Medical Pump

a pump and medical technology, applied in the field of medical pumps, can solve the problems of unsatisfactory pump efficiency and adjustment, and the cutting medium must be completely sterile, and achieve the effect of convenient improvement of cutting performance and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The same reference numbers will be used for the same parts and parts with the same function.

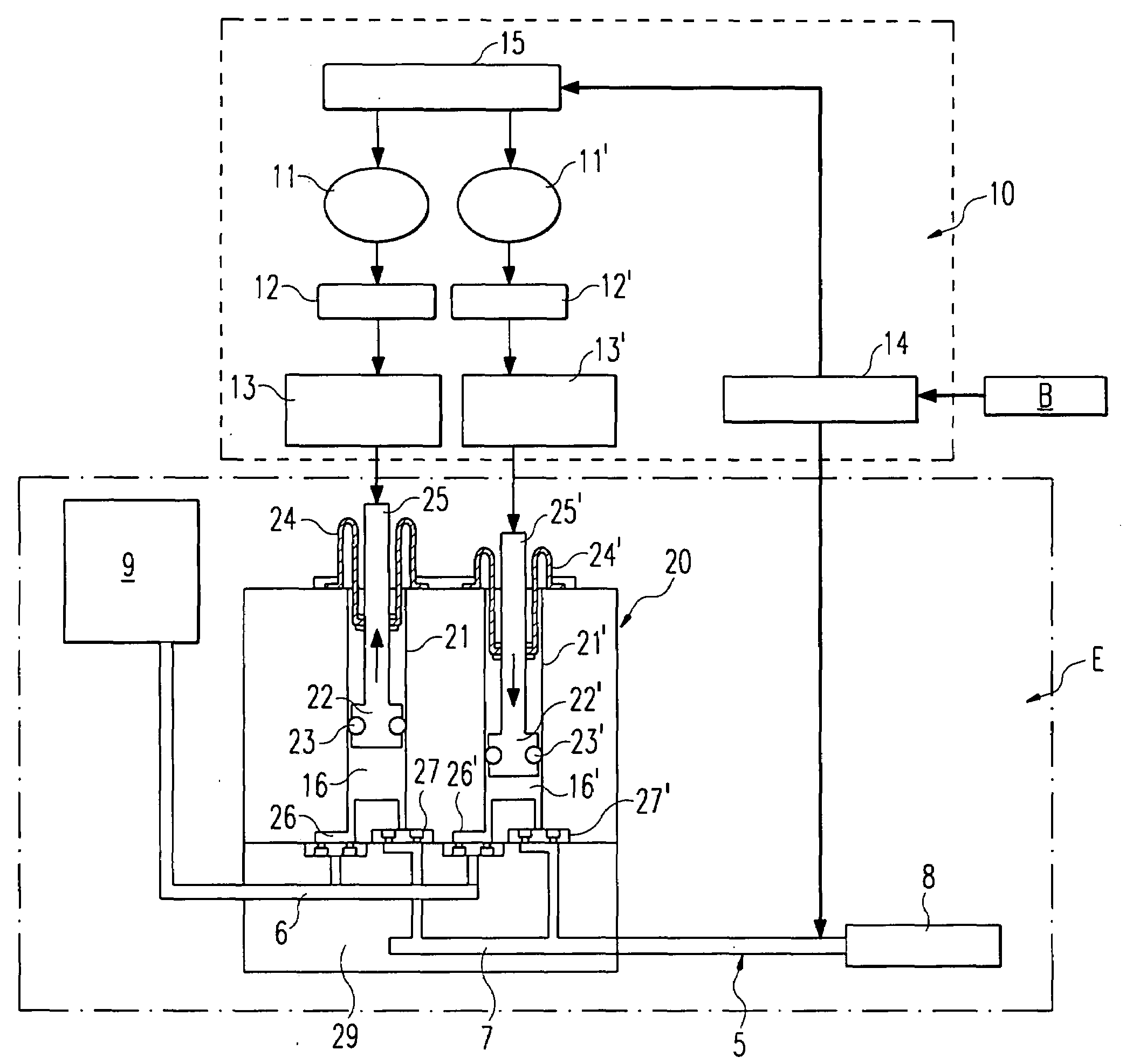

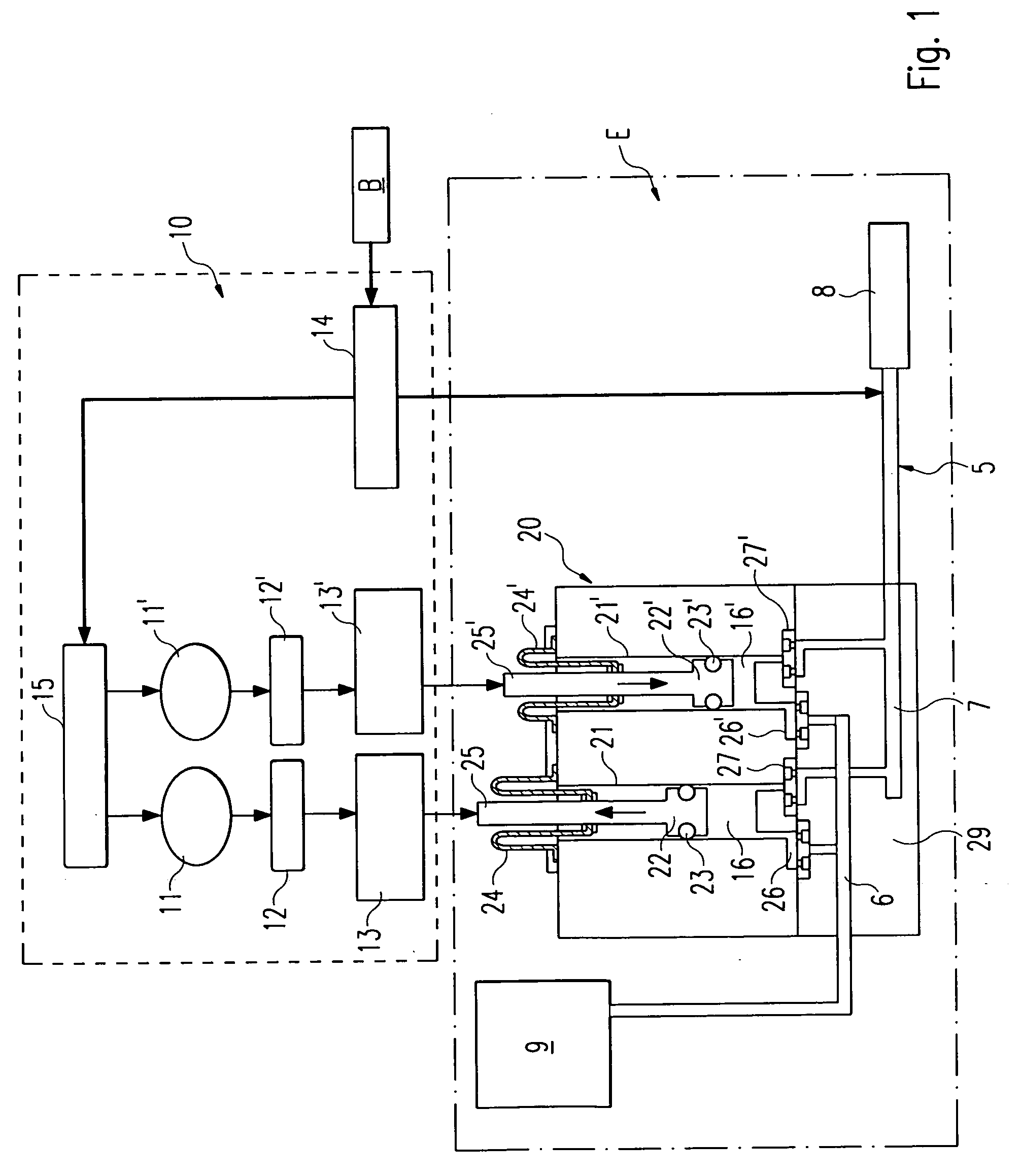

