Composite organic fertilizer dust-proof smashing device and control method thereof

The technology of a pulverizing device and organic fertilizer, which is applied in the direction of grain processing, can solve the problems of insufficient pulverization, increasing difficulty in the granulation process, and difficulty in meeting product requirements, so as to achieve the effect of improving the pulverization degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

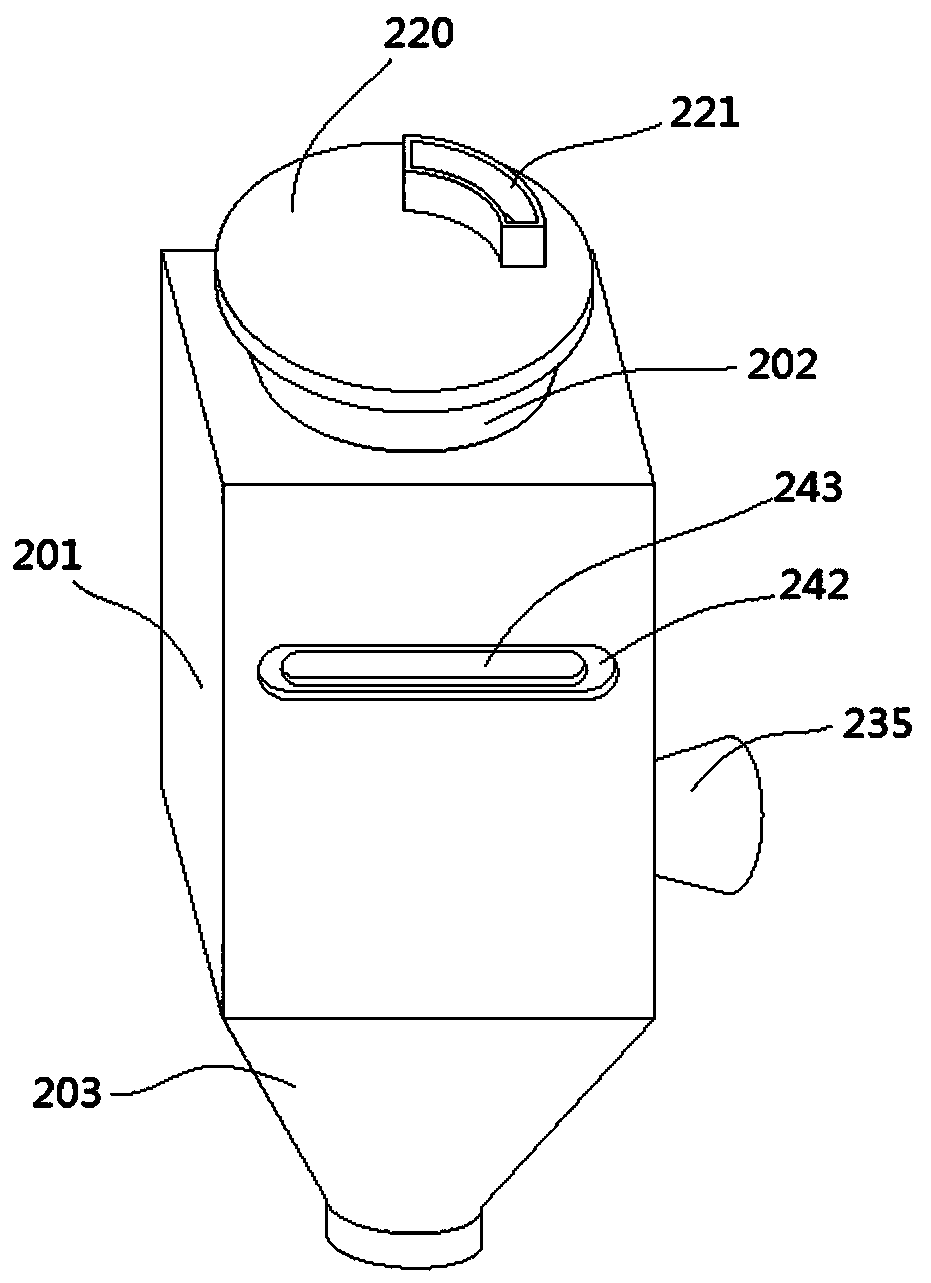

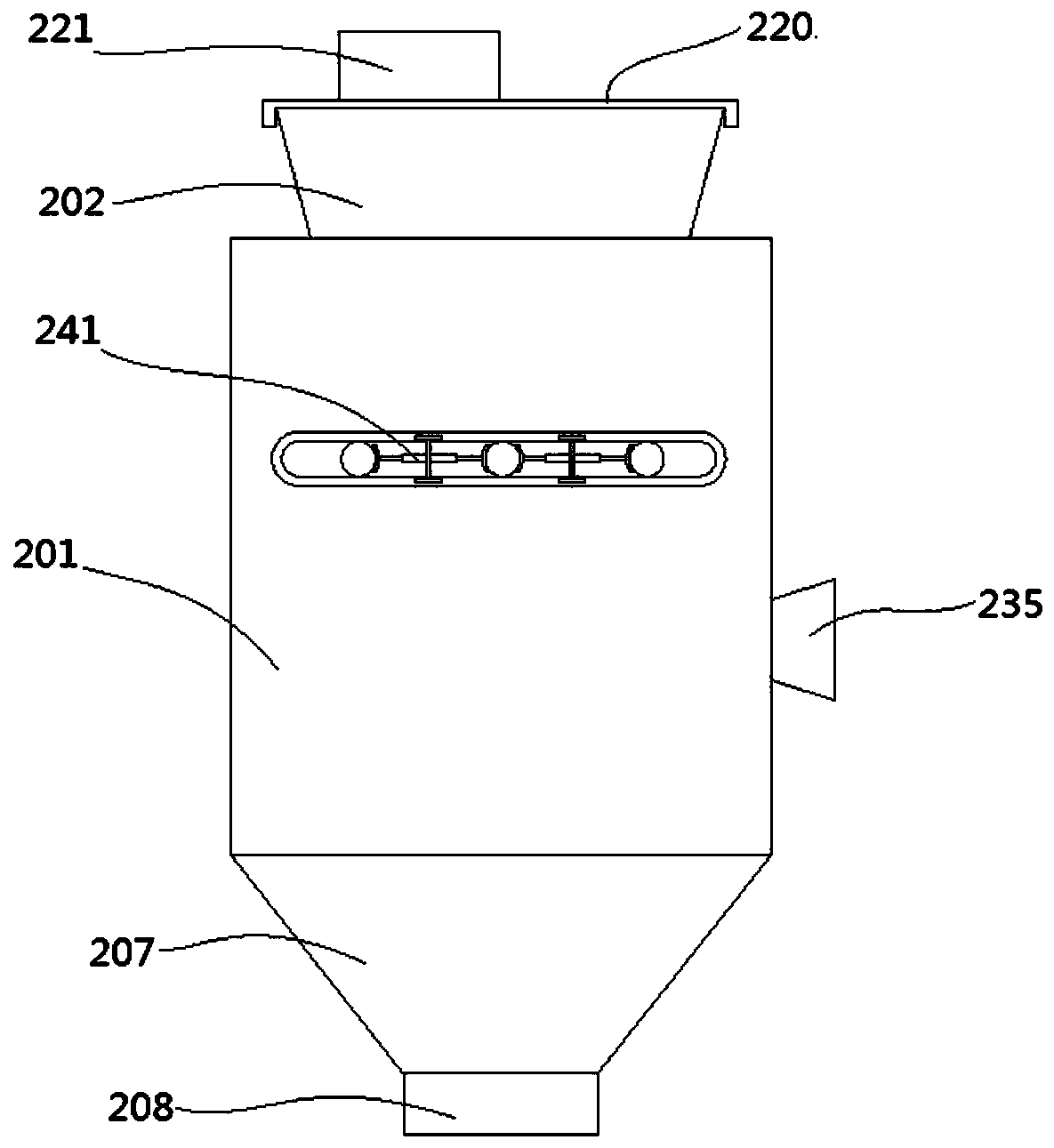

