Method and system for preparing solid fuel through biomass fluidized bed roasting

A solid fuel and biomass raw material technology, applied in the field of baking and molding, and lignin-based biomass crushing, can solve the problems of low particle strength, achieve high energy consumption, reduce costs, and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

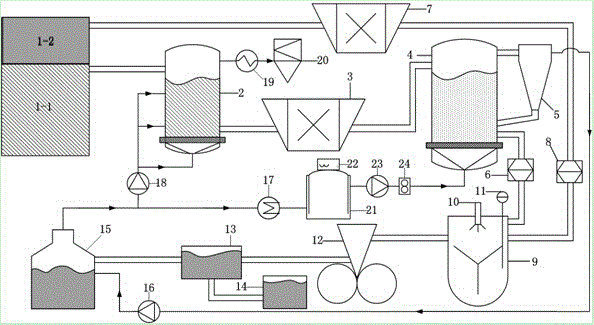

[0034] like figure 1 , 2 As shown, a biomass fluidized bed roasting system for preparing solid fuel includes a biomass pulverizing system, a fluidized bed roasting system, a biomass mixing molding system and a biomass burning system, and the biomass pulverizing system includes a first glass drying room 1-1 (i.e. drying room), dryer 2, second blower 18, gas cooler 19, bag filter 20 and pulverizer 3 for pulverizing biomass raw materials, in the biomass pulverizing system, the glass greenhouse There is a material output port. The dryer 2 is equipped with a material input port, a material output port, a gas input port and a gas output port. The material output port of the greenhouse 1-1 is connected with the material input port of the dryer 2 by a belt conveyor, and the material output port of the dryer 2 The port is connected with the pulverizer 3 input port by a pipeline belt conveyor, the gas input port of the dryer 2 is connected with the second blower 18 through a pipeline,...

Embodiment 2

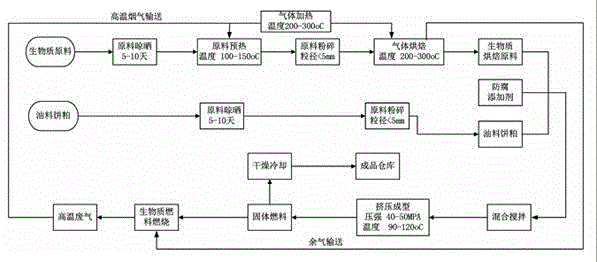

[0047] A process method for preparing solid fuel by biomass fluidized bed roasting, which is realized by the biomass roasting and molding system of the present embodiment above, and specifically includes the following steps:

[0048] (1) Biomass drying, preheating and crushing treatment: transport the camphor tree raw materials to the biomass drying room for drying by solar energy for 10 days, send the dried biomass raw materials to the biomass dryer, and pass through the high temperature generated during combustion. The exhaust gas preheats the biomass for 30 minutes, and the preheated biomass is transported to the pulverizer for crushing and sieving. The particle size of the pulverized biomass raw material does not exceed 5mm.

[0049] In the above process, the high-temperature exhaust gas preheated by biomass is transported to the dust collector for dust removal treatment;

[0050] (2) Biomass baking treatment: transport the pulverized biomass raw material to the inner cavi...

Embodiment 3

[0056] A process method for preparing solid fuel by roasting biomass in a fluidized bed, the method is realized by the system described in the above-mentioned embodiment 1, and specifically includes the following steps:

[0057] (1) Biomass drying, preheating and crushing treatment: the straw raw material is transported to the biomass drying room and dried by solar energy for 5 days, and the dried biomass raw material is sent to the biomass dryer to pass through the high temperature generated during combustion. The exhaust gas preheats the biomass for 10 minutes, and the preheated biomass is transported to the pulverizer for crushing and sieving. The particle size of the pulverized biomass raw material does not exceed 5mm.

[0058] In the above process, the high-temperature exhaust gas preheated by biomass is transported to the dust collector for dust removal treatment;

[0059] (2) Biomass baking treatment: transport the pulverized biomass raw material to the inner cavity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com