A pressure-maintaining automatic internal support fixture and clamping method

An inner support fixture and pressure-holding technology, applied in the direction of expanding the mandrel, can solve the problem of inability to guarantee the local rigidity of the thin-walled parts processing area, and achieve the effect of simple structure, uniform inner support and large driving force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

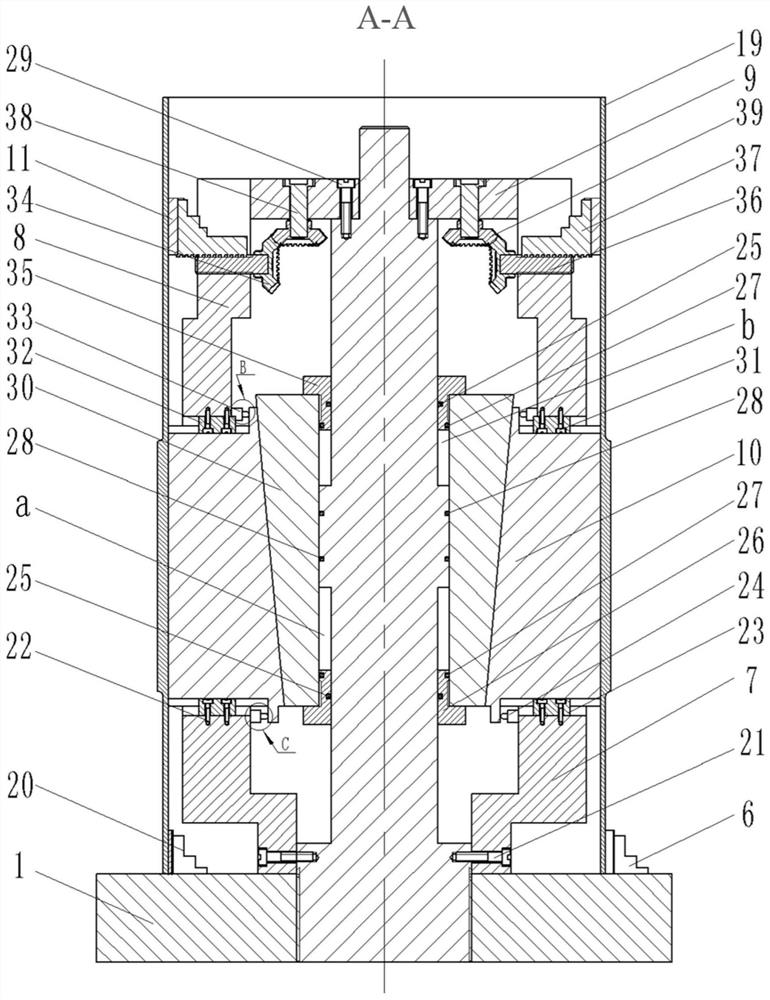

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

[0024] In the embodiment, the thin-walled cylindrical member 19 is made of 406A high-strength steel, with a diameter of 1000mm and a total length of 1800mm. It is formed by overall segmental spinning, and the wall is thin and uneven (the wall thickness of the front and rear cylindrical sections is only 3.5mm, and the wall thickness of the middle area to be processed is 8mm); the profile error is large, and the straightness error of the busbar in the middle area to be processed is only 1~3mm; the length of the area to be processed is 640mm, and its distance from the bottom surface of the workpiece is 520mm.

