Carbide slag crushing device

A crushing device and technology of calcium carbide slag, which is applied in the direction of local agitation dryers, static material dryers, dryers, etc., can solve the problems of unsatisfactory degree of carbide slag crushing, affecting crushing work, and increasing work difficulty. Achieve the effect of improving drying effect, improving fluidity and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

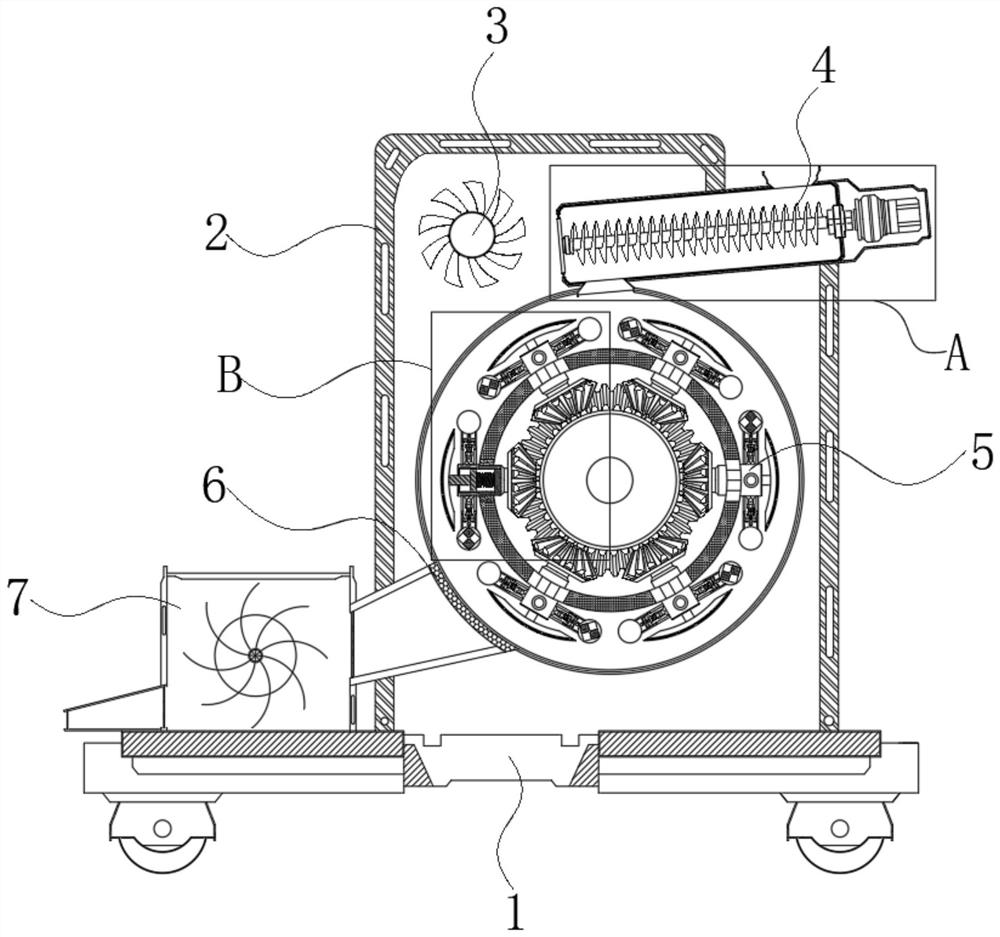

[0032] refer to figure 1 , the present invention provides a technical solution: a calcium carbide slag crushing device, including a base 1, a pre-drying assembly 4, a crushing assembly 5, and a drying chamber 7, wherein a plurality of The driving wheel is used to drive it to move. The outer casing 2 is fixed on one side of the upper end surface of the base 1, and the inner side of the outer casing 2 is provided with a cooling fan 3, so that the heat inside the outer casing 1 can be discharged ;