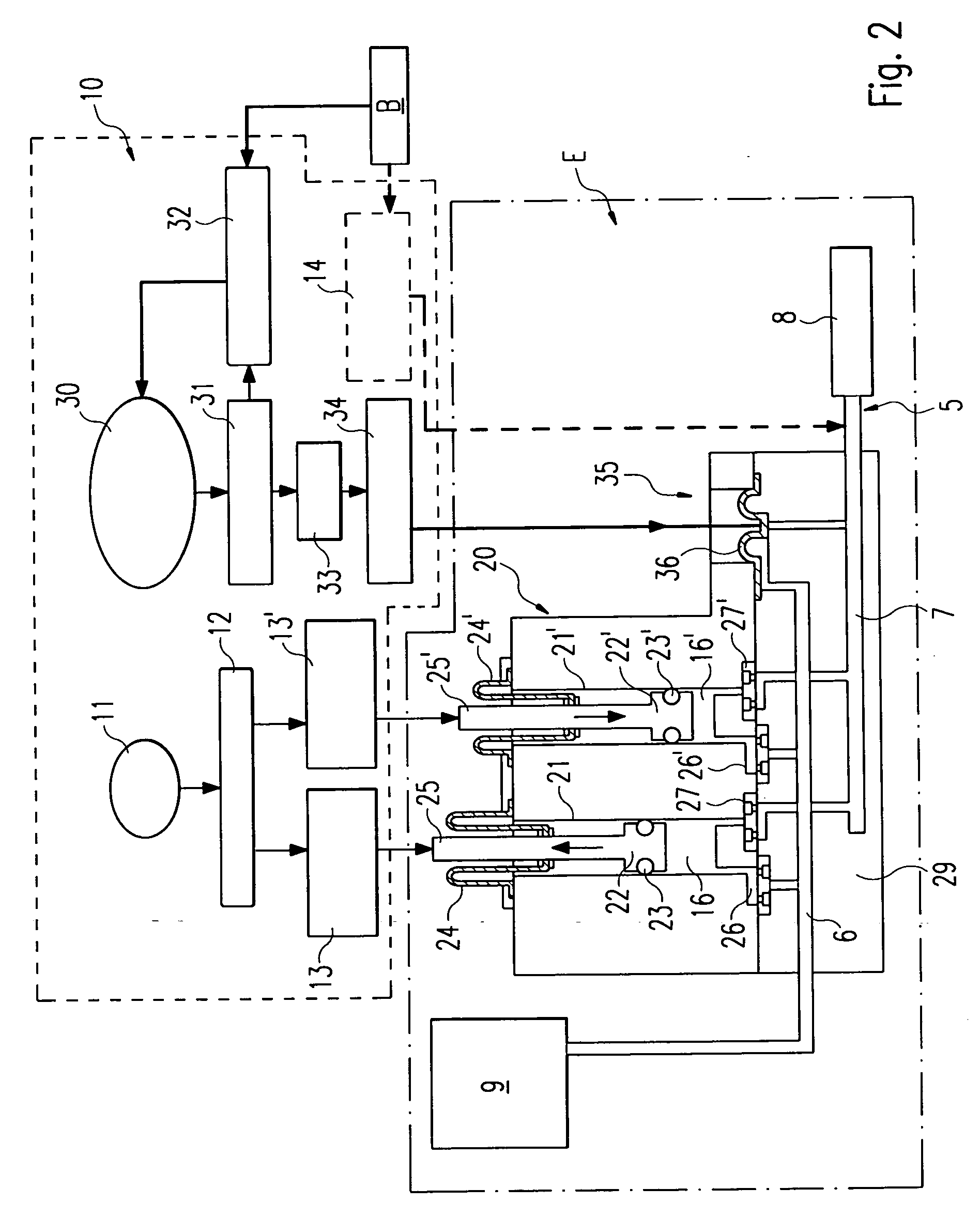

[0029]A pump actuation device 10 is intended for the embodiment of the invention shown in FIG. 1, which encompasses a motor control 15 for the control of two motors 11,11′, which are connected via gearing 12, 12′ and clutch devices 13, 13′ to the piston rods 25,25′. One operator B can operate the motor control 15 with suitable switches (foot switch or finger switch), so that the motors 11, 11′ displace the piston rods 25, 25′ and thus the pistons 22, 22′ in the cylinders 21, 21′ of pump unit 20 alternately via the described train, so that the volume of the pressure chambers 16, 16′ of the pump unit 20 is alternately enlarged and reduced.

[0030]In order to seal the pressure chambers 16, 16′ and the pistons 22, 22′ in relation to the cylinders 21, 21′ seals 23, 23′ are provided at the pistons 22, 22′. Moreover, the piston rods 25, 25′ maintain sterility with cup seals 24, 24′, which are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com