High performance pbt special fiber production process

A special fiber and production process technology, applied in the field of high-performance PBT special fiber production process, can solve the problems of decreased antibacterial performance of fabrics, poor silk strength and elasticity, unstable fabric size, etc., to improve washing resistance and spinnability High, the effect of reducing the difference in fiber shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

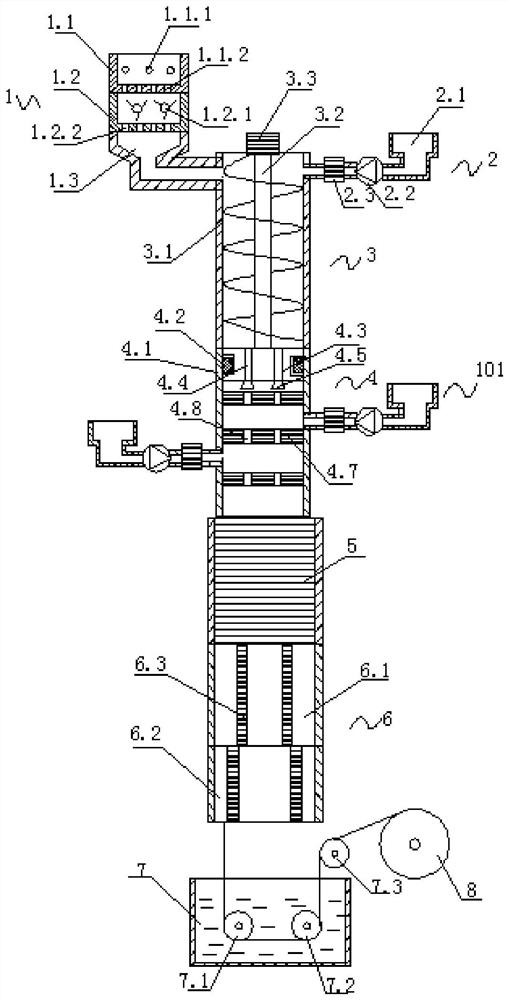

[0040] see Figure 1-9 , a kind of high-performance PBT special fiber production process that the present invention relates to realizes based on a kind of high-performance PBT special fiber manufacturing equipment, and this manufacturing equipment comprises melting material device 1, feeding device 2, mixing device 3, drawing device 4, Spraying device 101, cooling device 5 and heating device 6;

