Cleaning tool and method for manufacturing cleaning portion constituting the cleaning tool

a technology of cleaning tool and cleaning portion, which is applied in the field of cleaning tools, can solve the problems of not removing dust, offering satisfactory wiping performance, and the conventional duster has no wiping function, so as to achieve excellent wiping performance, easy cleaning of tight spaces, and easy catching of dus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

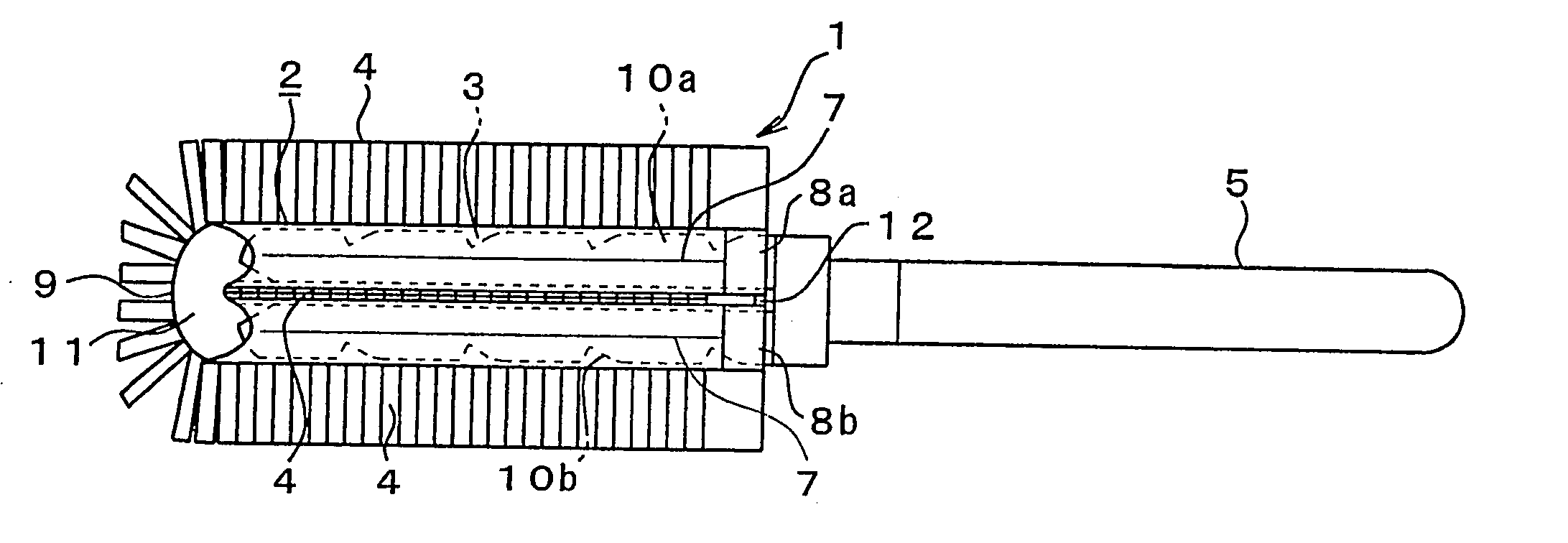

[0032]FIG. 1 shows the present invention. A cleaning tool 1 comprises a cleaning component 2 and a handle component 5, and the cleaning component 2 comprises a bulging component 40 bent in a U-shape, a handle insertion component 3 formed inside the bulging component 40, and a pleated component 4 formed along and underneath the bulging component 40. The cleaning component 2 is constituted such that a sheet bundle comprising a plurality of stacked sheets is bent twice as discussed below (in FIG. 1, 7 is the first bent component and 9 is the second bent component). A linear seal component 6 is provided, parallel to the bent component 7, to the sheet bundle that has been bent from the bent component 7. The space formed by the provision of this seal component 6 constitutes the handle insertion component 3. The seal component 6 is formed by heat fusion, for example. 8a and 8b are insertion openings in the handle insertion component 3.

