Method for preparing unbleached pulp from sunflower seed shells

A technology of sunflower seed hulls and natural color pulp, which is applied in the direction of pulping with inorganic alkali, non-woody plant/crop pulp, chemical/chemical mechanical pulp, etc., to improve pulp quality, high degree of polymerization, and ease the pulping and papermaking industry The effect of raw material pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

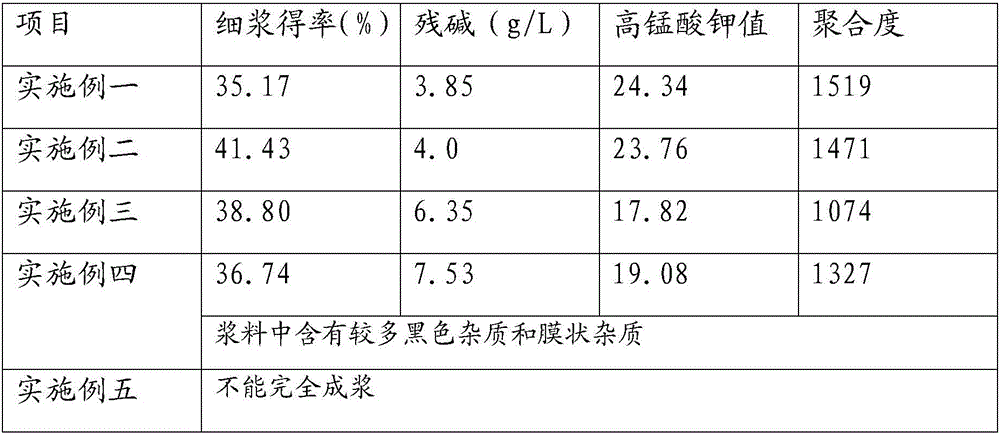

Examples

Embodiment 1

[0031] Buy raw sunflower seeds on the market, shell them manually, soak the raw sunflower seed shells in water at 40-50°C for 60 minutes, rub them, rinse them with water, squeeze out excess water with a filter, and dry them to control the water content at 8%-15%. Raw sunflower seed hull flakes are obtained. NaOH (as Na 2 (O meter) add-on is 17% (accounting for the wt% of dry raw material), Na 2 S (as Na 2 (O meter) add-on is 20% (accounting for the wt% of dry raw material), according to NaOH liquid and NaOH liquid 2 The volume ratio of S liquid is 1:3.5 to configure cooking liquid. Put 100g tablets (calculated on absolute dry mass) into small cooking pots in 4 layers, pour the prepared cooking liquid between the layers, and the pouring amount increases layer by layer from bottom to top, which are respectively the total cooking liquid 1 / 10, 1 / 5, 3 / 10, 2 / 5 of the volume of the liquid, sealed, shaken well, and immersed in a pool at a temperature of 60-70°C for 60 minutes, the...

Embodiment 2

[0033] Buy raw sunflower seeds on the market, shell them manually, soak the raw sunflower seed shells in water at 40-50°C for 60 minutes, rub them, rinse them with water, squeeze out excess water with a filter, and dry them to control the water content at 8%-15%. Raw sunflower seed hull flakes are obtained. NaOH (as Na 2 (O meter) add-on is 18.6% (accounting for the wt% of dry raw material), Na 2 S (as Na 2 (O meter) add-on is 20% (accounting for the wt% of dry raw material), according to NaOH liquid and NaOH liquid 2The volume ratio of S liquid is 1:3.5 to configure cooking liquid. Put 100g tablets (calculated by absolute dry mass) into small cooking pots in layers, pour the prepared cooking liquid between the layers, the amount of pouring increases layer by layer, seal, shake well, and place at a temperature of 60 Immerse in a water pool at -70°C for 60 minutes, and the frequency of shaking is 15 minutes. Put the small cooking pot directly into the rotary electric cooki...

Embodiment 3

[0035] Buy raw sunflower seeds on the market, shell them manually, soak the raw sunflower seed shells in water at 40-50°C for 60 minutes, rub them, rinse them with water, squeeze out excess water with a filter, and dry them to control the water content at 8%-15%. Raw sunflower seed hull flakes are obtained. NaOH (as Na 2 (O meter) add-on is 20% (accounting for the wt% of dry raw material), Na 2 S (as Na 2 (O meter) add-on is 22% (accounting for the wt% of absolute dry raw material), according to NaOH liquid and Na 2 The volume ratio of S liquid is 1:3.5 to configure cooking liquid. Put 100g tablets (calculated by absolute dry mass) into small cooking pots in layers, pour the prepared cooking liquid between the layers, the amount of pouring increases layer by layer, seal, shake well, and place at a temperature of 60 Immerse in a water pool at -70°C for 60 minutes, and the frequency of shaking is 15 minutes. Put the small cooking pot directly into the rotary electric cookin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com