A method for preparing porous starch by using alternating electric field

A technology of porous starch and alternating electric field, applied in the field of starch processing, can solve the problems of large amount of enzymes and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

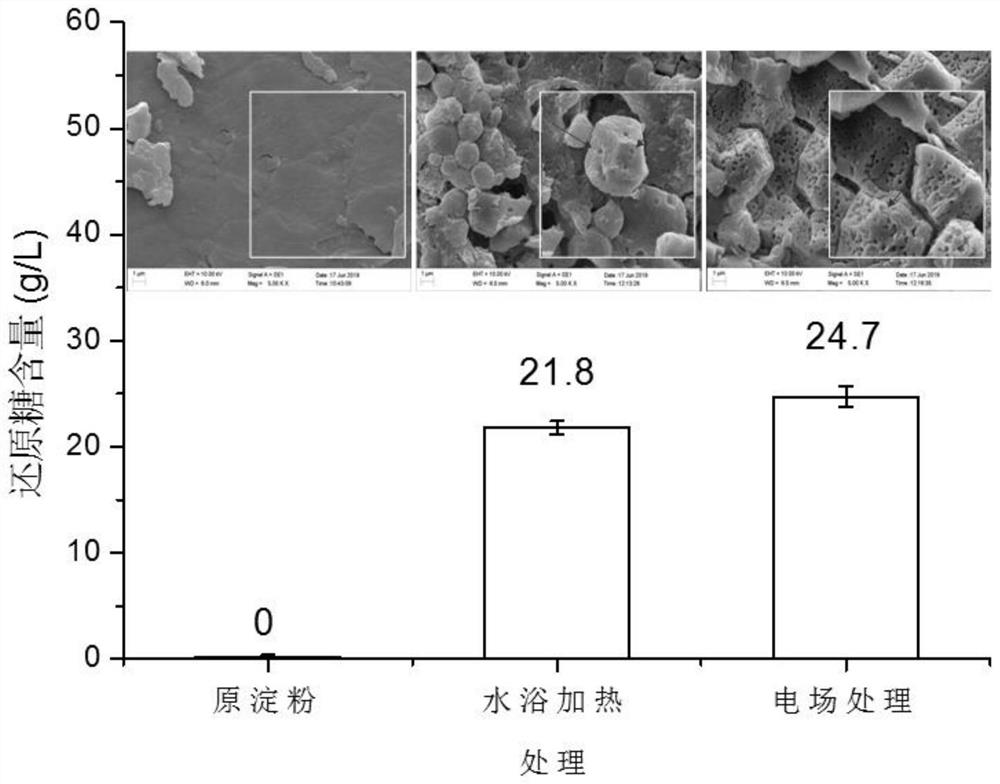

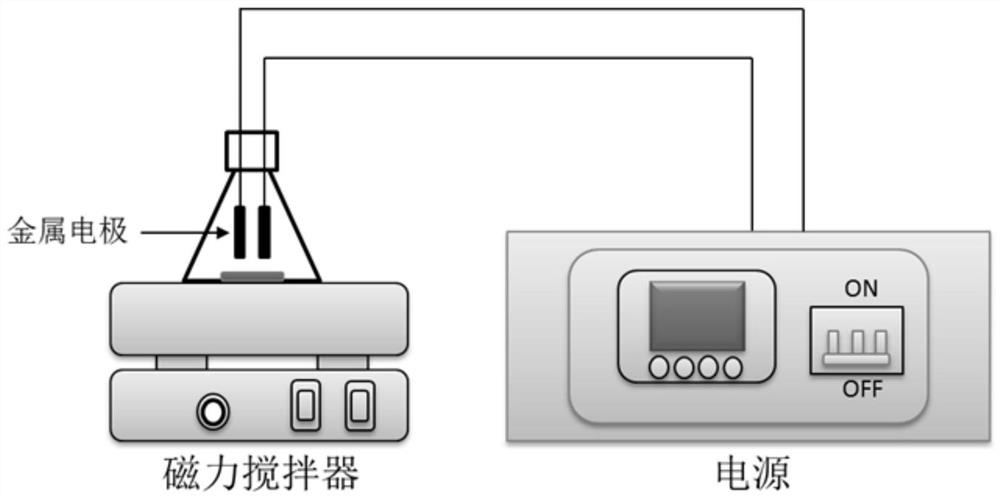

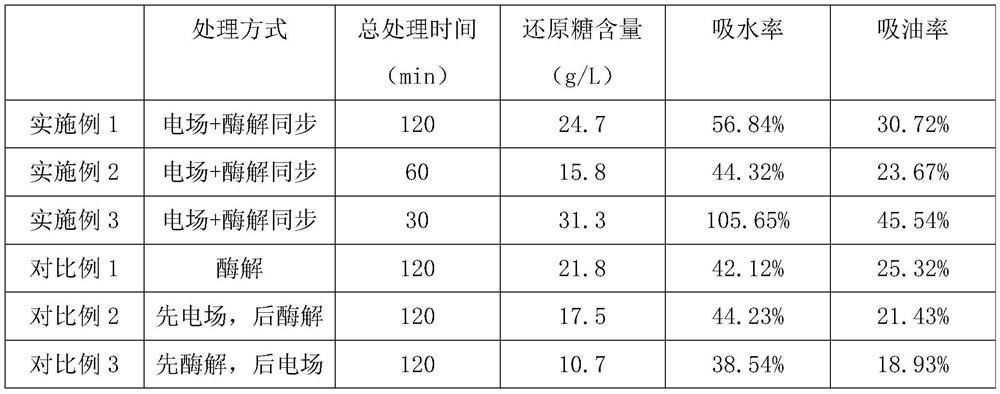

[0026] Use broken rice flour with a 0.3mm sieve as raw material, potassium phosphate buffer solution with pH 6.0 and conductivity 25.8mS / cm as reaction medium, high temperature resistant α-amylase as catalyst, 80mL buffer solution, 8.0g broken rice flour and After the high-temperature-resistant α-amylase (enzyme activity 20000U / mL) with 1% dry weight of starch was mixed evenly under the action of magnetic stirring, it was treated for 120min under the conditions of electric field strength 5V / cm, frequency 60Hz, temperature 50°C, and the pH was adjusted to 10.0 After inactivating the enzyme overnight, adjust the pH to be neutral, wash with ultrapure water, centrifuge, and freeze-dry to obtain porous starch with different pore structures.

Embodiment 2

[0028] The discarded potato peels and residues from industrially produced potato chips passed through a 0.3mm sieve were used as raw materials, potassium phosphate buffer solution with pH 6.0 and conductivity 12.1mS / cm was used as the reaction medium, and medium-temperature α-amylase (50U / mg) was used