Plugging and monitoring device for grouting material insteel bar grouting joint

A monitoring device and grouting material technology, which are applied in the direction of measuring device, lubrication indicating device, construction material processing, etc., can solve the problems of difficult joint sealing, reliable sealing of grouting material, environmental pollution on site of grouting material, and easy occurrence of grouting leakage, etc., so as to improve the connection strength. and connection quality, improve construction efficiency and work quality, and improve the effect of ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Some specific embodiments of the present invention will be described in detail below in an exemplary and non-limiting manner with reference to the accompanying drawings. The same reference numerals in the drawings designate the same or similar parts or parts. It should be understood by those skilled in the art that these drawings are not necessarily drawn to scale.

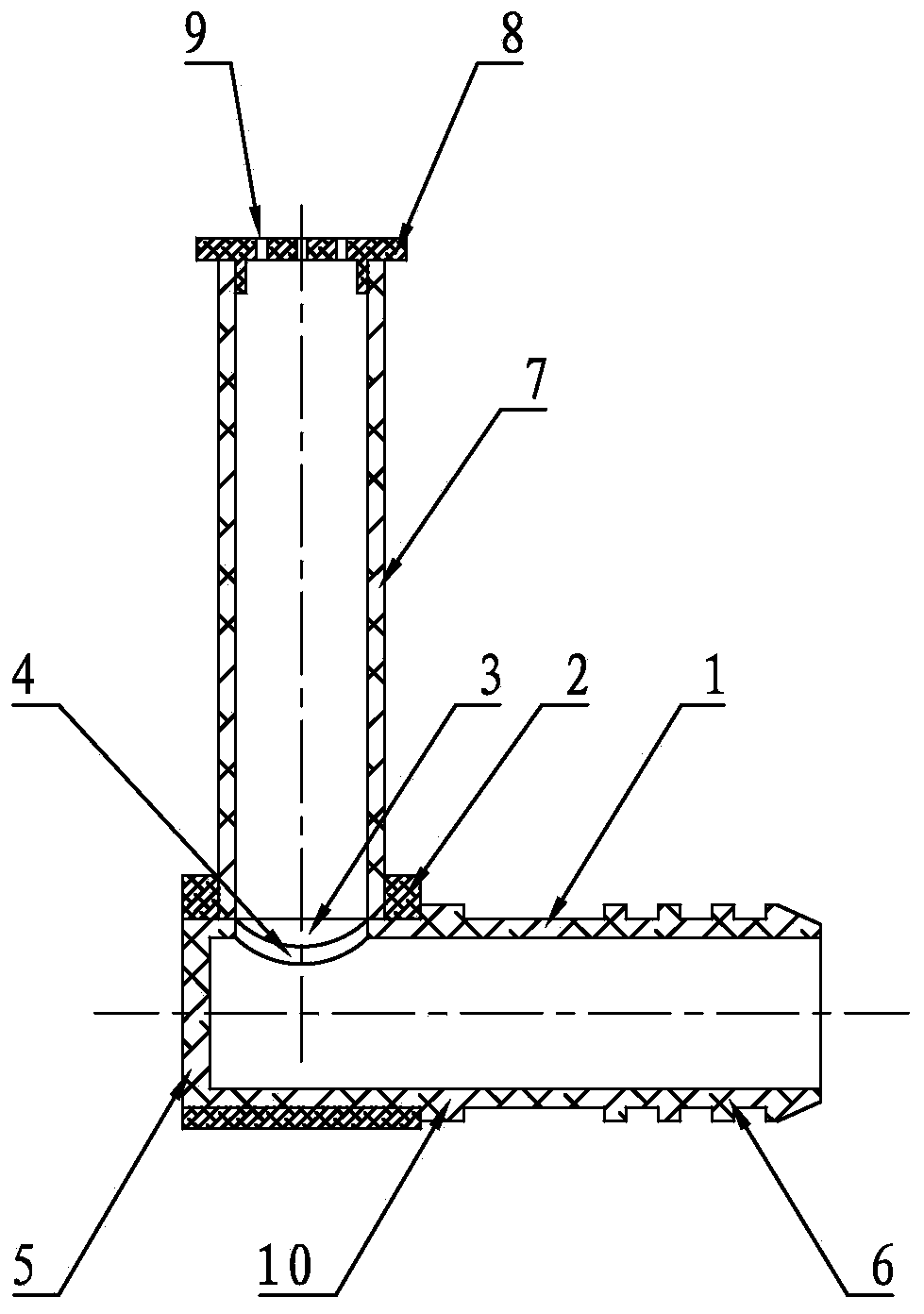

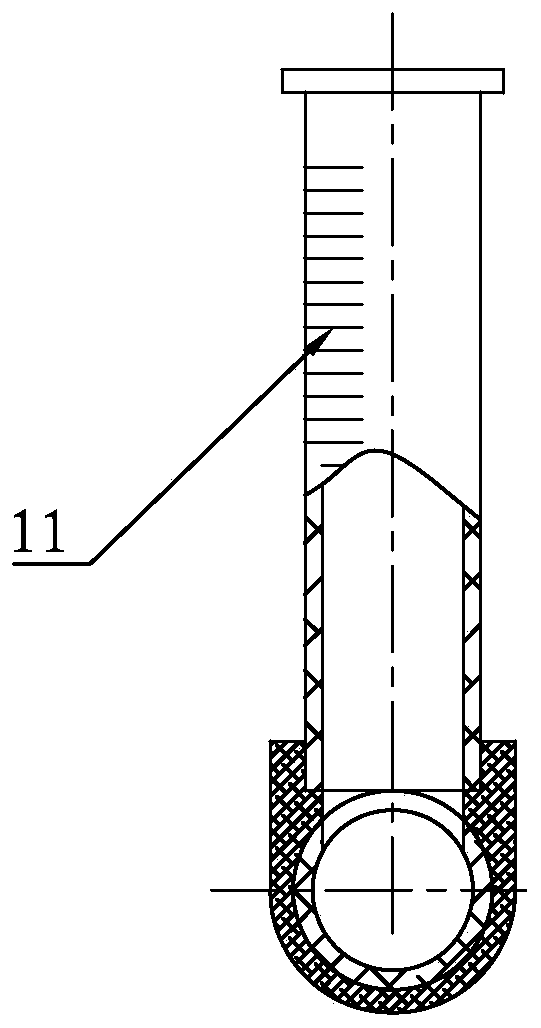

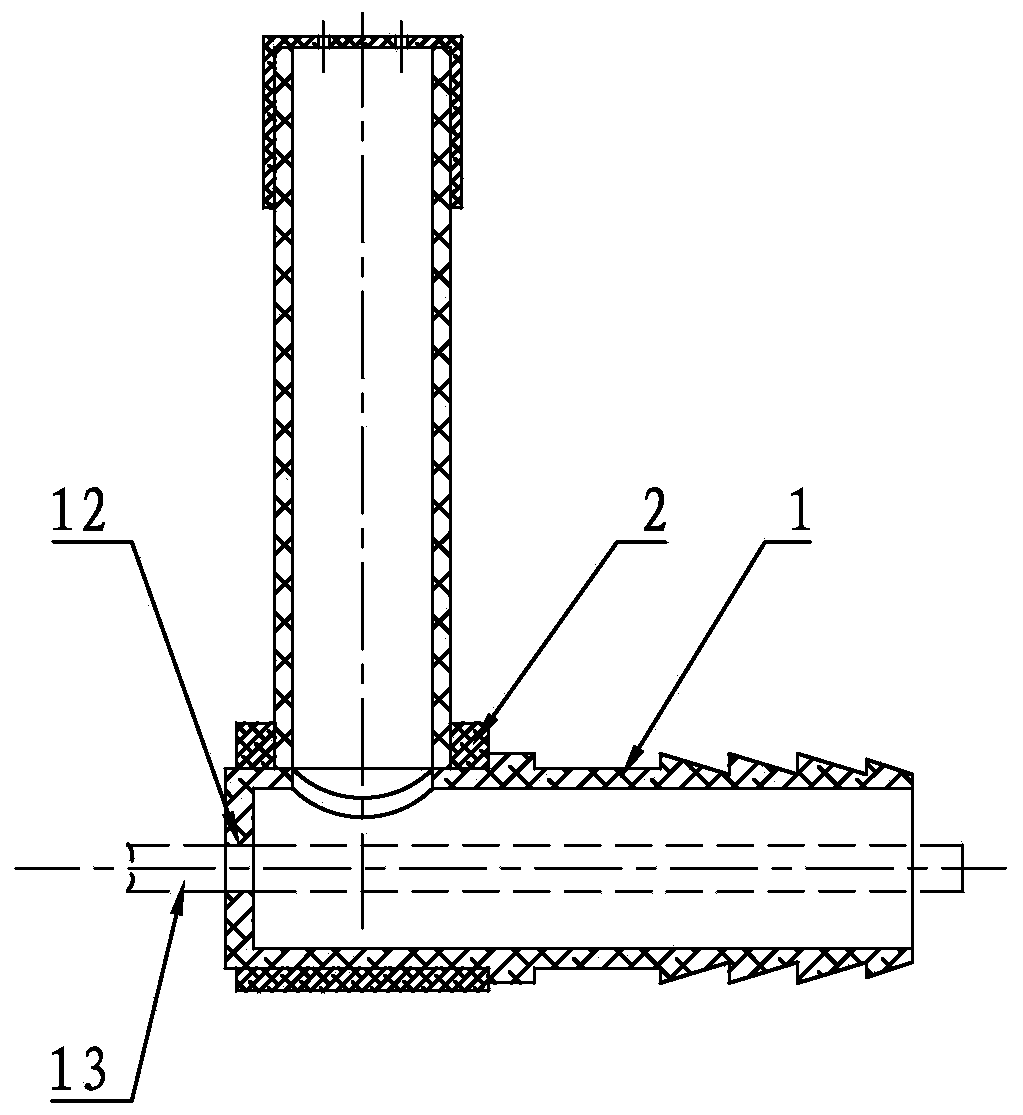

[0041] see Figure 1a and Figure 1b , the present invention provides a grouting plugging and monitoring device for steel grouting joints, comprising a plugging pipe 1, a closed ring 2, a monitoring pipe 7 and a venting cover 8, wherein the plugging pipe 1 is a pipe body with one end closed and the other open, The closed end of the plugging pipe 1 is provided with a transparent bottom surface 5, and the open end is connected to the grouting hole 19 of the steel bar grouting joint of the vertical prefabricated component, and the first grouting hole 4 is provided near the wall surface of the closed end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com