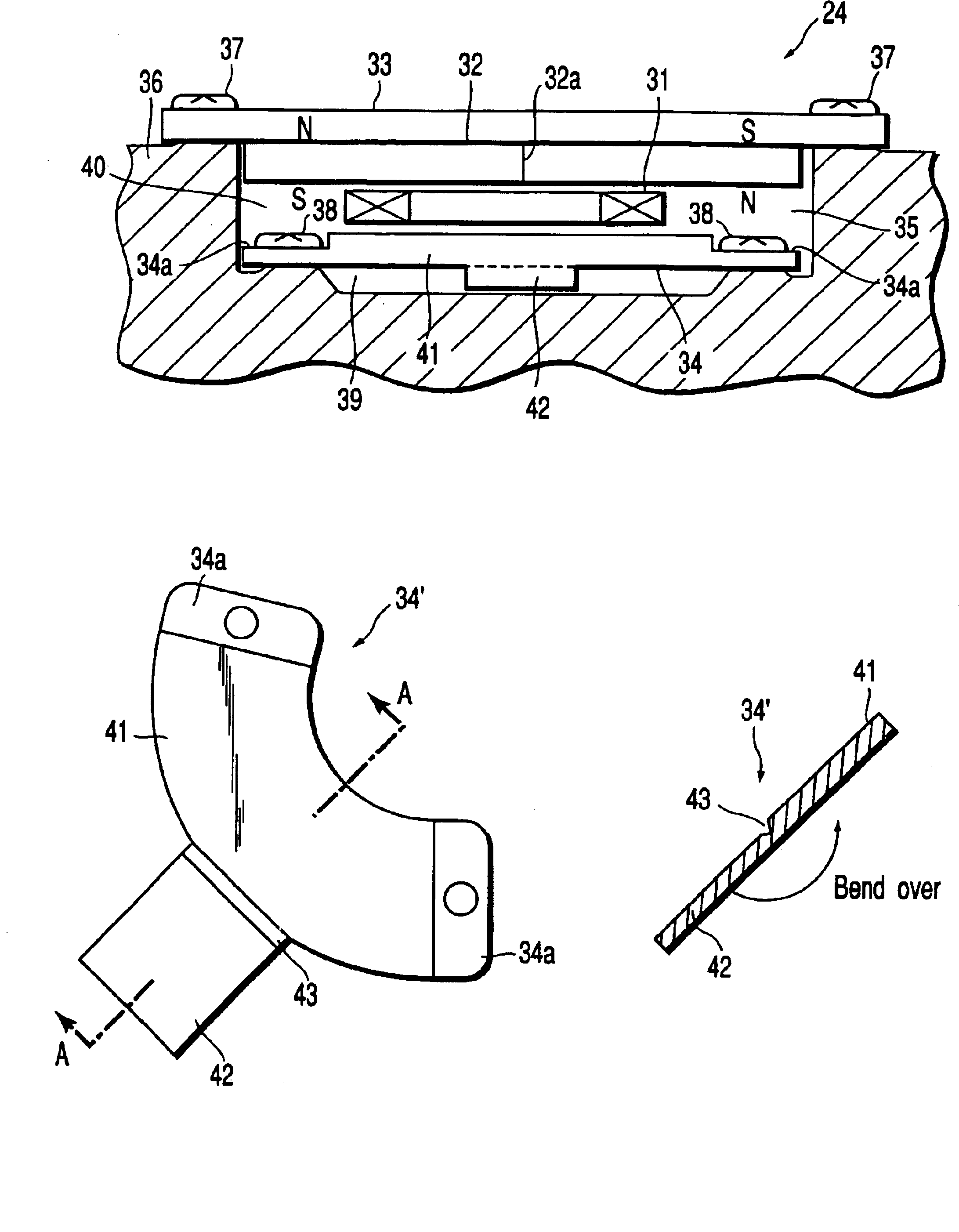

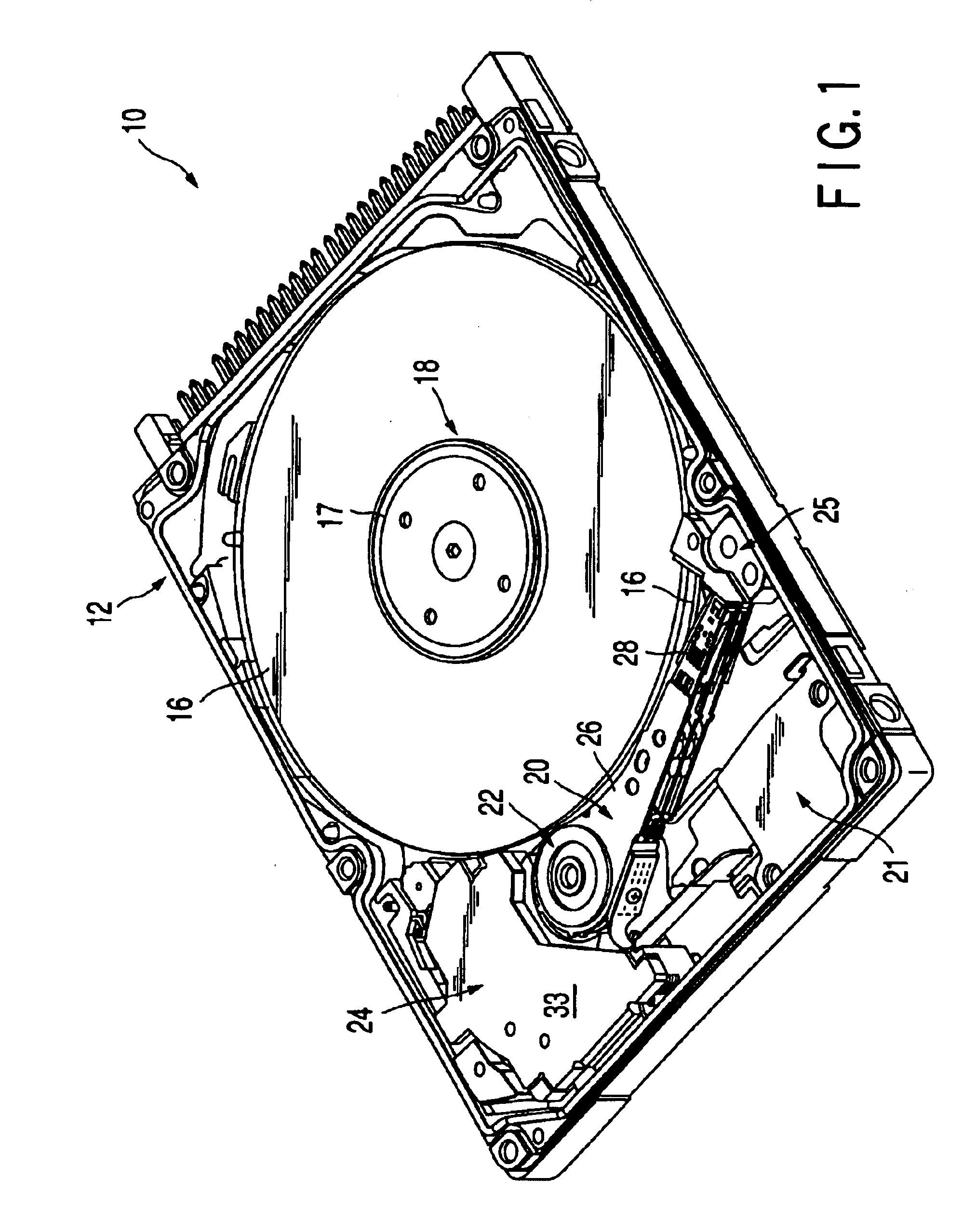

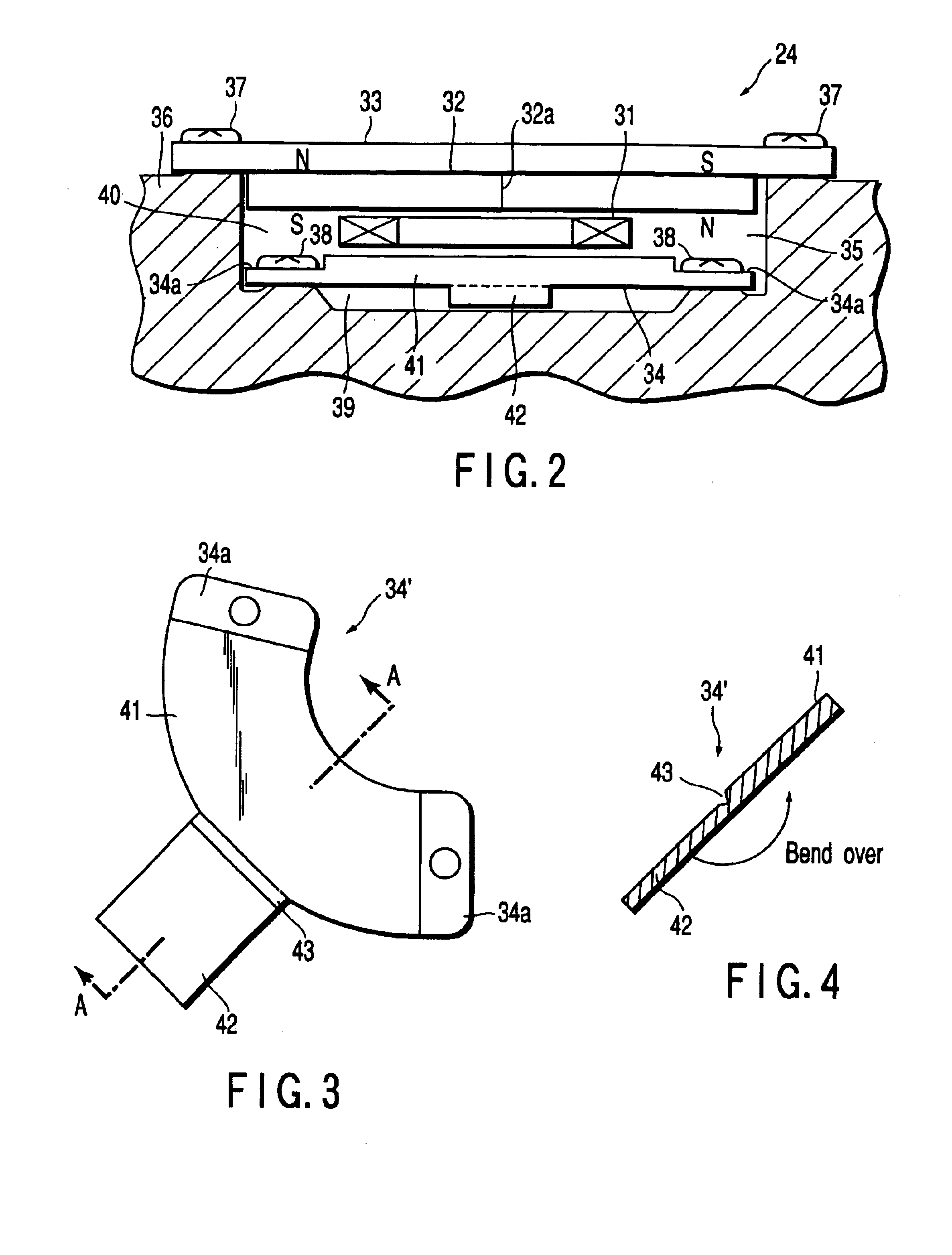

Disk unit, yoke built in disk unit and process of manufacturing same

InactiveUS6914755B2Suppression of Leakage FluxExercise sufficient performanceDisposition/mounting of recording headsRecord information storageEngineeringCantilever

A disk unit has a voice coil motor to oscillate a suspension arm mounted at the leading end of a head with respect to a disk. The voice coil motor has a voice coil integrally attached to the tail end of the suspension arm, a magnet to cause a magnetic field to act on the voice coil, and a pair of yokes provided in such a positional relationship that the voice coil and magnet are sandwiched therebetween. At least one yoke has a roughly fan-shaped main body and a plate piece portion provided in a condition extended from one end side of the main body. After the formation of the main body and plate piece portion by press working, the yoke is formed by folding the plate piece portion on the main body.

