Easy-to-clean chopper mixer

A chopping machine and cleaning technology, applied in the field of chopping machines, can solve the problems that the chopping machine does not have a cleaning function, which affects the chopping and cutting operation, and leaves meat filling or meat puree in the chopping room.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

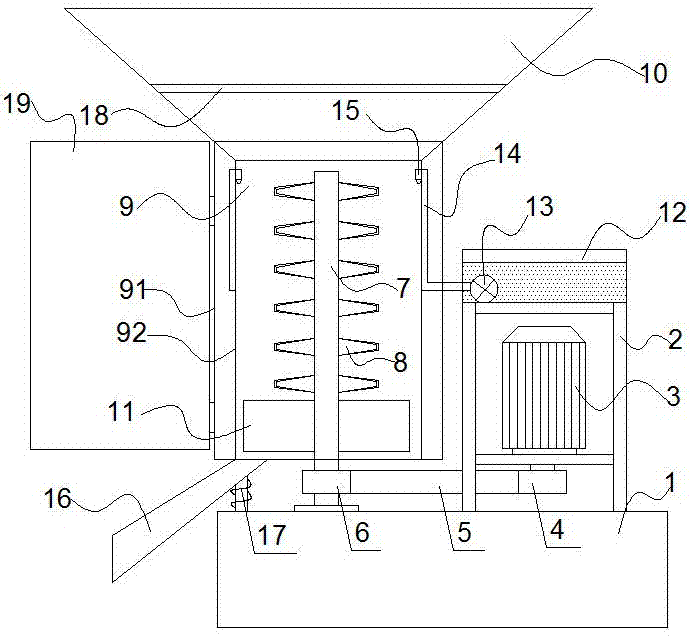

[0012] Such as figure 1 As shown, the invention discloses a chopping machine that is easy to clean, comprising: a base 1, a channel steel bracket 2, a channel steel bracket 2 welded and assembled is fixedly installed on the base base 1, and a channel steel bracket 2 on the channel steel bracket 2 The drive motor 3 is fixedly installed, the output shaft end of the drive motor 3 is fixedly connected to the drive pulley 4, and the drive pulley 4 is connected to the driven pulley 6 through the transmission belt 5, and the driven pulley 6 is fixedly arranged on the chopping shaft 7 , the chopping shaft 7 is vertically arranged, and the bottom end of the chopping shaft 7 is rotatably connected to the base 1, and the upper shaft section in the vertical direction of the chopping shaft 7 is arranged in the chopping chamber 9, And form the bottom surface of chopping and mixing chamber 9 to be rotationally connected.

[0013] The left and right ends of the outer circumferential shaft wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com