as the reaction medium. Catalyst, 80mL of buffer solution, 16.0g of potato waste, and medium-temperature α-amylase with 1% dry weight of starch were mixed evenly under the action of magnetic stirring, and then treated for 30min under the conditions of electric field strength 10V / cm, frequency 50Hz, and temperature 45°C Finally, adjust the pH to 10.0 and inactivate the enzyme overnight, adjust the pH to 7.0-8.0, wash with ultrapure water, centrifuge, and freeze-dry to obtain porous starch with different pore structures.

Embodiment 3

[0030] Common cornstarch passed through a 0.3mm sieve was used as raw material, potassium phosphate buffer solution with pH 6.0 and conductivity 25.8mS / cm was used as reaction medium, and high temperature resistant α-amylase (20000U / mL) and β-amylase (50U / mg) as catalyst, 80mL of buffer solution, 8.0g of cornstarch, and high temperature-resistant α-amylase with 1% dry basis weight of starch were mixed evenly under the condition of 50°C with magnetic stirring, and the After 10 minutes of treatment, 0.5% β-amylase on a dry basis of starch was added, and the treatment was continued for 20 minutes under the conditions of an electric field intensity of 10 V / cm and a frequency of 50 Hz. Afterwards, adjust the pH to 10.0 to inactivate the enzyme, adjust the pH to 7.0-8.0, wash with ultrapure water, centrifuge, and freeze-dry to obtain porous starch with different pore structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com