Owner:KK TOSHIBA

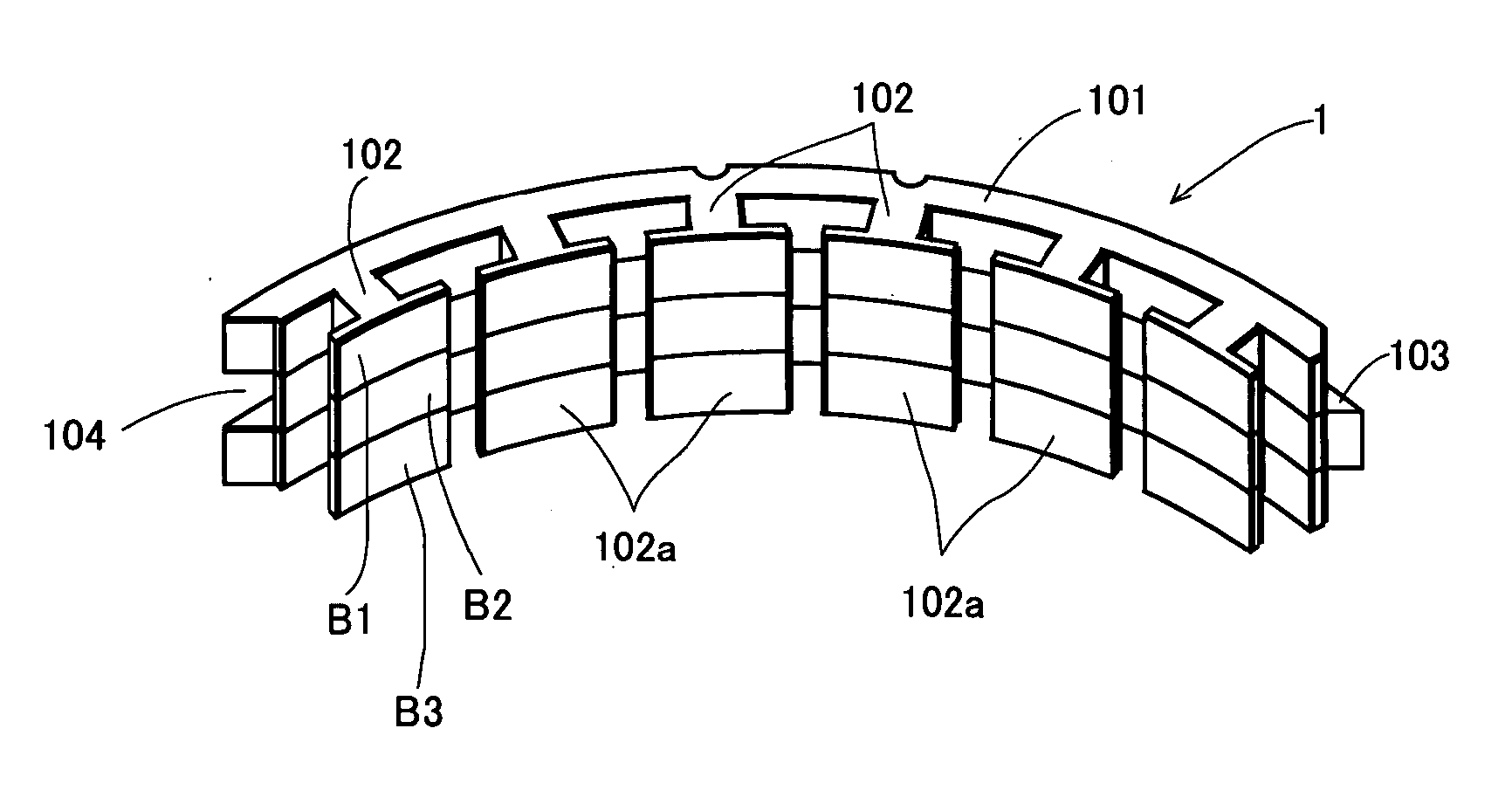

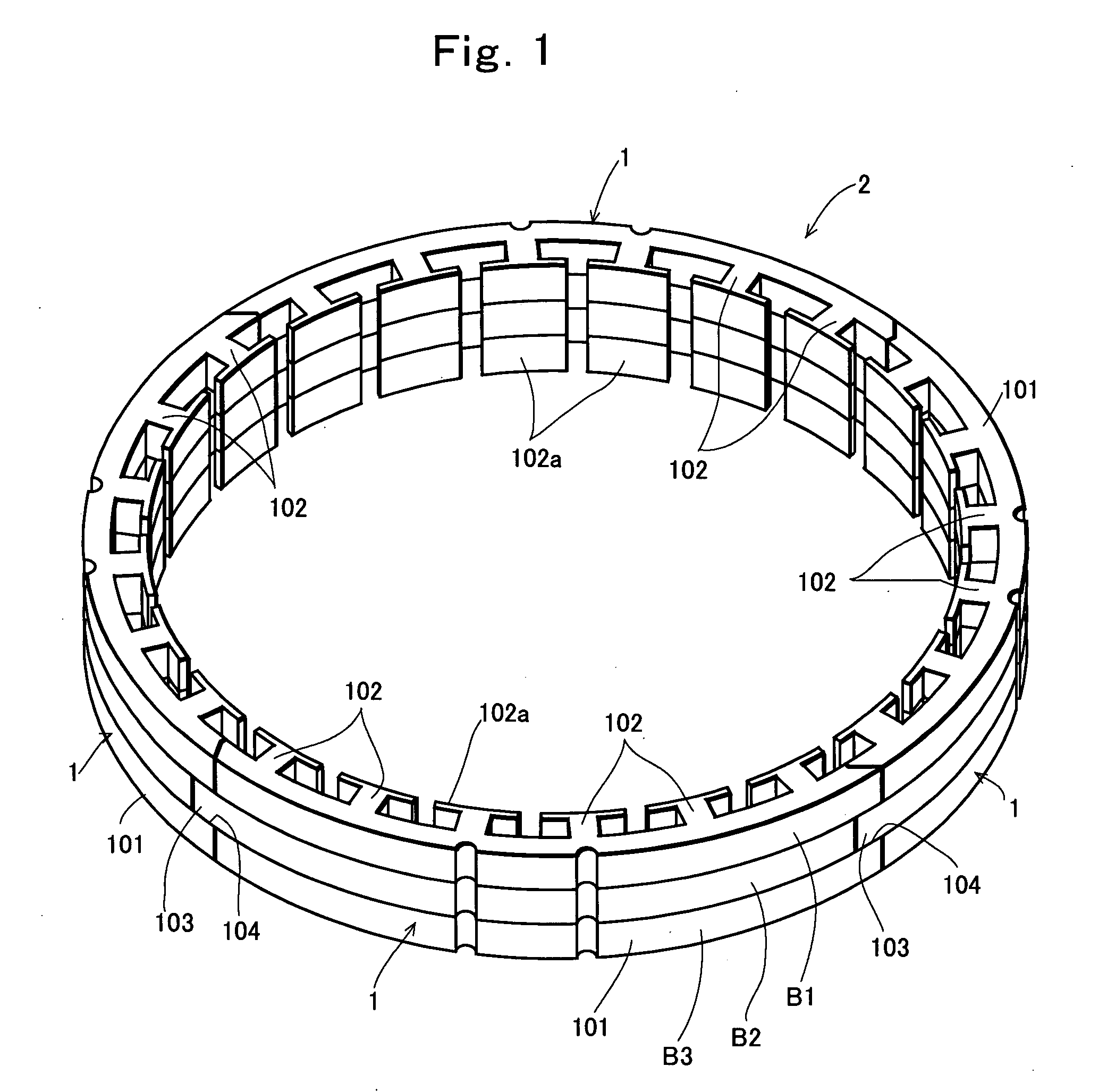

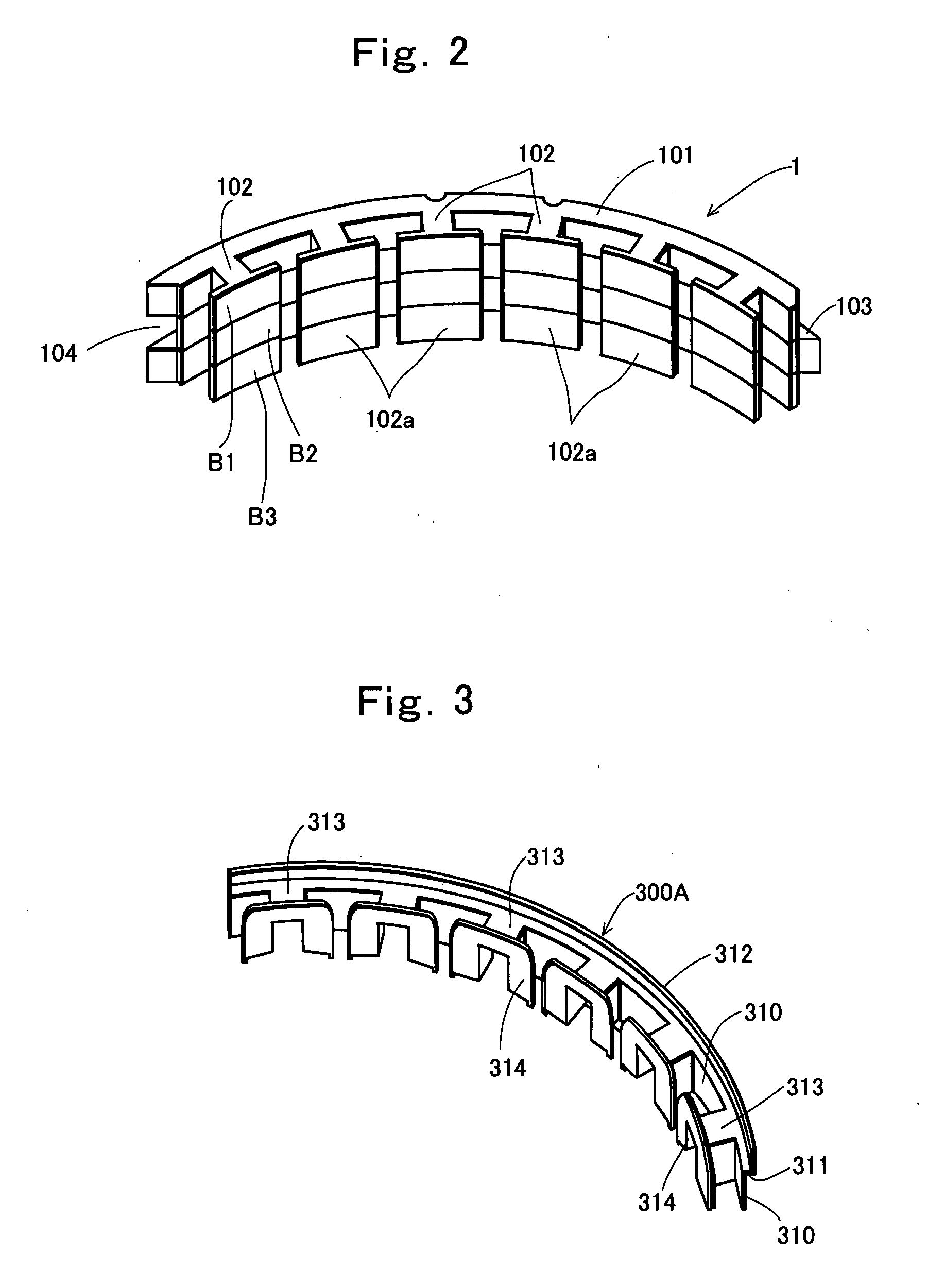

Stator for inner rotor type rotating electric machine

InactiveUS20070267932A1Reduce lossesReduce in quantityWindingsMagnetic circuit rotating partsBobbinElectric machine

A stator for an inner rotor type rotating electric machine including: an annular armature core comprised of a plurality of arcuate segmented cores circumferentially arranged; a bobbin assembly comprised of a plurality of arcuate segmented bobbins arranged circumferentially of the armature core to cover the armature core; and a coil wound around each salient pole portion of the armature core via a coil winding barrel of the bobbin assembly, wherein each segmented bobbin is placed across adjacent segmented cores, and when the armature core is covered with the plurality of segmented bobbins to assemble the bobbin assembly, the plurality of segmented cores that constitute the armature core are restrained and held by the bobbin assembly.

