Dust removal and noise reduction pulping equipment and control method thereof

A slurry-forming and equipment technology, applied in chemical instruments and methods, sound-producing equipment, mixers, etc., can solve the problems of limited effect, affecting the quality of the slurry, affecting the operation of workers, etc., to improve the sound insulation effect, improve the grouting quality, The effect of avoiding noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

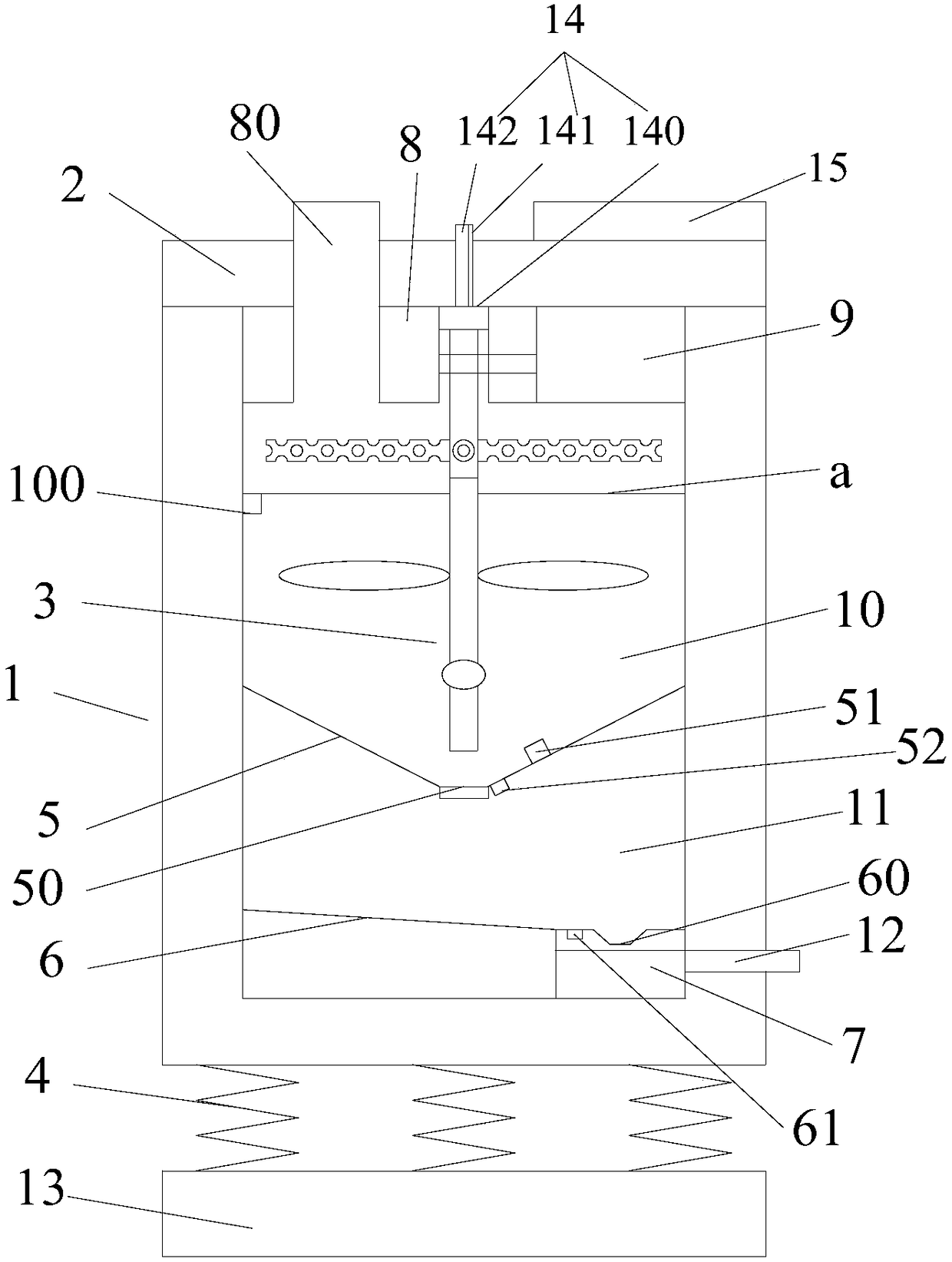

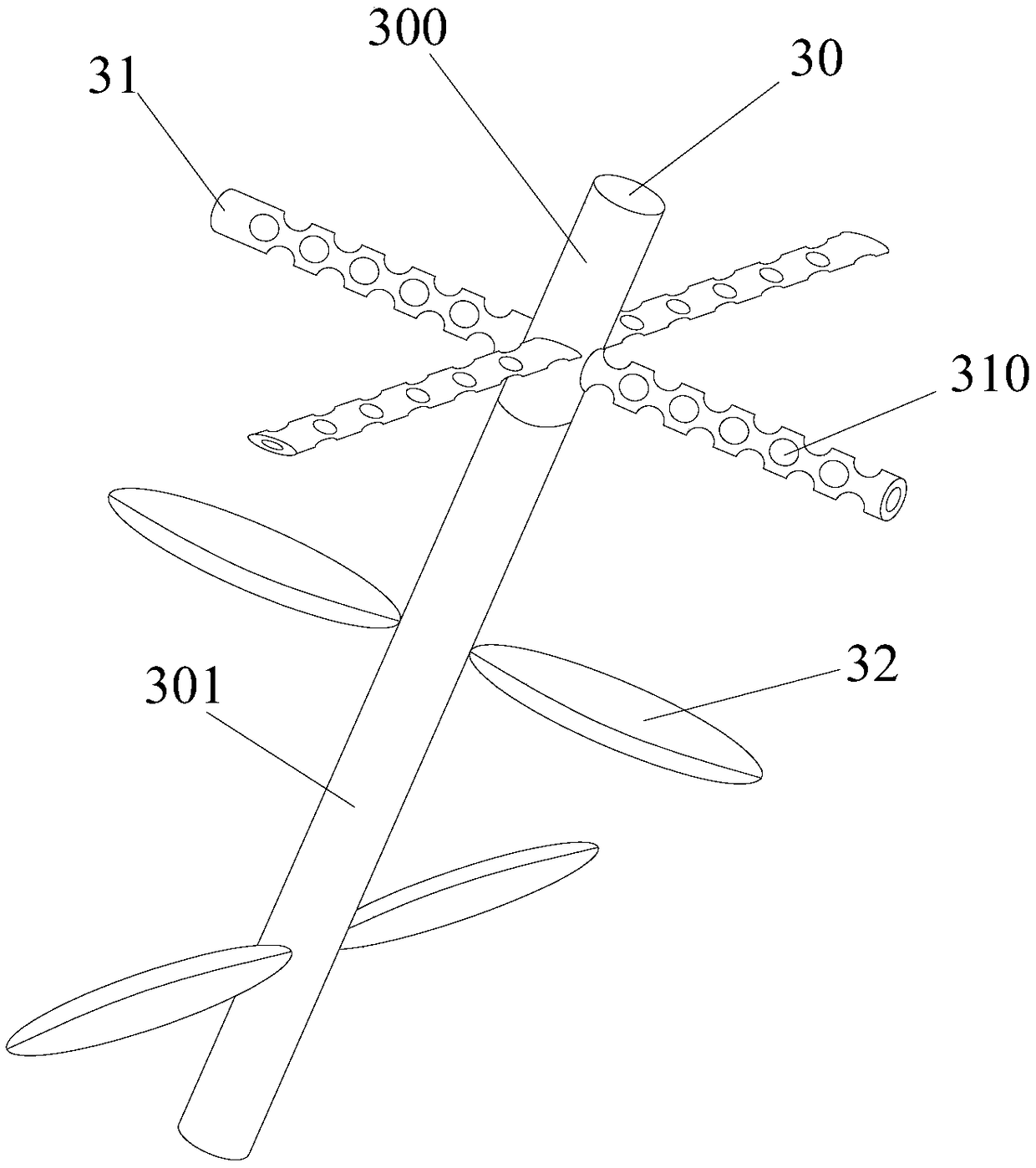

[0051] Such as figure 1 As shown in -2, a pulping equipment for dust removal and noise reduction, including: a cylinder body 1, a cover plate 2, a downward conical partition 5 is arranged in the middle of the cylinder body 1, and the inner cavity of the cylinder body 1 is separated It is an upper mixing bin and a lower storage bin 11, the middle part of the conical partition 5 is a discharge port 50, the upper part of the upper mixing bin is provided with a top plate 8; the bottom of the lower storage bin 11 is provided with a bottom plate 6. After the slurry is evenly stirred in the upper mixing bin, it can automatically enter the lower storage bin 11 under its own gravity; it ensures the uniformity of the grouting slurry and improves the quality of the grouting.

[0052] The inside of the bottom plate 6 is a hollow structure, and a slurry pump 7 is arranged in the hollow structure of the bottom plate 6. The feeding end of the slurry pump 7 communicates with the slurry outlet...

Embodiment 2

[0065] Embodiment 2 is the method for controlling embodiment 1,

[0066] Including the following steps:

[0067] (1) provide a slurry-forming equipment for dust removal and noise reduction, and plug in the power supply;

[0068] (2) The discharge port of the feeding device is connected with the outer feed port 80; the external water source is connected with the water inlet pipe 142; the liquid outlet of the additive storage device is connected with the additive pipe 141;

[0069] (3) Input the mixing ratio of the required grouting slurry on the control panel 15, click the start button, and then the control panel 15 controls the discharge valve to close, and simultaneously starts the automatic metering valve, metering pump 140, drive motor 9, and monitoring the state of the first liquid level sensor 100;

[0070] (4) When the control panel 15 received the liquid level signal of the first liquid level sensor 100, the control panel 15 closed the automatic metering valve and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com