Grass tumbling device driven by belt and capable of speed control

A control device, belt-driven technology, applied in hay tedders, applications, agricultural machinery and implements, etc., can solve the problems of limited tumbler uniformity, heavy labor, slow tumbler speed, etc., to protect precision and improve stability. performance and longevity, easy to adjust and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Attached below Figure 1-6 The present invention will be described in detail.

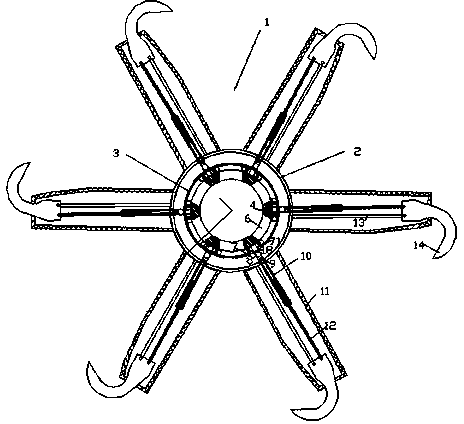

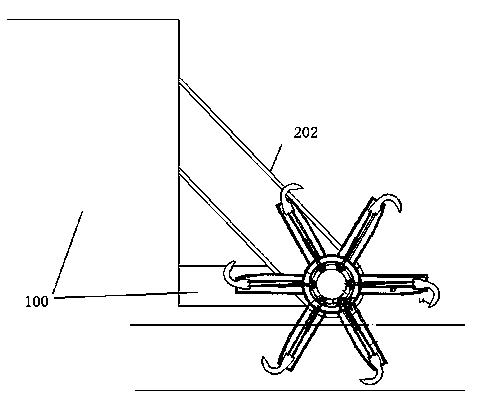

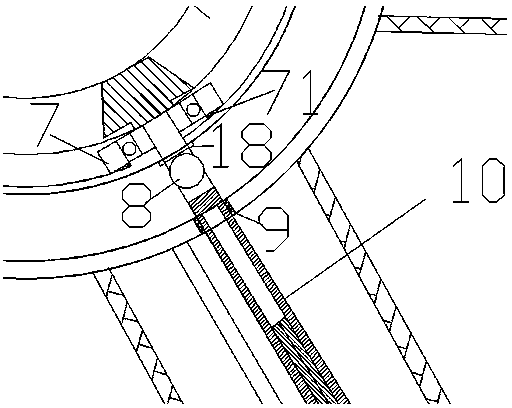

[0024] A forage tedding device driven by a belt and capable of speed manipulation, which includes an execution part and a connecting part, and the execution part is used for performing the tedding operation, which includes an outer support cylinder 2, an inner support cylinder 3 and six turning hook parts 1, and each flipping hook part 1 is evenly fixed on the cylindrical surface of the outer support cylinder 2 in the circumferential direction, and the six flipping hook parts 1 are fixed on the cylindrical surface of the outer support cylinder 2 In the circumferential direction of the shape, two pairs are arranged at intervals of 60 degrees, so that the six flipping hook parts 1 are evenly distributed in the circumferential direction of the cylinder of the outer support cylinder 2; It is connected to the agricultural vehicle 100, and the connecting part includes a power shaft 203, a turnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com