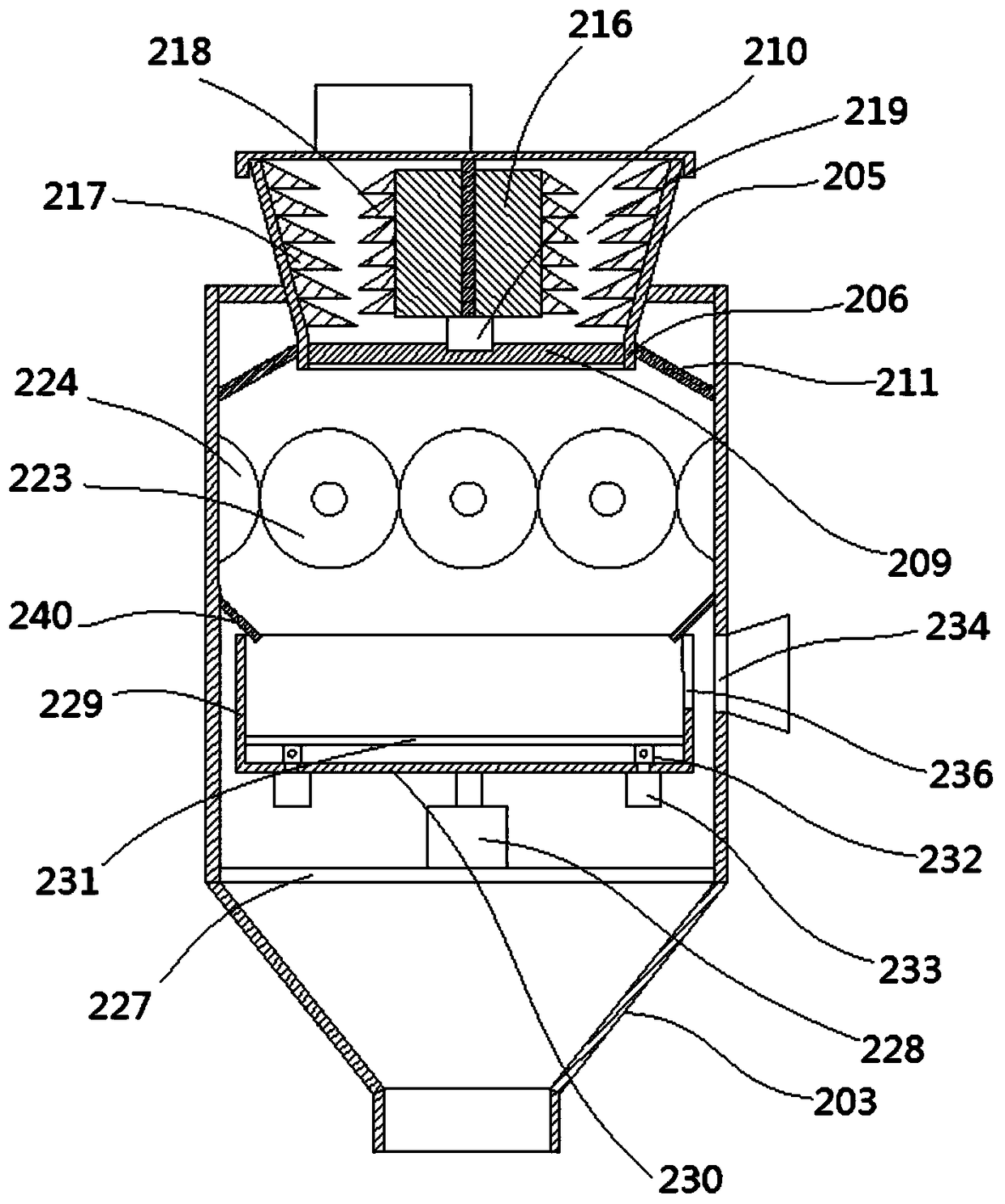

[0042] A compound organic fertilizer dustproof crushing device, such as Figure 1-Figure 9 As shown, it includes a crushing shell 201 in the shape of a square cylinder. The upper and lower ends of the crushing shell 201 are respectively provided with a feed section 202 and a discharge section 203. The feed section 202 is provided with a crushing mechanism 204. Section 202 includes a crushing section 205 that is a cone-shaped cylinder and an installation section 206 that is located above the crushing section 205 and is a cylindrical shell. The crushing section 205 and the installation section 206 are integrally formed and the crushing section 205 is from top to bottom The lower diameter gradually decreases; in addition, the discharge section 203 is fixed on the lower end surface of the crushing shell 201, and the discharge section 203 includes a diversion section 207 with a cone-shaped cylindrical structure and a diameter that gradually decreases and is located below the diversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com