Meat piece rolling and mixing device for processing meat

A meat processing and meat block technology, which is applied in the fields of processing meat, application, and mixed meat equipment, etc., can solve the problem that the surface of the meat block cannot be completely wrapped and adhered, the meat marinating time is increased, and the efficiency of meat marinating processing is adversely affected. problem, to achieve the effect of increasing the efficiency of the pickling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

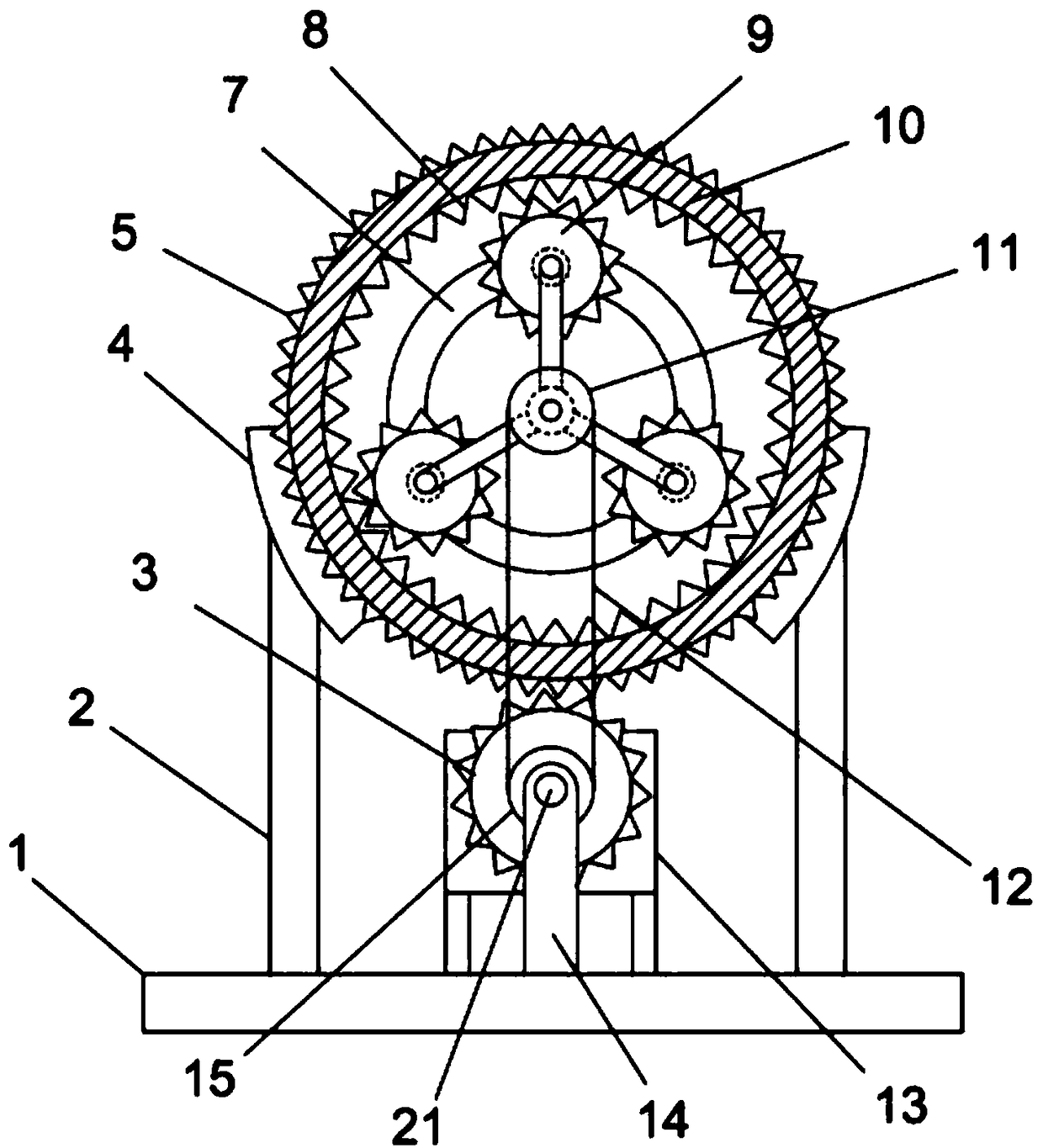

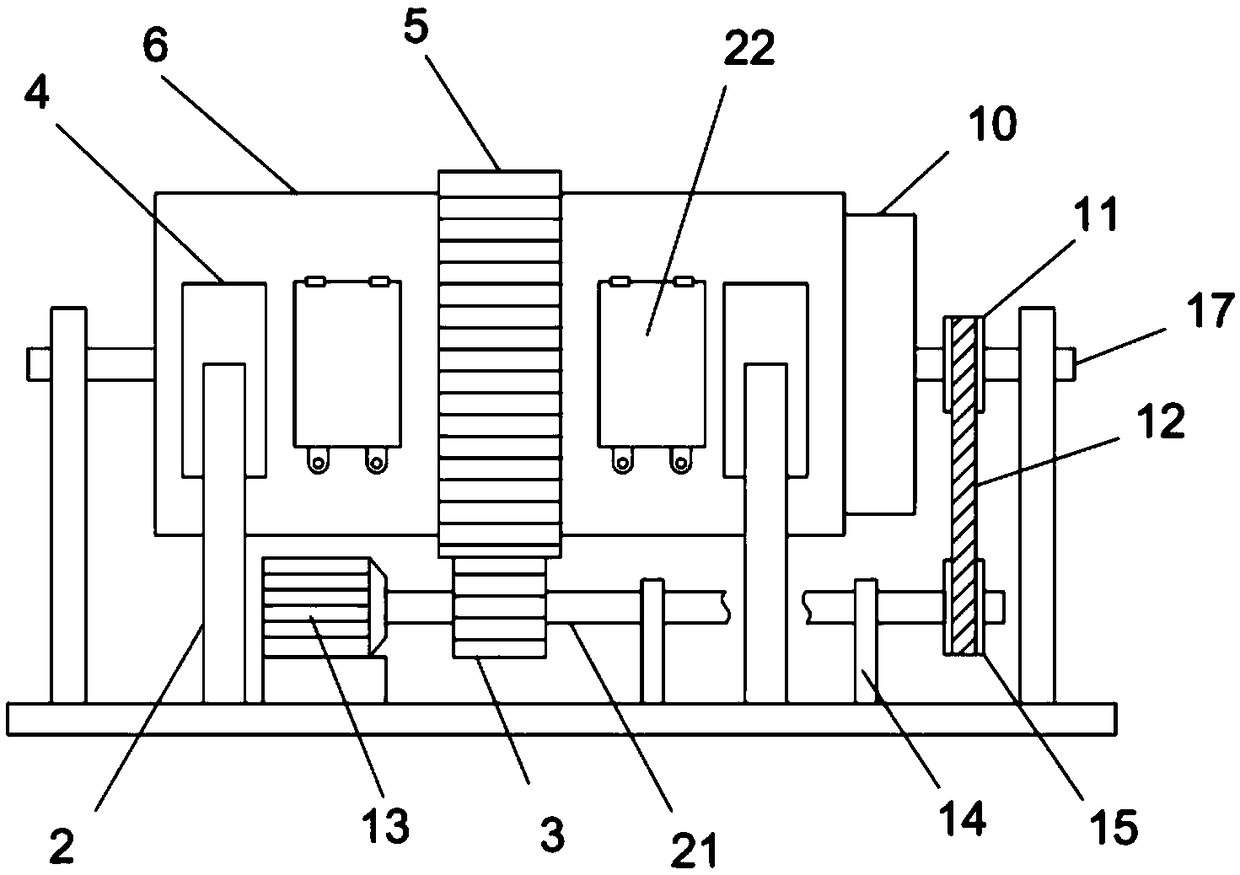

[0034] Open the dodge door 22 and pour the meat pieces and condiments into the mixing drum 6, start the drive motor 13 to drive the drive shaft 21 to rotate, the drive shaft 21 drives the drive gear 3 to rotate, and the drive gear 3 is connected to the external ring gear through meshing 5 drives the mixing drum 6 to rotate, and the rotation of the mixing drum 6 realizes the stirring and mixing of the meat pieces and seasonings inside it.

