Microcrystalline glass and substrate thereof

A technology of glass-ceramic and crystal phase is applied in the field of glass-ceramic and substrates using the glass-ceramic as a base material, and can solve the problems of low production efficiency and inability to carry out mass production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

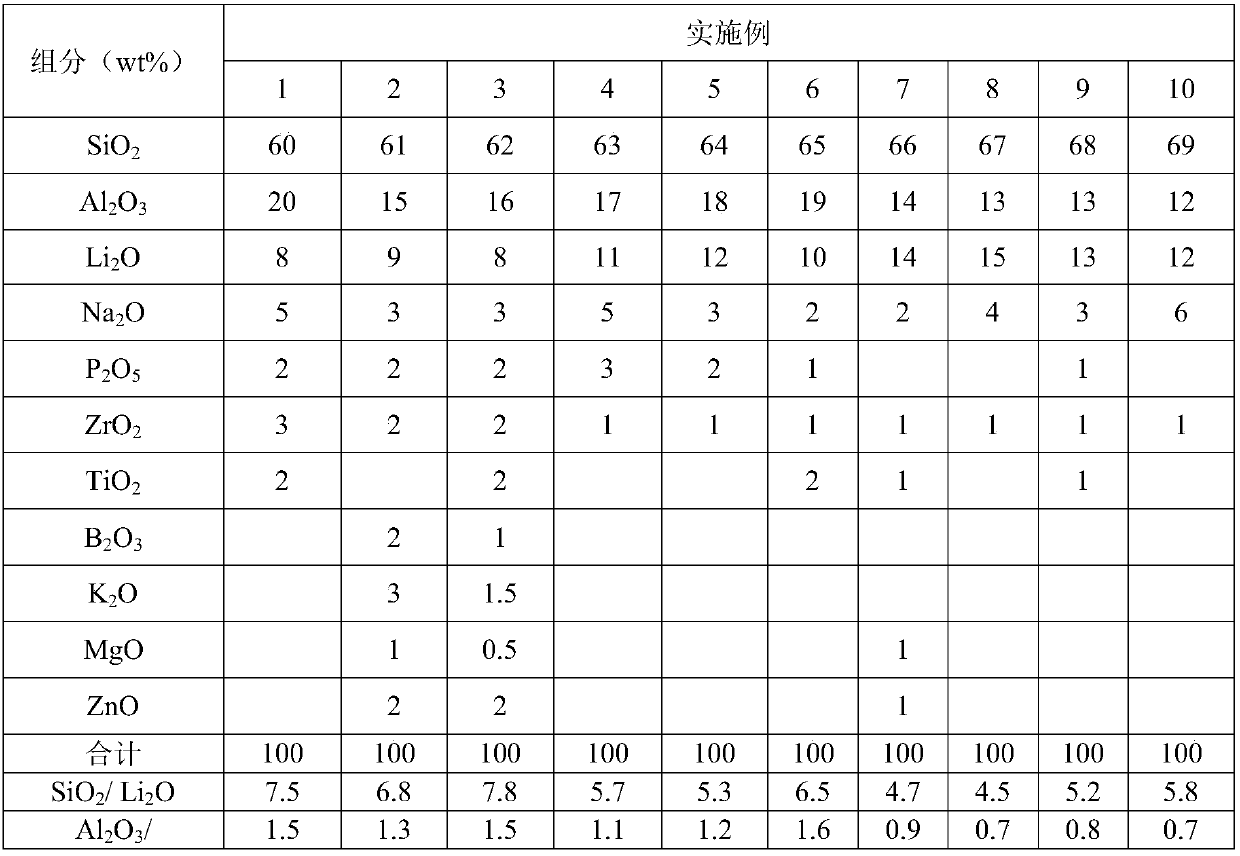

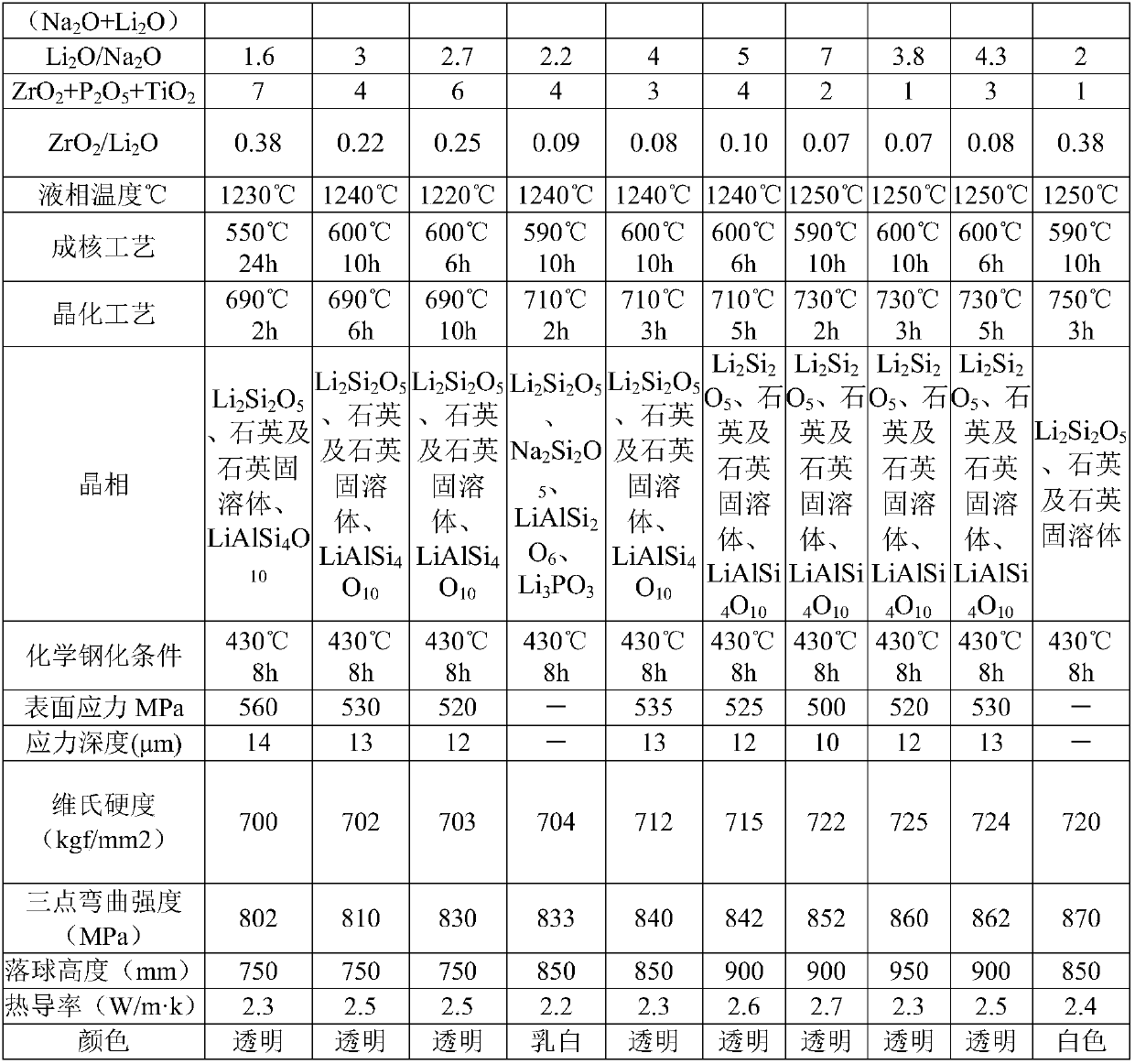

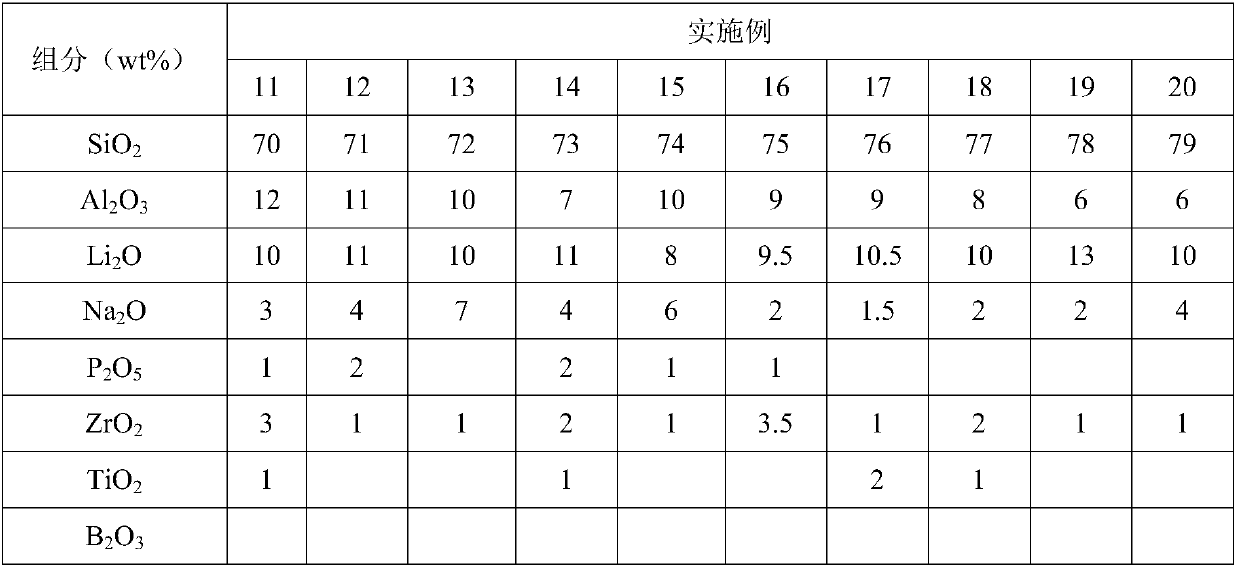

Examples

Embodiment Construction

[0031] The glass-ceramic of the present invention is a material having a crystalline phase and a glass phase, which is distinguished from an amorphous solid. The crystal phase of glass ceramics can be identified by the peak angle appearing in the X-ray diffraction pattern of X-ray diffraction analysis and by TEMEDX. In the crystallized glass of the present invention, the crystal phase contains R 2 SiO 3 , R 2 Si 2 o 5 , R 2 TiO 3 , R 4 Ti 5 o 12 , R 3 PO 3 , RAlSi 2 o 6 , RAlSiO 4 o 10 , R 2 Al 2 Si 2 o 8 , R 4 Al 4 Si 5 o 18 One or more of R, quartz, and quartz solid solution, wherein R is one or more of Li, Na, and K.

[0032]Among them, the above Li 2 Si 2 o 5 The crystal phase is lithium disilicate crystal phase, which is based on [Si 2 o 5 ] The orthorhombic crystal of the tetrahedral array, the shape of the crystal is flat or plate-like. In the interior of the glass-ceramic, the lithium disilicate crystal phase is an interlocking microstructur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com