Minced meat processing device

A technology of processing device and minced meat, which is applied in the direction of processing meat, mixed meat equipment, slaughtering, etc., can solve the problems of laborious efficiency, high labor intensity, complicated operation, etc., and achieve the effect of improving work efficiency and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

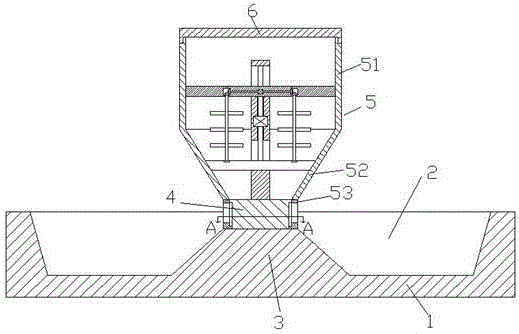

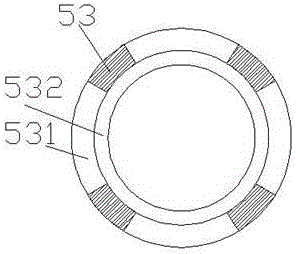

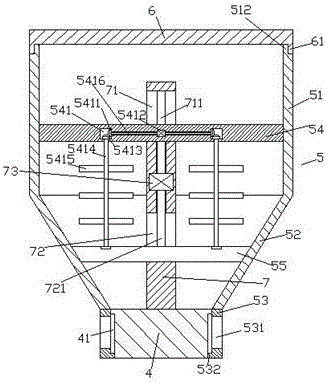

[0020] like Figure 1-Figure 5 As shown, a minced meat processing device of the present invention includes a pot body 1 and a container 5 arranged above the pot body 1. An arc groove 2 is arranged inside the pot body 1, and the inner middle part of the arc groove 2 is There is a top platform 3, the top of the top platform 3 is provided with a base 4, and the container 5 is composed of a first storage bin 51, a second storage bin 52 and a third storage bin 53, and the base 4. A sliding groove 41 is provided on the outside, and the third container 53 is sleeved on the outside of the base 4, and a convex ring 532 that enters into the sliding groove 41 and is slidingly fitted and connected is provided at the side of the inner bottom. , the outer walls on the four sides of the third container 53 are provided with slots 531, the top end surface of the base 4 is provided with a support column 7 extending upward, and the extended section at the top of the support column 7 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com