Method for preparing pulp using fresh palm empty fruit bunch and equipment thereof

A technology for palm fruit and palm, which is applied to the field of pulping preparation of fresh palm fruit bunches, can solve the problems of inability to effectively remove residual fruit and non-fibrous skin components, large water consumption, and reduce chemical consumption and production efficiency. High, high removal rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

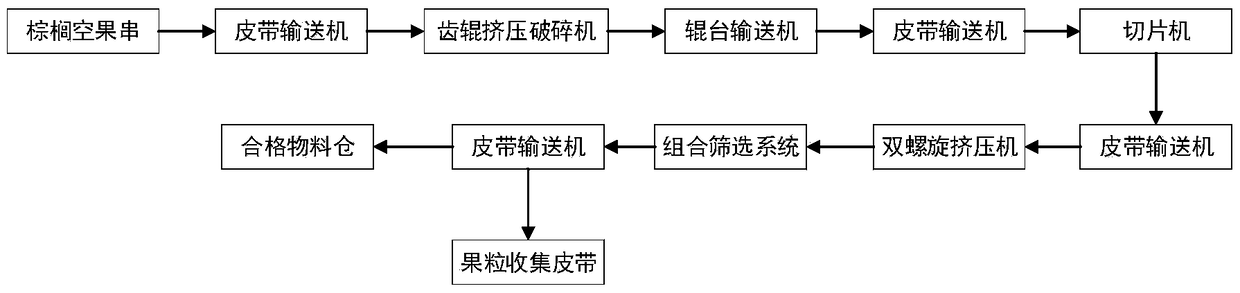

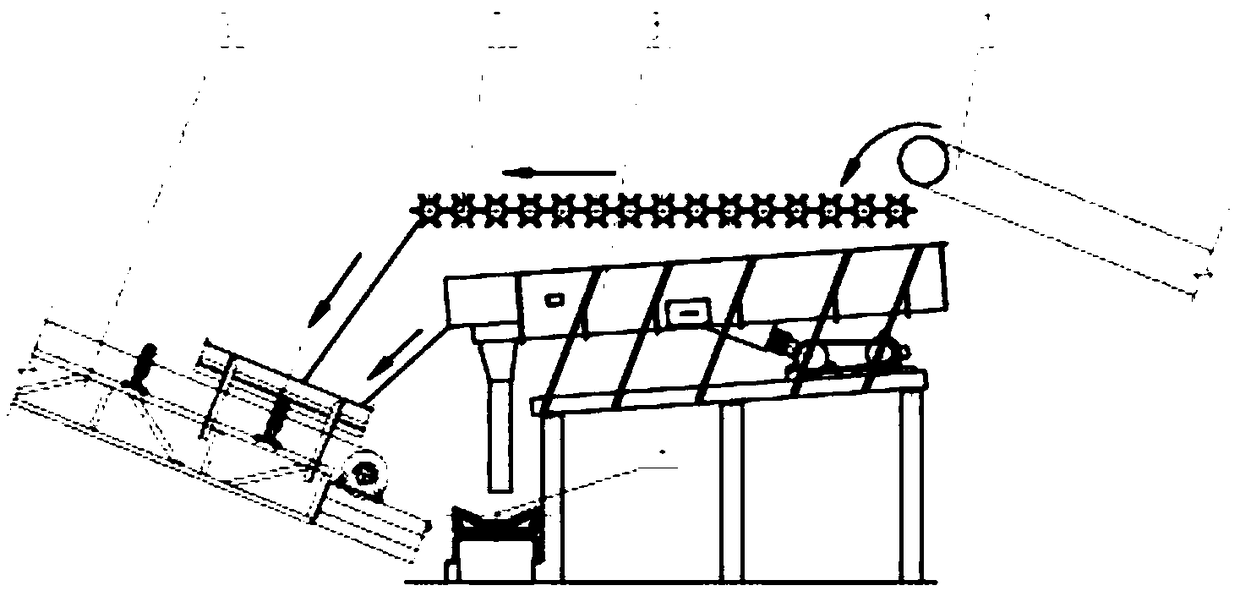

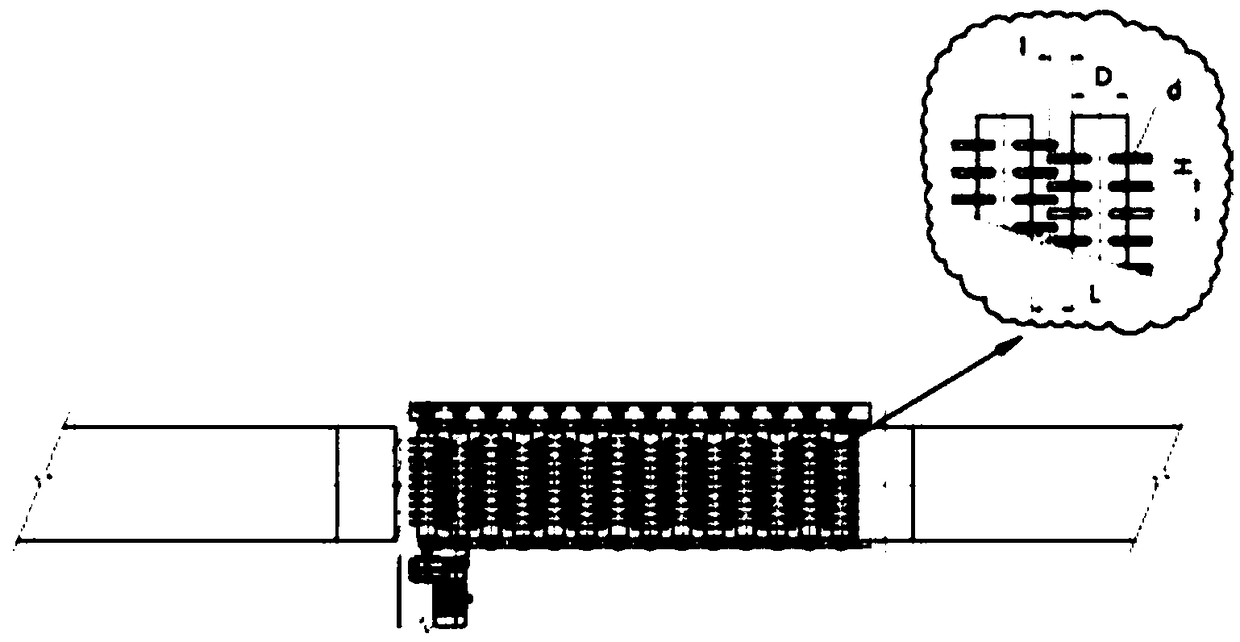

[0035]The fresh empty palm fruit bunches are first sent to the toothed roller crushing machine by the belt conveyor, and the ripe and unshed palm fruit grains on the palm fruit bunches are dropped by the squeezing and tearing effect of the upper and lower toothed rollers, and then sent to the rollers Conveyor, so that components such as the fallen palm fruit and some debris fall from the gap between the rollers of the roller table conveyor (the gap width is 30mm) to the collection belt conveyor below to remove the fallen palm fruit, Peel and debris. The palm fruit bunches on the roller conveyor are sent to the slicer for cutting (cutting size is 3-6cm, and the slicer can choose a grass cutter), and the chopped fruit bunch fibers are then extruded by a twin-screw extruder (compression ratio of 4:1), to remove part of the free water and residual oil in the palm fruit bunch, and at the same time, use the mutual extrusion and kneading effect between the materials in the screw extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com