A control valve and an electric pressure cooker equipped with the valve

A technology for controlling valves and valve cores, applied in pressure cookers, kitchen utensils, household utensils, etc., can solve the problems of long time cooking, difficult boiling of food in the pot, affecting the taste of food, etc., to achieve the function of maintaining pressure and ensure the taste of food. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

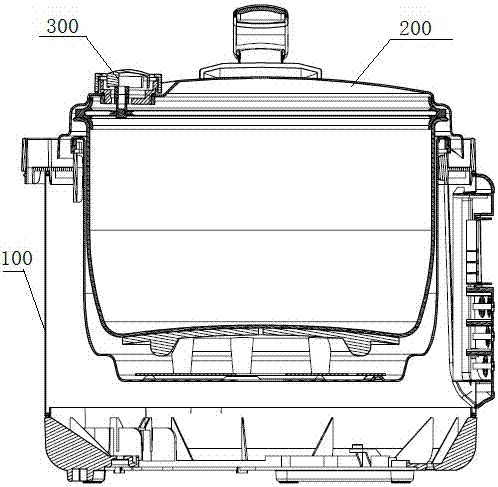

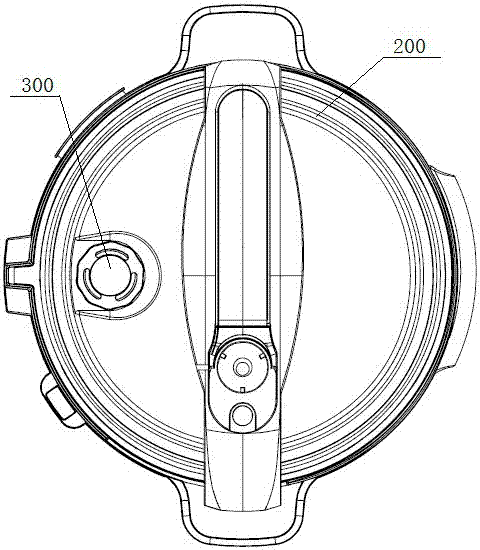

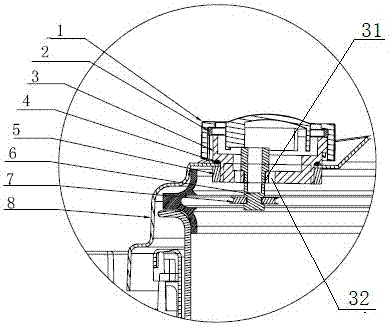

[0030] Such as Figure 1 to Figure 4 As shown, an electric pressure cooker includes a pot body 100 and a pot cover 200, the pot cover 200 is provided with a mounting hole, and a control valve 300 is embedded in the mounting hole, as image 3 , Figure 4 As shown, the control valve 300 includes a base 3 and a valve cover 1 buckled on the base 3, the base 3 and the valve cover 1 enclose a valve chamber, as Figure 9 , Figure 10 As shown, the base 3 is provided with a valve core hole 31 and an exhaust hole 32 communicating with the valve cavity, and the valve cavity is provided with a valve core 6, such as Figure 6 As shown, the spool 6 is cylindrical and includes two ends, respectively a first end 61 and a second end 62, wherein the diameter of the first end 61 is larger than the spool hole 31 on the base 3, and the second end The diameter of the portion 62 is smaller than the spool hole 31, therefore, the first end 61 of the spool 6 is located in the valve chamber, and the...

Embodiment 2

[0036] This embodiment has been further improved on the basis of Embodiment 1. The difference from Embodiment 1 is that the valve core 6 of this embodiment still includes two ends, the first end 61 is located in the valve chamber, and the second The two ends 62 protrude through the spool hole 31 , and the difference from the first embodiment is that the spool gasket 7 on the spool 6 is arranged inside the base 3 , that is, in the valve cavity.

[0037]When the bonnet 1 is rotated, the bonnet still has two positions: when it is in the first position, the spool 6 is blocked by the limit rib 12 and cannot move upwards, the pressure of the spool 6 on the limit rib 12 Move downwards so that the valve core gasket 7 is only attached to the vent hole 32 on the base, so that the air pressure in the pot body 100 cannot be discharged through the vent hole 32, and the air pressure in the pot body 1 increases, so that the food in the pot body 100 is in the Non-boiling state; when the valve...

Embodiment 3

[0040] This embodiment is partially improved on the basis of embodiment 1. The difference from embodiment 1 is that the control valve base 3 and the pot cover 200 are integrally formed in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com