System and method for repulping of paper products and improvement of water quality with dipolar solvents and recovery

a technology of dipolar solvents and paper products, applied in the direction of textiles and paper, digesters, raw materials, etc., can solve the problems of large disproportionality on the cellulose chain, carcinogenic, mutogenic and toxic to animal reproduction, etc., and achieve the effects of increasing the hydration power of fibrous materials, reducing the number of ink particles, and increasing the detachment of adhesives, additives and ink particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

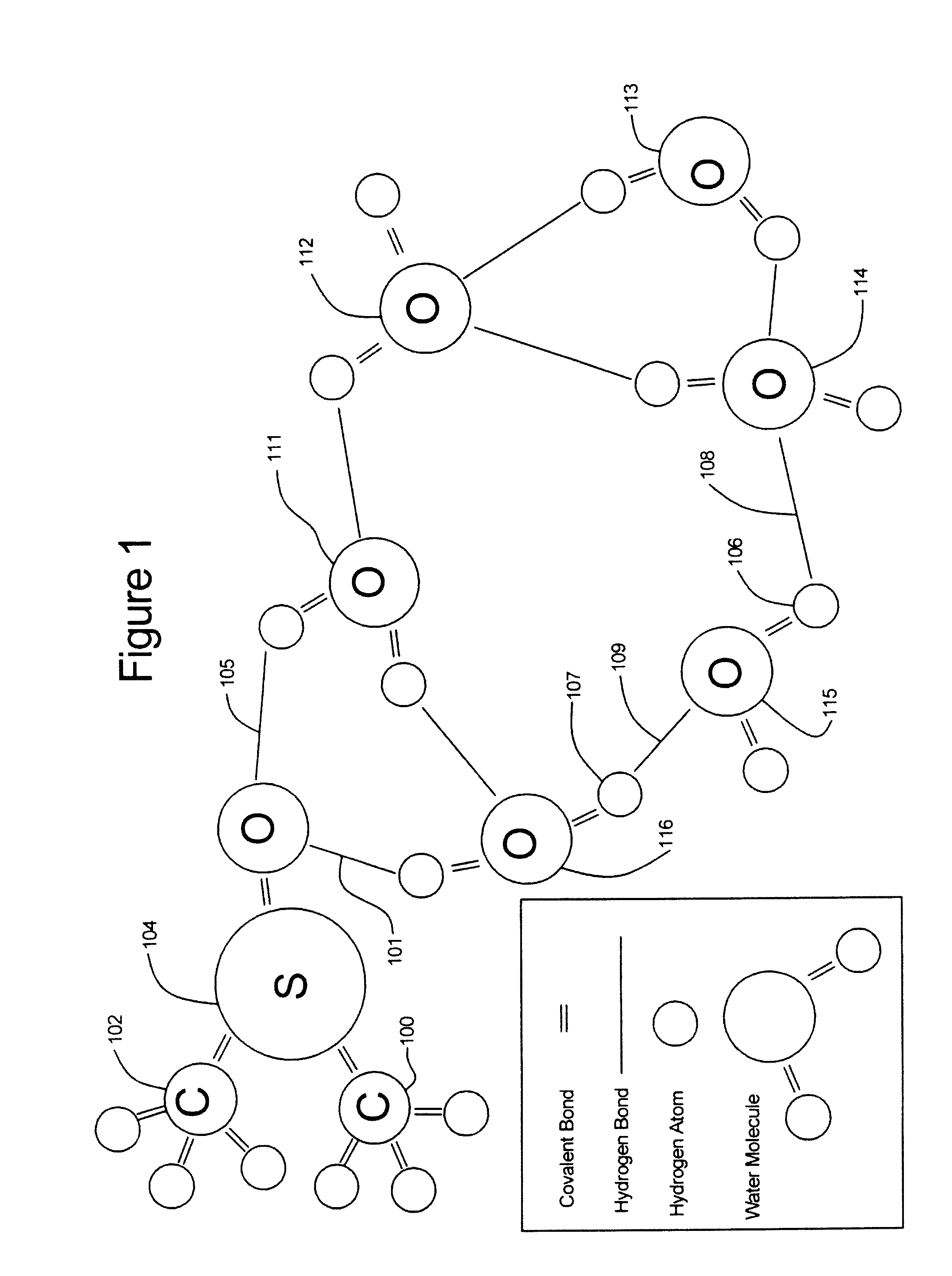

[0093]FIG. 1

[0094]Referring to FIG. 1, the formation of a 6-water molecule cluster is illustrated with the dipolar aprotic solvent dimethylsulfoxide shown in the upper left comprised of oxygen atom 103, sulfur atom 104 and two methane (CH3) molecules, 100 and 102. The dimethylsulfoxide forms hydrogen bonds with the water at 101 and 105. These bonds prevent other water molecules from bonding with the water molecules in the same place, thereby reducing the size of the water cluster. The 6-water cluster is defined by a ring of oxygen atoms 111, 112, 113, 114, 115, and 116 and hydrogen atoms such as 106 and 107 which are connected to oxygen atoms 114 and 115 respectively with hydrogen bonds represented by single lines 108 and 109 respectively. The molecules in the 6-water cluster may be connected to other water molecules or other molecule clusters by any number of branching hydrogen bonds.