Embodiment 2

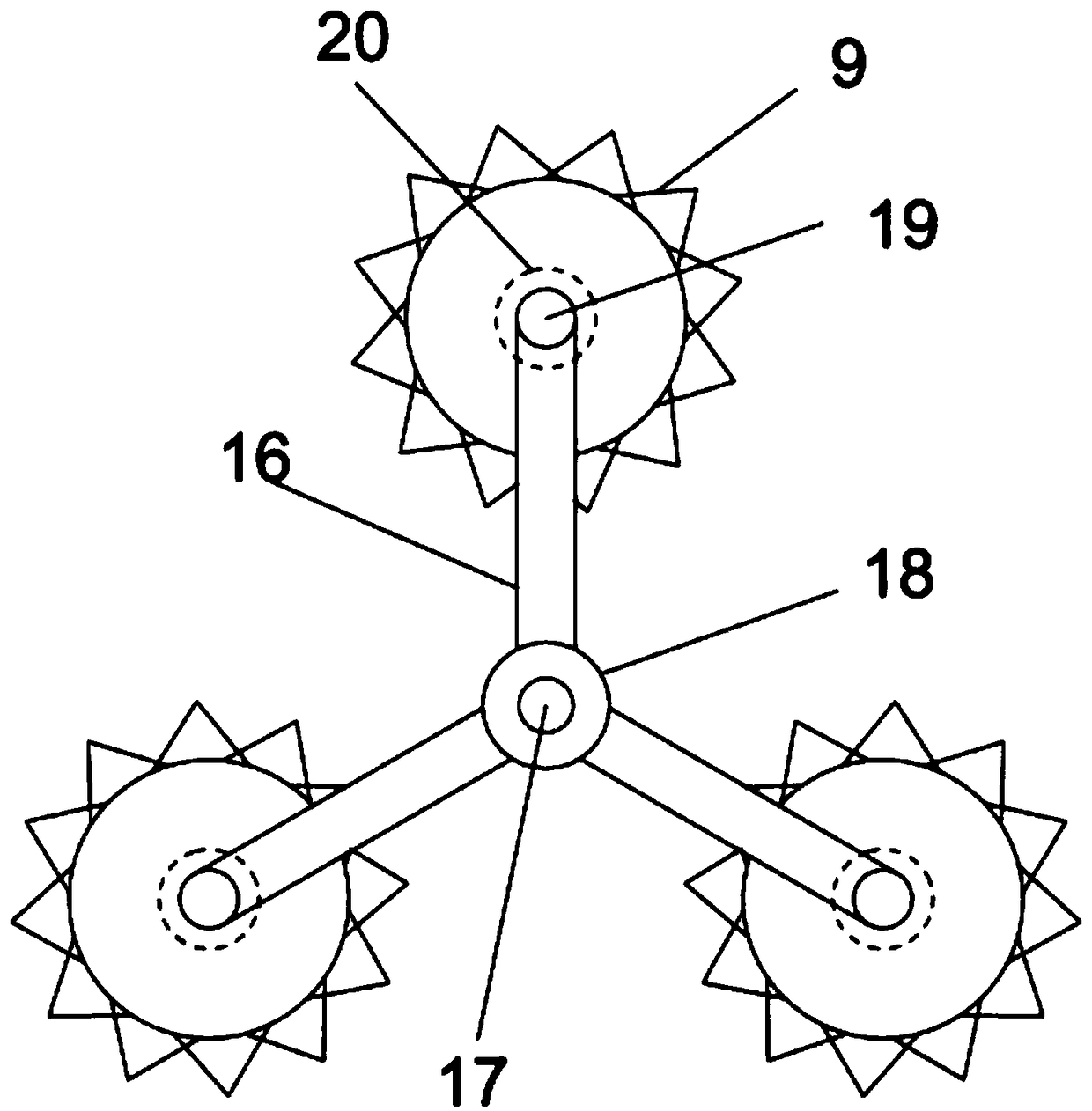

[0036] On the basis of Embodiment 1, since a mixing mechanism is also provided, the mixing mechanism includes a connecting collar 18 fixedly sleeved on the driven shaft 17, and the connecting collar 18 is fixedly equipped with Extended connecting rod 16, the number of connecting rods 16 is three, the connecting rod 16 is fixed on the side wall of the connecting collar 18 at a central angle of 120 degrees, and the end of the connecting rod 16 is rotatably provided with a secondary shaft 19, The auxiliary shaft 19 is coaxially fixed with a mixing rod 20, which drives the driving sprocket 15 to rotate during the rotation of the driving shaft 21, and the driving sprocket 15 drives the driven sprocket 11 to rotate through the roller chain 12, and the driven sprocket 11 rotates. Drive the driven shaft 17 to rotate, the driven shaft 17 drives the mixing mechanism to rotate, the connecting rod 16 of the mixing mechanism drives the auxiliary shaft 19 to rotate around the axis of the dri...

Embodiment 3

[0038] On the basis of Embodiment 2, it also includes a driven gear 9 that is fixedly installed on the surface of the auxiliary shaft 19 and is meshed with the ring gear 8. The mixing rod 20 runs through the limit guide slide hole 7 and extends horizontally to the mixing shaft. Inside the barrel 6, the surface of the mixing drum 6 is fixedly equipped with several turning straight plates 23 with equal central angles. The turning straight plate 23 is fixedly installed with a turning arc plate 24 at one end of the mixing rod 20. The plate 24 is an arc-shaped plate structure bent inward, and the outer arc surface of the material turning arc plate 24 is attached to the inner wall of the mixing drum 6; while the auxiliary shaft 19 rotates around the axis of the driven shaft 17, the driven gear 9. As the connecting rod 16 rotates, it meshes with the inner ring gear 8 and rotates to drive the auxiliary shaft 19 to rotate. The auxiliary shaft 19 drives the turning straight plate 23 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com