Owner:KOKUSAN DENKI CO LTD

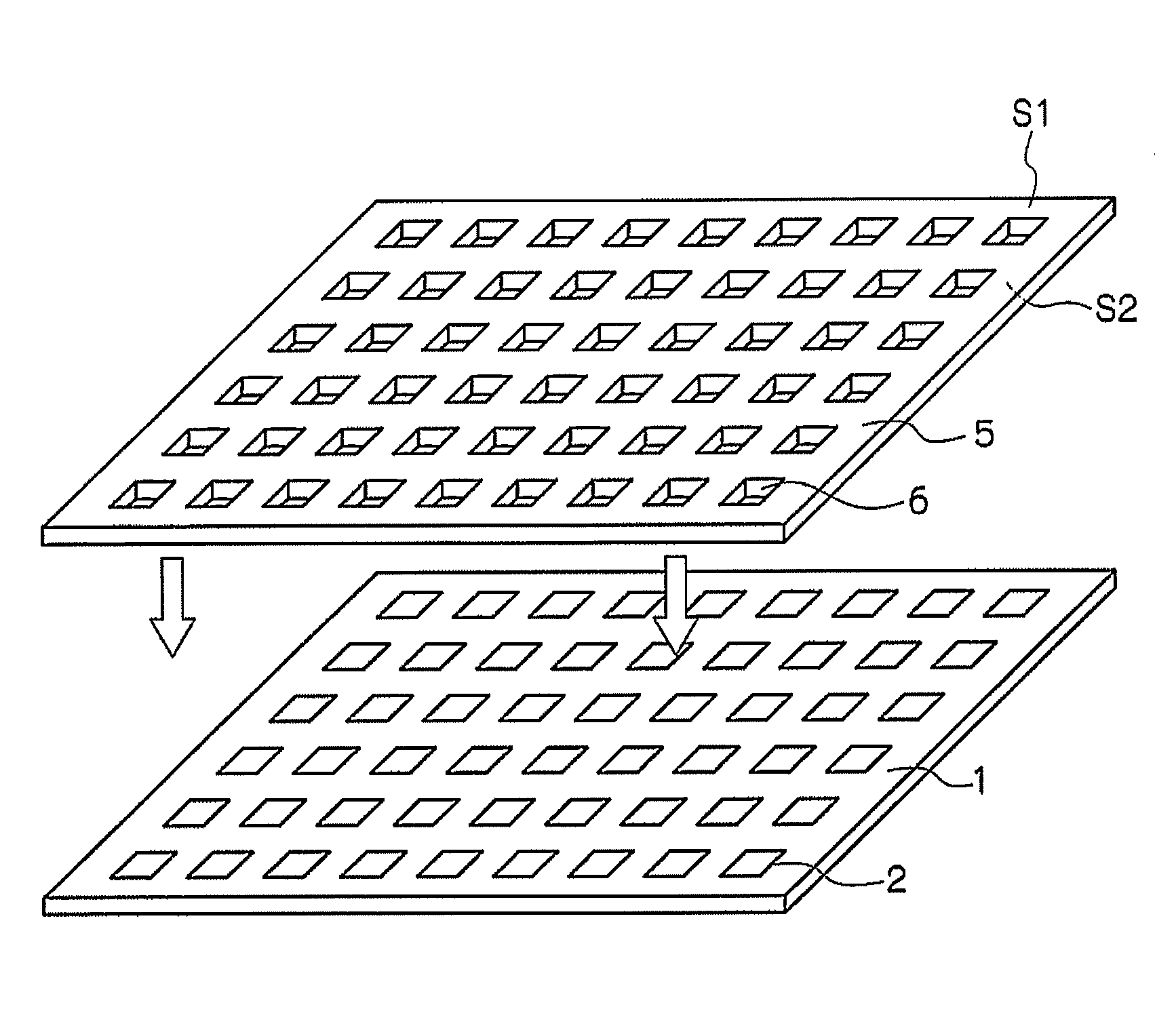

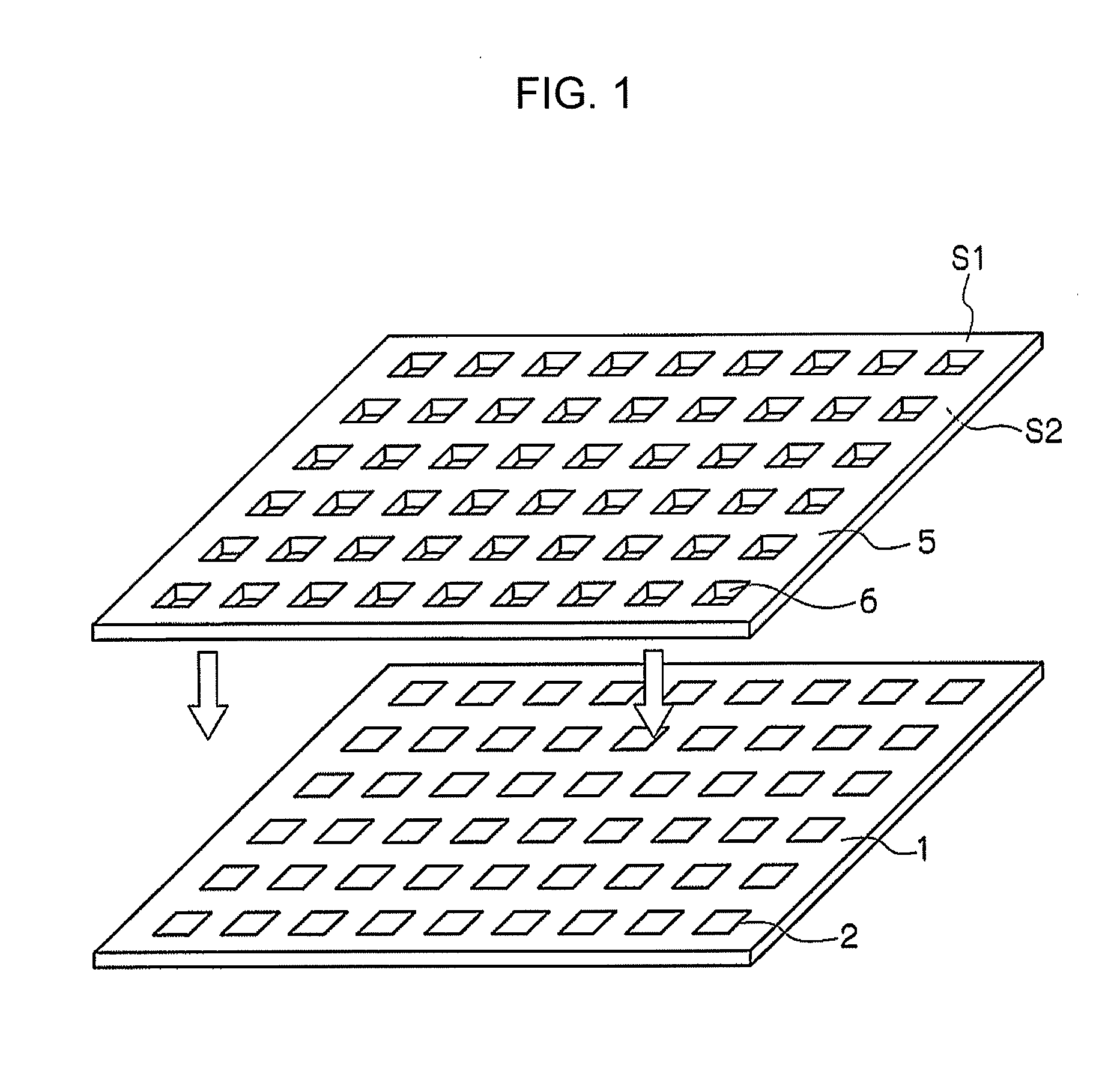

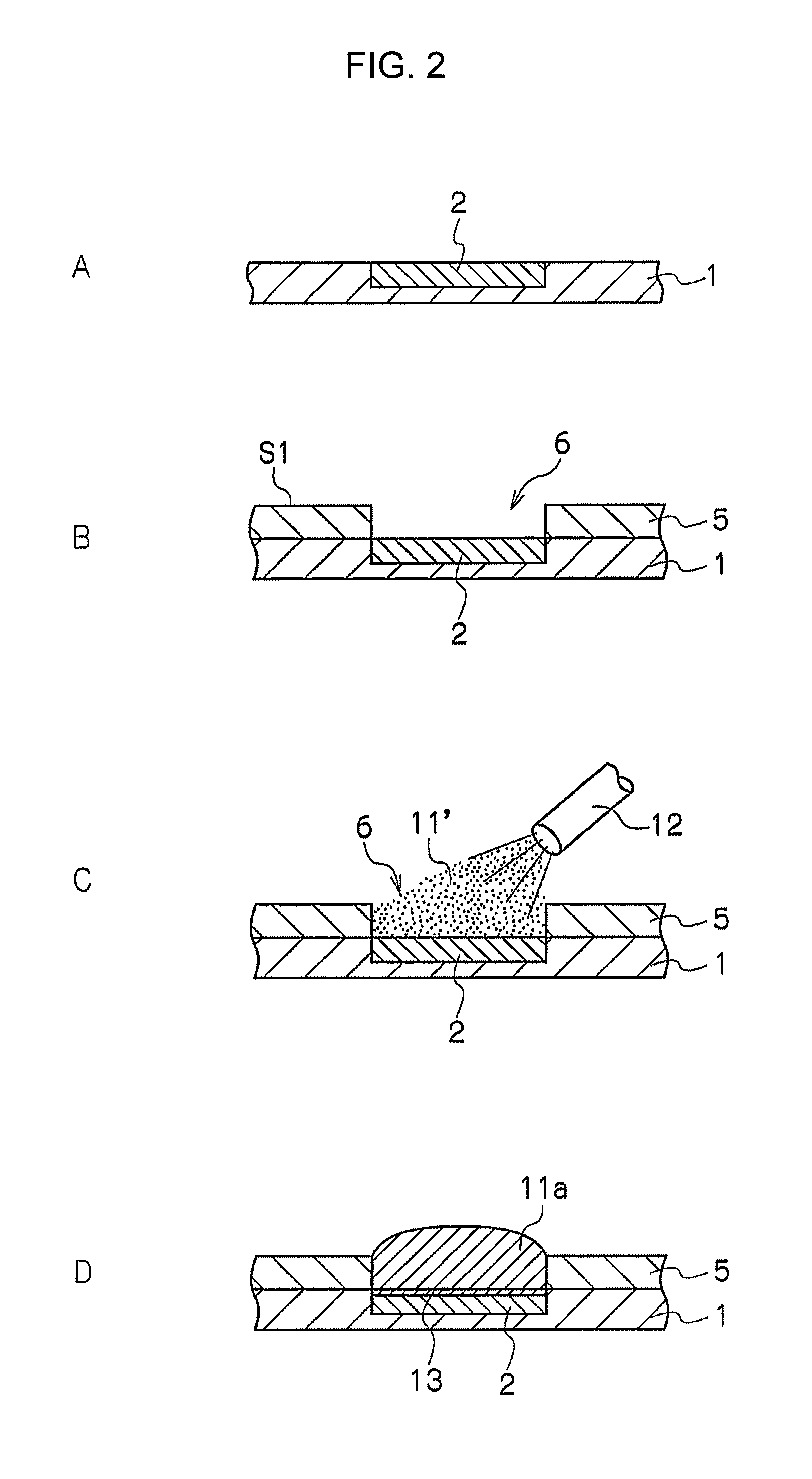

Solder bump, method for forming a solder bump, substrate provided with solder bump, and method for manufacturing substrate

InactiveUS20150115020A1Well formedHigh dimensional accuracySemiconductor/solid-state device detailsWelding/cutting auxillary devicesCopper electrodePrinted circuit board

Provided is a solder bump forming method capable of forming solder bumps having a desired constant thickness, without any failure such as copper corrosion, on a mounting board such as a printed circuit board having fine copper electrodes. The solder bump forming method includes: a process in which a prepared mask (5) is placed on a prepared substrate (1) and then a molten solder jet is blown to fill an opening of the mask (5) with molten solder (11a) until the molten solder (11a) exceeds the thickness of the mask (5); a process of removing a part of the molten solder (11a) that exceeds the thickness of the mask (5) to form a solder bump (11) having a predetermined thickness; and a process of removing the mask (5). The molten solder (11a) is molten lead-free solder that includes tin as a main ingredient and at least nickel as a sub ingredient, and further includes one or more other ingredients such as silver, copper, and germanium. The part of the molten solder (11a) that exceeds the thickness of the mask (5) is removed by using a blade or an air cutter or by spraying a solution (18) that includes organic fatty acid having 12 to 20 carbon atoms.

Owner:TANIGUROGUMI CORP

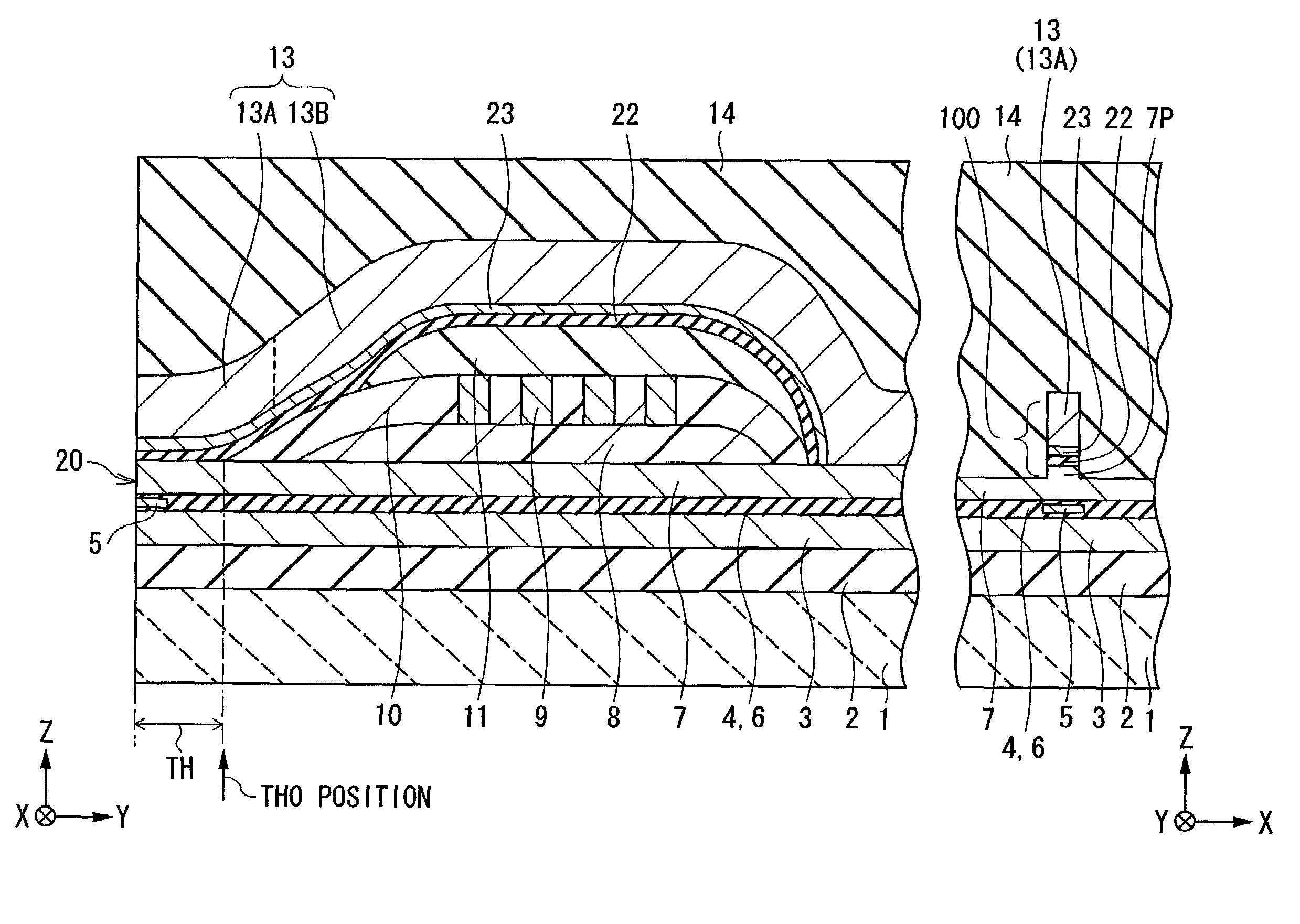

Thin film magnetic head and method of manufacturing same

InactiveUS7525770B2Shortening methodShorten the timeConstruction of head windingsManufacture head surfaceThin membraneConductive materials

A thin film magnetic head capable of shortening a manufacturing time and a method of manufacturing the same are provided. After forming a write gap layer by using a non-magnetic conductive material such as copper, a top pole is formed on the write gap layer by growing a plating film with the write gap layer used as a seed layer. Unlike the case where the write gap layer is formed by using a non-magnetic insulating material such as alumina, a step of newly forming a seed layer aside from the write gap layer and a step of selectively removing the newly formed seed layer become unnecessary. Therefore, the number of manufacturing processes is reduced, and the manufacturing time of the thin film magnetic head is shortened.

Owner:SAE MAGNETICS (HK) LTD

Via-filling material and process for fabricating semiconductor integrated circuit using the material

InactiveUS7030007B2Step can be unnecessarySimple structureSemiconductor/solid-state device manufacturingHydrogenBromine

Owner:MITSUBISHI ELECTRIC CORP

Method for producing printing plates

InactiveUS20070006761A1Improve adhesionReduce in quantityPlate printingFoil printingEngineeringPrinting press

A method for producing a printing plate, especially inside a printing press, wherein a printing plate with a rewritable surface is provided, and wherein to produce a permanent as well as an erasable image on the surface of the printing plate, the erasing of the surface and / or the imaging of the surface are carried out with the use of an atmospheric plasma.

Owner:MANROLANAD AG

Method for manufacturing a magnetic head

InactiveUS7596855B2Shortening methodShorten the timeConstruction of head windingsManufacture head surfaceEngineeringConductive materials

A thin film magnetic head capable of shortening a manufacturing time and a method of manufacturing the same are provided. After forming a write gap layer by using a non-magnetic conductive material such as copper, a top pole is formed on the write gap layer by growing a plating film with the write gap layer used as a seed layer. Unlike the case where the write gap layer is formed by using a non-magnetic insulating material such as alumina, a step of newly forming a seed layer aside from the write gap layer and a step of selectively removing the newly formed seed layer become unnecessary. Therefore, the number of manufacturing processes is reduced, and the manufacturing time of the thin film magnetic head is shortened.

