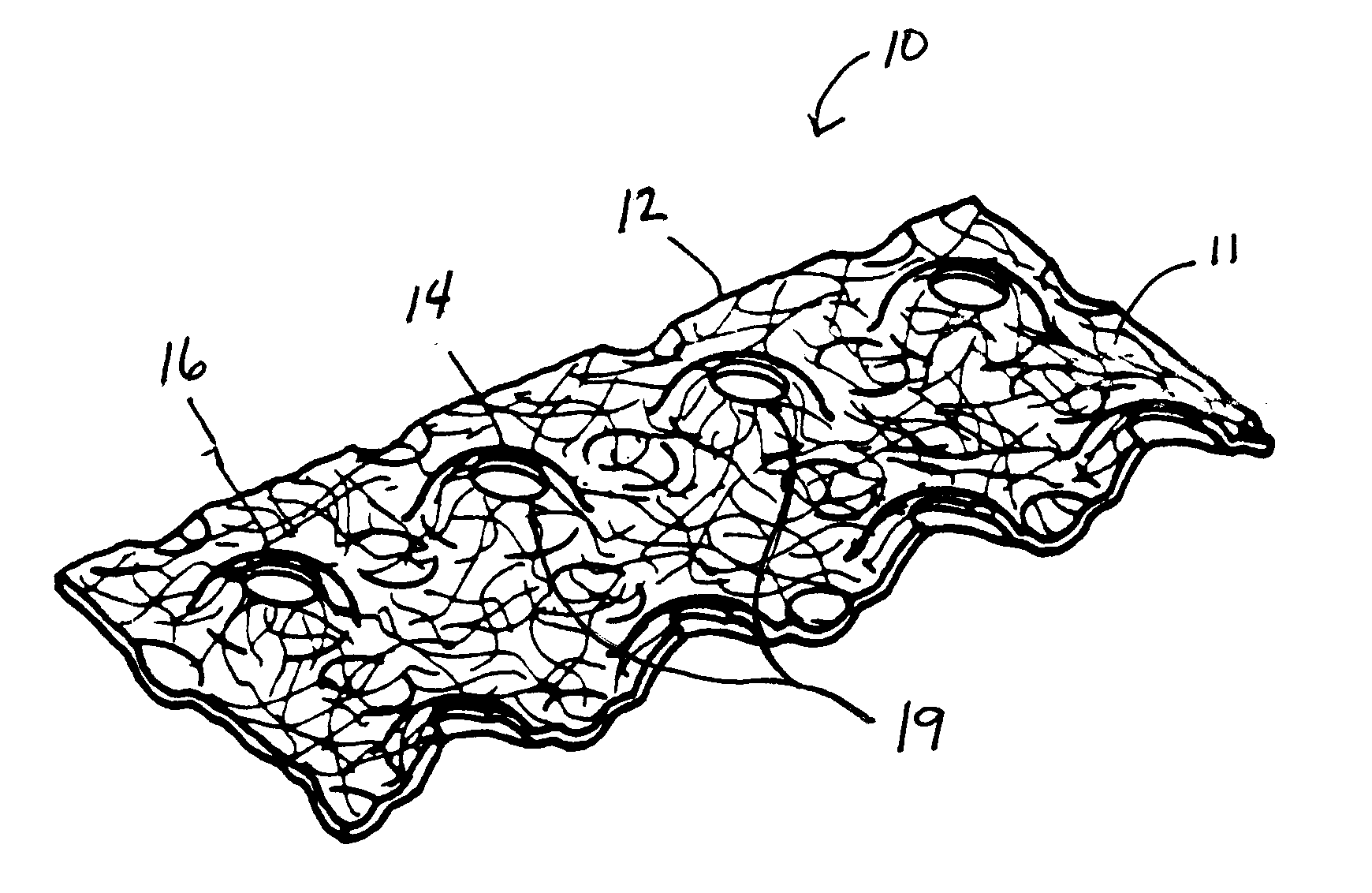

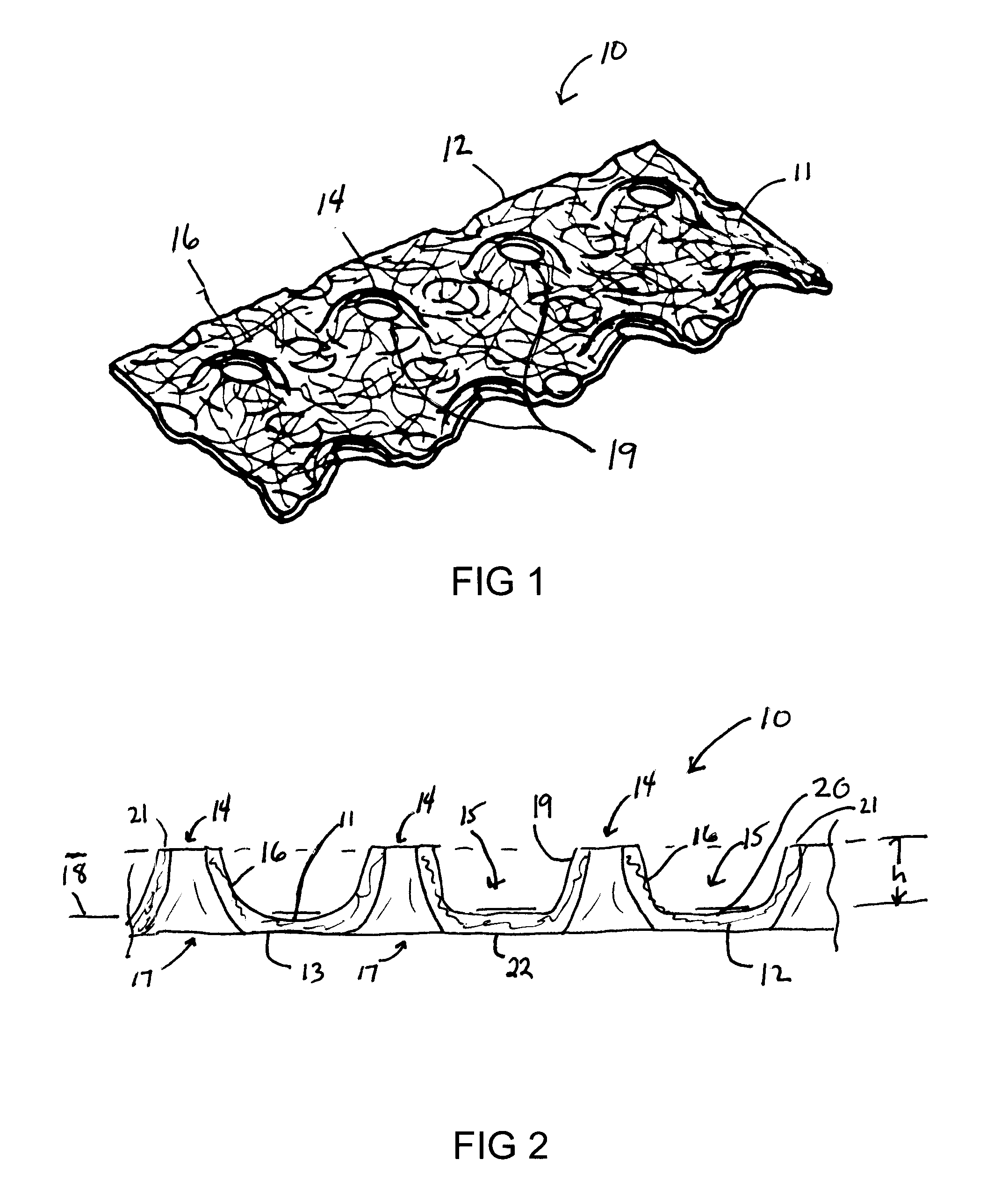

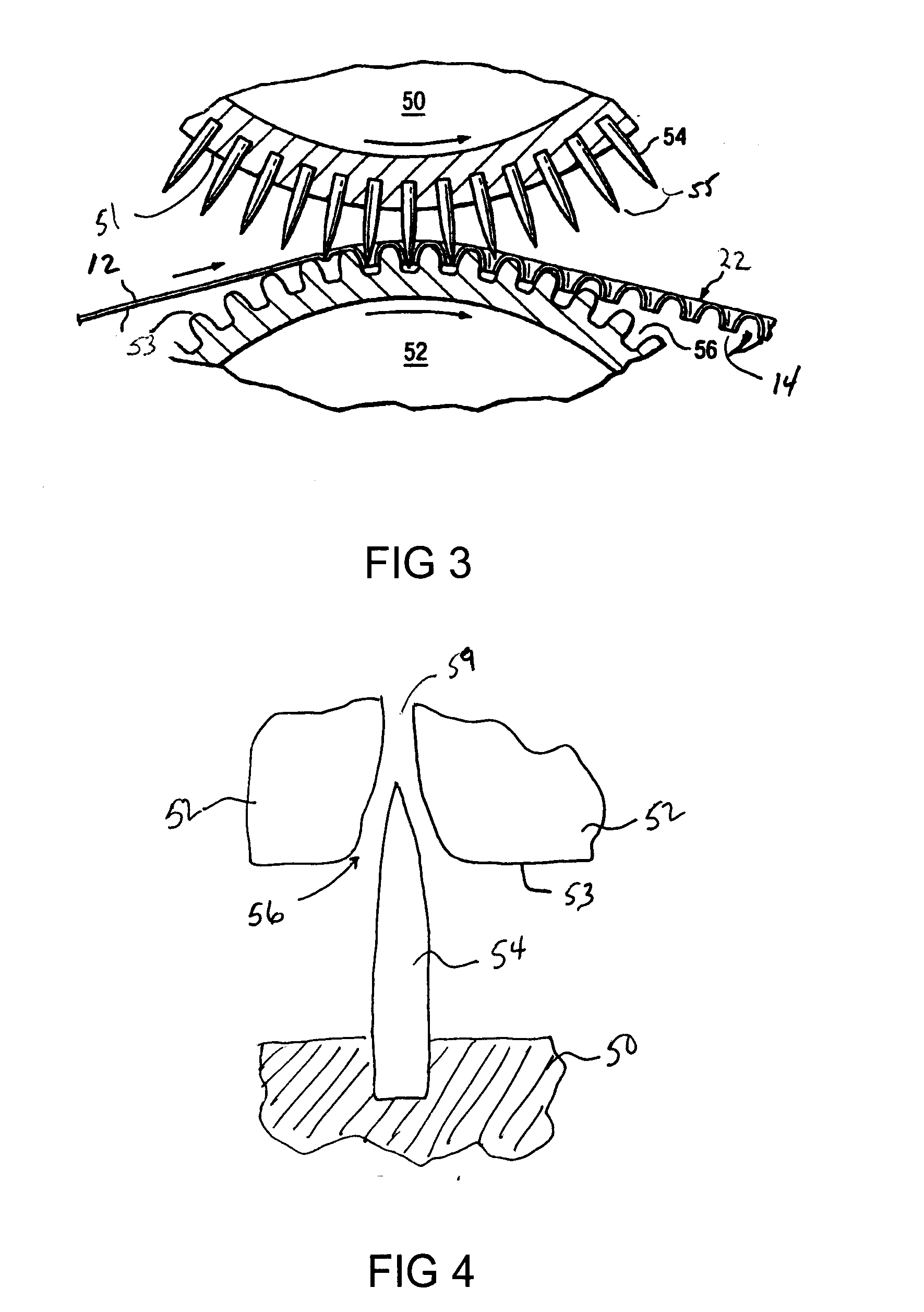

Apertured Wiping Cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0076]In this Example a hydroentangled nonwoven web having a basis weight of about 64 gsm is used as the wiping cloth As a control, a WYPALL X60 wiper available from Kimberly-Clark Global Sales, LLC, having offices in Roswell, Ga. was used. In the control and in each sample, the wiping cloth substrate is a polypropylene spunbond nonwoven web having a basis weight of about 13 gsm which is hydroentangled with pulp fibers. After hydroentangling the wiping cloth substrate has a basis weight around 64 gsm. The actual basis weight of each sample is shown in TABLE 1.