[0033] Providing the first seal component 6 parallel to...

second embodiment

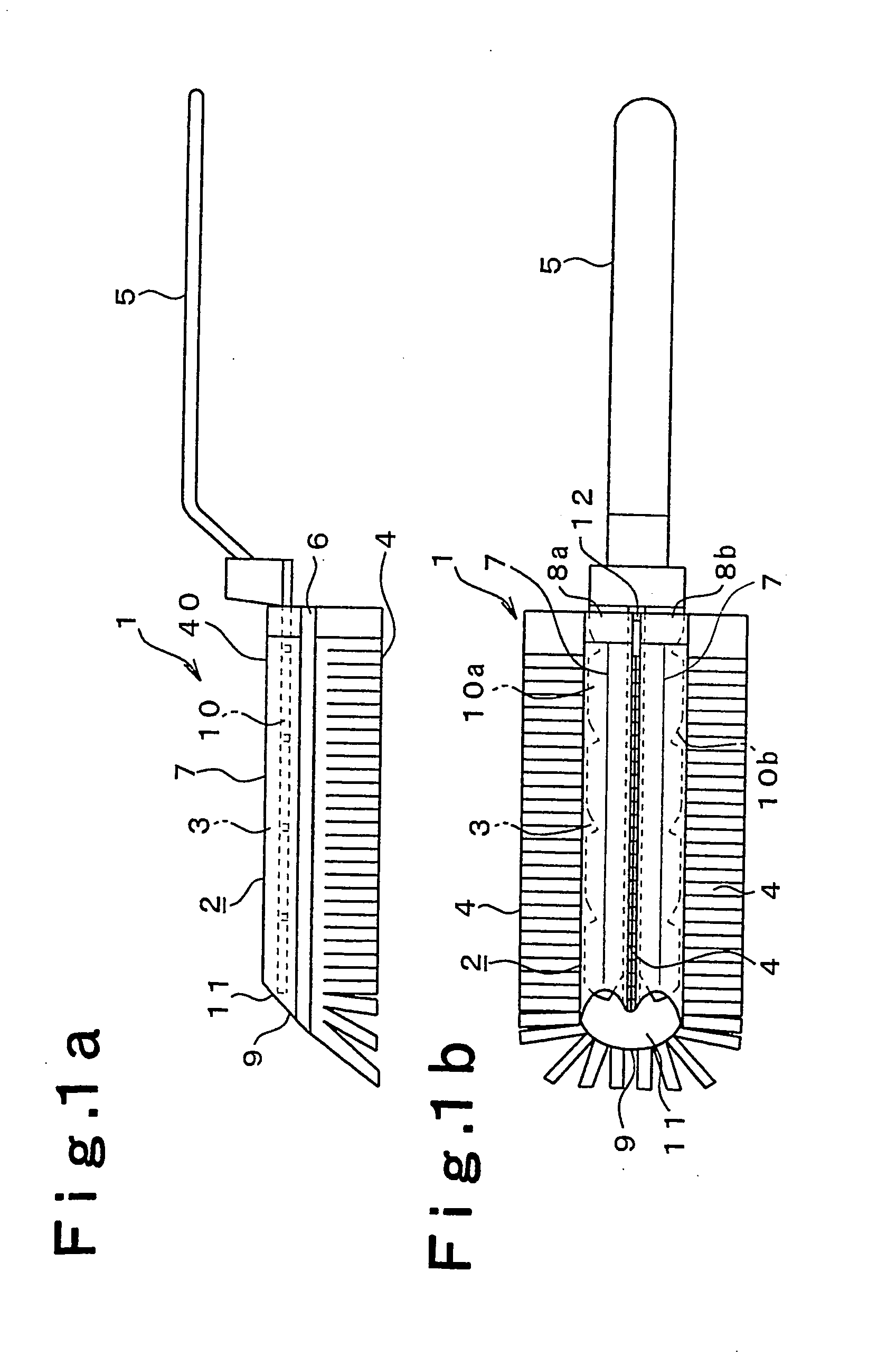

[0045]FIG. 2 illustrates the present invention. In this embodiment, a sheet bundle cut surface 15 is formed on the upper part of the bulging component 40, which forms a raised nap on the upper part of the bulging component 40. To form this raised nap on the upper part of the bulging component, cut lines should be made along the bend line in the first bending step of the sheet bundle. A nappy surface is formed in the course of this sheet cutting.