Owner:SAE MAGNETICS (HK) LTD

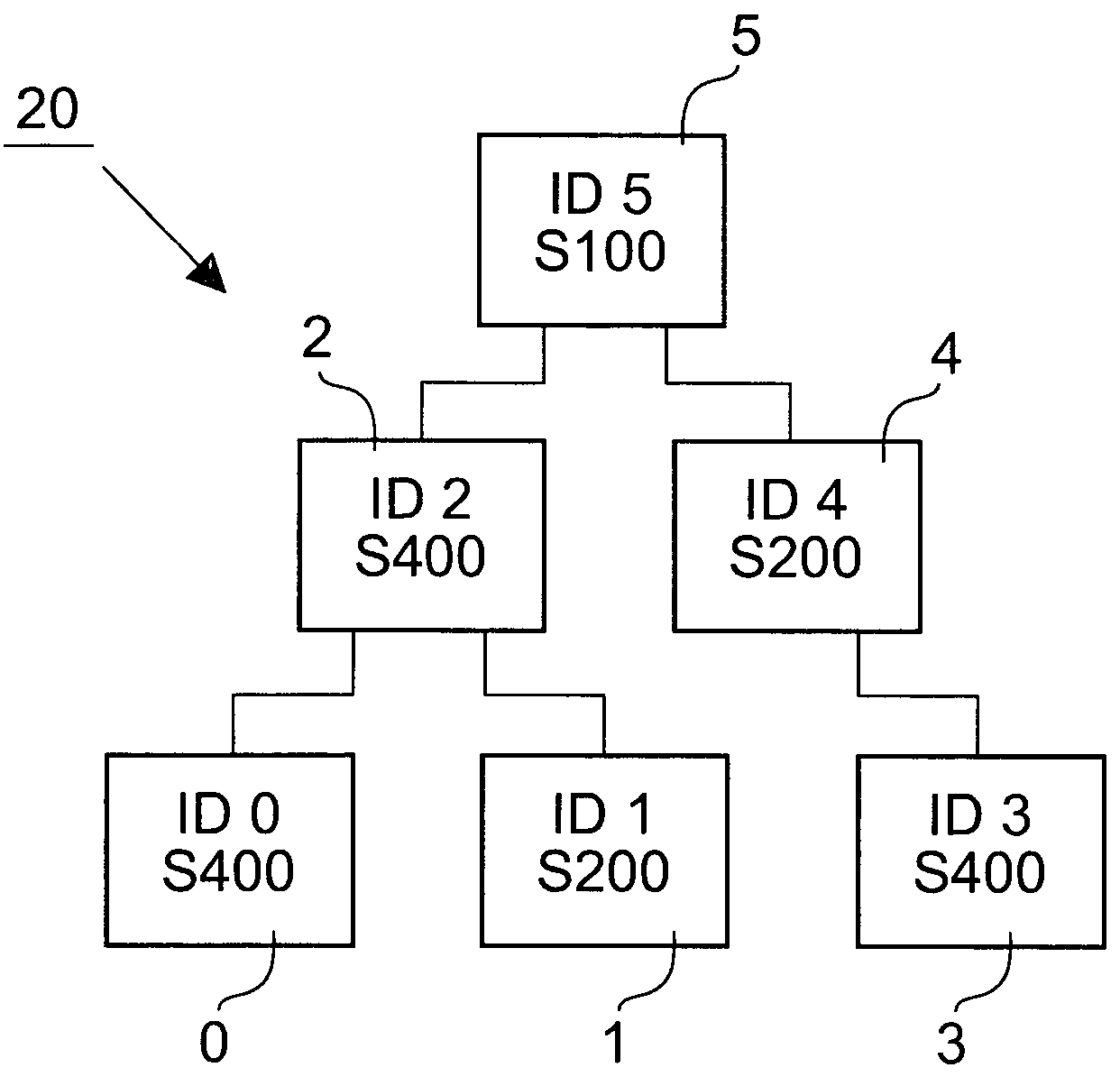

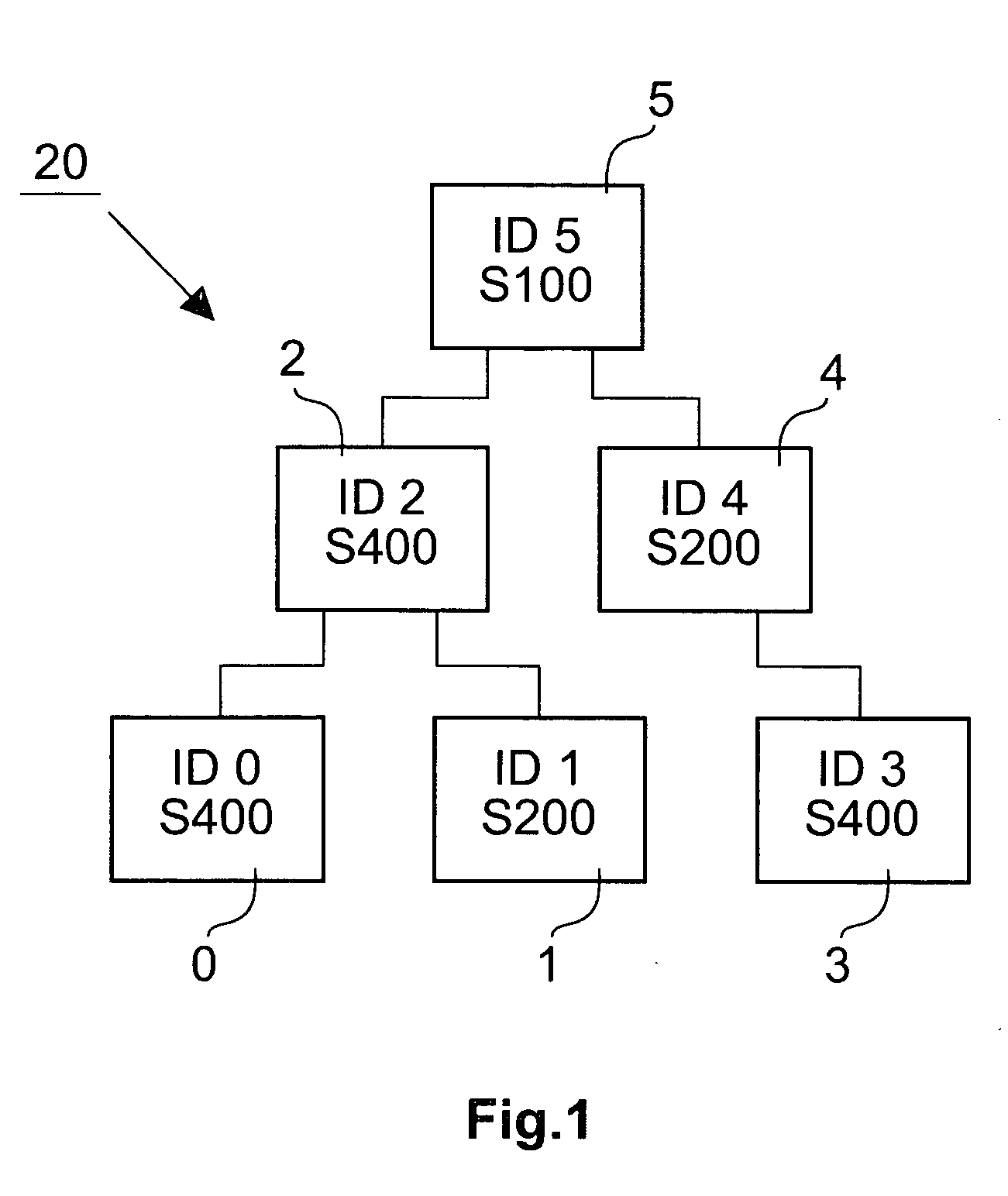

Method and device for acquiring electronic information about transmission speeds in a network

InactiveUS20050047349A1Facilitate data exchangeReduce in quantityEnergy efficient ICTError preventionTopology informationElectronic information

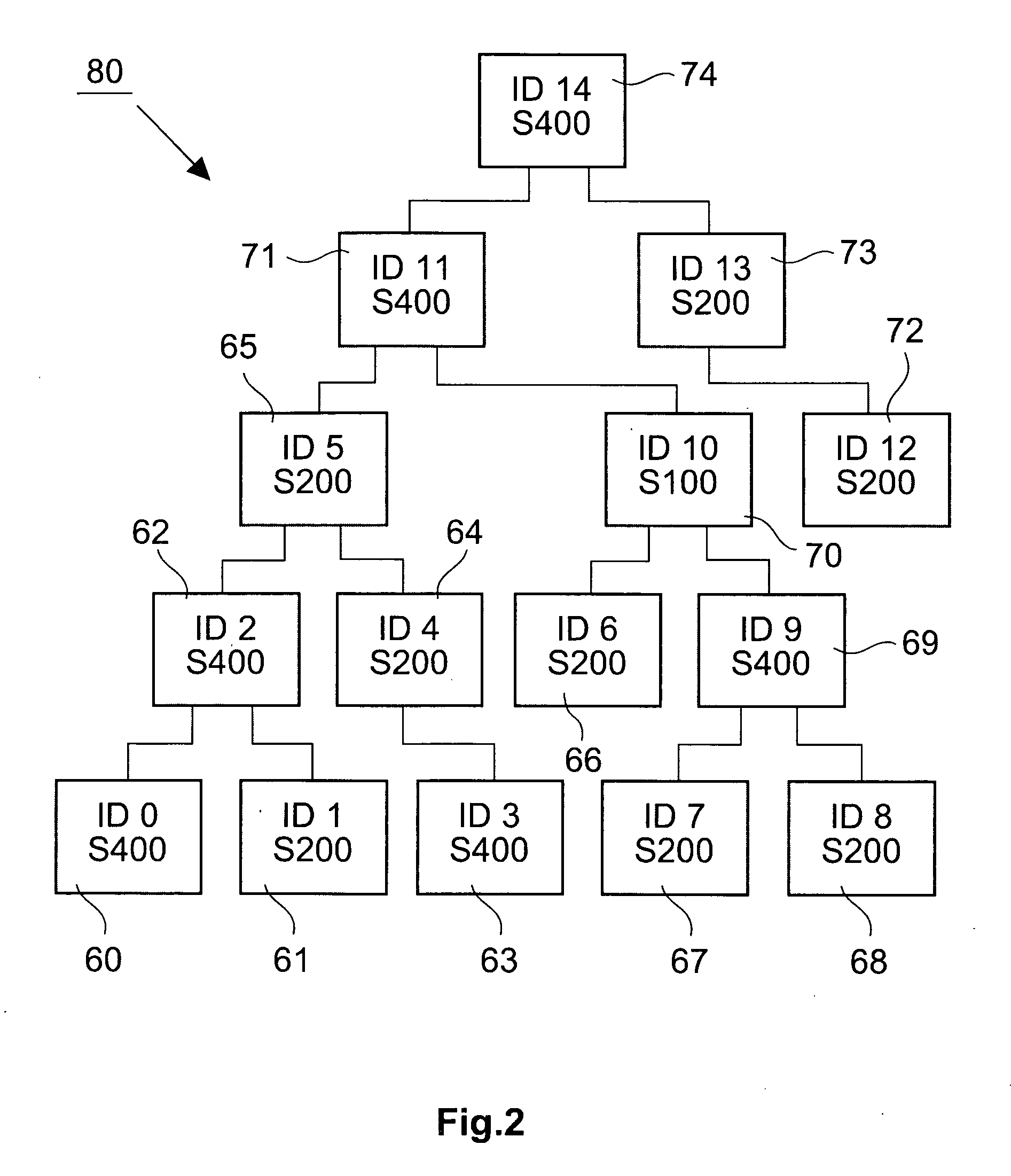

The invention relates to a method and a device for acquiring electronic information about transmission speeds between nodes of an acyclical network, in particular of an IEEE 1394 bus network, precisely one transmission link being present between in each case two of the nodes of the network, and a respective PHY transmission speed of the transmission link being determined by a minimum value of PHY speeds of the nodes of the network lying on the transmission link, in the case of the method the respective PHY transmission speed being determined for one subset of the transmission links in the network by acquiring the PHY speeds of the nodes lying on the transmission links and electronically acquiring minimum values of the PHY speeds; and the respective PHY transmission speed being electronically acquired for another subset of the transmission links, which is different from the one subset of transmission links, on the basis of one of the PHY speeds which have been determined for the nodes lying on the transmission links of the one subset, and electronic topology information about a topology of the network being electronically acquired using optimization means which are formed in a node of the network. The device is provided for carrying out the method.

