Carbon fiber reinforced ethylene-propylene-diene monomer rubber anti-ablation material and preparation method

A technology of EPDM rubber and carbon fiber, which is applied in the field of thermal insulation materials for solid rocket motors, can solve problems such as incompatible chemical interfaces, easy migration of free substances, and interface damage, so as to improve quality, service life, and process matching , the effect of excellent ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope expressed in the examples.

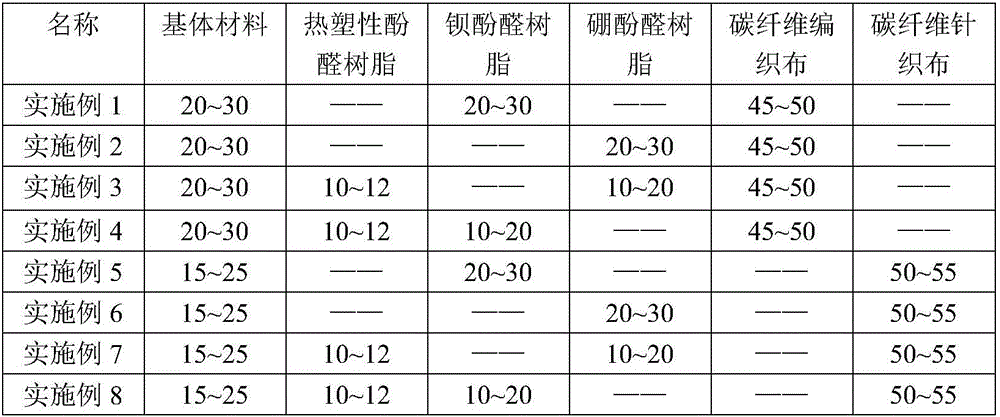

[0027] A carbon fiber-reinforced EPDM anti-ablation material, the formulation and component specifications of which are shown in Table 2, and the unit is parts by weight.

[0028]

[0029] Table 2

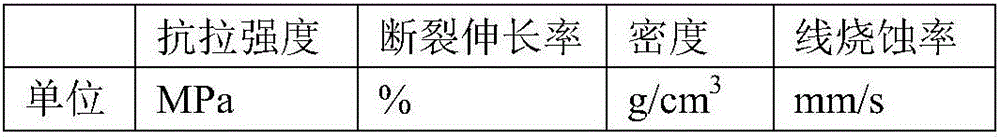

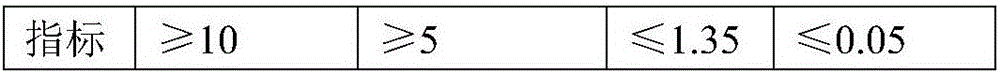

[0030] The EPDM base material described in the present invention is made of EPDM rubber, white carbon black, stearic acid, triethanolamine, accelerator M, accelerator TMTD, thermoplastic phenolic resin, settled sulfur or DCP, The conventional performance indicators of the prepared EPDM base material after vulcanization must meet the relevant requirements. The vulcanization temperature is 150°C, the time is 1h, and the pressure is 1MPa.

[0031] A method for preparing a carbon fiber reinforced EPDM anti-ablation material, the specific steps are:

[0032] 1) Base material prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com