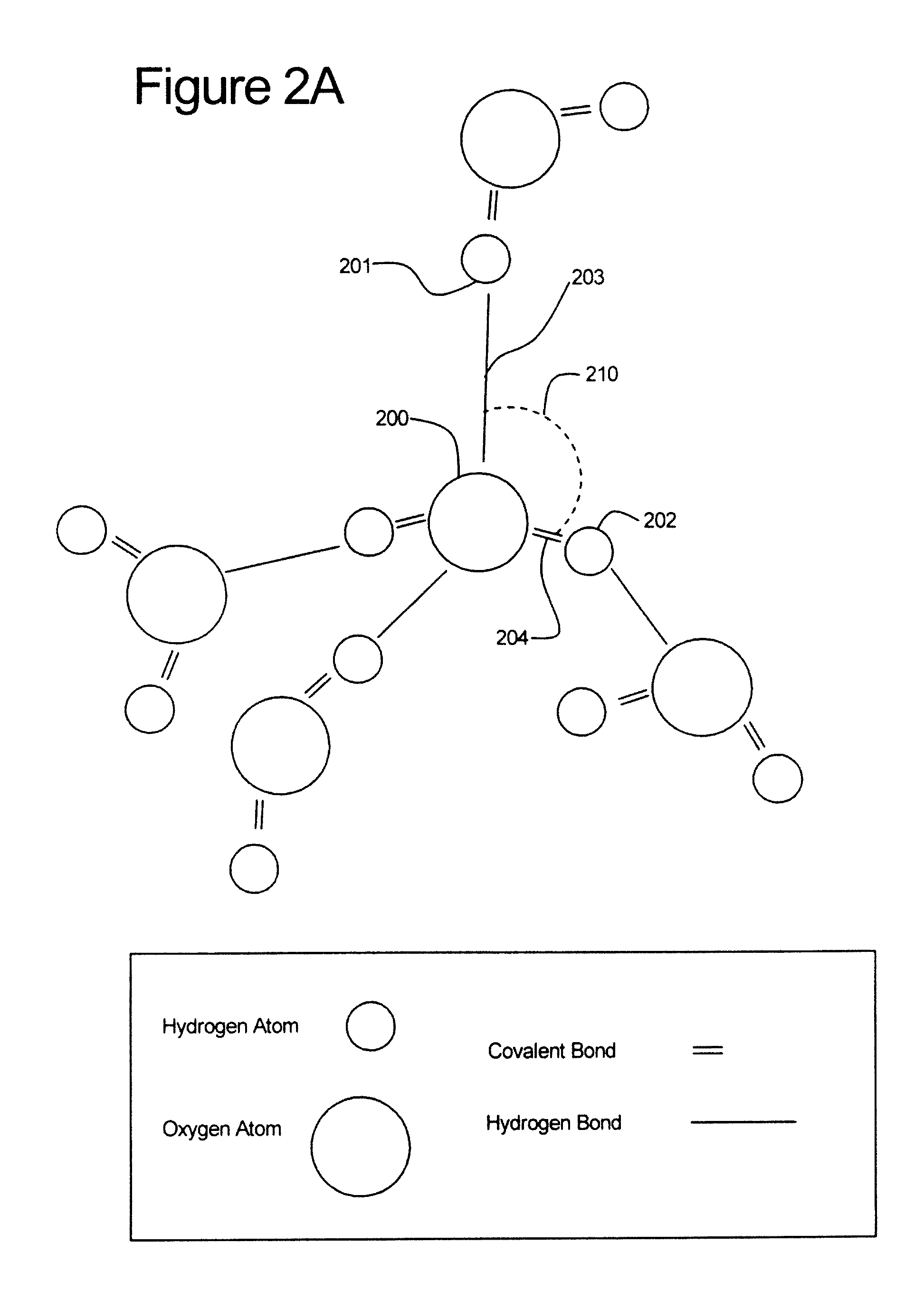

[0095]FIG. 2A

[0096]Referring to FIG. 2A, the effect of a dipolar aprotic solvent on the H—O—H angle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com