Owner:THOMSON LICENSING SA

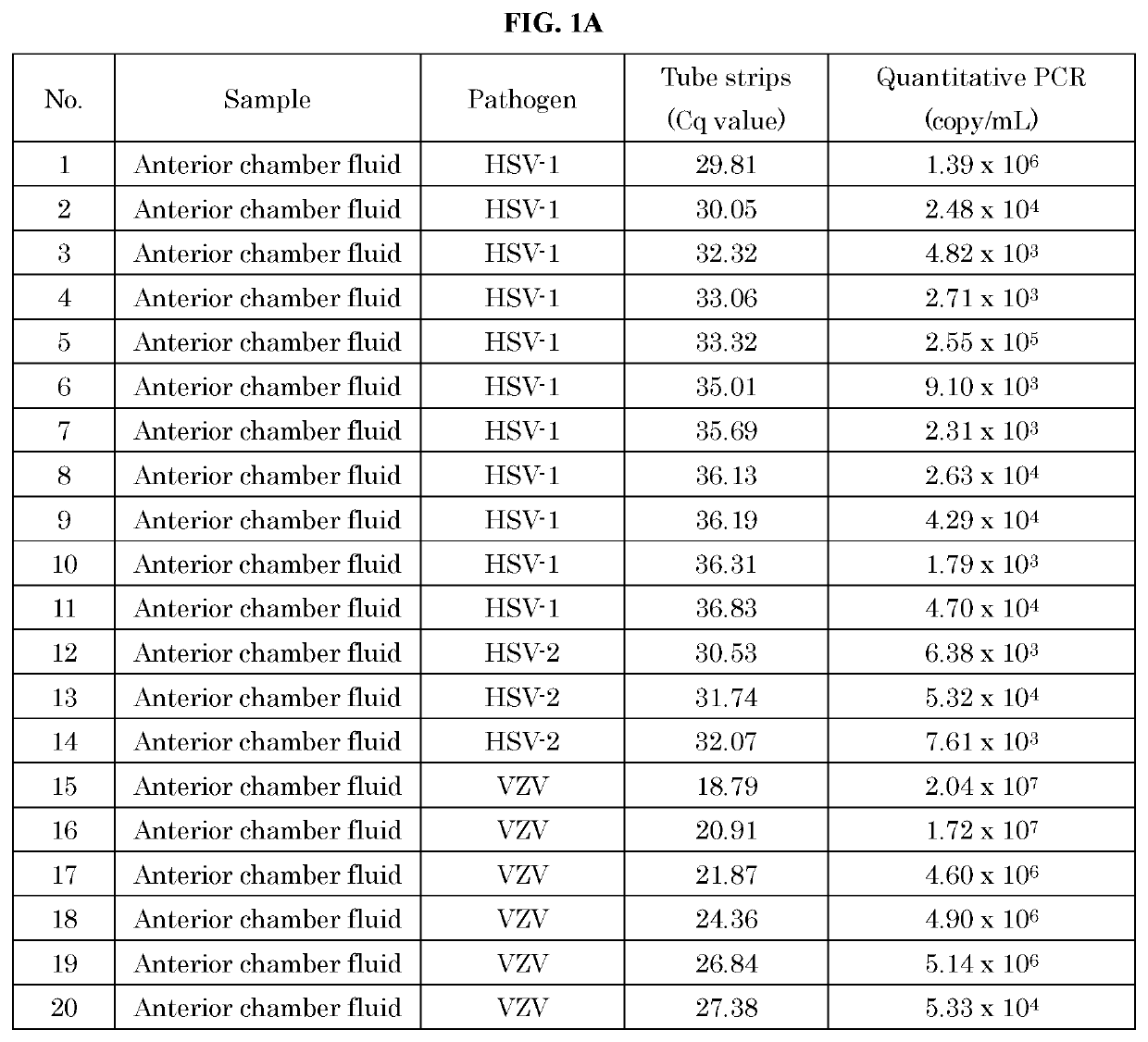

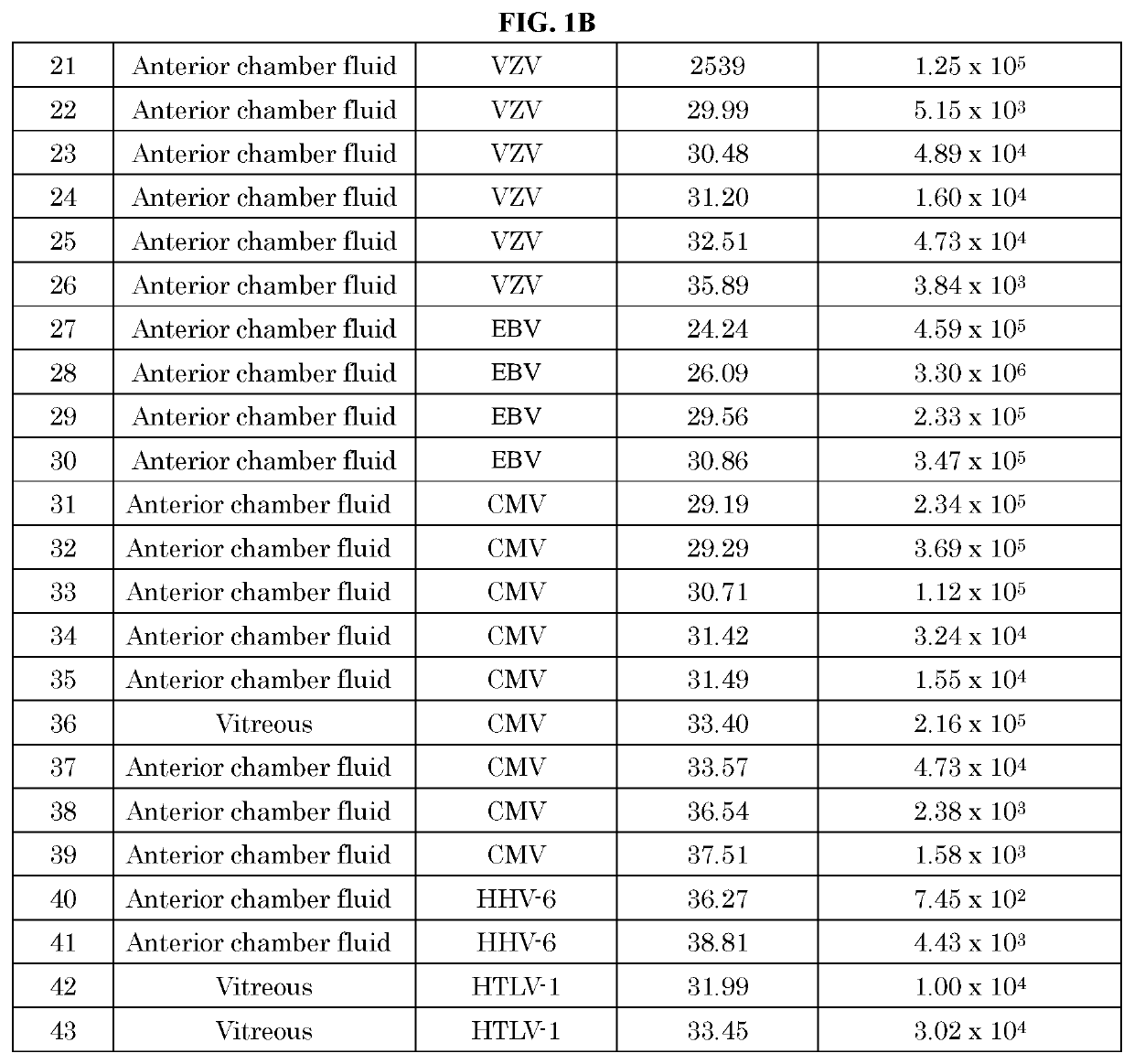

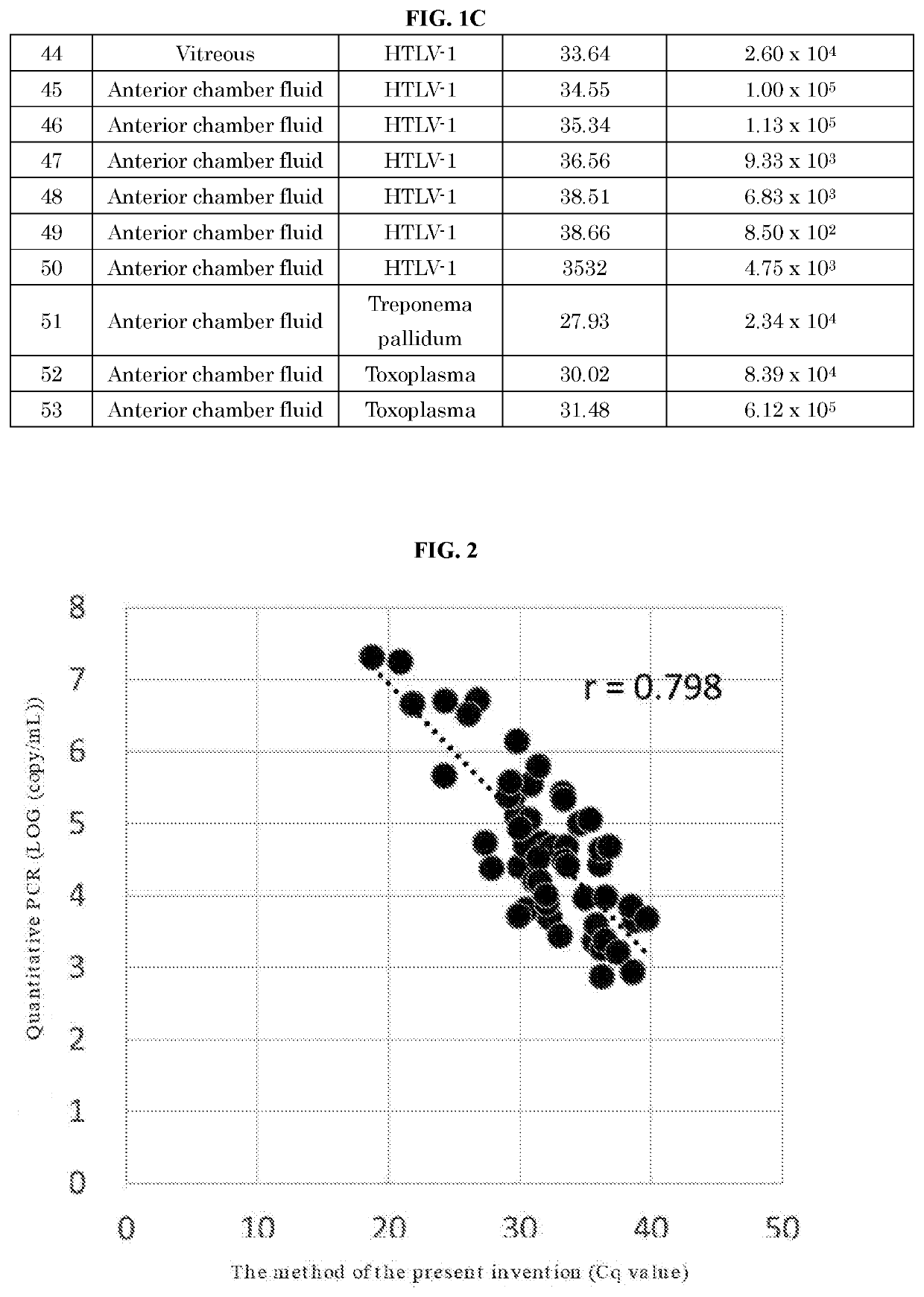

Method for detecting microorganisms

InactiveUS20200385784A1Avoid human errorStep can be unnecessaryMicrobiological testing/measurementFluorescence/phosphorescenceMicroorganismOrganism

The present invention relates to a method for simultaneously detecting a plurality of pathogens from biologically-derived samples, and a kit for carrying out the method. Specifically, the present invention relates to a method for simultaneously detecting a plurality of pathogens that cause infectious uveitis, one of eye infections from samples such as anterior chamber fluid or vitreous by polymerase chain reaction (PCR), and a kit for carrying out the method.

Owner:NAT UNIV CORP TOKYO MEDICAL & DENTAL UNIV +4

Display device including pixel electrode including oxide

ActiveUS9704894B2Improve featuresReduce manufacturing costSolid-state devicesNon-linear opticsDisplay deviceEngineering

To provide a display device including a transistor that includes an oxide semiconductor and has favorable characteristics, a pixel electrode electrically connected to the transistor, and a capacitor electrically connected to the pixel electrode. To provide a display device that can be manufactured at low cost. The display device includes a display element including a pixel electrode, a transistor that performs switching of the display element and includes a first oxide semiconductor layer serving as a channel formation region, a capacitor that is electrically connected to the display element and includes a dielectric layer between a pair of electrodes. The pixel electrode is a second oxide semiconductor layer formed on the same surface as that on which the first oxide semiconductor layer is formed, and also serves as one electrode of the capacitor.

