Electronic control pressure-maintaining mechanism of electronic mechanical brake and implementation method thereof

A braking motor and electronic control technology, applied in the direction of braking actuators, brakes, mechanical equipment, etc., can solve problems such as affecting the life of the motor, and achieve the effects of saving maintenance, fast timeliness, and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

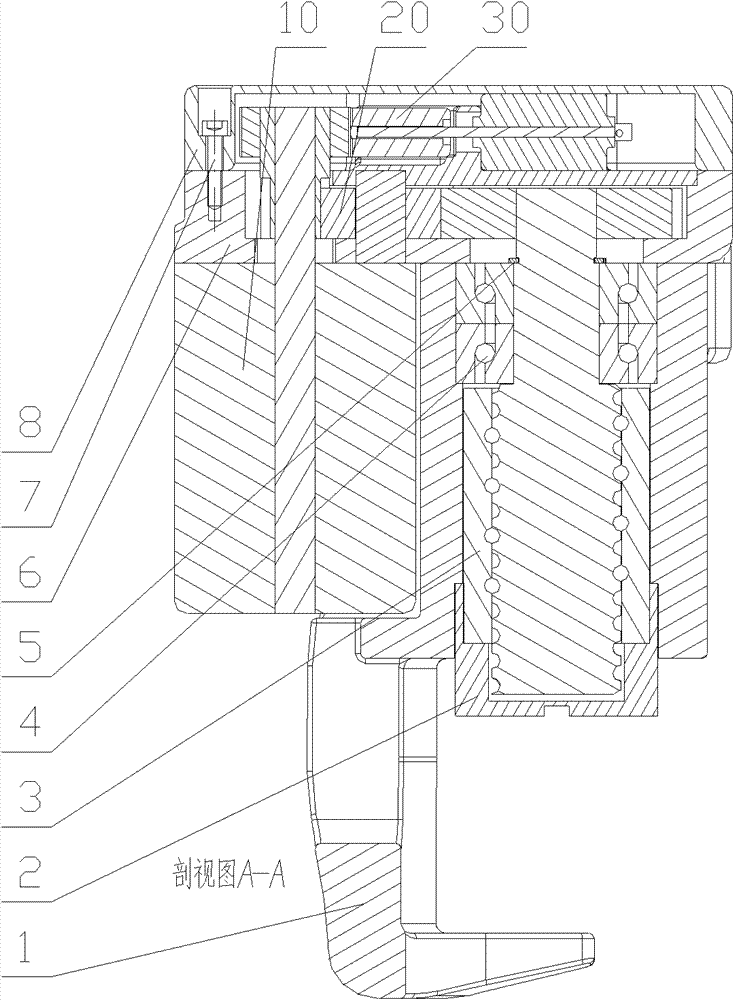

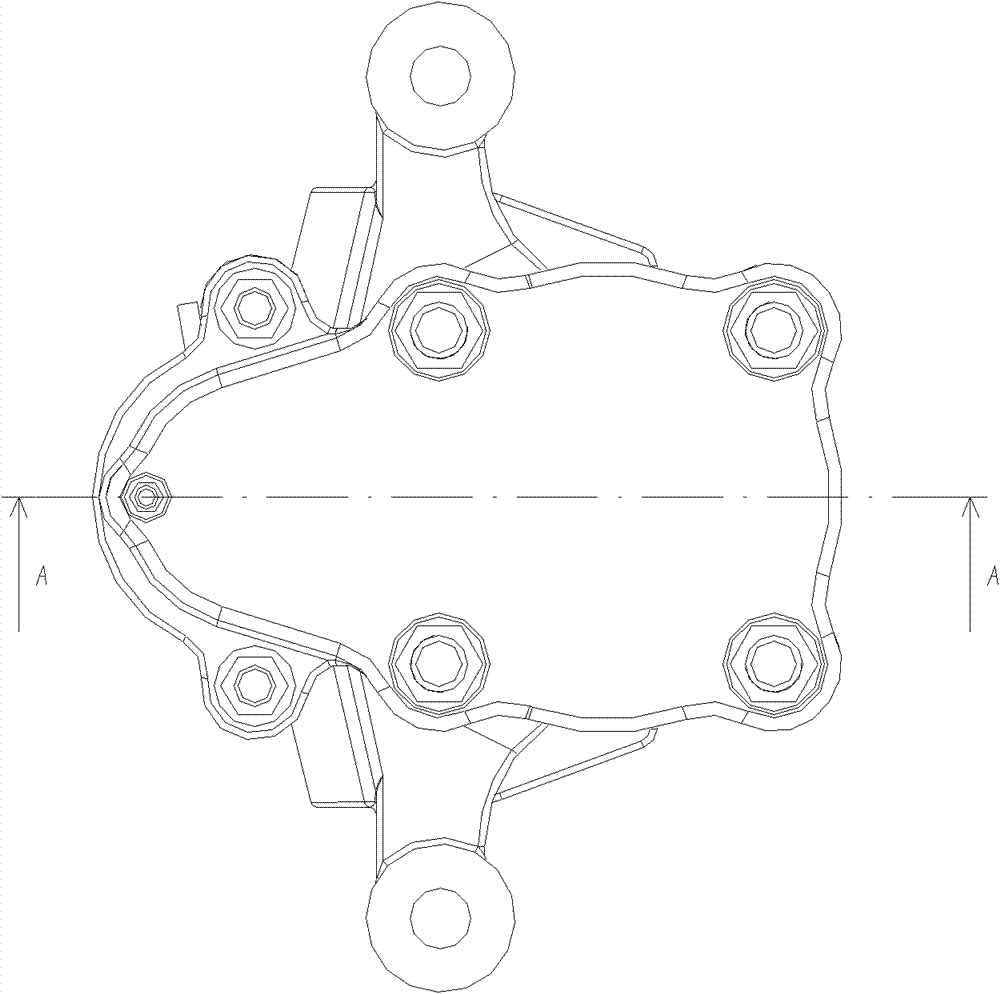

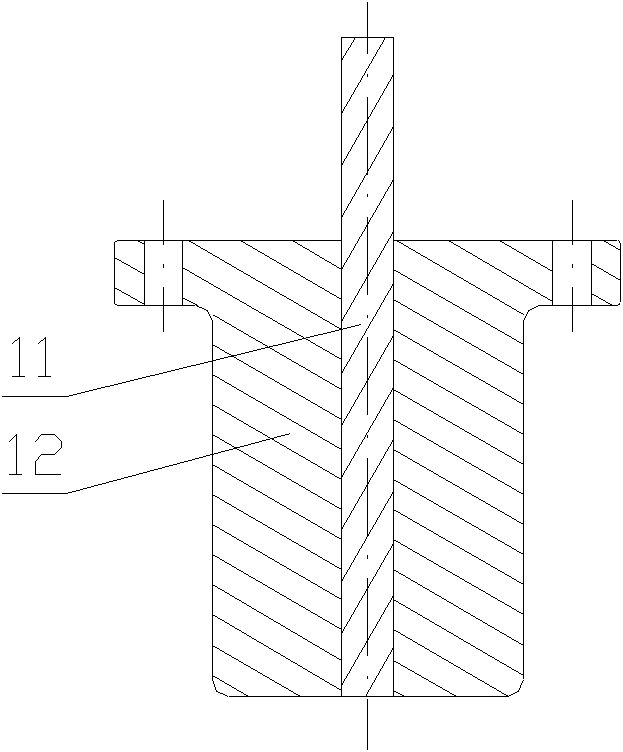

[0029] An electronically controlled pressure maintaining mechanism for an electromechanical brake proposed by the present invention and its implementation method will be described in detail below with reference to the accompanying drawings.

[0030] During the service braking process, when the ECU detects that the pedal displacement has changed within a certain range for a period of time, the system can determine that it needs to enter the pressure holding stage. At this time, the small motor rotates forward, and the threaded brushed motor mandrel rotates, pushing the self-locking nut and the hobbing slider to move forward in a straight line, so that the hobbing slider and the hobbing gear are occluded and locked. After the electronically controlled pressure holding is completed, the brake motor stops working, so that the brake will be braked with a constant braking force during the entire braking process. When it is necessary to end the constant braking force, as long as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com