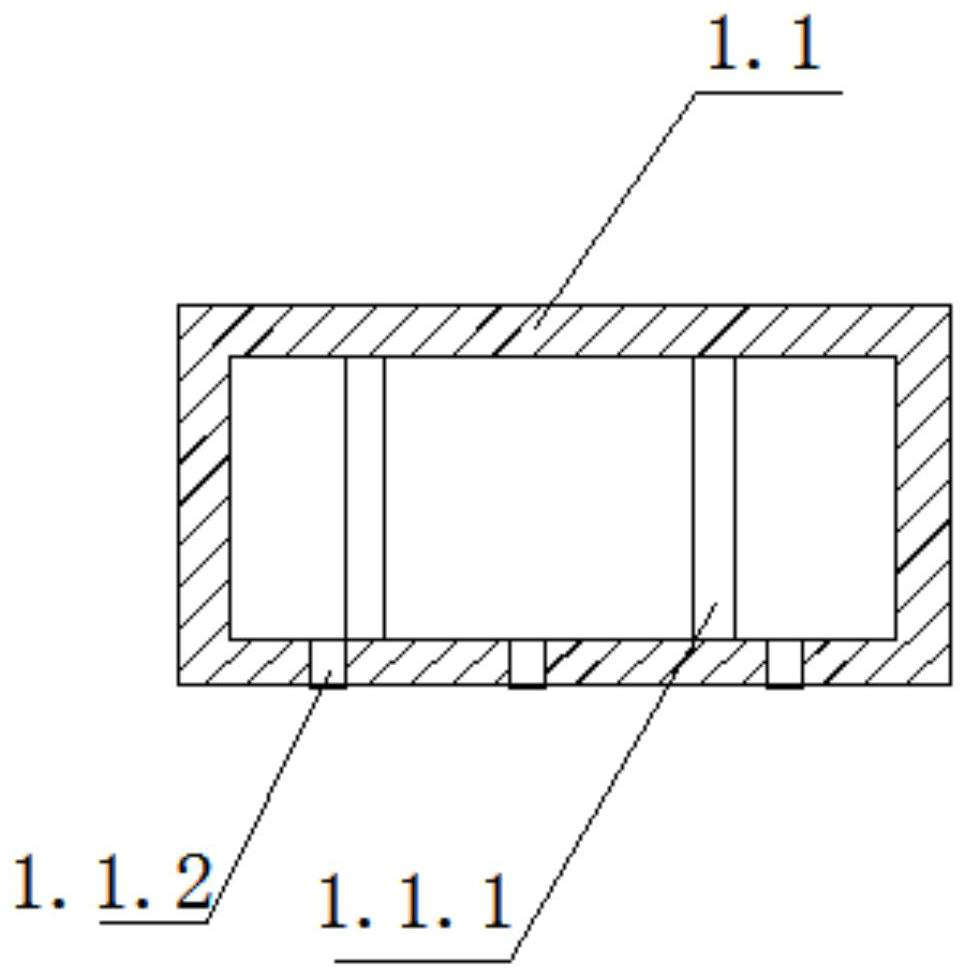

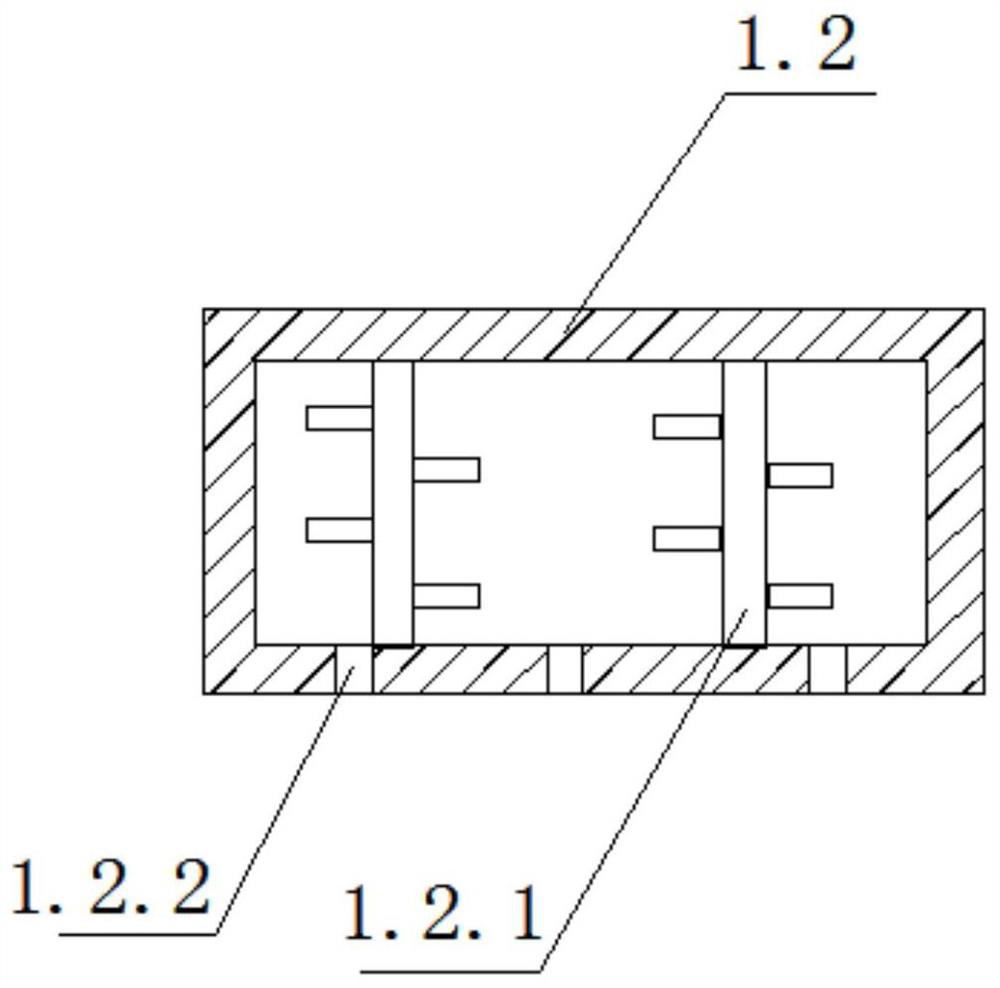

[0041] The melting material device 1 includes a heating box 1.1, a plurality of heating wires 1.1.1 are arranged in the heating box 1.1, and a plurality of through holes 1.1.2 are provided at the bottom of the heating box 1.1; a material storage box 1.2 is connected with the heating box 1.1, the storage box 1.2 is located directly below the heating box 1.1, the top open end of the storage box 1.2 is connected with the bottom of the heating box 1.1, and the storage box 1.2 is equipped with A plurality of stirring paddles 1.2.1, the bottom of the storage box 1.2 is provided with a plur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com