Integrated pulping system

An all-in-one, control system technology, applied in clay preparation devices, mixing operation control, mixing plants, etc., can solve the problems of unsuitable urban construction, poor work efficiency, time-consuming, etc., and save temporary construction work and transportation. cost, reduce labor intensity, and improve the effect of intelligent work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

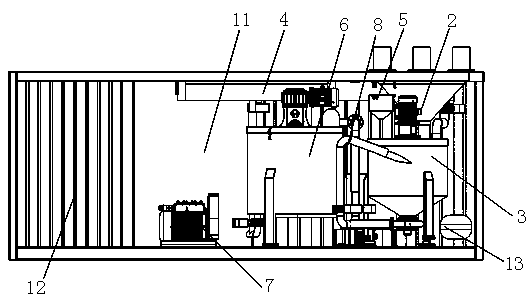

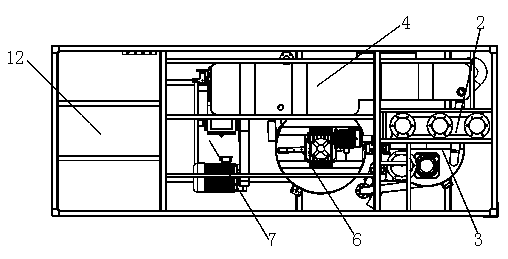

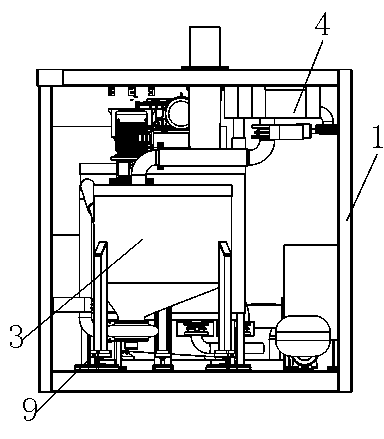

[0037] The existing pulping station has defects such as on-site assembly of various components at the construction site, which is not only troublesome, but also occupies a large area and has a low degree of automation in equipment operation. In order to overcome the defects of the prior art, this embodiment provides an integrated type pulping system, such as Figures 1 to 3 As shown, the working components included in the integrated pulping system are: pulping tank 3, pulp storage tank 6, pulp feeding device 7, water tank 4, centralized hopper 2, additive supply device 5, air compressor 13, etc. . On this basis, this embodiment also provides a container 1, in which all the above-mentioned components are installed, specifically, the container includes an integrated equipment installation room 11 and a control room 12, separated by a partition in the middle Concentrated into the hopper 2, slurry tank 3, water tank 4, admixture supply device 5, slurry storage tank 6 and slurry d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com