Production method for preparing chemimechanical pulp by synergy of biological enzyme and alkali

A production method and biological enzyme technology, applied in the field of pulping and papermaking, can solve the problems of low utilization efficiency of biological enzymes, high pulping resistance, low pulp strength, etc. The effect of high pulp strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

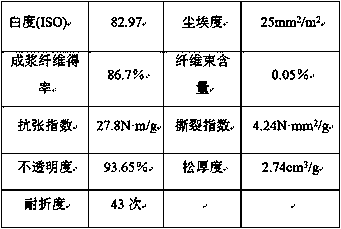

Embodiment 1

[0042] Example 1 A production method for the synergistic preparation of chemical mechanical pulp by biological enzyme and alkali

[0043] (1) Raw material pretreatment: Add poplar wood chips to pulp washing water for soaking and softening, add pulp washing water to wet the wood chips in the feeding tank by spraying, the temperature is 50-70 ° C, and the treatment time is 30 minutes;

[0044] The pulp washing water is the waste water obtained in the press dehydration step of the process, the pH is 9-10, and the content of hydrogen peroxide is 0.8-0.9%;

[0045] (2) Biological enzyme treatment: put the pretreated wood chips into the alkaline biological enzyme storage tank for treatment, the treatment temperature is 40°C, and the treatment time is 60 minutes. at 40%;

[0046]The alkaline biological compound enzyme, by weight ratio, comprises: 40% xylanase, 40% cellulase, 20% pectinase;

[0047] (3) Pre-steaming: In the pre-steaming chamber, add NaOH with a concentration of 30% ...

Embodiment 2

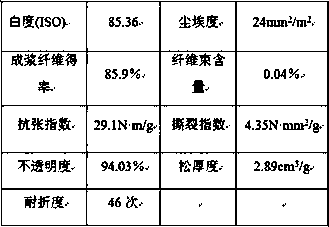

[0063] Embodiment 2 A kind of production method of bio-enzyme and alkali synergistically preparing chemical mechanical pulp

[0064] (1) Raw material pretreatment: Add poplar wood chips to pulp washing water for soaking and softening, add pulp washing water to wet the wood chips in the feeding tank by spraying, the temperature is 55°C, and the processing time is 35 minutes;

[0065] The pulp washing water is the waste water obtained in the press dehydration step of the process, the pH is 9.2, and the content of hydrogen peroxide is 0.85%;

[0066] (2) Biological enzyme treatment: the pretreated wood chips enter the alkaline biological enzyme storage tank for treatment, the treatment temperature is 35°C, and the treatment time is 70 minutes. After adding water and washing, they enter the thickening tank and dehydrate through inclined spirals to control the water content of the wood chips by 40%. ;

[0067] The alkaline biological compound enzyme, by weight ratio, comprises: 40...

Embodiment 3

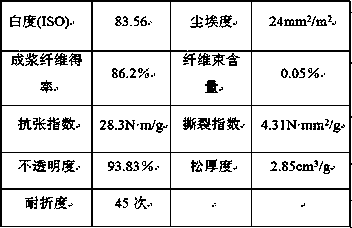

[0094] Embodiment 3 A kind of production method of synergistically preparing chemical mechanical pulp with biological enzyme and alkali

[0095] (1) Raw material pretreatment: Add poplar wood chips into pulp washing water for soaking and softening, add pulp washing water to wet the wood chips in the feeding tank by spraying, the temperature is 70°C, and the treatment time is 35 minutes;

[0096] The pulp washing water is the waste water obtained in the press dehydration step of the process, with a pH of 9.9, and wherein the content of hydrogen peroxide is 0.9%;

[0097] (2) Biological enzyme treatment: the pretreated wood chips enter the alkaline biological enzyme storage tank for treatment, the treatment temperature is 40°C, and the treatment time is 60 minutes. %;

[0098] The alkaline biological compound enzyme, by weight ratio, consists of: 40% xylanase, 35% cellulase, 25% pectinase;

[0099] (3) Pre-steaming: In the pre-steaming chamber, add NaOH solution with a mass conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com