A kind of high-efficiency and energy-saving crepe wood pulp composite spunlace cloth and preparation method thereof

A high-efficiency, energy-saving, spunlaced fabric technology, applied in the direction of non-woven fabrics, textiles, and papermaking, can solve the problems of product strength, wear resistance, etc. Feel thick and flexible, increase the wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

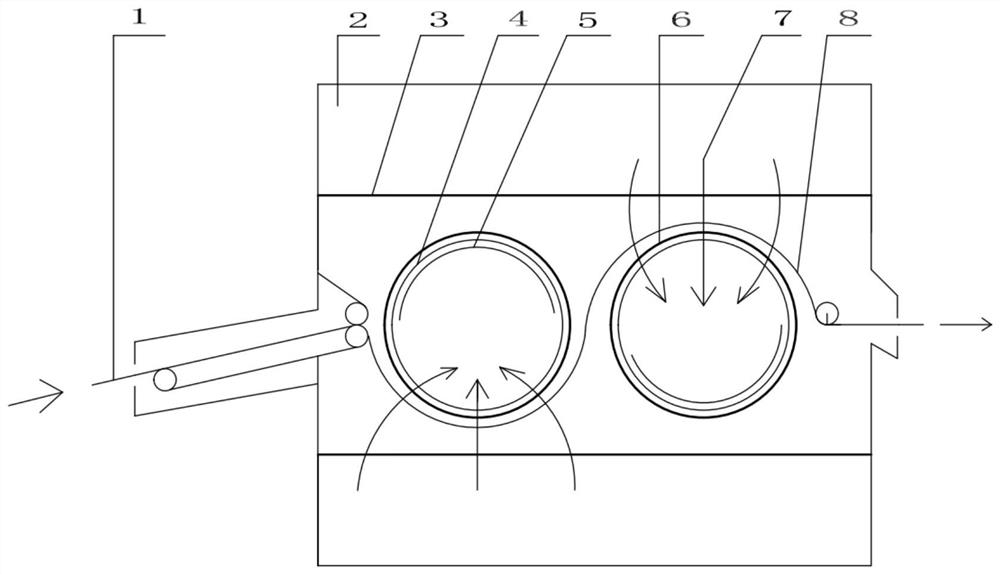

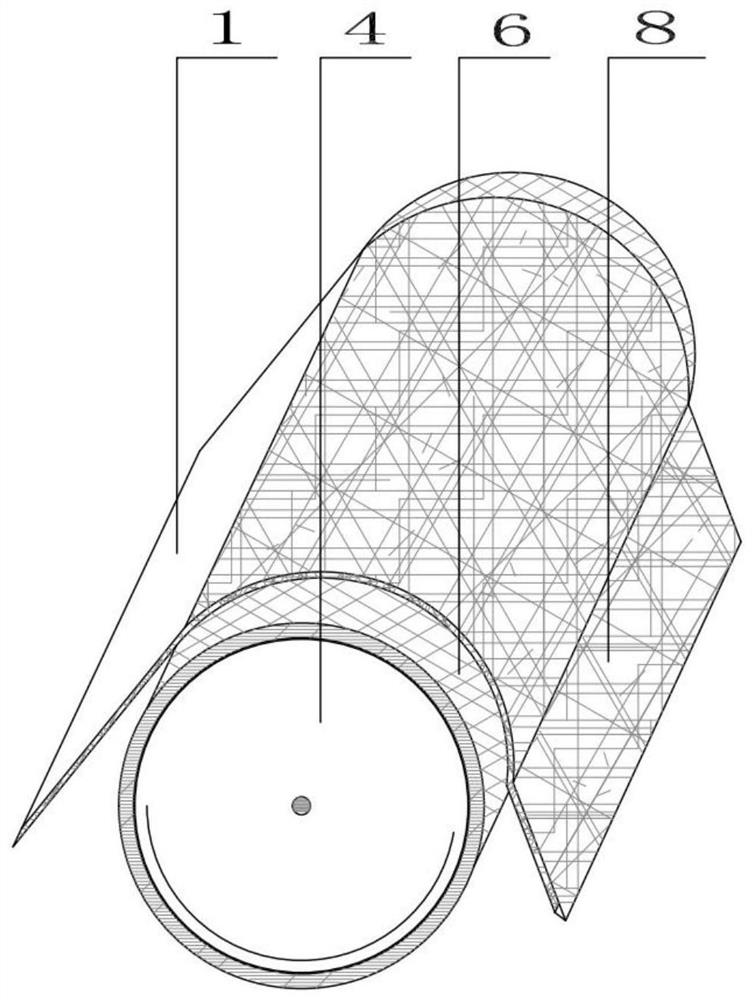

Method used

Image

Examples

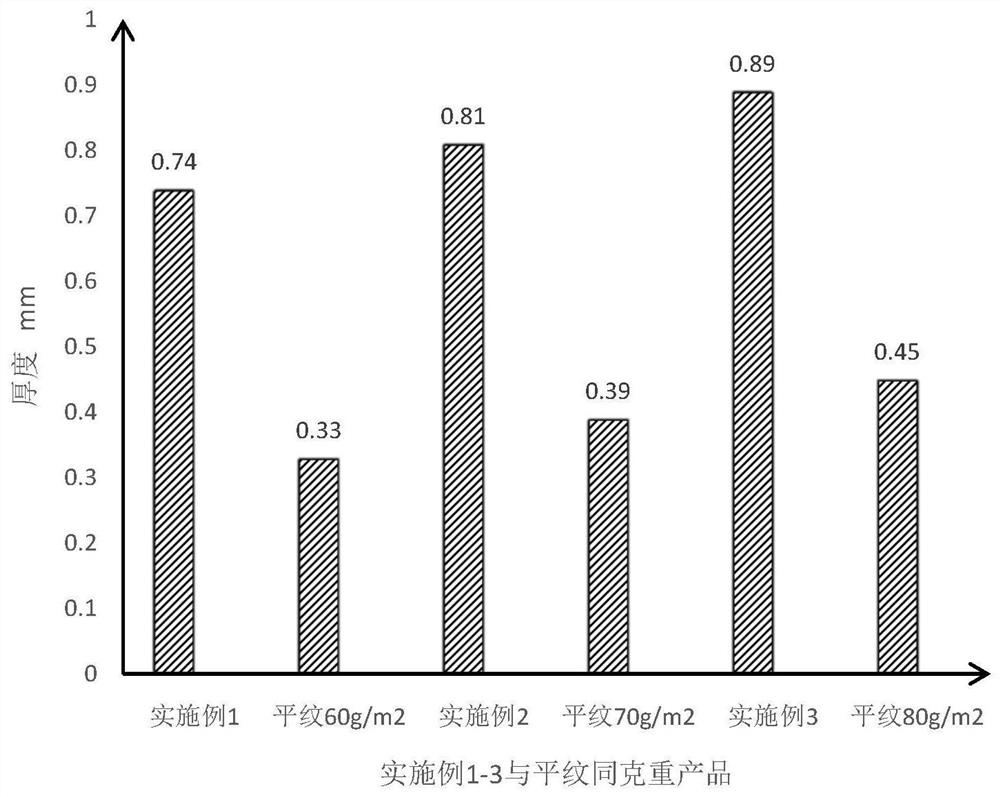

Embodiment 1

[0034] The present embodiment provides a method for preparing the above-mentioned 60g / m2 high-efficiency and energy-saving wrinkled white wood pulp composite spunlace cloth, including the following steps:

[0035] Prepare raw materials: choose polyester fiber, specification 1.4D×38mm; choose polypropylene fiber: specification 1.4D×38mm, the two are fed in a raw material ratio of 60%:40% (mass percentage), and the gram weight of the mixed fiber is 30g / ㎡, accounting for 50% of the wrinkled wood pulp composite spunlace cloth; and white wood pulp paper, with a thickness of 0.035mm, the gram weight of the white wood pulp paper is 30.0g / ㎡, and the white wood pulp paper is The unwinding method is used for wood pulp spunlace composite in the spunlace process.

[0036] Feeding, mixing and opening: Set the feeding amount of No. 2 bale opener to 1950g (1#) and 1050g (3#) respectively, the working frequency of the feeding roller of the bale opener is 38Hz, and the working frequency of the...

Embodiment 2

[0045] This embodiment provides a method for preparing the above-mentioned 70g / m2 high-efficiency and energy-saving wrinkled light blue wood pulp composite spunlace cloth, including the following steps:

