Sea-island composite fibers, microfibers and composite spinnerets

A composite fiber and composite spinning technology, which is applied in the direction of spinneret assembly, conjugated synthetic polymer artificial filament, fiber treatment, etc., can solve the problem of not considering the composite material flow of the polymer, and achieve the suppression of broken Effects of chipping or falling off, high productivity, and suppression of stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

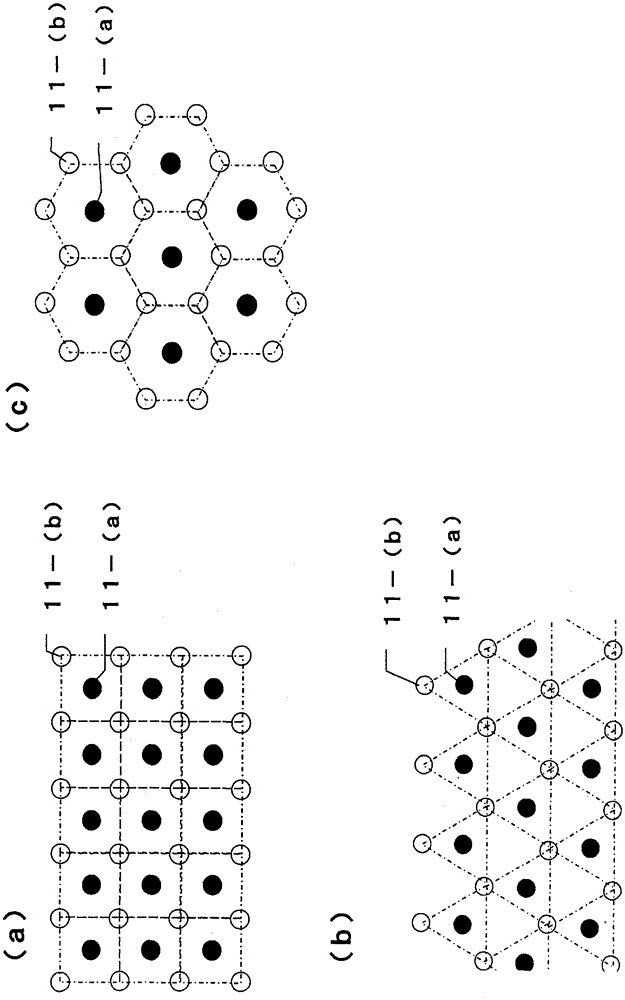

Method used

Image

Examples

Embodiment 1

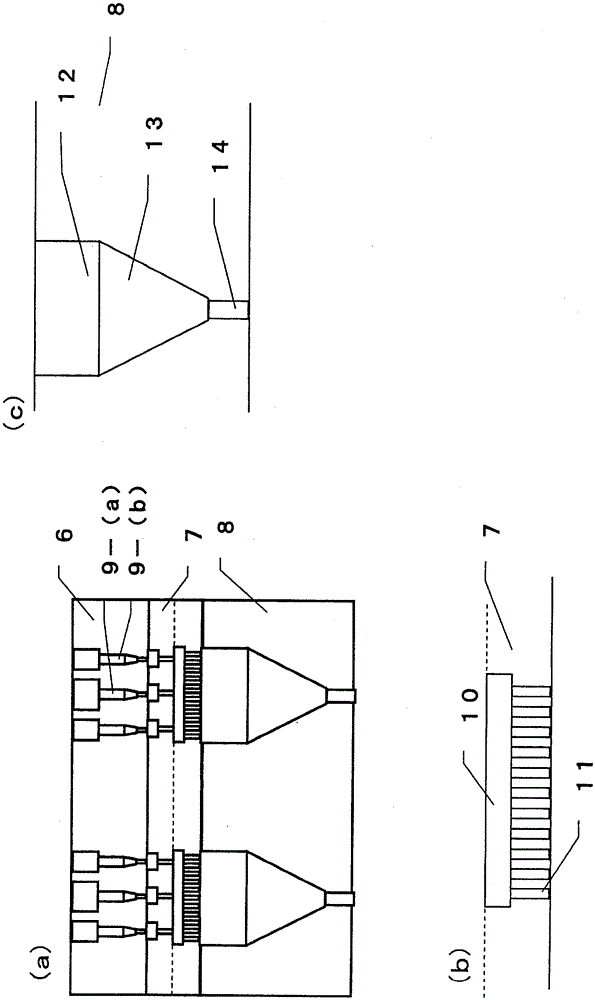

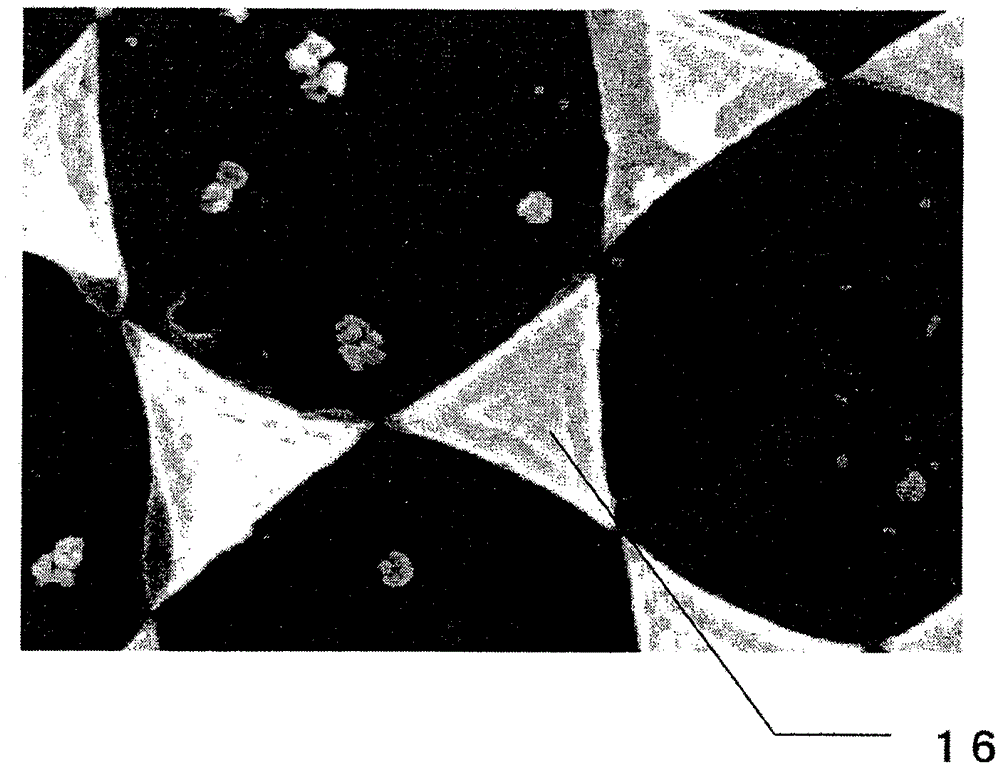

[0178] Polyethylene terephthalate (PET1 melt viscosity: 120 Pa?s Toray Co., Ltd. T301T) as the island component, and 5.0 mol % of 5-sodium isophthalate copolymerized as the sea component PET (copolymerized PET1 melt viscosity: 140Pa?s A260 manufactured by Toray Co., Ltd.) was melted at 290°C, measured, and flowed into the assembly figure 2 The spin pack of the composite spinneret shown discharges the composite polymer stream from the discharge orifice. It should be noted that four metering plates are stacked, and the flow path is set in such a way as to expand downstream, and the aggregation of sea components and island components is measured step by step through orifices (φ0.4L / D=1.5) in each metering plate things. In addition, 10 distribution plates are stacked, and a flow channel for distributing a fine polymer flow in the fiber cross-sectional direction is provided. 1000 distribution holes for the island components are perforated on the distribution plate directly above...