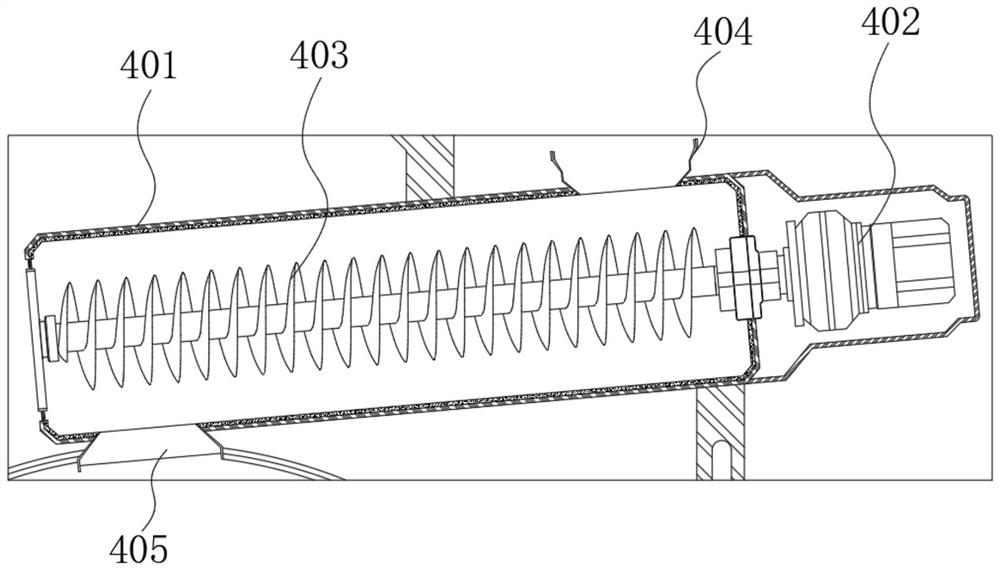

[0033] A pre-drying assembly is also provided through the inside of the outer box shell 2, and the pre-drying assembly 4 can perform primary drying treatment on the carbide slag placed therein. The discharge end of the pre-drying assembly 4 is connected to the Component 5 is connected;

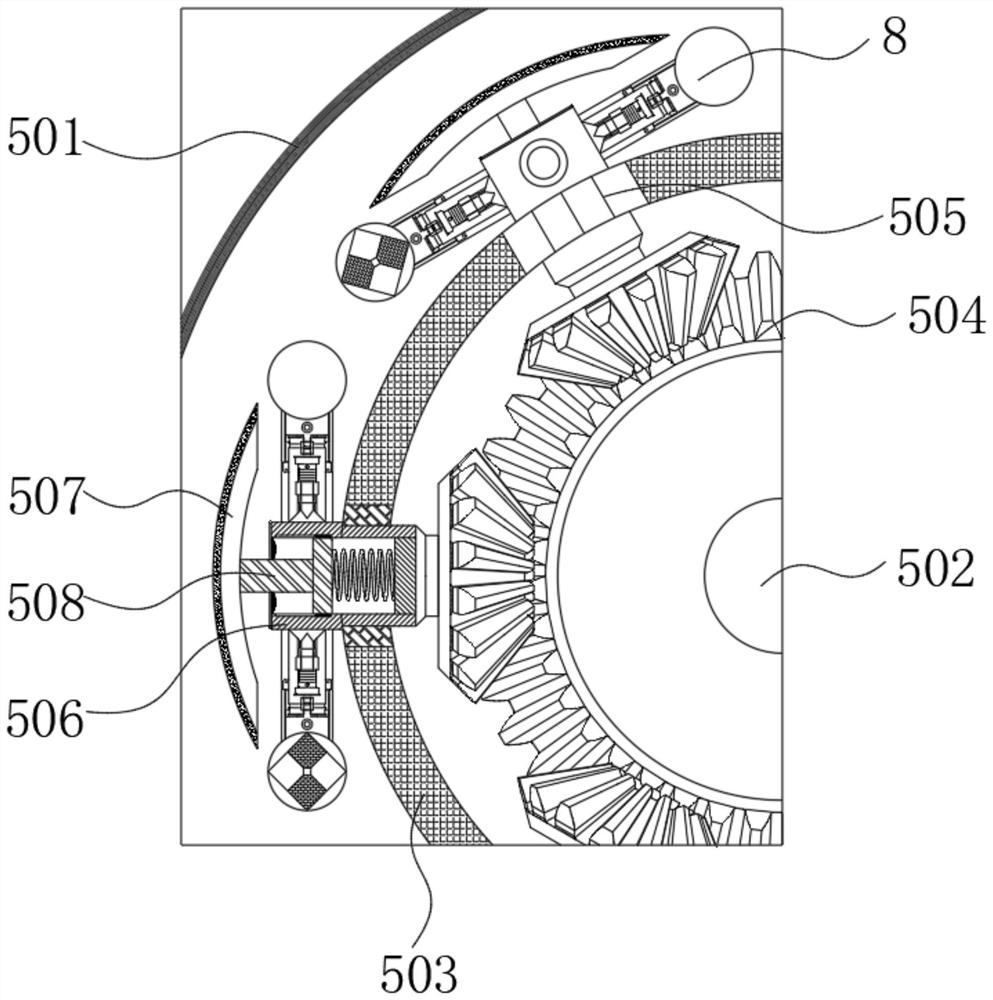

[0034] The discharge port of the crushing assembly 5 runs through the outer casing 2 and is connected to the drying chamber 7 fixed on the upper end surface of the base 1. The drying chamber 7 can p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com