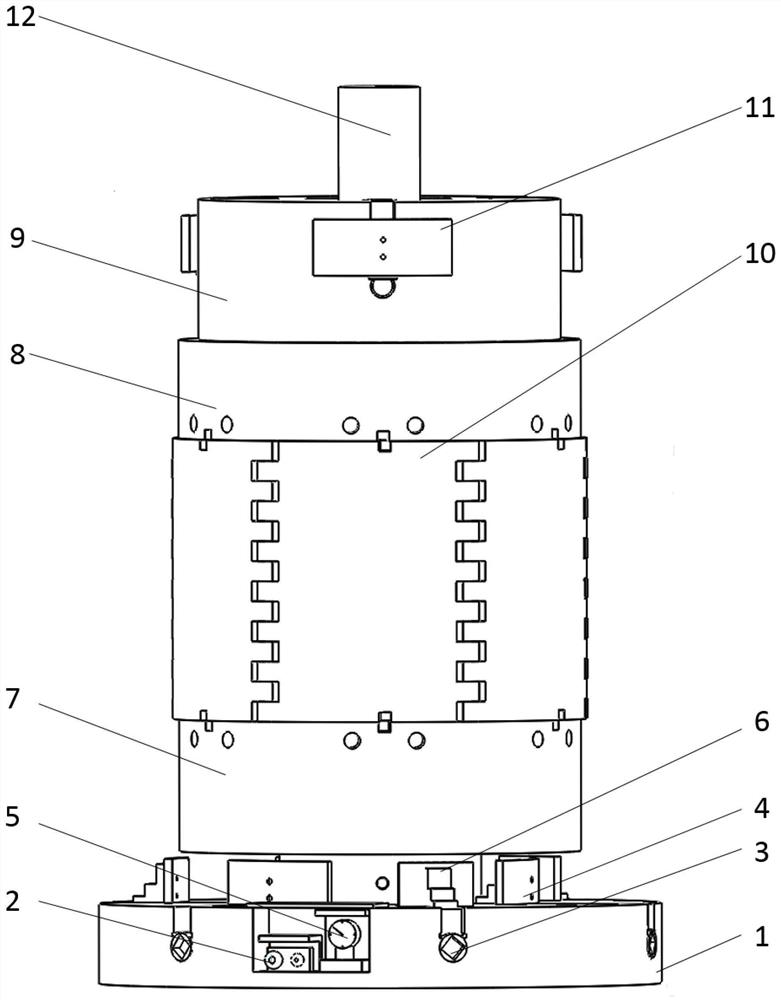

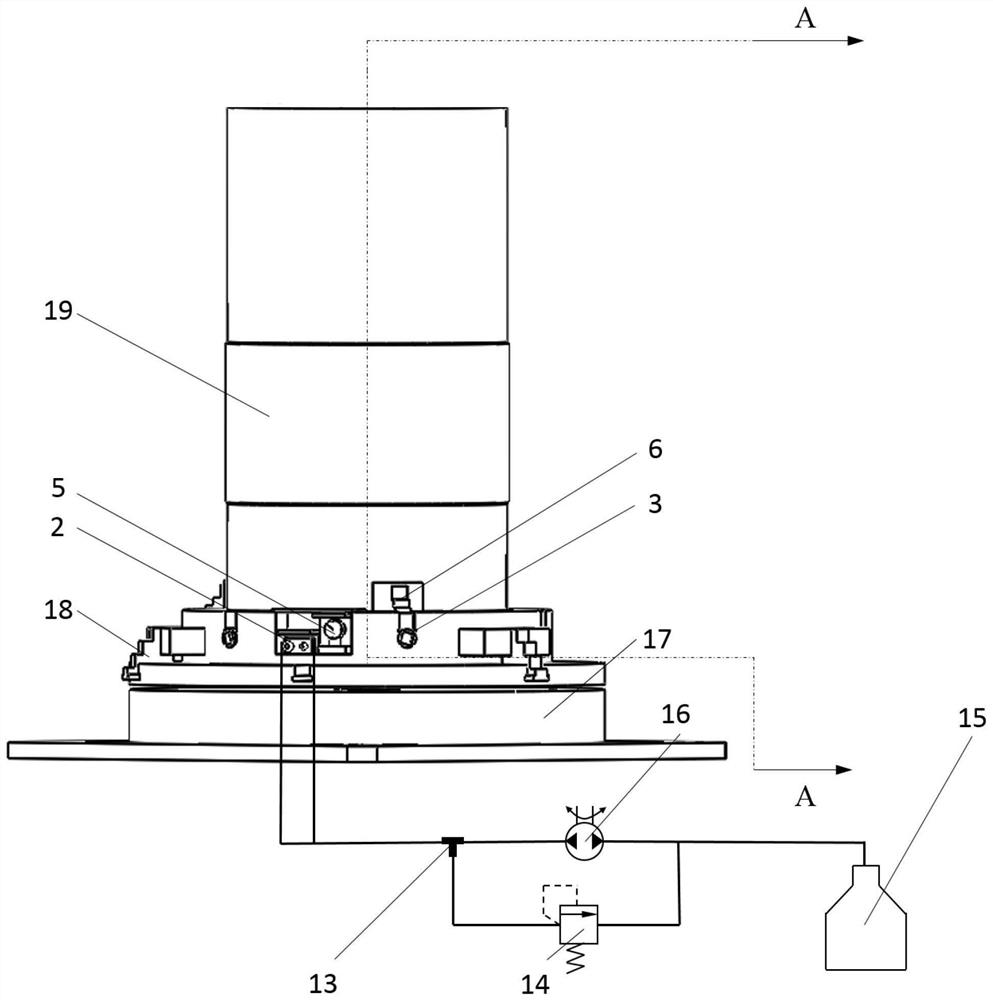

[0025] First, assemble the pressure-holding type automatic inner support fixture equipment, as attached figure 1 , 2 , 3 shown. The fixture is composed of a positioning clamping device, an auxiliary device, and a hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com