Owner:SEMICON ENERGY LAB CO LTD

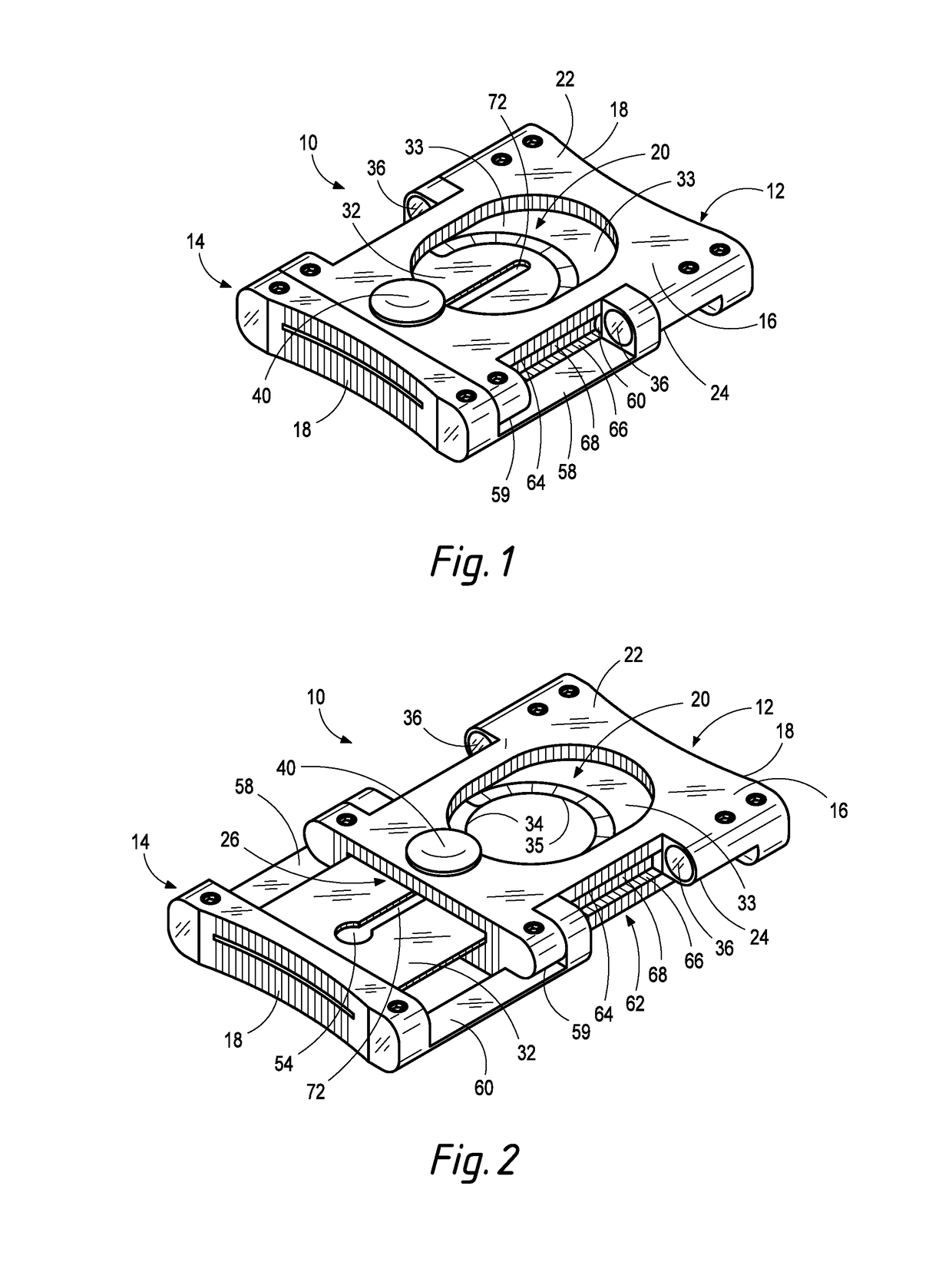

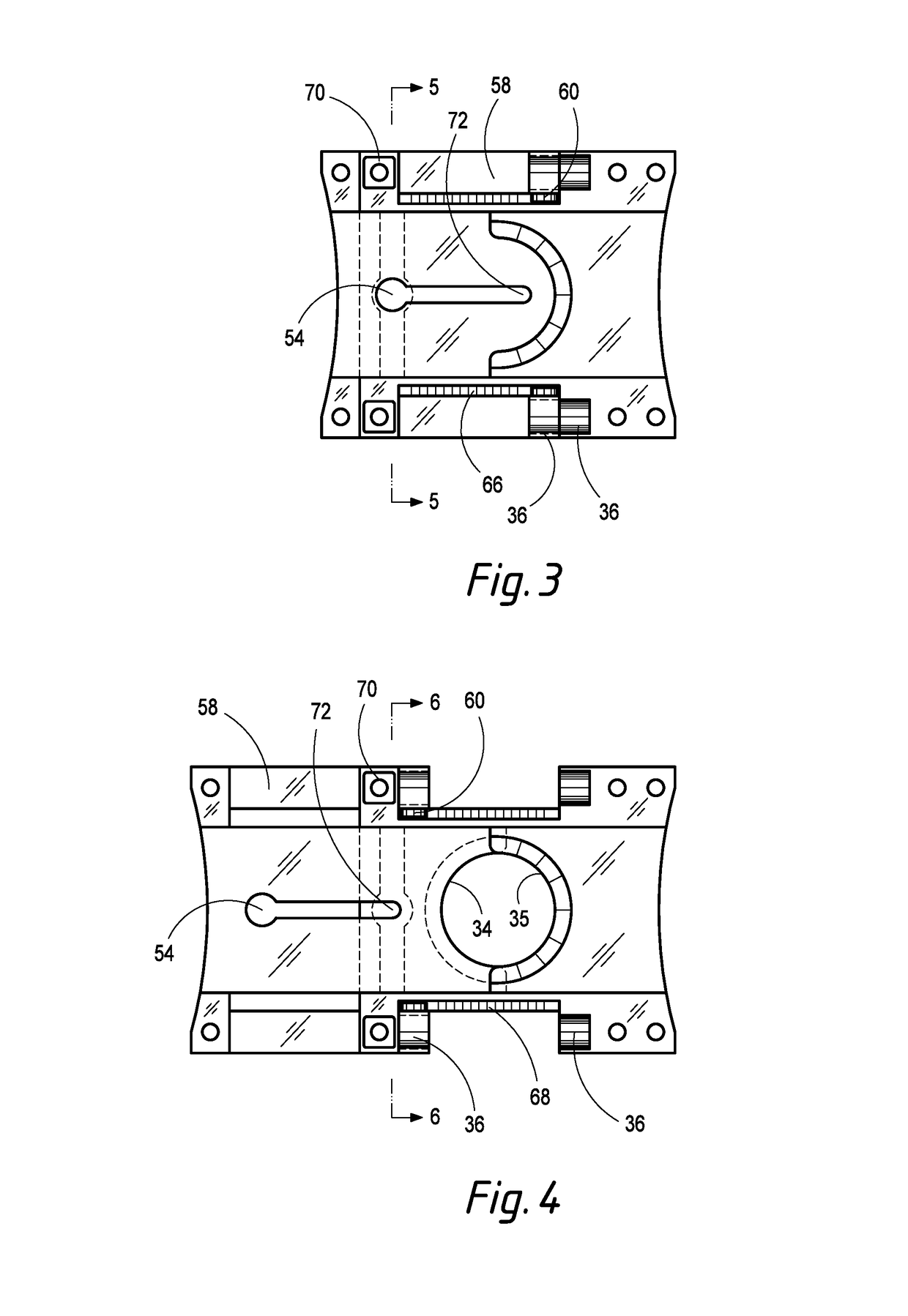

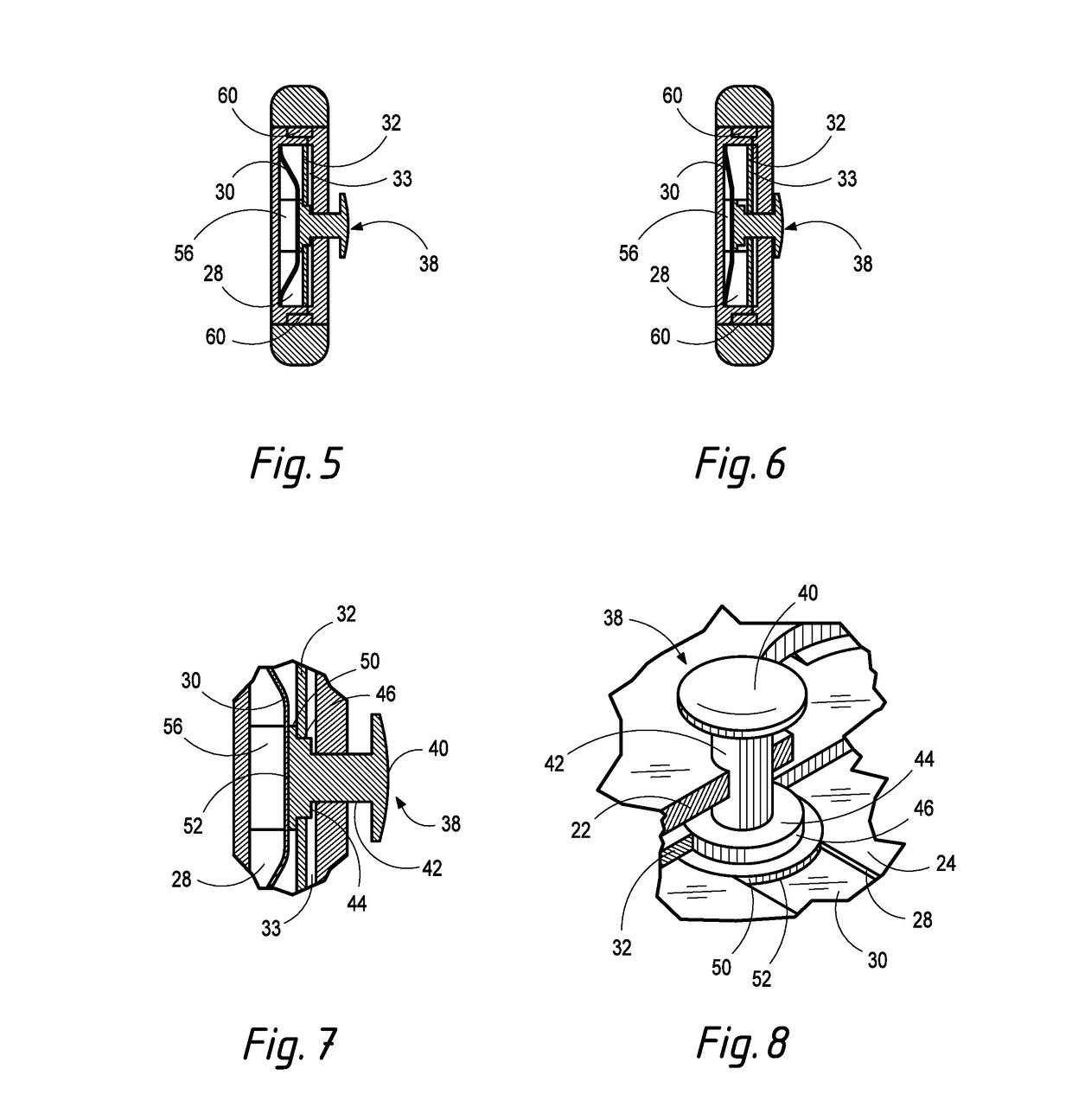

Cigar cutter employing magnetic fields

A guillotine-style cigar cutter. The cutter includes a body with a central aperture and a pair of blades disposed on opposite sides of the aperture and configured to move translationally across the aperture to cut an end of a cigar in preparation for smoking. Magnets are disposed to each blade to provided movement of the cutter open or closed depending on the orientation of the magnetic poles relative to one another.

Owner:FISCHER BRETT WILLIAM

Method for manufacturing crystalline semiconductor film and method for manufacturing thin film transistor

InactiveUS7960261B2Simple stepsShorten the timeTransistorSolid-state devicesIrradiationCrystalline semiconductor

The present invention relates to a method for manufacturing a polycrystalline semiconductor film that can be used for a semiconductor device. In the method, an amorphous semiconductor film is irradiated with a femtosecond laser to be crystallized. By laser irradiation using a femtosecond laser, when an amorphous semiconductor film over which a cap film is formed is crystallized with a laser, it becomes possible to perform crystallization of the semiconductor film and removal of the cap film at the same time. Therefore, a step of removing the cap film in a later step can be omitted.