[0046] Preparation of raw materials: polyester fiber is selected, the specification is 1.4D×38mm, the mass percentage of polyester fiber feeding is 100%, and the fiber gram weight is 40g / ㎡, which accounts for 57% of the wrinkled wood pulp composite spunlace cloth by weight; and The light blue wood pulp paper has a thickness of 0.04mm, and the gram weight of the light blue wood pulp paper is 30.0g / ㎡.

[0047] Feeding, mixing and opening: set the working frequency of the feeding roller of the bale opener to 38Hz, the working frequency of the fine opening licker-in roller to 45Hz, the working frequency of the fine opening equalizing roller to be 35Hz, and the working frequency of the fine opening feeder roller to be 35Hz. is 35Hz. The polyester fiber is grabbed by the opener an...

Embodiment 3

[0056] The present embodiment provides a method for preparing the above-mentioned 80g / m2 high-efficiency and energy-saving wrinkled white wood pulp composite spunlace cloth, including the following steps:

[0057] Prepare raw materials: choose polyester fiber, specification 1.4D×38mm; choose polypropylene fiber: specification 1.4D×38mm; the two are fed in a ratio of 60%:40% of raw materials, and the gram weight of the mixed fiber is 42g / ㎡, The weight percentage of the wrinkled wood pulp composite spunlace cloth is 52.5%; and the white wood pulp paper, the thickness is 0.07mm, the gram weight of the white wood pulp paper is 38.0g / ㎡, and the white wood pulp paper is unrolled. Wood pulp spunlace lamination is carried out in the spunlace process.

[0058] Feeding, mixing and opening: set the working frequency of the feeding roller of the bale opener to 38 Hz, the working frequency of the fine opening licker-in roller to 46 Hz, the working frequency of the fine opening equalizing r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com