[0077]The apertured samples are apertured in different pin densities and different pin penetration. The hydroentangled substrate is apertured using a pin density of 7 pins per square centimeter, 11 pins per square centimeter or 18 pins per square centimeter. The diameter of the pins for each pin density is different. 7 pins per square centimeter uses pins having a diameter of 3.1 mm, 11 pins per square centimeter uses pins havi...

example 2

[0093]Further testing of the wiping cloths of the present invention was carried out. Samples B-1 and B-2 are the same samples as in Example 1. The cleaning ability of these wiping cloths were compared to three commercially available wiping cloths. The three commercially available wiping cloths are all flat apertured wiping cloths. The bonded carded web (BCW) is a WYPALL Workforce Xtra Food Service Towel, 70 gsm, which is available from Kimberly-Clark Global Sales, LLC, having Offices in Roswell, Ga. The spunlace is Saniwork Deluxe Food Service Towel that has been apertured hydraulically during the hydroentangling process and is available from Hospeco, having offices in Cleveland, Ohio. The wiping cloths are used in wiping test as both dry wiping and wet wiping. In this example, modified gear grease (MGG) and modified engine oil (MEO) are used. Modified gear grease is Sta-Lube Wheel Bearing Grease mixed with 4% carbon black, by weight. The modified engine oil is Valvoline VRL Racing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com