Owner:SEMICON ENERGY LAB CO LTD

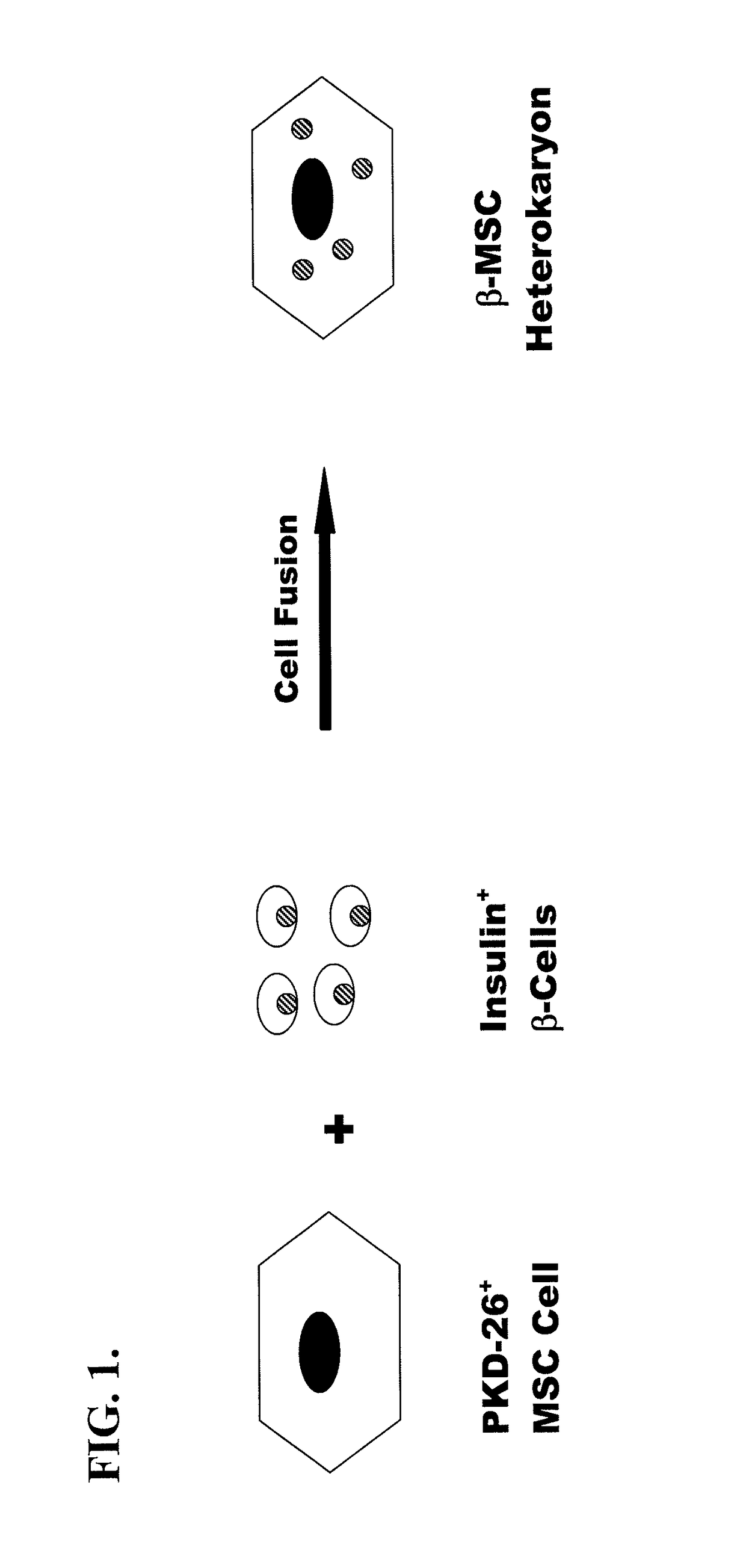

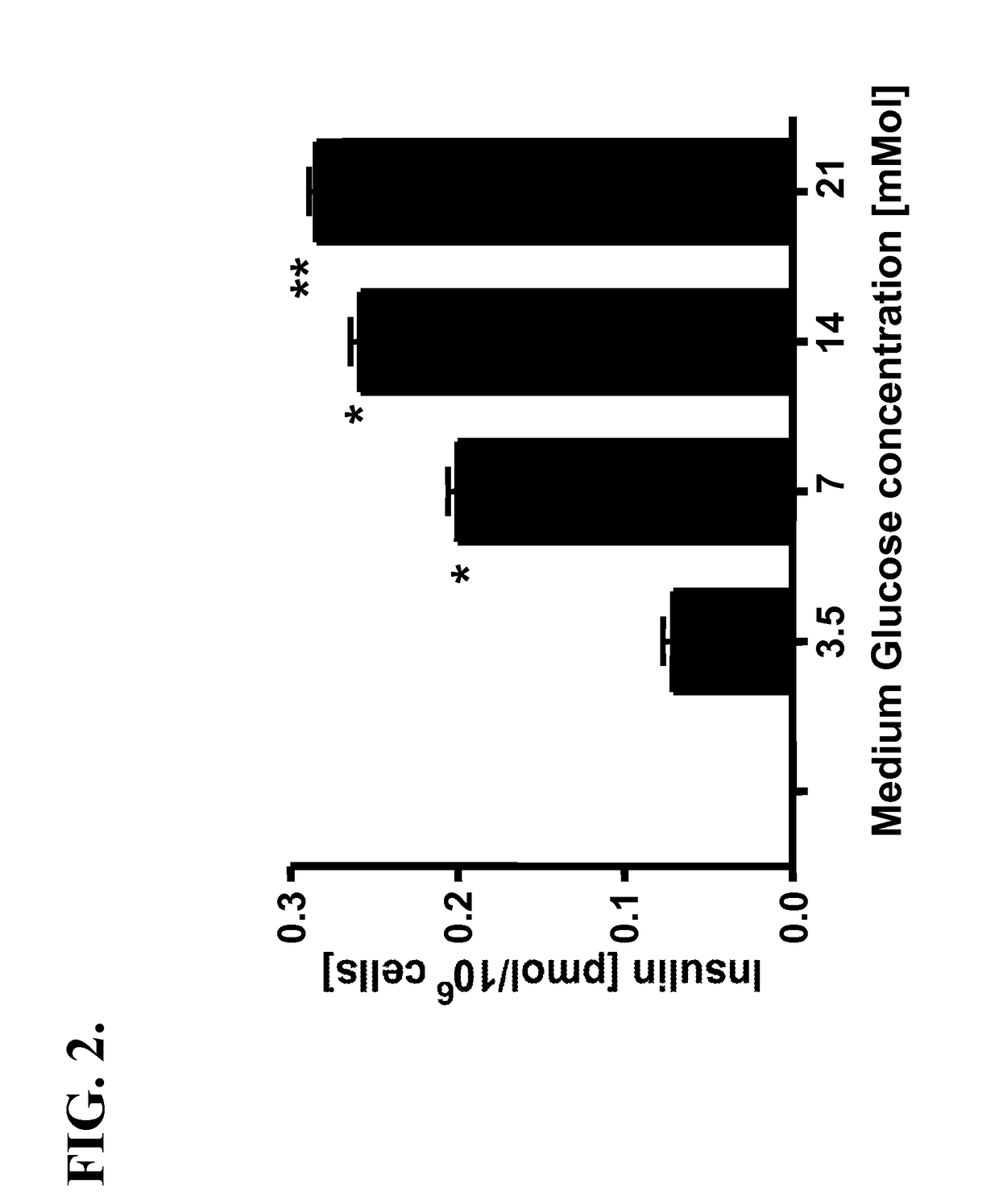

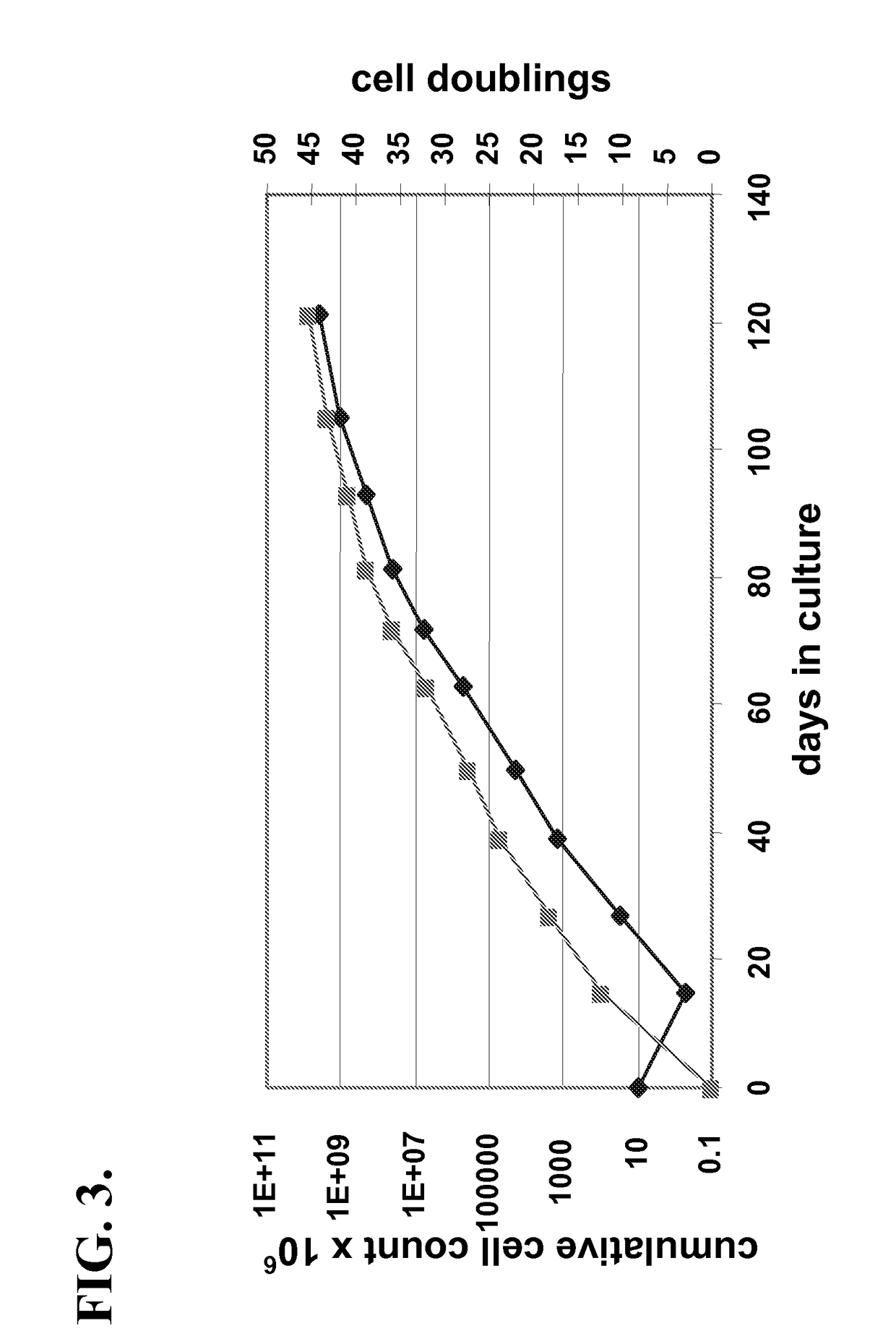

Marrow stem cell and pancreatic beta cell fusion cell useful for the treatment of diabetes

InactiveUS8119120B2Improve scalabilityEasily augmentedBiocideMetabolism disorderPancreasBone Marrow Stem Cell

Methods disclosed include methods of treating T1DM, said method comprising delivering a therapeutic amount of β-MSC to a subject in need thereof. Further disclosed are fusion cells comprising and MSC and a second cell wherein the nuclei of the MSC and the second cell are not fused in the fusion cell.

Owner:UNIV OF UTAH RES FOUND +1

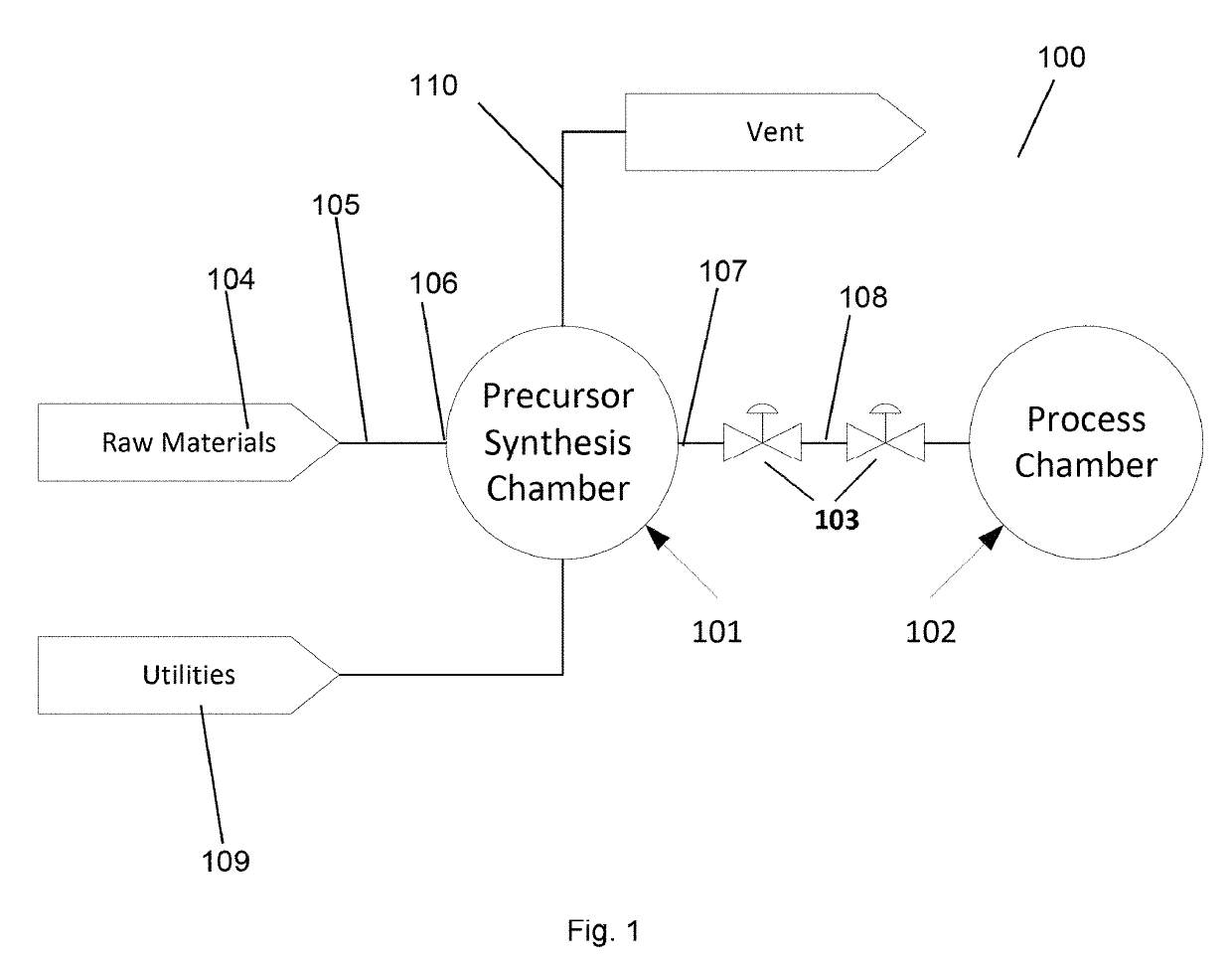

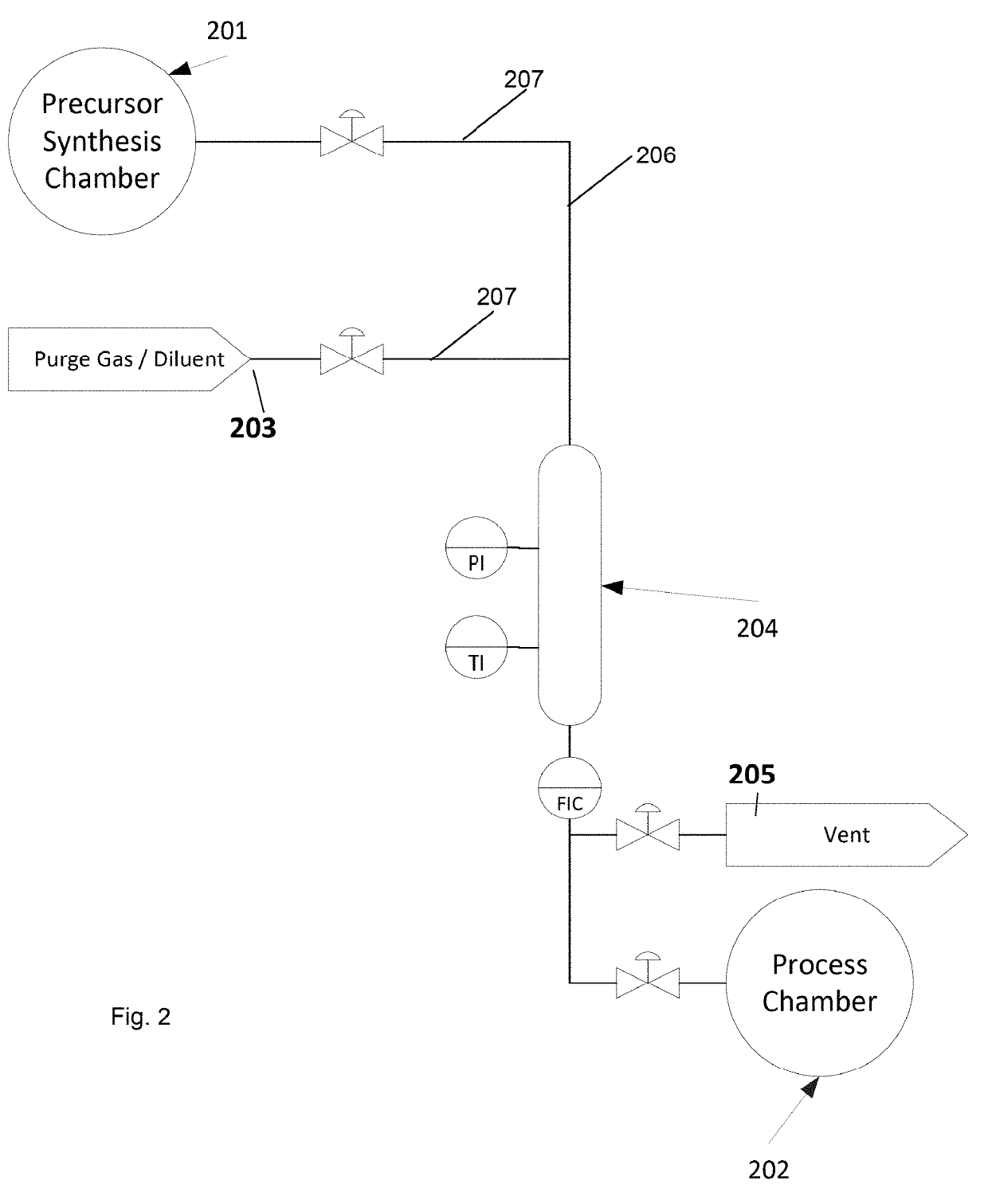

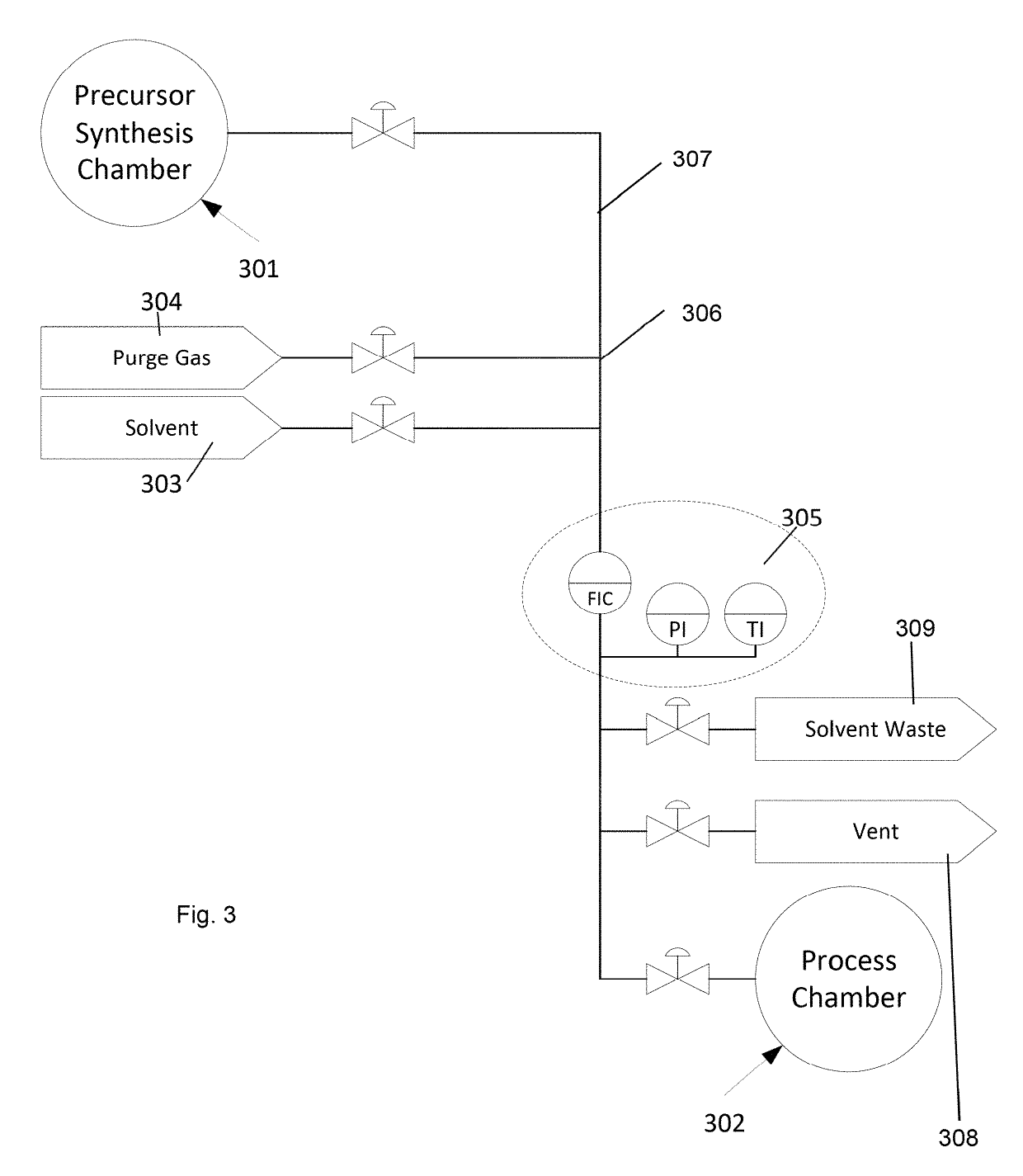

Methods and System for the Integrated Synthesis, Delivery, and Processing of Source Chemicals for Thin Film Manufacturing