[0046] Also, in this embodiment two seal components, a first seal component 6 and a second seal component 17, are provided as the seal component, and the space formed by these two seal components constitutes the handle insertion component 3.

third embodiment

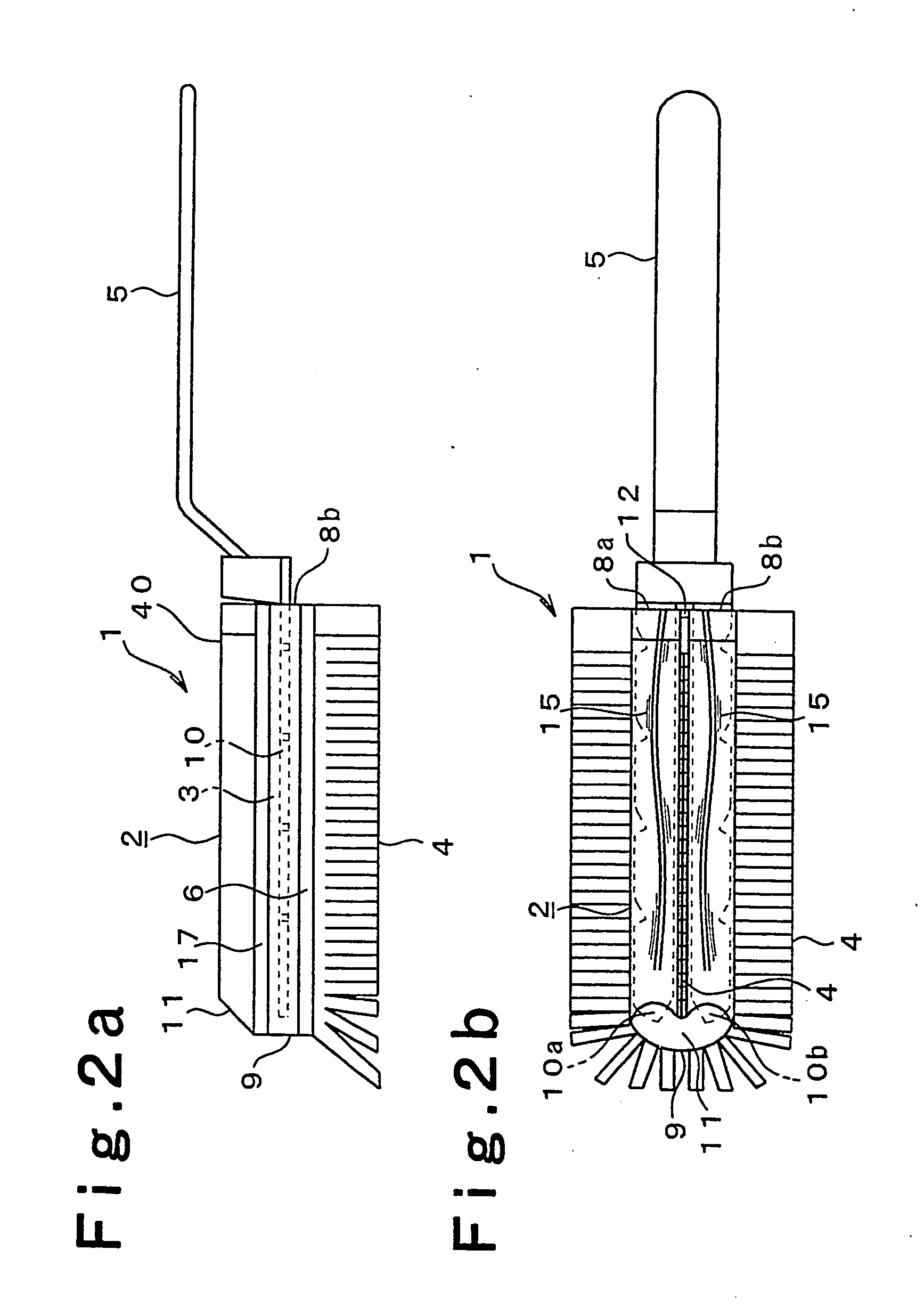

[0047]FIG. 3 illustrates the present invention. In this embodiment, a pleated component 16 is provided to the bulging component 40 itself. The pleated component 16 is provided to the upper part of the bulging component 40, and has the same narrow rectangular shape as the pleated component 4 under the bulging component 40.

[0048] To form this pleated component 16 on the upper part of the bulging component 40, a cut line is made along the bend line in the first bending step of the sheet bundle, and numerous cuts are made along the cut end faces of this cut line.

[0049] Again in this embodiment, two seal components, a first seal component 6 and a second seal component 17, are provided as the seal component, and the space formed by these two seal components constitutes the handle insertion component 3.

[0050] Next, an example of the method for manufacturing the cleaning component 2 will be described through reference to FIGS. 4 to 6.

[0051] First, a sheet is manufactured by piling up sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com