Method for preparing non-woven wiping cloth

A non-woven and wiping cloth technology, applied in textiles and papermaking, cleaning equipment, applications, etc., can solve the problems of low instantaneous water absorption capacity, reduced decontamination efficiency, and low water absorption speed of the wiping cloth, achieving good wiping effect and durability Good abrasiveness and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation process of the nonwoven wiping cloth of the present invention mainly includes the following three steps: (1) base cloth preparation; (2) coating finishing; (3) baking process; (5) opening finishing. Especially the formulation of the coating agent and the coating process, and the setting of the opening parameters.

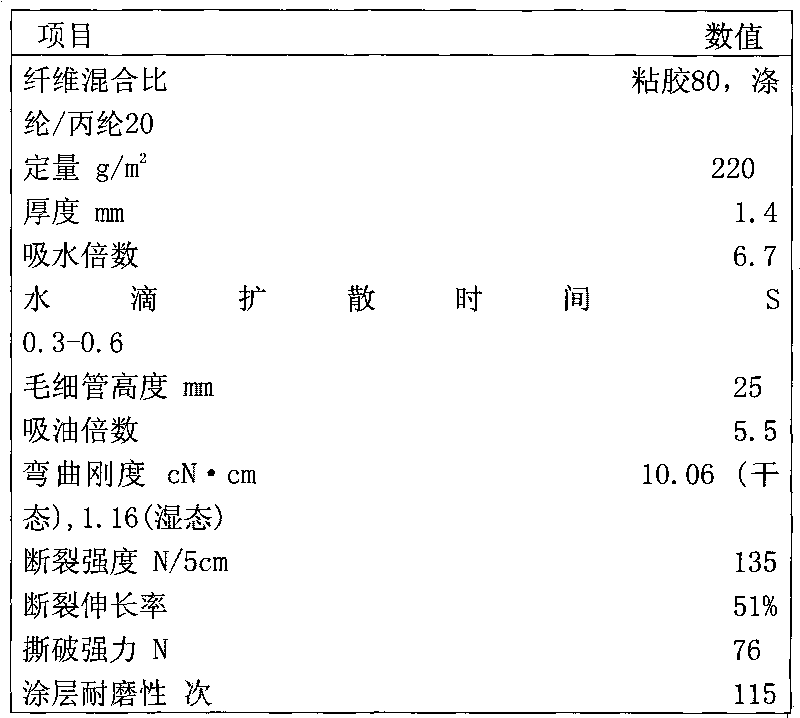

[0020] The wiping cloth referred to in the present invention should meet the requirements of high water and oil absorption, good softness, no crumbs when wiping, and good wear resistance. The present invention adopts the coating process, mainly to solve the problem of shavings caused by the surface hairiness of the needle-punched base cloth during the wiping process, and to improve its instantaneous water and oil absorption performance. However, the coating will sacrifice part of the water and oil absorption rate and softness of the wiping cloth, so the present invention further designs the opening of the wiping cloth. Experimental studies ha...

Embodiment 1

[0037] (1) Selection of base fabric: select needle-punched base fabric mixed with viscose fiber / polyester fiber at 55 / 45, and its weight is 450g / m 2 ;Thickness 3.7mm.

[0038] (2) Coating agent formula: acrylate adhesive 700ml / L, foaming agent 20g / L, stabilizer 12g / L, tackifier 30g / L, water absorbing agent 30g / L, crosslinking finishing agent 20g / L , softener 60ml / L and water 300ml / L.

[0039] (3) Coating process: Stir at high speed with a foaming machine, and control the foaming ratio at 5.5 times. Use a foam applicator to evenly coat the generated foam on the base fabric, use a doctor blade to coat, the coating thickness is 0.5mm, and the amount of glue is 200g / m 2 .

[0040] (4) Baking process: the temperature is 185°C, and the time is 3 minutes.

[0041] (5) Hole finishing: hole diameter 1mm, hole density: 78 pcs / 5cm 2 .

Embodiment 2

[0043] (1) Base fabric selection: choose needle-punched base fabric mixed with viscose fiber / polyester fiber at 80 / 20, quantitative 320g / m 2 ; Thickness 2.8mm. .

[0044] (2) Coating agent formula: acrylate adhesive 300ml / L, foaming agent 10g / L, stabilizer 6g / L, tackifier 4g / L, water absorbing agent 25g / L, crosslinking finishing agent 3g / L , softener 30ml / L and water 600ml / L.

[0045] (3) Coating process. Stir at high speed with a foaming machine, and the foaming ratio is 12 times. Apply the generated foam evenly on the base cloth with a foam applicator, use a doctor blade to coat, the coating thickness is 0.1mm, and the amount of glue is 20g / m 2 .

[0046] (4) Baking process: the baking temperature is 160° C., and the time is 5 minutes.

[0047] (5) Hole finishing: hole diameter 0.6mm, hole density: 57 pcs / 5cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com