Mortar mixer

A mixer and mixer bucket technology, applied in cement mixing devices, clay preparation devices, mixing operation control devices, etc., can solve the problems affecting the quality of the output, the inability to realize the crushing of raw materials, and the impact on mortar mixing and output efficiency, etc., to achieve Less maintenance, simple structure, good hydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

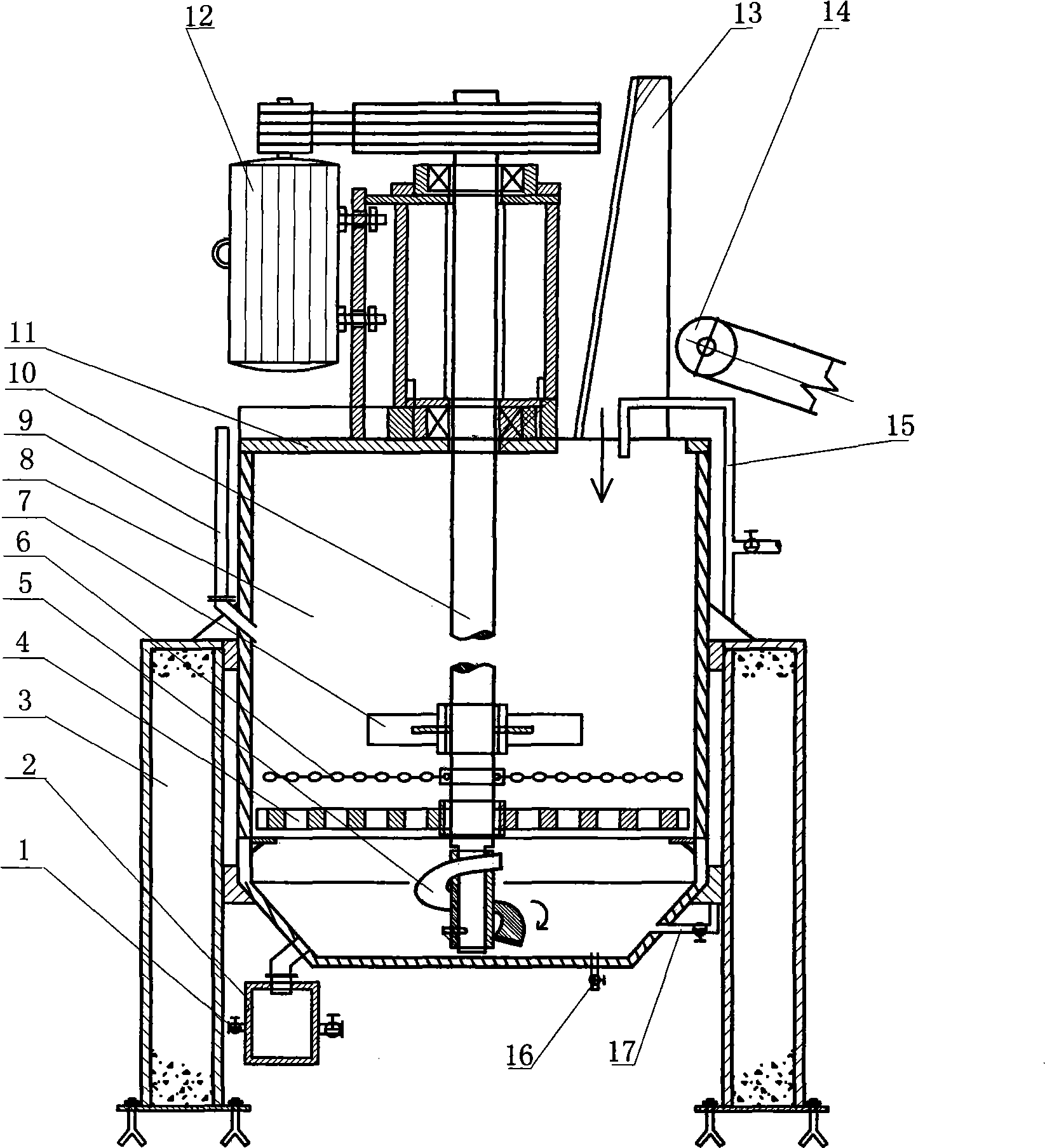

[0019] Such as figure 1 As shown, a mortar mixer includes a mixer barrel 8 and a transmission device. The mixer barrel 8 is placed on a leg column support 3, and the leg column support 3 is fixed on the ground. The leg column support 3 is a barrel-type steel structure, and the interior is filled with Concrete; transmission device is fixed on one end of mixer barrel body 8, and its main body is a motor 12, and motor 12 drives stirring main shaft 10 through belt pulley, and stirring main shaft 10 penetrates into mixer barrel body, is connected with stirring on the mixing main shaft 10 in mixer barrel body. Rotary blade 7, one end of the mixer barrel is designed with a feed inlet, the other end of the mixer barrel is designed with a discharge port, the mixer barrel 8 is a vertical structure, and the motor 12 is placed on the top mixer cover 11 of the mixer barrel 8, The mixing spindle 10 penetrates vertically into the barrel body 8 of the mixer, and the feeding port is also opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com