PendingUS20190112709A1Accurate flowPermit useChemical vapor deposition coatingPhysical chemistryThin membrane

An integrated system for synthesis of a film-forming precursor, consumption of the precursor and formation of a thin film on a substrate is provided. The integrated system includes a raw material source, a precursor synthesis chamber in communication with the raw material source, a thin film processing chamber in communication with the precursor synthesis chamber for supplying the precursor from the precursor synthesis chamber to the thin film processing chamber in a controlled manner for consumption of the precursor to form the thin film on the substrate, a monitoring system for monitoring of the thin film formation in the thin film processing chamber and / or the precursor synthesis in the precursor synthesis chamber, and a controller for controlling a rate of the precursor synthesis, precursor consumption and / or thin film formation. The rate of precursor synthesis is synchronized with the rate of precursor consumption for formation of the thin film.

Owner:GELEST

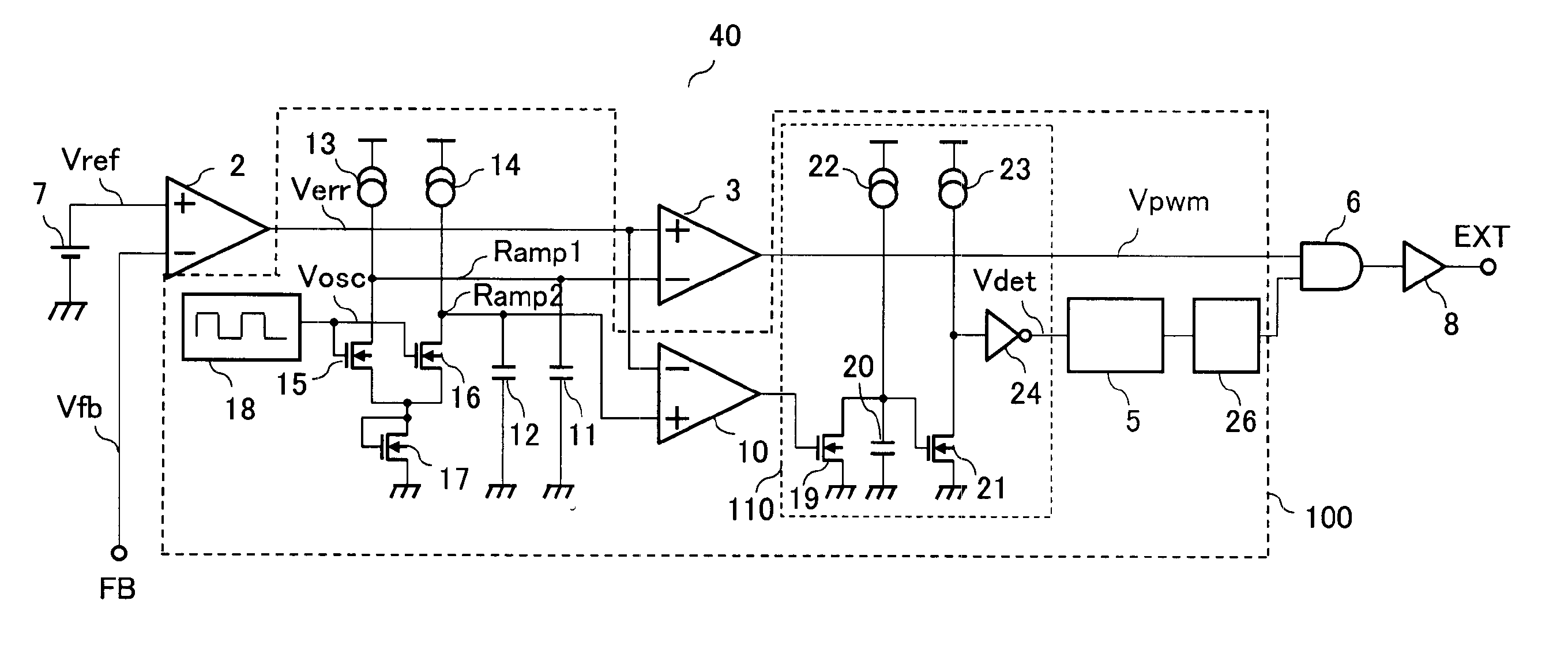

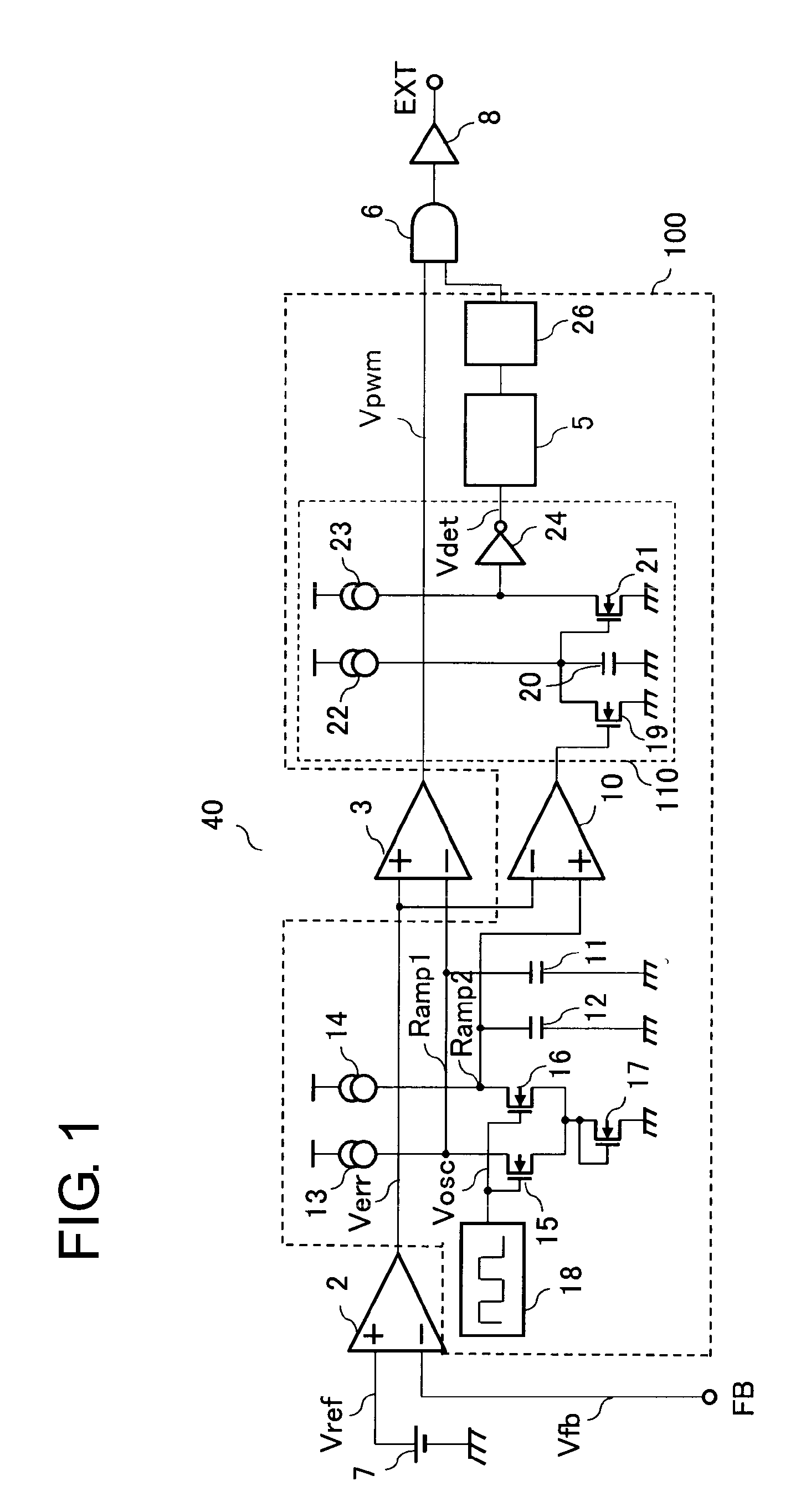

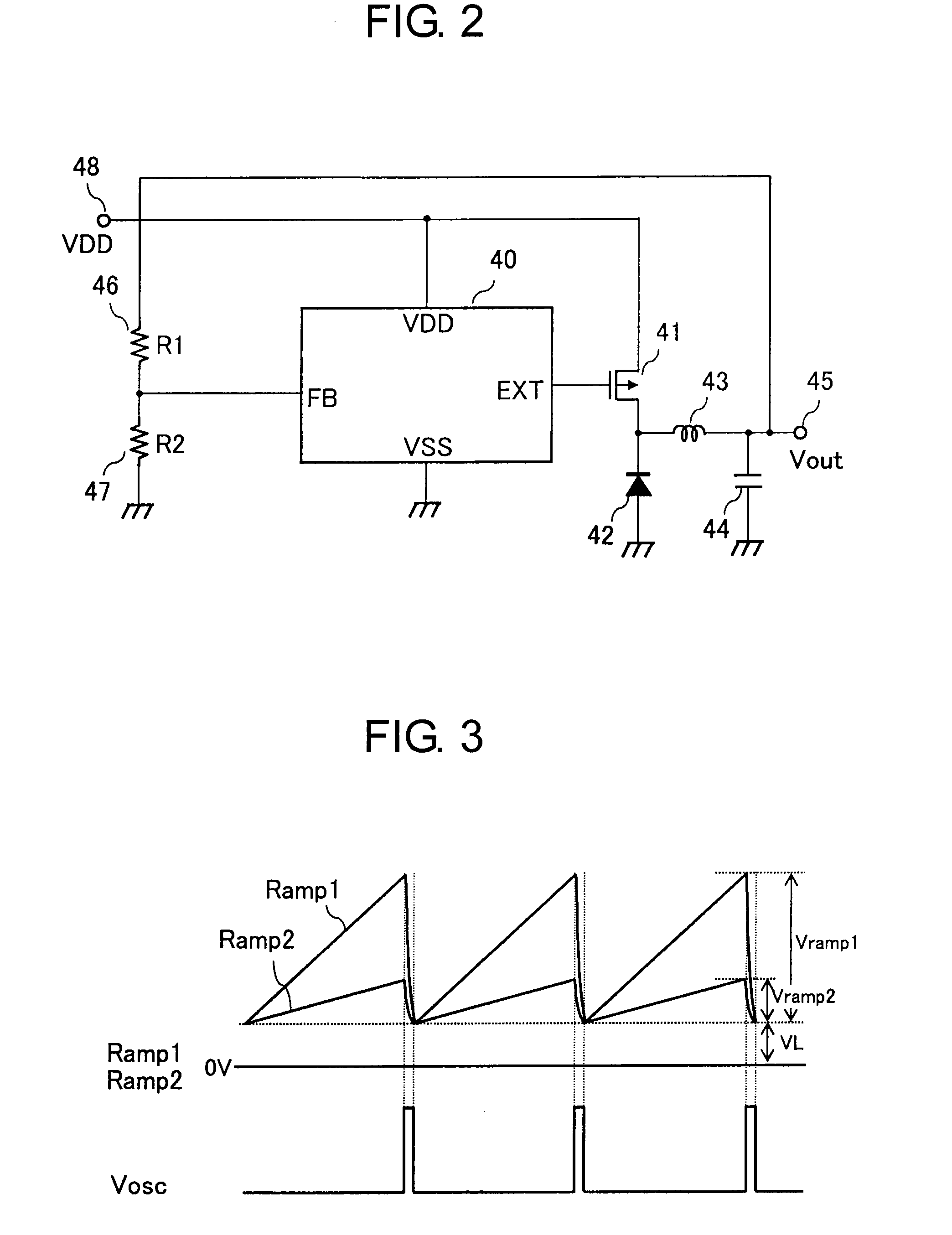

Switching regulator control circuit and switching regulator

InactiveUS20120194154A1Suppress manufacturing fluctuationImprove accuracyDc-dc conversionElectric variable regulationCapacitanceEngineering

Provided is a switching regulator including an overload protection circuit, which has high accuracy even without requiring adjusting means in a test step. The switching regulator includes: a first triangle wave generation circuit for generating a first triangle wave which controls Duty of a PWM signal; and a second triangle wave generation circuit for generating a second triangle wave for overload detection, which has a crest value smaller than that of the first triangle wave. A ratio between the crest value of the first triangle wave and the crest value of the second triangle wave is set based on respective capacitances or constant currents thereof.

Owner:ABLIC INC

Manufacturing method for a magnetic material core-embedded resin multilayer board

ActiveUS9748652B2Reduce and prevent deterioration and variationIncreasing number of stepLoop antennas with ferromagnetic coreAntenna supports/mountingsElectrical conductorEngineering

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com