Embodiment 2~4

[0183] From the method described in Example 1, except that the composite ratio of the sea / island component is changed stepwise to 20 / 80 (Example 2), 50 / 50 (Example 3), and 70 / 30 (Example 4) , implement according to embodiment 1. The evaluation results of these island-in-the-sea composite fibers are shown in Table 1. Similar to Example 1, the circumscribed circle diameter and shape homogeneity of the island components were excellent, and there was no change (◯) even after 72 hours. The results are shown in Table 1.

[0184] [Table 1]

[0185]

Embodiment 5

[0197] In addition to using polyethylene terephthalate (PET2 melt viscosity: 110 Pa?s Toray Co., Ltd. T900F) as the island component, 8.0 mol% of 5-sodium isophthalate is copolymerized as the sea component PET (copolymerized PET2 melt viscosity: 110 Pa?s), except that the draw ratio was 4.0 times, all were implemented as in Example 1. The sea-island composite fiber can be stretched at a high ratio, so that the strength can be relatively increased. Other evaluation results are shown in Table 3. As in Example 1, the circumscribed circle diameter and shape homogeneity of the island components were excellent.

[0198] In addition, the manufacturing method of the copolymerized PET2 used as a sea component in Example 5 is as follows.

[0199] Add 8.7 kg of dimethyl terephthalate, 1.2 kg of dimethyl isophthalate-5-sodium sulfonate (equivalent to 8 mol% relative to the total acid content of the obtained polymer), 5.9 kg of ethylene glycol, 50 g of lithium acetate was heated to 140-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com