Special yarn, double-sided jacquard fabric, high-absorbent double-sided jacquard sponge structure fabric for cleaning and production method thereof

A double-sided jacquard and high water absorption technology, applied in the field of yarn materials, can solve the problems of low water and oil absorption rate, slow adsorption rate, single function, etc., achieve good antibacterial properties, increase adsorption capacity and adsorption rate, and increase contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The special yarn is blended with natural plant fibers and man-made fibers, and its structure is fluffy and does not shed hair, wherein the natural plant fibers are one of long-staple cotton fibers, soybean fibers or corn fibers, and the natural plant fibers are The ratio of the blending formula with the man-made fiber is 8:2, the blending technology adopts the rotor spinning technology of rotor spinning, and the spinning equipment is Schlafford 312 type imported from Germany. The preparation method of the special yarn includes the following steps: ingredients→ Grabbing→opening→mixing→impurity removal→carding→head and drafting→finish and drafting→air spinning, wherein the yarn process design is: fineness 30S, twist 360T / m.

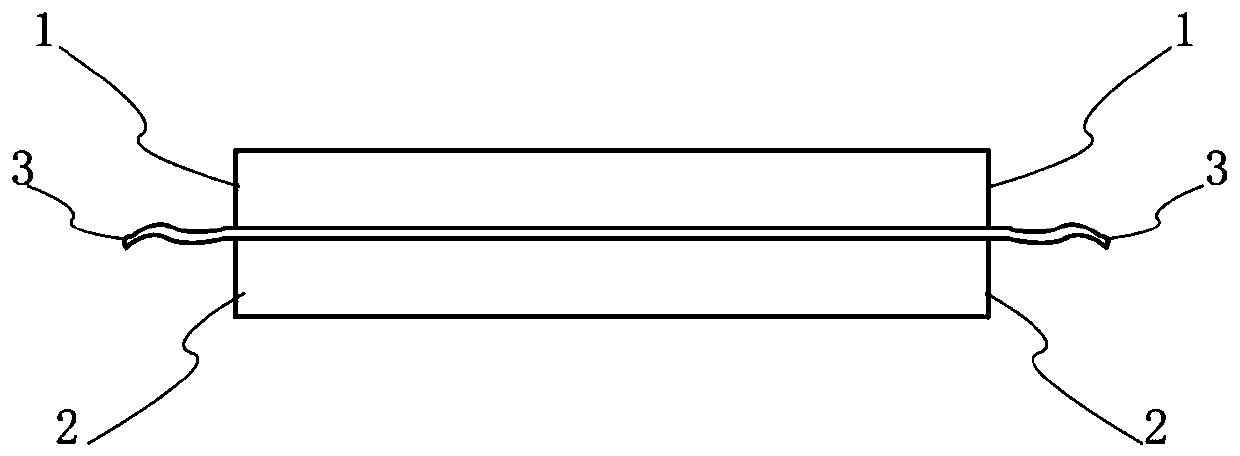

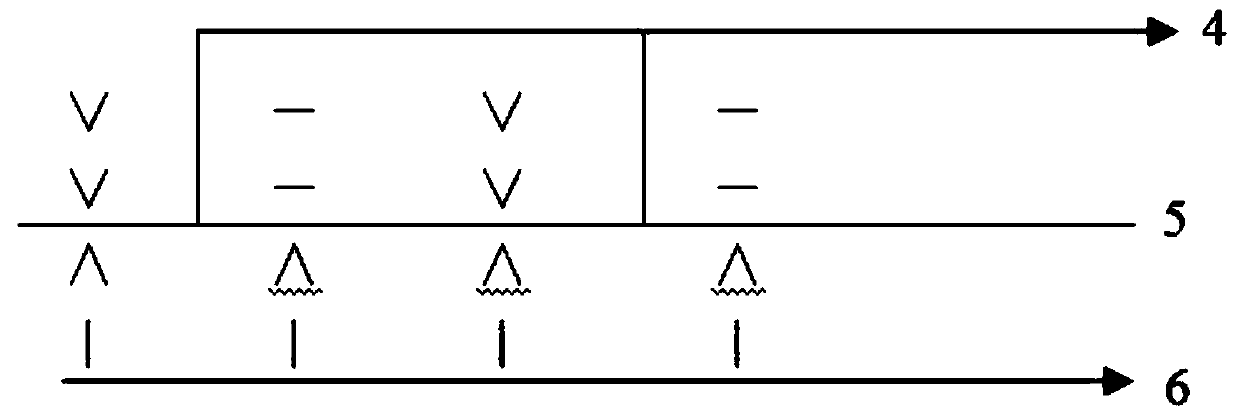

[0054] The double-sided jacquard fabric includes a special yarn layer, a rayon fiber layer and a special yarn layer from top to bottom, and the special yarn layer, the rayon fiber layer and the special yarn layer are interwoven and formed, wherein the...

Embodiment 2

[0085] The special yarn is formed by blending natural plant fibers and man-made fibers, wherein the natural plant fibers are one of long-staple cotton fibers, soybean fibers or corn fibers, and the blending formula ratio of the natural plant fibers and the man-made fibers is It is 7:3, the blending technology adopts rotor spinning technology of air spinning, and the spinning equipment is Schlafford 312 type imported from Germany. The preparation method of the special yarn includes the following steps: batching→grabbing→opening→mixing→ Impurity removal → carding → head and drafting → finishing and drafting → air spinning, wherein the yarn process design is: fineness 35S, twist 380T / m.

[0086] The double-sided jacquard fabric includes a special yarn layer, a rayon fiber layer and a special yarn layer from top to bottom, and the special yarn layer, the rayon fiber layer and the special yarn layer are interwoven and formed, wherein the double-sided jacquard fabric The weaving met...

Embodiment 3

[0117] The special yarn is formed by blending natural plant fibers and man-made fibers, wherein the natural plant fibers are one of long-staple cotton fibers, soybean fibers or corn fibers, and the blending formula ratio of the natural plant fibers and the man-made fibers is It is 6:4, the blending technology adopts rotor spinning technology of air spinning, and the spinning equipment is Schlafford 312 type imported from Germany. The preparation method of the special yarn includes the following steps: batching→grabbing→opening→mixing→ Impurity removal → carding → head and drafting → finishing and drafting → air spinning, wherein the yarn process design is: fineness 40S, twist 390T / m.

[0118] The double-sided jacquard fabric includes a special yarn layer, a rayon fiber layer and a special yarn layer from top to bottom, and the special yarn layer, the rayon fiber layer and the special yarn layer are interwoven and formed, wherein the double-sided jacquard fabric The weaving met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com