Method for preparing electroplating roller

A technology of electroplating drums and drums, which is applied in the direction of electrolysis process and electrolysis components, etc. It can solve the problems that the products cannot meet customer requirements and uneven coating, and achieve the effect of large loading capacity, simple drum structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

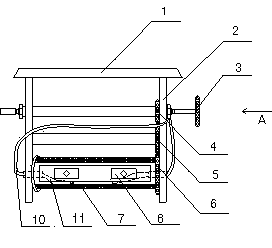

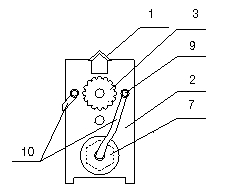

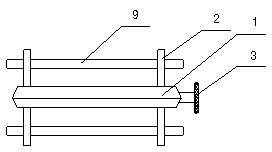

[0016] attached by figure 1 And attached figure 2 It can be seen that the drum designed in the present invention includes a suspender 1 and two support rods 9, and also includes two side plates 2, the suspender 1 is arranged on the top of the side plates 2, and a roller 7 is arranged between the two side plates 2. , one end of the drum 7 is provided with a drum gear 6, and the side plate on one side of the drum gear 6 is provided with a secondary gear 5 and a main gear 4, and the drum gear 6 is connected to the secondary gear 5 and the main gear 4 in turn, and the main gear is connected to the side plate 2 external power gears 3 are provided. When the power gear 3 rotates, it drives the main gear 4, the auxiliary gear 5, and the drum gear 6 to rotate, and finally drives the drum 7 to rotate. A cathode wire 10 is connected to each of the two support rods 9, and the two cathode wires 10 enter the drum 7 from both ends of the drum 7, and the drum 7 is respectively provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com